Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

The HACCP system is considered the gold standard for measuring food safety.

HACCP stands for Hazard Analysis Critical Control Points and is an acronym for three of the plan's essential components: Hazards, Analysis, and Critical Control Points.

A HACCP plan is made using a series of preliminary HACCP steps including building a HACCP team, describing the product and its distribution, identifying the product's intended use and target consumer, developing a diagram of the process flow, and verifying the flowchart.

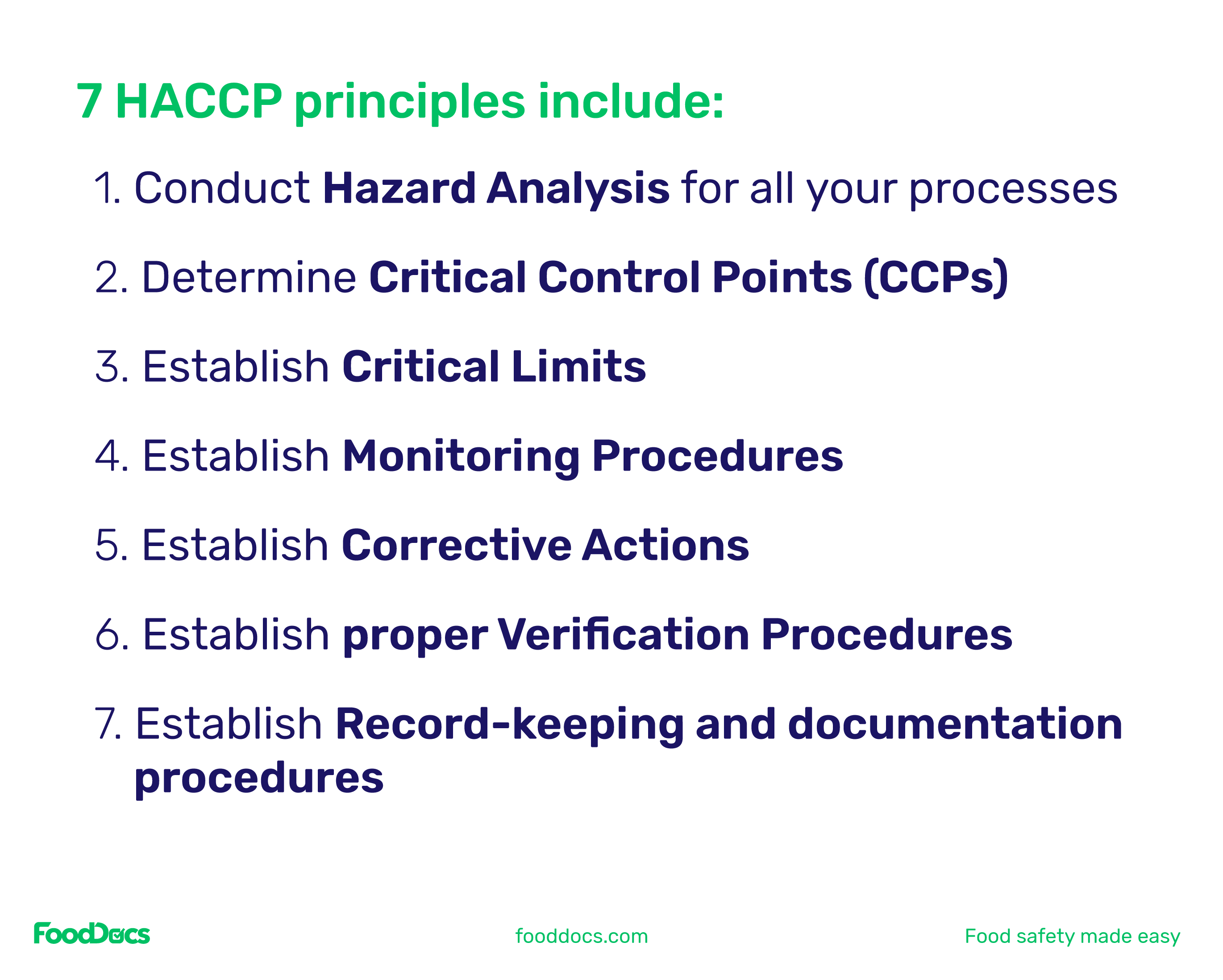

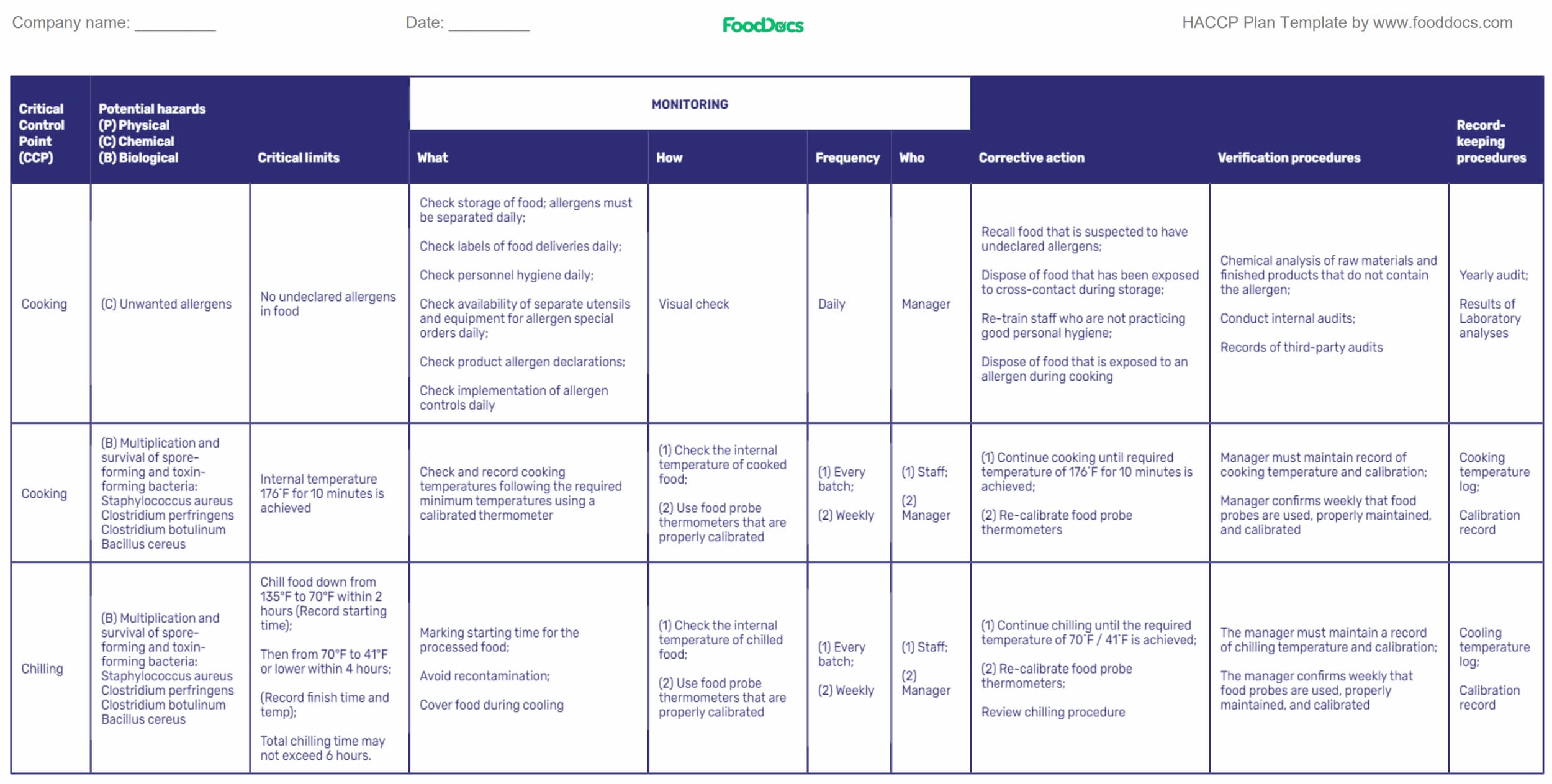

After meeting the five preliminary steps, your team must then establish the 7 HACCP principles that include hazard analysis, establishing critical control points, critical limits, monitoring procedures, creating corrective actions, verification procedures, and record-keeping methods.

Hazard Analysis Critical Control Point (HACCP) is a systematic food safety management system and is the most recognized system for controlling food safety risks and hazards in the food industry.

Different types of food preservation methods require specific HACCP procedures.

Under regulations implemented by the US Food and Drug Administration and the USDA, beverage processing, seafood and related product, meat and poultry processing, and vegetable farming and storage operations are required to have a HACCP plan or at least a food safety plan.

The HACCP system is a food industry regulatory standard adopted by most developed countries. It is considered a critical approach to food safety. The program lays out the necessary risk assessment and appropriate controls to ensure that food business operations are safe and protect public safety. It serves as a basis for other higher-ranking food safety and food quality systems developed after its establishment.

Building a HACCP plan to produce wholesome food requires the efforts of the entire team of a food business. A comprehensive HACCP plan covers all areas of the food chain to ensure that food safety hazards are well-addressed and controlled for public safety. While food safety is the primary concern of a HACCP plan, it also helps a food business establish its brand regarding service and quality of approach to protecting customers from hazardous risks.

This article was made to give you an essential and in-depth overview of the important points in building a HACCP plan and for its successful implementation in your food business.

In this article, we go through the HACCP system in detail with the following topics, as well as share how you can get an auditor-approved HACCP plan in just one hour.

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

WHAT WE'LL COVER:

Before we start, here are a few short definitions of the terminologies used in this article:

See a full food safety glossary.

HACCP stands for Hazard Analysis Critical Control Points, a systematic approach to managing food safety by analyzing potentially present hazards and establishing controls with a scientific basis for managing food safety hazards and risks.

HACCP is a food safety management system that aims to control hazards in the food supply chain and prevent unsafe operating conditions. It aims to protect public health from food safety hazards.

This food safety system covers all areas of food production, starting from raw material production and procurement up to product packaging, food manufacturing process, distribution of finished products, and consumption by consumers. It involves food safety management procedures that will help prevent your business from causing harm to public health and produce only safe products.

Learn more about the food safety system from our detailed article on HACCP's history.

In practical terms, HACCP means managing food safety by controlling processes instead of inspecting finished products.

Rather than reacting to food safety failures after they occur, the HACCP system requires food businesses to identify where hazards could arise and put controls in place at critical points to prevent unsafe food from reaching consumers.

This preventive approach is why HACCP is widely used as the foundation for modern food safety management systems.

Below, we go through the meaning of the five-letter acronym in detail:

Hazard identification is the first and main target of this food safety management system. Foodborne hazards are any contaminations that could be the result of inadequate processing, dirty raw materials or cooking utensil, or even cross - contamination in cooked materials. Potential hazards can be physical, biological, chemical, or allergenic and can cause severe health effects.

They are called food safety hazards because of the potentially unacceptable health risk they carry that could harm public health through unsafe food for consumption once they exceed an acceptable level.

The detection of contaminants at an early stage is key for safer food production in any manufacturing plant or food service in the food industry. Also, it's important to evaluate the degree of risk of each hazard and source of contamination to come up with appropriate direct control factors.

This aspect comes after hazard identification and pertains to the implementation of the evaluation part of a HACCP plan. The HACCP is a food management system that deals with all stages of hazard analysis and accurate identification of hazards that could arise from the previously mentioned list of hazards.

The analysis includes the assessment of the whole food operation from raw material production, food composition analysis, procurement up to processing, conditions of storage, shelf life, and consumption.

HACCP determines at which point hazards could contaminate the process and the product and whether they can be considered critical control points using science-based methods of analysis or not. The proper and comprehensive analysis builds a solid foundation for your entire food safety plan and will significantly affect its successful implementation.

The last component of the acronym HACCP is the Critical Control Points (CCPs). These points are the controllable processing steps within the whole food chain that need accurate evaluation and control factors to remove potentially or naturally present food safety hazards or reduce them to an acceptable level. Critical control points require corrective action procedures and aspects of verification to support control measures to ensure the safety of food products.

HACCP plan is commonly mistaken to be synonymous with a food safety plan and termed singularly as the HACCP system. Both plans are considered food safety management systems but have a few differences. Where a food safety plan is only concerned with establishing preventive measures, a HACCP plan also requires monitoring and comprehensive verification reports. In addition, a HACCP plan is focused on monitoring critical control points, whereas a food safety plan is concerned with all other food service operations.

Building a HACCP plan involves several documentation processes. The conceptualization and successful implementation of your initial plan can span from 1 to 12 months, when using the pen-and-paper system, depending on the skill of your HACCP team. This duration can also extend depending on the revisions that you need to apply. Although some AI-based food safety software, such as FoodDocs, can create and implement your HACCP plan in only 1 hour just by based on your answers to some questions about your business.

No matter the executor of your HACCP plan, it is a thorough, yet critical process.

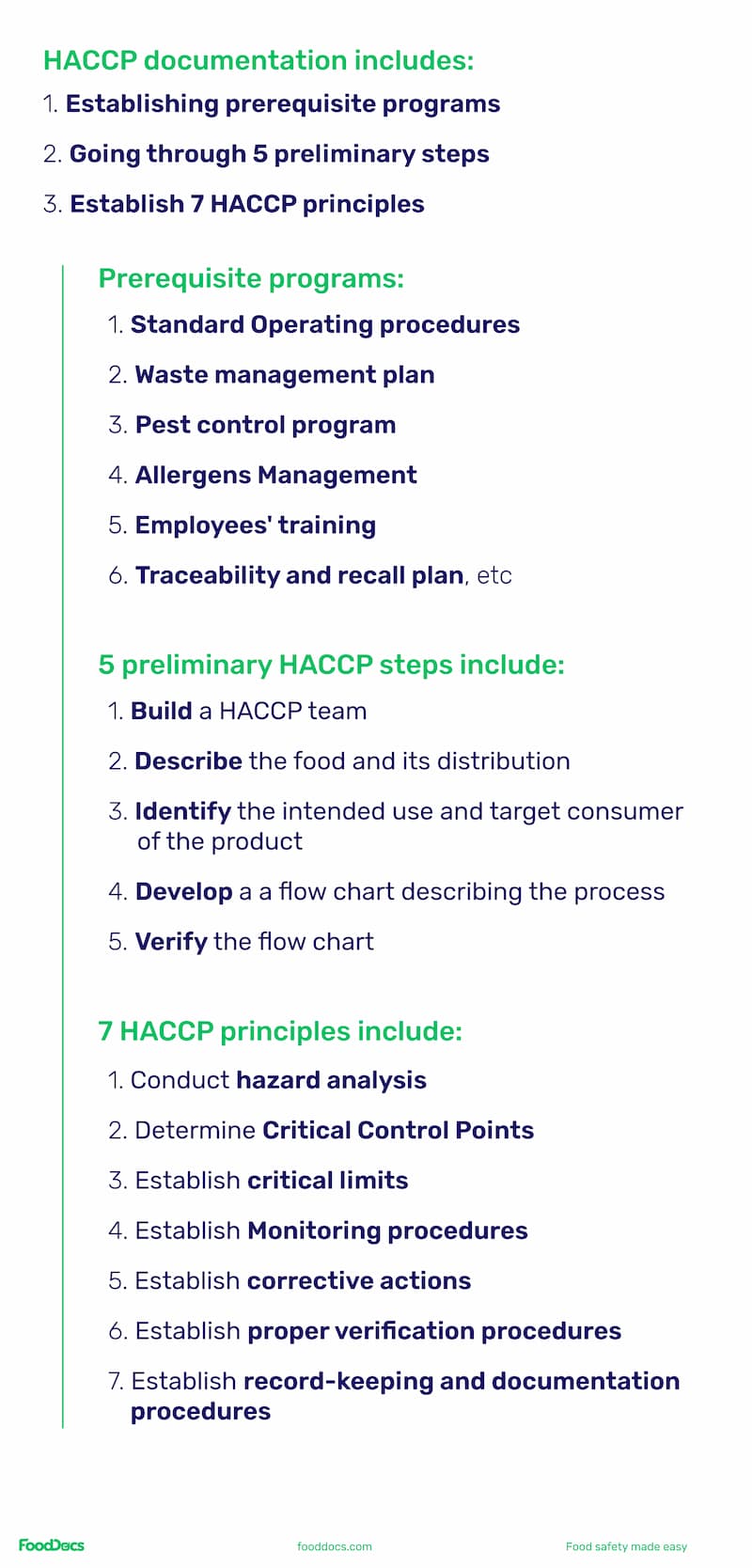

Three of the most critical phases of HACCP documentation are the following:

All operations, control measures, procedures for monitoring, critical limits, corrective action plans, and other essential tasks must be comprehensively documented and stored in a HACCP plan for a successful implementation.

The development of process for a HACCP plan will start with common prerequisite programs, continue with five preliminary steps, and finally end with 7 principles of HACCP. Now, let's discuss all three HACCP documentation processes step-by-step:

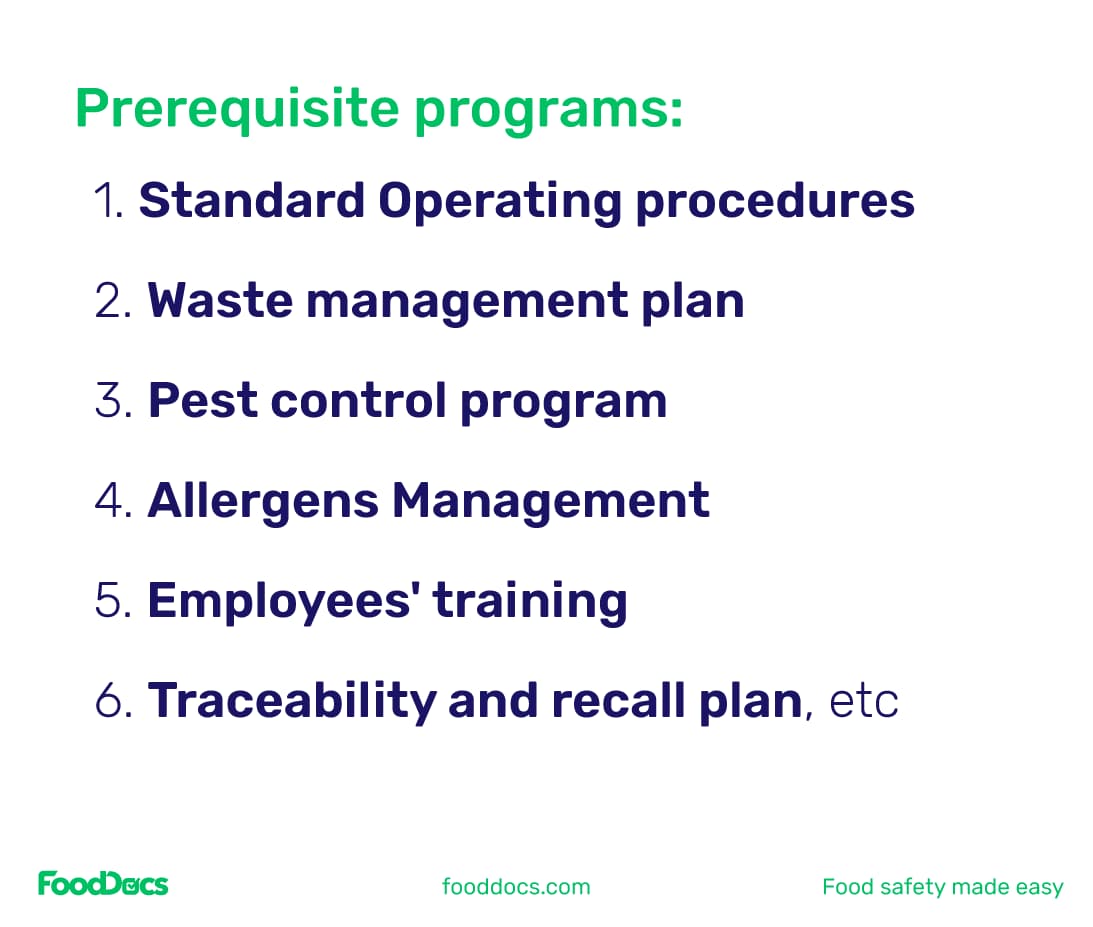

Prerequisite programs (PRP) in food safety are strategic systems composed of different operations that provide the basic sanitary conditions to operate in a safe environment for the production of wholesome food.

Before creating an efficient HACCP food safety system and implementing it, common prerequisite programs must be implemented to prevent loss of control. Prerequisite programs are the essential foundation of food safety and the HACCP system and are composed of basic food safety principles.

The process of conceptualizing a HACCP program starts by ensuring that all prerequisite programs and standard operating procedures are fulfilled and that all key food handlers have effective training on food safety and ingredient handling practices.

They are concerned with the hygiene, environmental conditions, and sanitary design principles of a business aimed at reducing the unacceptable health risk of potential hazards. Put simply, your company needs to implement prerequisite programs before making a HACCP plan. Some of the most common prerequisite programs include Good Manufacturing Practices and Sanitation Standard Operating Procedures.

These prerequisites apply to any nature of the food business and are general requirements for employee practices, equipment design, and sanitary conditions for working. They also ensure minimum environmental conditions for food safety.

Some prerequisite programs are used as guidelines in building suitable criteria for food safety. These criteria include processing facility design with basic conditions and proper verification reports if they comply with minimum criteria for producing wholesome food for consumption.

Some of the most common prerequisite programs include:

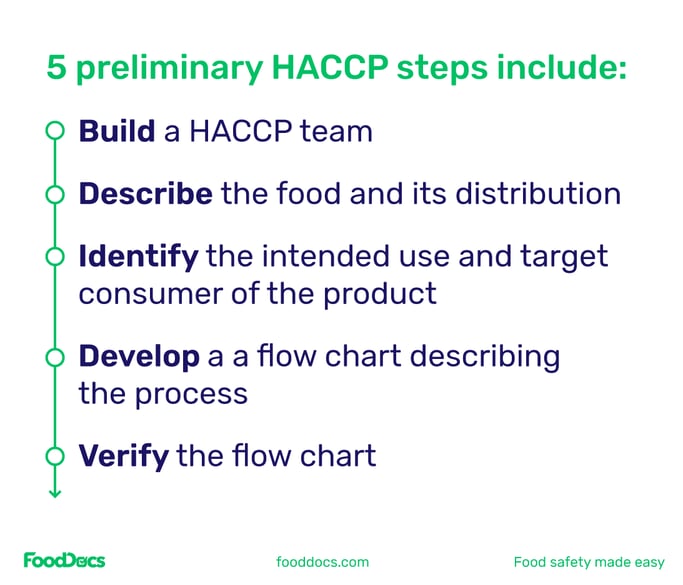

Building food safety plans for a HACCP system takes a lot of consideration, time, and thought processes. Before even knowing what the main HACCP principles are, there are at least five preliminary steps for you to take. These steps aim to prepare you and your business for making comprehensive HACCP food safety plans.

A HACCP food safety management system can be very product or process-specific and is more concerned with safety rather than quality concerns. This means that expertise in certain fields is required. Next, we talk about the five different preliminary HACCP plan steps in detail.

Five preliminary steps of HACCP

Five preliminary steps of HACCP

HACCP Team example

HACCP Team example

The first step in HACCP plan-making is to gather a group of individuals with enough expertise in the different aspects of the process steps and factors that make food unsafe. Each chosen member will be responsible for sharing their input on the potential foodborne hazards from their area and aid the entire team in establishing the identified controls. It is important to have representatives with knowledge of production, quality assurance, food safety, and food microbiology to avoid loss of control in any aspect of the process.

Some experts that are most likely to be included in the team may come from the engineering, production, quality assurance, sanitation, and research and development departments. Members do not necessarily have to be from the top positions. In fact, having your workers participate as a member of the HACCP team can benefit the program. The HACCP principles are based on preventing any potential hazard from happening during the different processes of food production. In-line workers see everything that is happening during any process step and can give very valuable inputs.

The team will be tasked to identify potential food safety hazards, analyze them, establish critical limits and standard parameters, create corrective actions for variations, monitor, and record these events. All participating members must have knowledge of what the potential hazards are.

Select members who also have experience in your everyday operations. In addition, your team may also include a third-party food safety expert who will guide your team in identifying potential hazardous areas through their expert advice.

Example of product description

After building a HACCP team for a specific product, your food must be comprehensively described in preparation for the seven HACCP principles. List down all of the necessary food composition or raw materials, finished product groups, required conditions of storage, and the appropriate conditions of distribution. Describing your food means listing all of its ingredients with some of the derivatives it may contain and the manufacturing process for your product.

Your HACCP team must describe the general food group of your safe food product to identify any related food safety hazards.

Knowledge about the product is crucial at this point. All ingredients must be mentioned and analyzed because some of their by-products can potentially become hazards in the wrong processing method.

Food groups can tell your team a lot about the product, such as when categorizing the food as a Bakery product. This tells you that the food item is made with wheat and can potentially be allergenic to some customers.

Listing the ingredients and characteristics of the product would also help the team analyze the proper distribution conditions for it. Food products such as ready-to-eat meals packed in lunch boxes have the tendency to become spoiled during distribution at elevated surroundings and internal temperatures.

Another example is when you categorize your food as a salad; it means that raw materials in this product group will require stringent monitoring of storage temperatures and quality control. Storing this product at ambient temperature will spoil it faster than in cool storage conditions. Maximum and minimum temperature requirements for the transport of such food products are needed to be declared as a control for safety.

Under this preliminary step to the seven HACCP principles, the team will be tasked to identify the target consumers and those that must be warned to practice caution in consuming your product. Intended consumers maximize the economic appreciation of your product since they are most likely to buy it.

Contrary to intended consumers, those who might have any hypersensitivity to the product must also be identified. Vulnerable groups may include pregnant individuals, immunocompromised patients, the elderly, and infants. This step helps prevent any food safety issues under the HACCP principles.

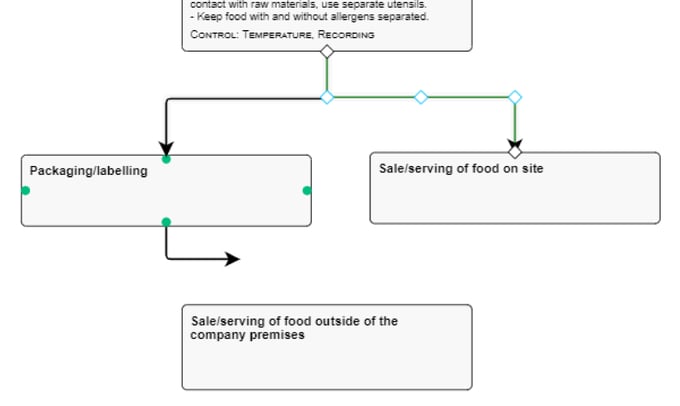

Example of flow chart diagram

Example of flow chart diagramTo properly map out all the intended processes related to your product, your HACCP team must create a flow diagram of your production scheme. This diagram does not have to be expertly made to look like an engineering drawing. It can be a graphical representation of a linear product flow. What is important is that all methods and conditions under each process are mentioned in a logical sequence for assessment.

This step will help determine which process brings a potential hazard with it. Under a good flow diagram, a potential risk must have a succeeding step that will help eliminate it or bring it back to acceptable levels.

Here is an easy and FREE tool to build your flowchart diagram.

After building the HACCP flow chart diagram, the last preliminary task is to verify whether all areas are covered through an on-site plant observation.

Visual observations such as differences in equipment or process flow presented in the flow chart diagram must be duly considered as these may greatly affect decision-making in the HACCP plan-making process.

Aspects of verification and initial validation activities do not entail additional documentation; rather, revisions of the existing flow chart diagram will only be done when inaccuracies are observed.

Once inaccuracies are observed from the verification report, your team must revise the flow chart diagram, so choose a template for flow chart that is easily and fully customizable from the start to save you time in the future.

An accurate block-type flow diagram is key in introducing the whole process to the team and identifying all potential food safety hazards. Inaccuracies in the diagram can cause unidentified hazards and potential loss of control over food safety.

Upon finishing all preliminary tasks and verification reports, your team is not set to create your HACCP plan. Expertise in each area of your food business will contribute to identifying and analyzing all potential hazards.

After addressing the five preliminary HACCP plan steps and establishing a solid HACCP team, the 7 steps of HACCP can be fulfilled. Under these HACCP principles, potential biological, chemical, and physical hazards are identified and analyzed for their potential to cause food safety issues.

HACCP Principles

HACCP Principles

The HACCP principles are a structured set of seven steps used to design, implement, and maintain an effective HACCP plan.

Each principle focuses on a specific aspect of hazard control, from identifying food safety risks to monitoring critical limits and maintaining proper documentation. Together, these principles ensure that food safety hazards are consistently controlled throughout operations.

HACCP principles apply to food businesses involved in the preparation, processing, storage, or distribution of food, particularly where food safety hazards must be systematically controlled.

Food Safety Managers and Quality Leaders are typically responsible for ensuring that HACCP principles are correctly implemented, documented, and maintained across operations.

Purpose: Identify and evaluate biological, chemical, and physical hazards that could reasonably occur at each stage of the food process.

The first of the seven HACCP principles is a two-step process. The processes involved in this HACCP step are (1) hazard identification and (2) hazard analysis. Under this HACCP principle, the team will list down the food safety hazards that are most likely to occur in relation to the product at hand.

Proper identification of hazards and their analysis are the most important steps in a HACCP plan. Inadequate identification and improper analysis of hazards can increase the chance for product contamination and cause unacceptable health risks.

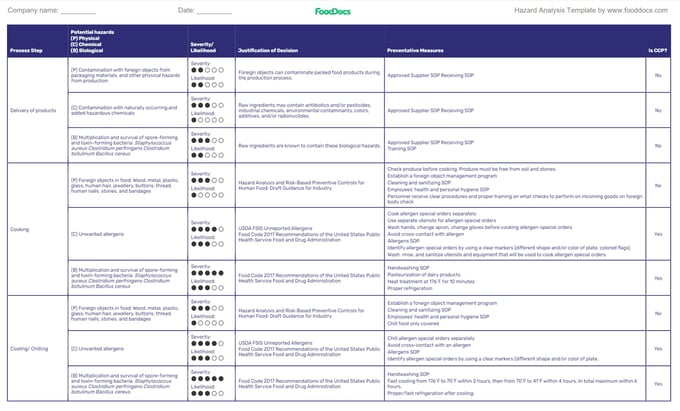

Hazard analysis is done for all steps of the production line to identify any potential hazards that may cause food safety issues.

Here is a step-by-step guide with an example below on how to compose your hazard analysis:

Under this HACCP step, the team must have considerable knowledge of the potential severity of hazards, the likelihood for consumers to be exposed to these food safety issues, the potential frequency of occurrence of each hazard, and relevant food safety laws. Accurate evaluation would need a lot of technical knowledge about the safe product, its behavior, raw materials, and potential contaminants. Some information may come from scientific studies or a comprehensive sequence of observations on-site.

Below is an example of some common food safety hazards and how they are analyzed in the process.

An example of a hazard in cooking as a process step is when your team identifies that there is a risk of survival of any toxin-forming enteric pathogen from cooking, such as Staphylococcus aureus or cells of Salmonella. These pathogens are known to cause significant health issues but are very susceptible to any heat process.

When left uncontrolled with proper practices such as a cooking process, this pathogen and health hazard can potentially cause catastrophic food safety issues, such as severe health effects, and has a moderate likelihood of occurring as well.

After identifying these parameters, the hazard must be assigned with appropriate preventive control measures such as proper handwashing, a thorough cooking process, cooling at ambient temperature, and proper refrigeration.

Another example would be the detection of physical hazards such as glass or torn packaging material debris. When undetected and uncontrolled, this physical agent can cause minor problems, such as injury to customers. This type of food safety hazard can be prevented by applicable standard operating procedures, including reviewing equipment design and glass control.

Hazards may differ from one operation to another. Simple differences in equipment can introduce new hazards.

The successful initial implementation of the succeeding HACCP principles relies on the accuracy of the hazard analysis stage.

Unidentified and unanalyzed food products could lead to potential food safety issues in the future. The likelihood and severity of each hazard would determine if it needs to be considered in the HACCP plan. A food service business dealing with both nut-free and nut-containing products, which are considered high-risk foods, must emphasize sanitation steps to prevent cross-contamination during production and releasing hazardous food to the public. On the contrary, they do not have to be concerned with temperature control fluctuations during storage.

Use FoodDocs' free template for hazard analysis that you can use for your HACCP plan-making process.

Example of HACCP Hazard Analysis

Example of HACCP Hazard Analysis

Purpose: Identify the specific steps in the process where control is essential to prevent, eliminate, or reduce a food safety hazard to an acceptable level.

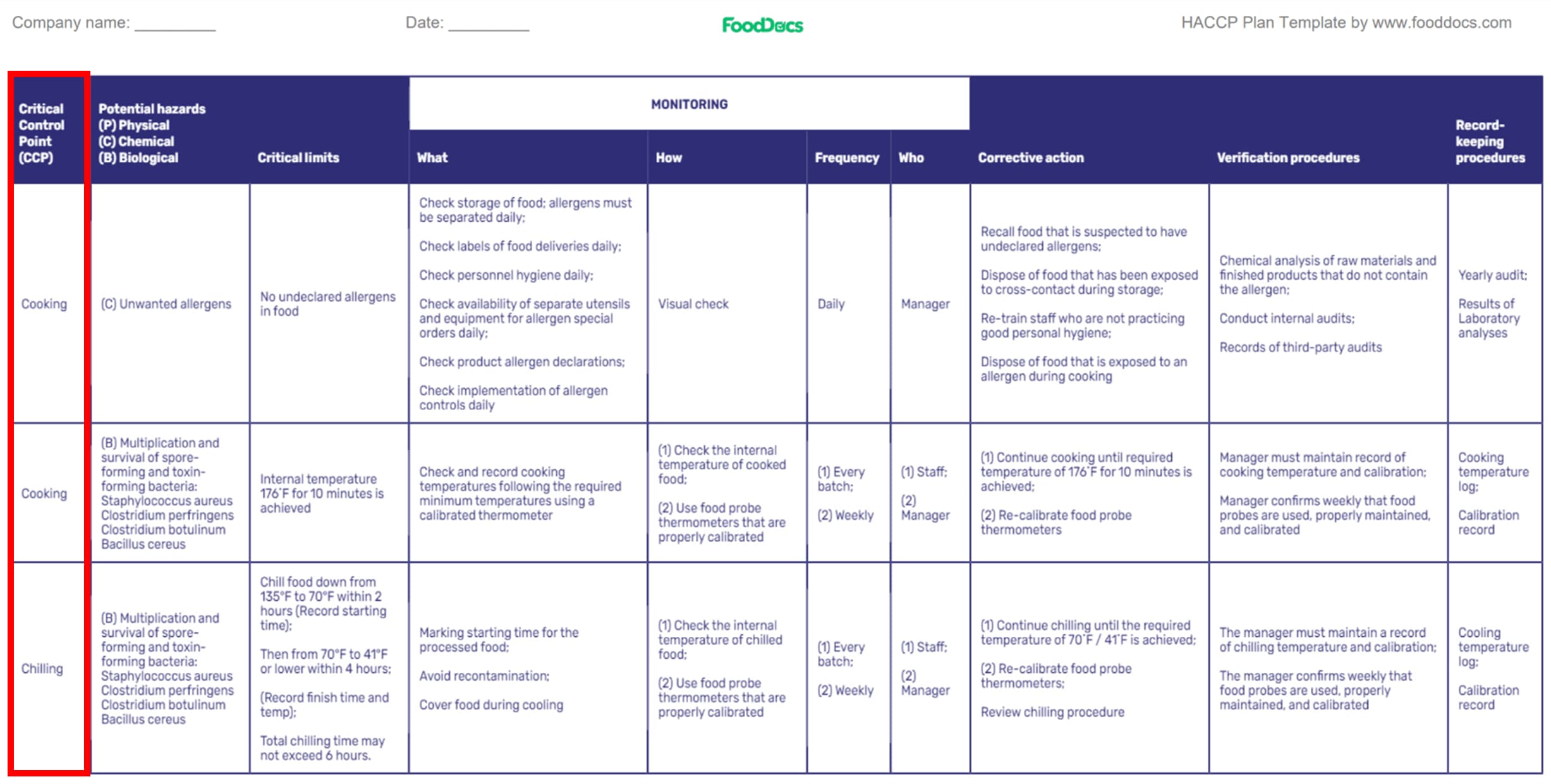

Next, every processing step must be clearly identified in your HACCP table, whether it is a CCP (YES) or not (NO). Identification of CCPs is a task that will help ensure the safety of your operations from hazards.

Critical control points are processing steps that are applied to the product to keep it safe and free from any health hazard. The most common CCPs are the cooling of potentially hazardous foods, thermal processing, and consistent maintenance of temperature for cooked food and ingredient storage, such as in hot holding foods. Other less common CCPs include physical hazard detection, thermal process, refrigeration, chemical testing, and even some advanced testings such as RT-PCR detection of pathogenic microorganisms.

Cooked materials and ingredient storage are considered as CCPs because improper storage of the two categories of food can contaminate ready-to-eat foods, which will only pass by the minimal thermal process before they are served. In this situation, conditions of storage between packaging must be considered a CCP.

Your business would consider these steps crucial if they control the identified hazards and must always be monitored if they are constantly met. Critical control points for products and processes greatly vary from one another. A practical example of a critical control point is the proper keeping of food temperature for cooked rice. Studies have shown that rice can be easily contaminated by the microbial pathogen Bacillus cereus, which can cause severe food poisoning as a result of ingesting its toxins. If rice were a high-acid product, this hazard would not be a major concern. As a solution, the critical point in this situation is to keep the product at low temperatures to control the levels of pathogens.

For every analyzed hazard that has been identified to cause significant negative effects on public health, your team must proceed to the development of process that will determine which operations can be considered critical control points to control hazards to an acceptable level.

A food processing operation must satisfy a few requirements for it to be considered a critical control point that will ensure the production of safe food products. To help your team in the identification of CCP from other food operations, the traditional procedure is to use a HACCP decision tree. Using a tool such as a decision tree for HACCP, your team will be able to classify if an operation is a CCP or not clearly. This tool consists of questions with a Yes or No answer that will arrive at a definite decision.

If you are not familiar with examples of decision trees, then our free tool is the perfect solution for you.

A CCP is generally known as the last controllable processing method to manage food safety and health hazards, such as hindering the multiplication of pathogens to unsafe levels through the cooking process before the food item reaches the consumer.

This HACCP principle needs careful and expertly guided considerations for a successful implementation. Process steps are considered a critical control point if the deviation from their established standards will cause serious food safety issues. In the food industry, the practice of using a decision tree can potentially speed up the identification of CCPs.A decision tree is a block-type flow diagram consisting of two questions that eventually lead to the decision of whether the process is a CCP or not.

Examples of CCPs

Examples of CCPs

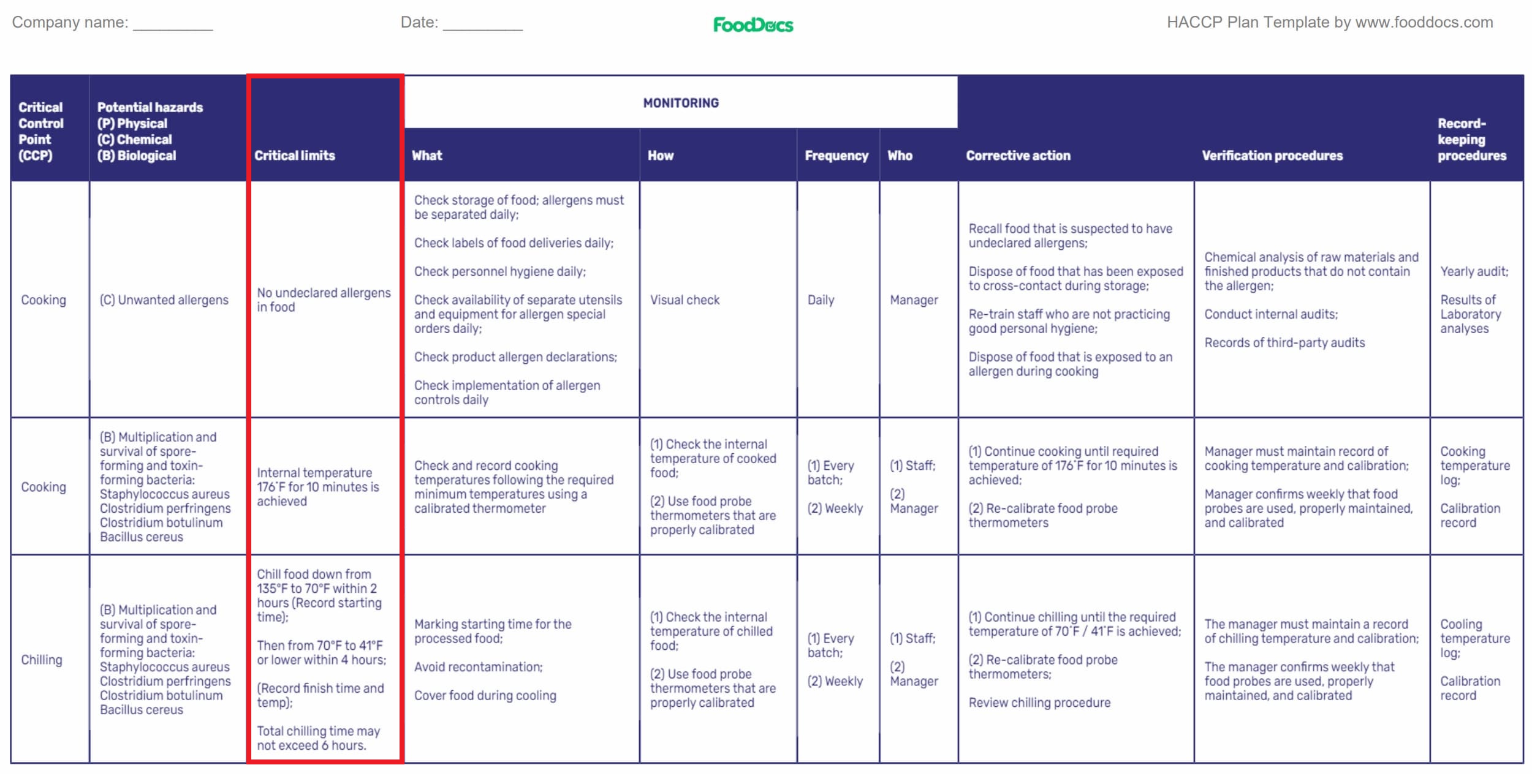

Purpose: Define measurable minimum and maximum values (such as temperature, time, or pH) that must be met to ensure each CCP is under control.

All succeeding principles will only be applied to operations identified as CCPs. After establishing which process steps are CCPs, all classified steps must be carefully analyzed and assigned with appropriate control measures. The succeeding principles will be used to ensure that CCPs are always in check.

To know whether a process serves its purpose in maintaining food safety, regulatory requirements must be set. In the food industry and the context of HACCP principles, these standards are termed critical limits. These limits are established based on scientific literature and are usually presented in numerical values.

It means that each CCP must be assigned a minimum and maximum allowable limit, which will signal to food business operators if the process is still safe or otherwise.

A good example of critical limits would be the minimum internal temperature for cooking foods. For cooking poultry raw meat, the food must be cooked to at least 165°F (74°C) with specified heating times to ensure that cells of Salmonella and other pathogens are removed.

Below this limit, the dish may be considered unsafe food and cause severe illness when consumed. Some more specific critical limits may include information such as minimum oven temperature and adequate time to hit the target internal temperature.

Critical limit determination and criteria for food safety are established through the information available in related literature and food safety standards released by regulatory agencies. These limits are significantly studied to ensure the production of safe food products. If critical limits are not met, your business may face serious complaints from consumers and regulatory authorities as a result of severe food safety issues.

Critical limits may be values based on the physical and chemical measurements monitored in your food operations.

The Food and Drug Administration has listed factors that could be used in establishing critical limits and their corresponding preventive controls. These factors include correct temperature, time of processing, solid content, titratable acidity level, moisture level, preservatives, water activity, salt concentration, proper sizes, and others.

Physical contaminations are usually controlled by establishing an allowable amount of the contaminant in the food. As an example, rejection or acceptance of a shipment of sugar can be decided depending on the weight of sieved physical contaminants on a sample batch.

In some cases, metal contamination is assessed based on the presence and sizes of shards in the product. Maximum and minimum limits are set together with preventive measures for critical control points.

Preventive controls come in different forms in a food manufacturing setup. For a business dealing with intermediate moisture foods such as fruit preserves, whose moisture level is around 15-50% to prevent any potential microbiological pathogen from spoiling the food.

Examples of critical limits

Examples of critical limits

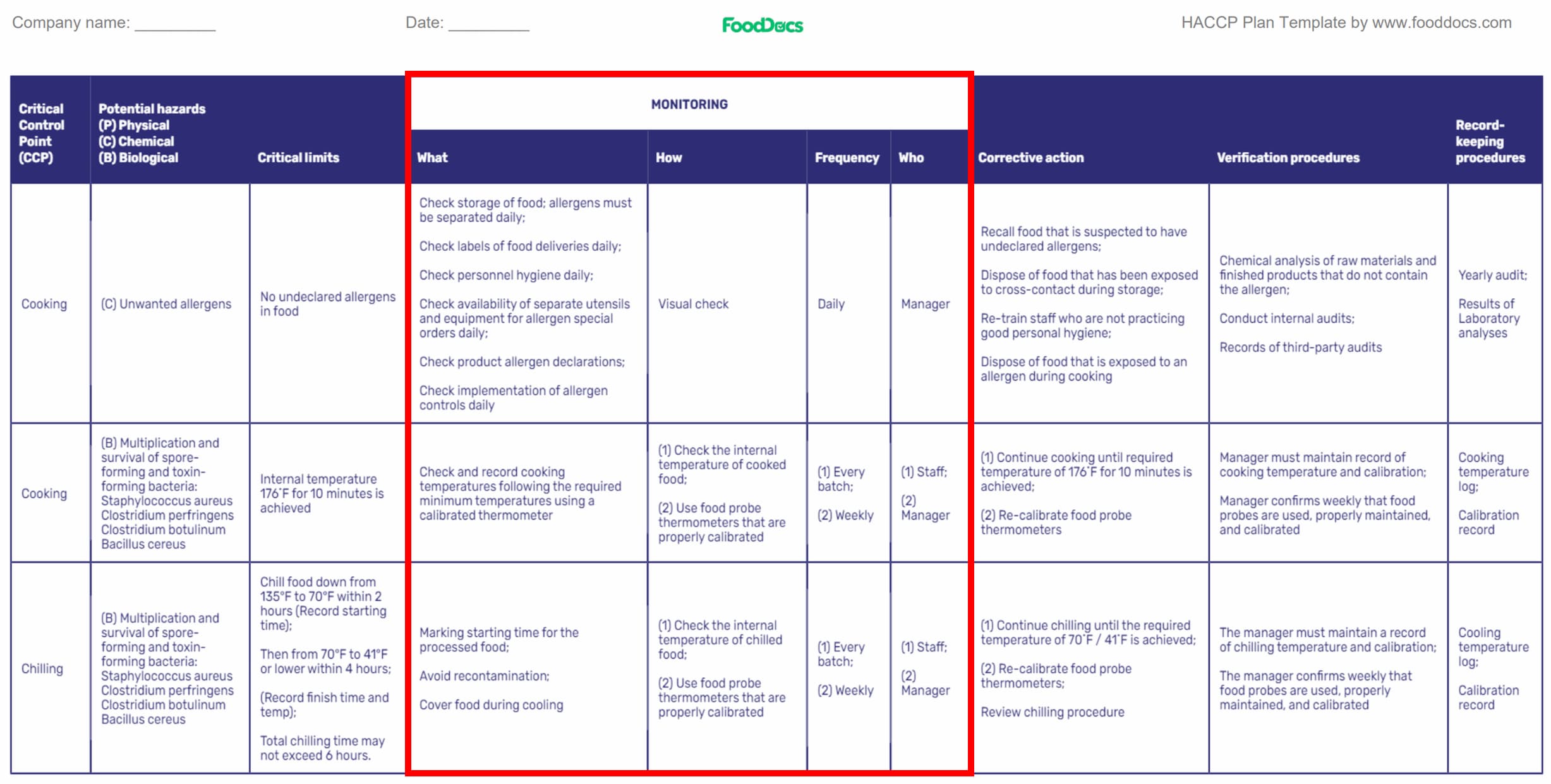

Purpose: Set up routine observations or measurements to confirm that critical limits at each CCP are consistently met.

Non-compliance from established critical limits requires a strict monitoring technique. You will only know if your product has undergone the correct degree of processing if adequate CCP monitoring procedures are in place. The monitoring procedure serves as a tracking record for your operations as well as a written document of deviations that occur.

Clearly identify parameters that need to be monitored to ensure that food safety compliance is consistently maintained.

Assigned personnel, particular parameters to be monitored, and the frequency of procedures for monitoring must be specified in this step. These monitoring components are usually presented as the following:

A procedure's criticality can determine the required monitoring frequency. Continuous monitoring procedures are essential operations in maintaining compliance with food safety. Consistent monitoring can help detect critical limit deviations and allow food handlers to apply corrective actions immediately.

Example of monitoring procedures

Example of monitoring procedures

The fourth HACCP principle requires your team to come up with comprehensive and precise monitoring forms that will be able to capture the important information needed for your food service operations and serve as control measures. Critical limits and appropriate preventive controls must be noted in the concerned monitoring forms for reference. Proper and effective training on how to test for specific parameters must be prioritized in your business.

As one International Food Safety & Quality Network shared:

If the same people who did the initial hazard analysis train new staff, it's less likely for the new folks to benefit the process by being a "fresh set of eyes" so to speak... When I became HACCP certified, I enjoyed the fact that examples used were food products that I wasn't super familiar with. It was a good learning experience.

Monitoring documents can then be used for future reviews if improvements at any point of food operation are needed or if further preventive controls must be applied. Procedures for monitoring must be clear, accurate, and effective. Monitoring procedures will involve the use of documents such as cleaning schedules, thermometer calibration schedules, and cooking logs. Decisions and corrective actions will be based on what information is written on your monitoring sheets.

Monitoring procedures must be fast as the results will be used for decision-making. Analytical testing is only used for verifying the results. In case monitoring procedures on a continuous basis are not applicable, a batch basis must be applied. Batch basis monitoring means applying examples of monitoring activities to a representative sample. The complexity of monitoring may depend on the number of identified CCPs and critical limits that need to be monitored.

Procedures for monitoring are often done through physical and chemical tests with backup monitoring techniques using microbiological testing. Physical measurement usually involves inspection of visual appearances, temperature monitoring, water activity, sensory analyses, weighing, and rigidity tests.

On the other hand, chemical tests can be in the form of titration or pH testing. Monitoring results must be fast and accurate because these results will be the basis for decision-making. Employees monitoring the products are often also associated with quality control.

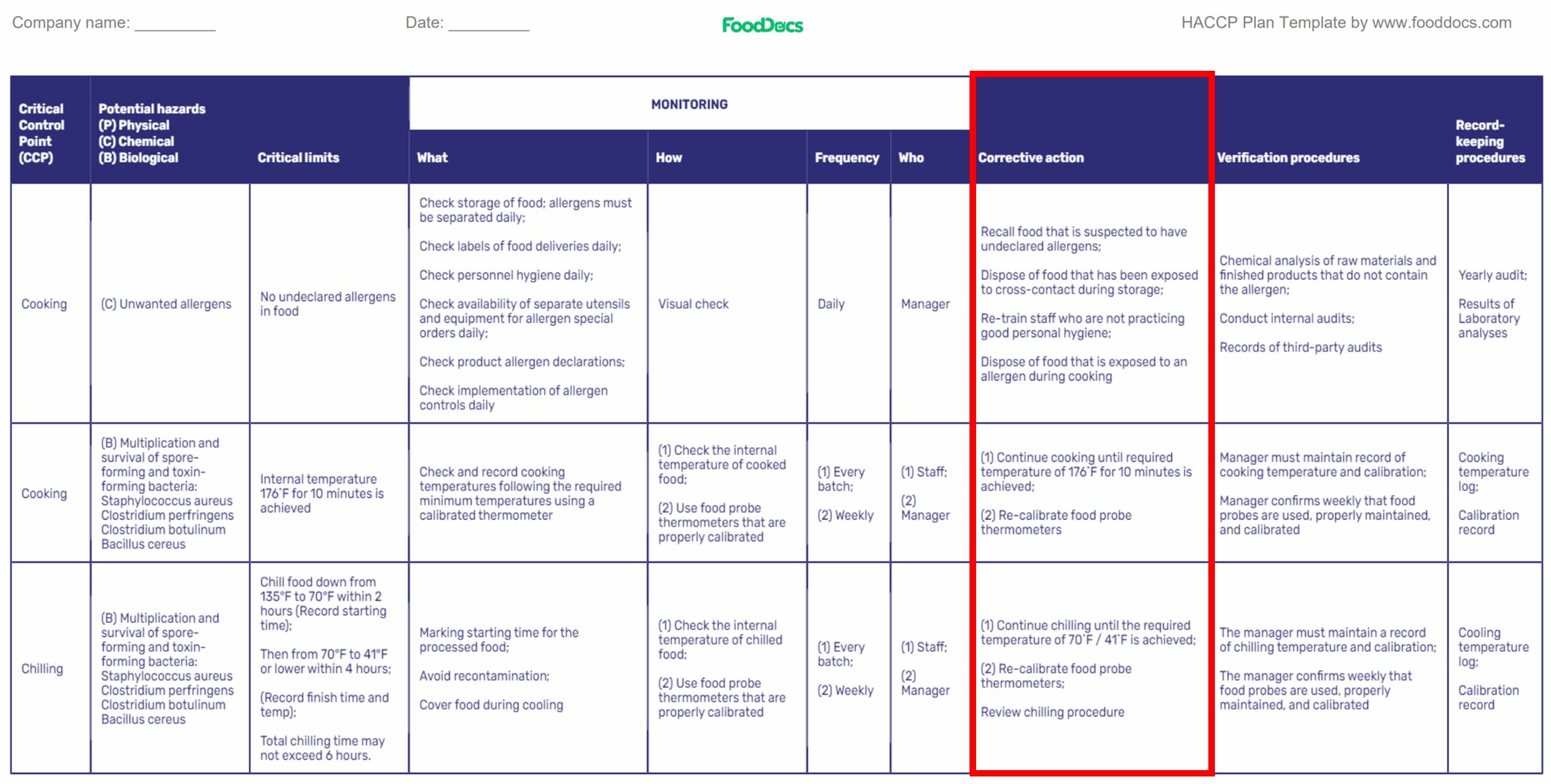

Purpose: Define the actions to be taken when monitoring shows that a critical limit has not been met, including handling affected product.

Despite having a preventive nature, your HACCP food safety program is not designed to be a zero-fail system. The loss of control and occurrence of deviations cannot be totally eliminated; rather, it is only minimized. This fact is especially true for high-risk processes. Although, frequent occurrences of deviations and risks would mean that modifications to your operations may be needed.

To address deviations from the set critical limits, your team must establish a set of definite corrective actions that will bring the concerned parameter to safe levels and prevent any potential severe health effects.

To prevent deviations from causing harm and productivity loss from unnecessary food waste, your team must be equipped with the appropriate instructions for correction methods.

If in case maximum or minimum limits are not met in your processing, appropriate corrective actions must be taken. These actions are considered solutions to non-compliant products. The decisions may either be, but are not limited to, reprocessing, extended processing, or disposal of unsafe products.

A good example of corrective action for a food safety program is when the monitored internal temperature during heating times is still inadequate. In this situation, the cooking staff must decide on the appropriate action, which is to continue cooking until the target temperature is reached.

Corrective actions are important in the effective implementation of HACCP food safety plans. They aim to minimize profit loss due to deviations and protect both the consumers and your food establishment from food safety issues. Deviations from critical limits may lead to the complete disposal of unsafe food products. This decision means a loss of profit from the used raw materials, time, and manpower.

In addition to implementing corrective actions, documenting the actions taken and their results are equally important. This part of the HACCP principles will help trace the source of potential hazards or complaints which might occur in the future.

Examples of corrective actions

Examples of corrective actions

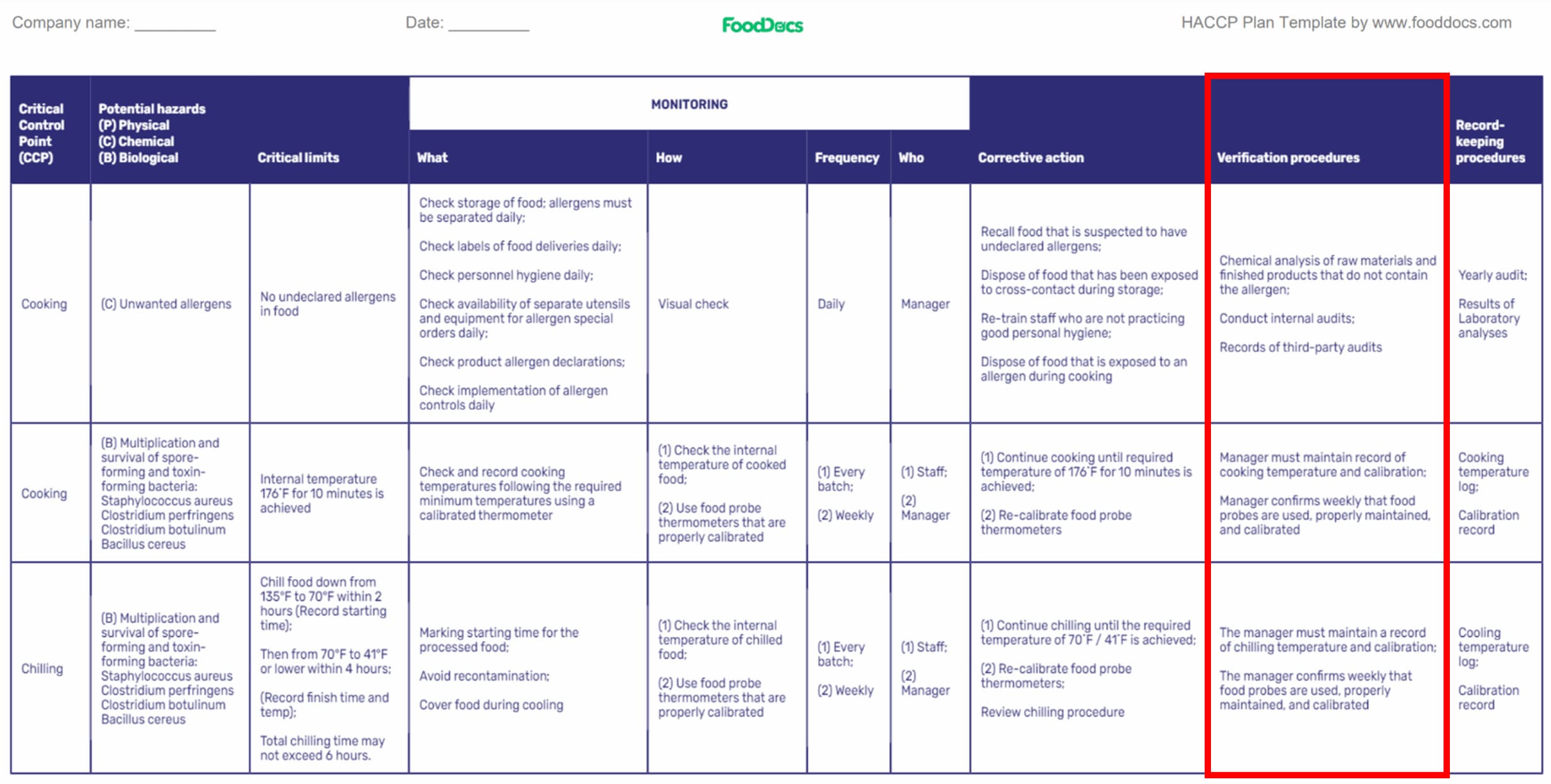

Purpose: Confirm that the HACCP system is working effectively through activities such as record review, calibration, and internal audits.

The HACCP team must also create plans for regular aspects of verification that will help ensure that the food safety plan is functioning as expected.

This HACCP principle includes the verification activities of the hazard evaluation itself, identification procedures, monitoring, and authorized corrective actions. Over time, operations will change as much as raw materials will. This means that the appropriateness of your HACCP food safety plans may also change.

The verification principle also ensures that the current HACCP system is being followed by the whole team. It also allows your HACCP team to reevaluate any food safety hazards that might have been developed and were not included in the current HACCP system. The verification process step must include procedures to help reevaluate the HACCP plan and update it according to new legal requirements for the improvement of a safe food production process.

Verification steps usually come with food regulatory agency audits, which will extensively reassess the validity of the businesses' HACCP system. Verifications are especially important when new methods are introduced to the operations. Reassessment of potential health hazards that this new method of preparation may have is required by the HACCP system.

This procedure has three stages: Initial validation, ongoing activity of verification, and reassessment. The first validation is concerned with the first few days after the initial implementation of the HACCP plan. This type of verification procedure usually includes 3 months of food processing. Initial validation and proper verification procedures are performed by supervisors by reviewing previous records and performing on-site inspections.

After establishing that the food safety plan is working, periodic assessments or annual reviews and continuous monitoring are scheduled to maintain the integrity of the plan. Reassessment entails routine reviews of the whole plan to see if they are still following the HACCP principles after a few years of operation. Frequent reviews of your operations will allow your team to assess whether the HACCP system is working or not.

Example of verification procedures

Example of verification procedures

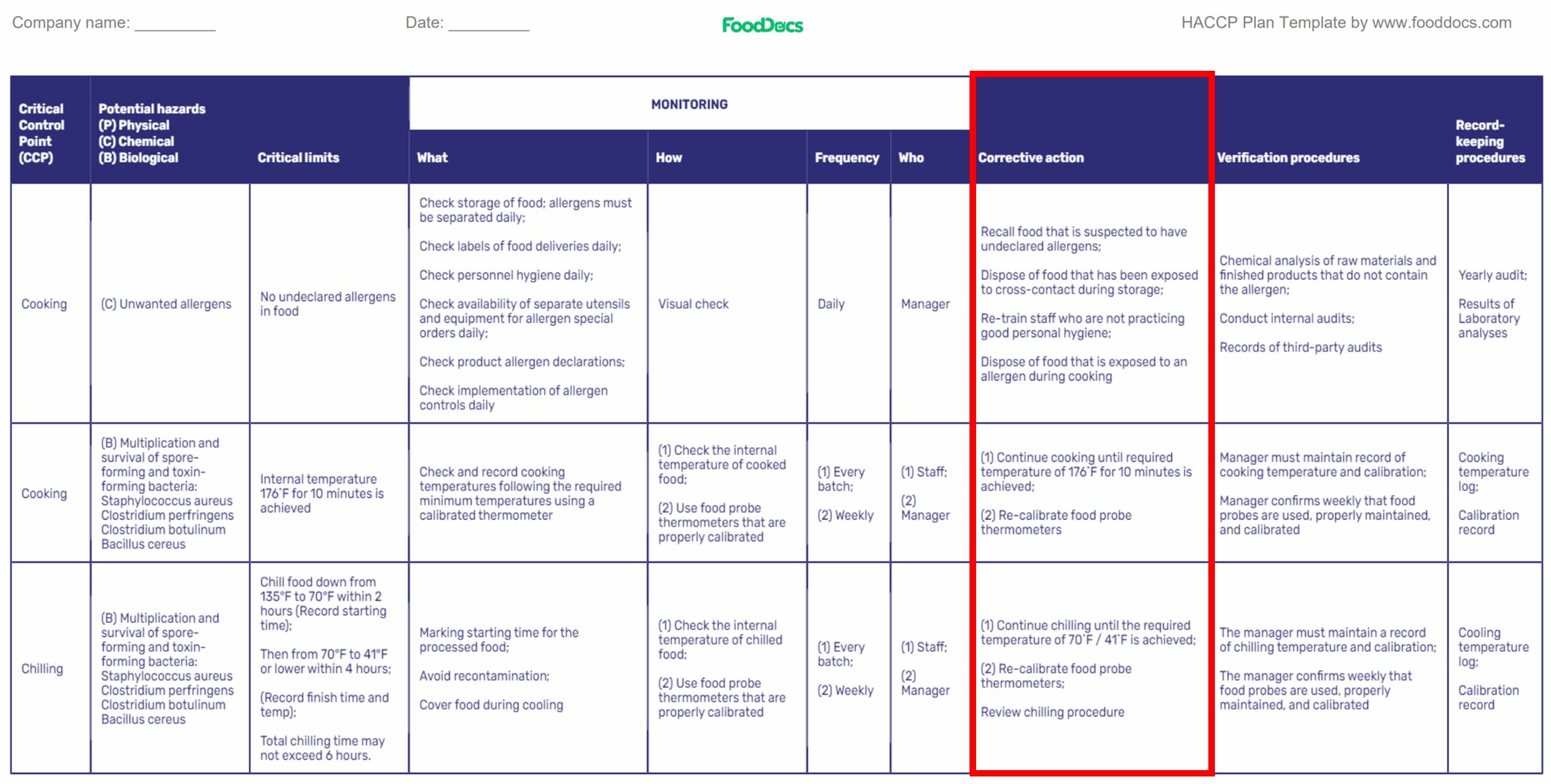

Purpose: Maintain written evidence that the HACCP system is properly designed, implemented, monitored, and verified.

All food safety documents related to the HACCP system must be properly documented and filed.

A part of the seven HACCP principles requires record-keeping procedures for all important activities, such as the HACCP plan itself, the summary of food safety hazard analysis, monitoring program, deviations, corrective actions, verifications, and standard operating procedures.

Your HACCP plan will also serve as a tool for traceability purposes should a food safety issue present itself and create an unsafe product. This compilation is also needed for regular audits to help your team assess if the current HACCP program is still effective.

Because your operation is not expected to be perfect, deviations from the established standards will occur. Following the HACCP principles, corrective action procedures which have been applied must be monitored. Once these products are released to the market, there are small instances that consumers will be able to detect them. Your team can then use your records to verify if the product being complained about is part of the batch with deviations.

Example of corrective procedures

Example of corrective procedures

Documentation of accurate records will serve as proof of whether the HACCP plan is effective or not. Include an executive plan summary table of your entire HACCP plan. Accurate record-keeping will also entail compiling other documents such as CCP monitoring records, employee training records, verification reports, and biological risk assessments involved with your HACCP plan.

Some of the most important records are monitoring forms such as a cooking temperature log, fridge temperature log, and thermometer calibration log. Complete documentation can help you secure a good rating for future reviews or certifications.

The best way to present your HACCP plan is through a summary table where only the most important information is added for accessibility and ease of understanding. Not familiar with this table? We've got you covered at FoodDocs. Use our free HACCP plan template as a reference and guide for building your own summary table.

Complete HACCP plan template on FoodDocs free tools page

Complete HACCP plan template on FoodDocs free tools page

Need a faster and smarter solution than a free template? Use our built-in customizable HACCP plan to get all sections done in just 1 hour. Sign up with us and answer a few basic questions about your food operations to get your digital HACCP plan now.

In making a traditional HACCP plan and implementing it, the most important part of the process is proper hazard identification and analysis. The team with direct control of hazard analysis must accurately perform the task.

Hazard analysis is the first step of HACCP and requires several hours of analysis as well as expert advice regarding the food production process.

Failure to identify these hazards can lead to potential problems such as loss of batch products, more food waste, product recall, or worse, customer complaints. All of these problems can lead to a bad reputation for your business in the food industry. In identifying and analyzing hazards, in-depth information and science-based assessment for illness caused are important.

Based on the basic principles of HACCP, your products require very little end-product testing. The HACCP food safety management system is based on a preventive approach and focuses on all testing and verification during food production operations and almost none for finished products.

In making such a complicated and comprehensive document, several revisions and endless meetings are in your future. Not to mention the big chunk of time you will spend on rewriting your HACCP plan to fit any food operation as well as the local and international regulatory standards.

To address these safety concerns, we have developed a digital HACCP plan builder. In just 1 hour, you can build a comprehensive HACCP food safety plan that is compliant with your country's legislation. No more long hours of meetings and looping revisions. We can help you comply with all of the HACCP principles and make a plan fit for your food business by just answering a series of questions.

Establishing a HACCP plan reduces the chance for product contamination and unnecessary risks to a company's profits and reputation. It also reduces the need for end-product testing in the production of wholesome food. Your approach to food safety is crucial for running a food business and serving safe food products.

HACCP was developed to address food safety risks and the sources of contamination before they even cause bigger problems, such as starting a foodborne illness outbreak from a processing facility. The principles linked to a HACCP food safety program lay out a solid foundation for controlling potentially unsafe foods from reaching consumers through sanitary conditions and even improving food quality to a point.

Food safety risks and hazards will always be present in the food business. As such, food companies such as food processing plants and food service businesses must use such a plan, or at least a related plan, to protect their customers from the severe health effects of hazards.

Food recalls were estimated to cost at least $10M in expenses, excluding the damage caused to the brand's reputation. This cost may even be higher for larger food businesses and food processing plants. This is something that you do not want to happen to your food business.

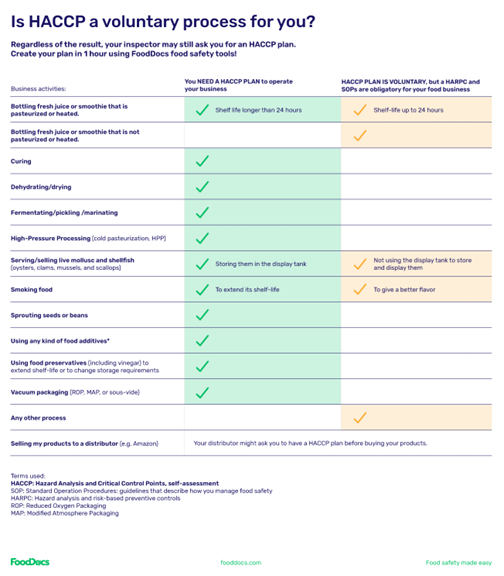

If you are a new food processor or an entrepreneur starting out on your business, the first food safety question that you may have might be, "Is HACCP a voluntary process?"

The requirement of implementing a HACCP plan is dependent on a country's food safety regulations and the types of food businesses. In the UK, all food businesses are required to implement a HACCP plan.

On the other hand, the requirement for a HACCP plan in the US is a bit more complicated. Generally, businesses under the United States Department of Agriculture Food Safety and Inspection Service (USDA FSIS) must have a HACCP plan. This includes businesses that handle processed and raw meat and poultry.

Businesses handled by the Food and Drug Administration concerned with beverage and seafood products are required to have a seafood and juice HACCP plan, respectively as well. All other food businesses must undergo an evaluation to understand if they need a HACCP plan or not.

In line with the Food Safety Modernization Act of 2011, food businesses that are not required to have a HACCP plan must at least have a Hazard Analysis and Risk-Based Preventive Controls (HARPC) system. This food safety system was established under the FSMA law, which covers a wider set of regulations on types of hazards and the nature of required preventive controls.

Different types of food preservation methods require specific HACCP procedures. Basically, any process that functions as a method to control a health hazard significantly will require a HACCP plan. Loosely speaking, almost all processes will eventually require you to implement a HACCP plan to keep public health safe and prevent any foodborne illness from occurring.

Under regulations implemented by the US Food and Drug Administration and the USDA, the following food manufacturing operations are required to have a HACCP plan or at least a food safety plan:

Under these industries, the following process operations and types of food preservation may need to be assessed under the lens of a HACCP process and its team:

Below is a table that clearly shows which food businesses require a HACCP plan in the US:

Guide for food businesses that need a HACCP plan

Guide for food businesses that need a HACCP plan

A HACCP certification is the process of evaluating a food business based on the effectiveness of its HACCP food safety management system and awarding them a certificate of recognition as proof.

A qualified third-party food safety auditor performs the certification process. The HACCP audit consists of an on-site inspection and a thorough official review of documents to detect any cases of loss of control. All documents ranging from prerequisite programs such as employee training records to the last process for building a HACCP plan will be reviewed.

A HACCP certification process involves a series of inspections and frequent reviews, both on-site and documentation aspects, of your food safety management procedures. Certification for HACCP costs quite a lot and requires a big amount of your team's time, so you must ensure that you are always prepared for it.

As you see, a lot of paperwork must be stored and found on time for a HACCP audit. The easiest way to store all this documentation is to have a digital HACCP program where everything is stored automatically on a continuous basis and easily found. Yes, exactly like it is in FoodDocs.

Learn the basic conditions and in-depth processes involved in acing a HACCP audit and certification here.

The process of HACCP certification includes the following steps:

1. Get your HACCP plan done

2. Establish your HACCP system

3. Invite a third-party food safety auditor to review your HACCP plan

4. If the auditor finds everything satisfactory, your business will receive the certification.

In case your business does not pass the certification process, review all recommendations and immediately apply.

HACCP certification process

To ensure the success of your HACCP process plan, there are a number of preparation processes that you could make with your team to build a solid foundation for your system. These preparations can even be done before building your HACCP food safety plan to understand further why there is a need to emphasize the assurance of food safety and how can the HACCP food safety program address this.

Additional information and increased awareness of food safety issues can help you to create your HACCP process. To achieve this, you can enroll your team in seminars, educational programs, and training for HACCP.

These programs can be an essential foundation of the HACCP-making process. They commonly contain information on the fundamentals of the HACCP process, including what hazards are, their common causes, and what are the most effective steps to control them. In addition, training and seminars must orient your company employees with their specific tasks and the importance of their roles in the HACCP process.

An option for making a HACCP food safety plan is hiring food safety consultants and specialists with expert knowledge of food safety. This option can be particularly costly even for only the initial review fees. There are a huge amount of training resources available on the internet for you to use.

Depending on the training you need, you may find something for free or a reasonable price that covers all of the information you need. The most important premise of these training courses is to know the fundamentals of the HACCP process.

Remember to shop around when looking for HACCP training online, as you may be able to find some specific to your industry type. Certifications may also act as employee training records which may be requested by health inspectors during audits.

As shared in this thread, Tony Connor (Chief Technical Advisor, IFSQN) is the instructor of a webinar called Practical HACCP Training for Food Safety Teams for $97 USD per person and covers:

If your team lacks the time and has very little information on how to make your HACCP process work, try out digital solutions such as FoodDocs. We give you an easy-to-use HACCP planning option, especially if you are starting a food establishment and are unsure of how to set up your HACCP process. By answering a few basic questions, we use our built-in software to create your HACCP plan in one hour, saving you time and money and helping you to create your HACCP plan and set up your entire HACCP process smoothly. Beyond that, you can use the FoodDocs app to create monitoring sheets and record any audits you perform there, as well as schedule your team training and set up notifications for any necessary tasks.

A digital solution can be a great help when you are not used to the processes required, especially in monitoring. Our mobile app reminds you of your everyday tasks and can alert you if the observed values of your CCPs are beyond the critical limits. Get HACCP compliant in just 1 hour!

You can write your HACCP plan manually or through the use of support software. Previously, you only had the solution to write the plan manually traditionally, which meant excessive paperwork for your team.

The traditional practice of writing a HACCP plan involves intensely studying food safety news, regulations, and literature. Writing a HACCP plan manually can take you an average of 1 to 12 months to finish depending on the complexity of your plan and if you have knowledge of the essential foundation of HACCP.

You can significantly increase the progress of your HACCP plan writing by hiring a food safety consultant or seeking independent expert advice. Writing your plan can take only an average of 70 hours, but the cost can significantly double.

With the help of technology, you can now use software programs to generate a comprehensive HACCP plan template and be HACCP audit-ready. The whole process can cut the traditionally needed time to just 1 hour.

An example is the HACCP plan food safety software from FoodDocs, which uses artificial intelligence and machine-learning program to accurately create a detailed template for your specific needs:

.png?width=1065&height=924&name=HACCP_template%20(1).png) Digital HACCP plan from FoodDocs

Digital HACCP plan from FoodDocs

What makes a Hazard Analysis Critical Control Point plan hard to complete fast is the idea that it must cover every corner of your food business and that this process must be repeatedly done for every process or food item. HACCP food safety management is often product or process-specific, making them unsuitable for other processes in your food business.

At FoodDocs, we offer a digital solution to provide you with a comprehensive and customizable HACCP plan template builder for the food chain industry. Our food safety software uses artificial intelligence and machine learning program to generate a comprehensive template for you.

Our system can generate your digital HACCP plan with ease using the following features:

The process would only require you to answer a few questions regarding your operation, and our system can do the rest. Generating your HACCP plan template can be done in an average of 1 hour.

When you use our HACCP plan template software, you can get the following:

What's more, our system also fulfills other HACCP requirements, such as prerequisite programs, standard operating procedures (SOPs), and other preliminary tasks that will ensure the safest and most solid foundation for your operations, including the following:

This list is non-exhaustive, and you can get more when you sign-up and use our services.

Our system can help you create a HACCP plan 500x faster and 15x cheaper than hiring a consultant or creating it independently. You can focus more on the successful implementation of your HACCP plan.

Start your food safety compliance journey now and join at least 35,000 companies that have signed up with FoodDocs. Use our free 14-day trial and build your HACCP plan in an average of 1 hour.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...