Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Cross-contamination is the transfer of harmful bacteria, allergens, or chemicals from one food, surface, piece of equipment, or person to another, making food unsafe to consume.

Below are five clear, real-world examples of cross-contamination commonly found in commercial kitchens and food operations:

Each of these examples shows how easily contaminants can spread when employees don't follow food safety controls.

Food security and an enjoyable eating experience can only be achieved if the food you are served is safe. This goal is hard to achieve when the main reason for foodborne illnesses is something that cannot be seen. Pathogenic microorganisms that bring forth foodborne diseases live on the food you prepare as well as on the food handlers themselves. These microorganisms can then travel from one place to another and spread their potential to cause disease. This event is exactly what cross contamination is.

Despite the efforts of food safety agencies to minimize the occurrences of foodborne illnesses, mistakes and the lack of commitment to food safety contribute to the dominant existence of food safety concerns. In fact, cross contamination is a significant cause of contamination in food and has led to many food poisoning outbreaks and food recalls in the past. Cross contamination is a sure sign of improper food handling and speaks for a poor food safety management system in your establishment. It is important to educate all food handlers on the importance of food safety and how cross contamination can negatively affect it.

WHAT WE'LL COVER:

Cross contamination is defined as the movement of a contaminant such as harmful microorganisms from one point to another. These contaminants can be physical, chemical, or biological contaminants. Cross contamination usually occurs due to poor handling practices and can cause significant food safety concerns such as foodborne illnesses.

Most commonly, cross-contamination is best defined as the spread of harmful bacteria and other pathogens from one location to another. Despite this, the unwanted transfer of chemicals, allergens, and other toxins can also be addressed as cross contamination. In addition, the unknown presence of allergens can also be considered as cross contamination. The consequence of these events is that pathogens from raw food ingredients can be transferred to cooked food and contaminate them.

The knowledge of what contaminants have the most potential risk of affecting your products as well as proper food handling practices are key to addressing this concern. Cross contamination can easily be addressed with proper training and orientation.

Cross contamination can occur at any point in the food supply chain. It starts by improperly handling raw food which normally contains high amounts of bacteria. These harmful microorganisms are then transferred by skipping food hygiene practices such as handwashing in between touching raw food, equipment, cooked products, and from a different food worker.

Additionally, contaminants can come from water, air, unclean equipment, clothing, soil, employees, and food contact surfaces within the production area. Specifically, here are some situations where cross contamination examples may most likely occur from:

These are just some examples of how cross contamination can occur in your kitchen area. Logically, it can also happen by bringing materials from the foodservice floor into the kitchen without properly sanitizing it. Cross contamination can be minimized with proper knowledge of their identity and how to prevent them. These pathways for the occurrence of cross contamination can be categorized into three different classifications.

To properly identify and create strategies to prevent cross contamination from happening, food manufacturers must be aware of the primary sources and types of cross contamination. These courses are classified based on the source of contamination.

The main classifications of cross contamination in food are the following:

As we have mentioned, all food naturally has both harmful, beneficial, and common microorganisms. These microorganisms are killed to prevent causing any changes to the food item and causing foodborne illnesses. Before processing, these microorganisms can be transported from the surface of the food item to another ingredient. Some instances when this type of cross contamination occurs include the following:

This pathway for cross-contamination is often caused by improper sanitation. Food equipment can become contaminated even when they are stored properly. Putting back a knife in its placeholder can be a source of contamination as it comes into contact with food. As such, equipment such as cooking utensils, processing machines, and kitchen surfaces must always be cleaned and sanitized before use. Specifically, equipment-to-food contamination can occur in these instances:

Some pathogens including Staphylococcus aureus are considered commensal. This term means that they naturally live on their hosts which happen to be humans. They are concentrated in the nose and skin areas and can easily transfer to anything that we touch.

Additionally, employees can easily carry pathogens such as raw meat bacteria to other places in the kitchen which can cause widespread cross contamination. This is why handwashing and strict food hygiene are prerequisites to a good food safety management system. Additionally, the following practices can also cause cross contamination:

All of these pathways of cross contamination are likely to occur with improper food safety management systems. This includes the lack of training and proper knowledge on how to conduct proper food handling practices.

Cross contamination causes serious health effects including vomiting, headache, diarrhea, and nausea. A single report of cross contamination can cause big problems for your food business and can significantly affect your operations.

To help you address sources of cross contamination before they even cause bigger problems, you can use our digital Food Safety Management System at FoodDocs. With this digital solution, you switch to a digital platform that can automatically generate and provide you with the most important food safety documents fit for your operations. The best part is that the switch only takes an average of 15 minutes and that the process only requires you to answer a few basic questions.

Throughout the years, there have several occurrences of foodborne disease outbreaks. The majority of them have been reported to be caused by improper food handling. Some foods are more linked to outbreaks than others. This means that these foods can be considered high risk and must be handled properly.

They are more likely to cause cross contamination than others. Some foods related to such incidence include lettuce, chicken, deli meats, eggs, milk, fish, and precut fruits.

In 2006, 71 persons were reported to have experienced food poisoning and the reason was traced back to a fast-food restaurant. Out of the 71 ill patients, 53 were hospitalized and 8 developed kidney problems. The outbreak was concluded to have been caused by the improper handling of previously contaminated lettuce which was a common ingredient in the foods consumed by the affected consumers. The lettuce was found to be contaminated by E.coli 0157:H7 which is a dangerous strain of this bacteria.

Perhaps one of the most common foodborne disease-causing microorganisms is Salmonella. Annually, at least 19,000 people fall ill due to poisoning because of Salmonella.

A notable outbreak caused by this pathogen is the multistate Salmonella outbreak traced to cucumbers. This outbreak affected at least 720 people of whom 204 were hospitalized. The reports of the FDA suggested that the bacteria was spread through cross contamination of the cucumbers and the crates used in transportation. Another cucumber-related outbreak from December 2024 resulted in 100 reported cases and 25 hospitalizations.

In more recent outbreak news, Salmonella was also the culprit in an outbreak related to egg fried rice in China. In January 2022, at least 220 people fell ill and experienced diarrhea, high fever, abdominal pain, nausea, and vomiting. Authorities revealed that the cause of the outbreak was because the cooked egg fried rice was placed in previously used basins that contained residual egg fluids.

In a comprehensive study of multistate foodborne outbreaks in the United States from 2010 to 2017, cross contamination was identified as a leading cause of outbreaks. The study mentioned that cross contamination is likely to occur within the distribution chain and while implementing poor food safety and agricultural practices. Cross contamination was ranked alongside the production of sprouts and fresh produce importation as contributors to multistate outbreaks.

On many different occasions, the lack of proper food safety practices leading to cross contamination has been implicated as the cause of foodborne disease outbreaks. These occurrences happen despite the strict rules and regulations of food safety agencies. Cross contamination is prevented by improving commitment to food safety. As such, implementing a comprehensive and effective food safety management system can help control these occurrences.

As mentioned, cross contamination serves as a carrier of microorganisms and is a common source of food poisoning. There have been several reports of foodborne illness outbreaks that have stemmed from improper food handling. Whether it may be from foods, equipment, or employees, cross contamination is a serious food safety hazard. All consumers, especially the immunocompromised groups, are susceptible to the effects of cross contamination.

As part of the food safety training of every food business, employees must have substantial knowledge of the main causes of cross contamination. The following are the most common reasons why cross contamination occurs in the restaurant kitchen.

The use of low-quality raw materials is a common factor for cross contamination. All food suppliers are required to comply with strict food safety standards. Low-quality materials are a sign of a lack of monitoring and inspection in food operations. These raw materials can have a high amount of physical contaminants such as rodent hair, soil, insect parts, dust, unwanted debris, pieces of metal, and glass. These contaminants carry disease-causing microorganisms and can be transferred to your food preparation area and other food materials.

These low-quality materials may have also undergone inadequate analysis for chemical and toxin composition. Not only does this mean more work for your food business, but it also has a greater risk of causing foodborne illnesses and outbreaks. When purchasing raw materials, ensure that your supplier has the necessary documents such as a certificate of analysis to prove the quality of their products.

Food safety training includes teaching food handlers about the importance of food safety, what is food contamination, and how it can be prevented. This type of training program teaches food employees basic food safety steps such as the following:

These food safety practices are just some of the common and standard ways to maintain a safe environment in your restaurant kitchen area. They can be further improved by teaching food employees the consequences of not observing these safe practices in the kitchen. It is not enough for food employees to know how to do them.

As a food business owner and food safety manager, you must also define cross contamination and explain the importance of preventive measures. Implementing these food safety practices almost ensures the complete safety of your operations.

An unappreciated concept in some food companies is the team's food safety culture. This concept is the collective thoughts, beliefs, and views of food employees toward food safety. Put simply, a positive food safety culture ensures that food handlers will uphold high food safety standards even when no one is looking or monitoring them.

This can be achieved by helping food handlers appreciate food safety even more. It's not enough to just define cross contamination and food safety practices to them. When food handlers are committed to their purpose, food safety management becomes easier. A positive food safety culture can also be achieved through the following steps:

Ensure your compliance with food safety laws

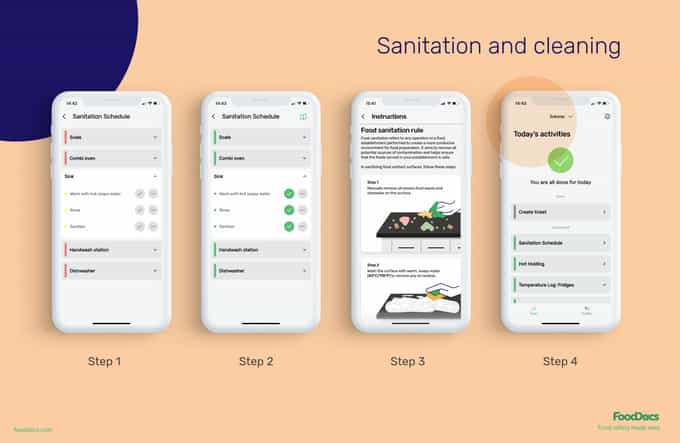

A food facility that is filled with filth and has a bad waste management system is a good breeding ground for foodborne illness-causing pathogens. Proper cleaning and sanitation are part of the prerequisites of higher food safety management systems. Working in an environment that is unclean significantly increases the chances of cross-contamination. To create a cleaning working environment, follow these steps:

A comprehensive, effective, and efficient food safety management system (FSMS) ensures that all food safety tasks are performed and that food handlers keep their focus on their specified jobs. Your FSMS must be able to monitor your operations to address any concerns such as the lack of proper knowledge on proper cooking and sanitation. It encompasses all key elements to prevent cross contamination. Under your FSMS, you must be able to regularly monitor the following practices:

Cross contamination is a sign of lapses in the food handling practices of a food business. It could occur as a result of carelessness or because the whole management system is ineffective. The effects of cross contamination can be prevented if your team of food handlers knows what they are dealing with. The first step to addressing it is to know what is cross contamination and then how to prevent it.

Cross contamination is thought to be the leading cause of the spread of foodborne diseases. This process can easily occur in areas with poor food handling practices. Because microorganisms are too small to see yet are always present everywhere, the only way to address them is to prevent them from further spreading.

To prevent cross contamination you should orient all employees in your foodservice establishments with proper practices. Below are some major steps commonly used in preventing cross contamination from occurring or further causing damage.

1. Monitor suppliers. As mentioned, cross contamination is prevented by acquiring good-quality raw materials. If there are very few contaminants in the foods that you use, there will be a lesser need for strict cooking procedures. To achieve this, food suppliers must be able to present any proof that they are compliant with the most recent food safety laws and regulations applicable to their products and services. Demand for a copy of their certifications and licenses as well as proof of analyses for their products. Food suppliers must regularly update these documents, whereas your food safety team is required to verify their compliance with food safety standards by performing verification procedures.

2. Implement strict hygiene standards. The food-handling team's hygiene status affects the safety of the food being prepared. Food employees must know the proper way of handwashing and maintain a neat presentation of themselves. A single strand of hair on the food they are preparing can easily cause commotion in the food community and pose a threat to public health. As such, food safety uniforms such as hairnets, face masks, and gloves where applicable must be properly maintained and worn. Hygiene standards also include reporting any signs of sickness in food handlers. This can be cough, common flu, cold, or anything that can become contagious and can contaminate the working area.

3. Choose an effective pest control system. Pests can accumulate as a result of poor waste management. Different types of pests can carry several disease-causing microorganisms. As such, their control is an important task to prevent cross contamination. In preventing the spread of pests, follow these rules:

4. Store foods correctly. Storage of foods plays a crucial part in preventing cross contamination from occurring. Proper storage means segregating raw foods from ready-to-eat ones in the refrigerator. A proper arrangement is suggested when storing foods. Anything that can drip when thawed must be placed at the bottom, whereas ready-to-eat foods and those that require very minimal processing must be on the top shelves.

Even in dry cabinets, improper storage of foods can cause cross contamination. Unclean packaging materials filled with dust can cause contamination of foods that have minimal packaging. Additionally, the temperature of the storage area can encourage the growth of pathogenic microorganisms and can increase the chances of causing cross contamination. As such, proper stacking and storage temperature must always be considered to prevent the growth of bacteria.

5. Practice strict food handling standards. Cross contamination is prevented by food handling practices such as proper sanitation of food contact surfaces and proper preparation and cooking process of food materials. Sanitation includes using the right amount of cleaning chemicals that will not affect the food to be prepared. This practice must be done regularly before and after operations. Food contact surfaces such as the preparation table will receive most of the ingredients for daily operations and therefore must be always clean.

After sanitizing, the preparation comes next. During preparation, cross contamination is most likely to occur when not careful. The simple use of a single, clean cutting board for all foods to be prepared in a day is a sure way to cause bacterial cross contamination. Use separate cutting boards and a set of knives for preparing raw meat and raw vegetables. If you have limited utensils, at least clean the boards and knives in between use.

The juices of the raw meat can be transferred to the raw vegetables which will only require minimal processing. This would mean that the bacteria from the meat juices can persist even after preparation. As such, practice proper segregation of foods during preparation and be cautious with the cleanliness of your surroundings including your preparation area and utensils.

Additionally, finished products must also be separated from each other especially when one has allergens and the other has none. The likelihood of allergens contaminating two different products made within the same manufacturing location is very high. As such, proper segregation and conduct of preoperational procedures must always be observed.

6. Cook foods to the proper temperature. The importance of cooking must also be emphasized. Applying heat to raw foods significantly reduces the number of pathogens in them. Microorganisms are killed once they are subjected to the correct and required temperature for processing. This is the reason why thorough cooking is required. Heat must penetrate the food you are preparing up until its center which is the coldest point.

Even though cooking will reduce the pathogens in food, this does not mean that you can rest easy with preparation. Cooking is only effective for a certain amount of microorganisms. If the level of contamination becomes too much, the effects of applying heat will decrease. Additionally, cooking cannot remove toxins produced by some of these pathogens and therefore, will not be effective and will still cause foodborne illnesses.

Beyond these 6 control measures to prevent cross contamination, there are more practices that a food business can apply. Cross contamination can be prevented by addressing food safety hazards before they even multiply or get out of hand. Applying the mentioned practices can significantly increase the confidence of your team and the whole food business with your operations. Additionally, public health can rest easy that you are only producing safe food.

Read more about how to avoid cross contamination here.

The best way to address cross contamination is to implement practices that will prevent its occurrence. In doing so, constant monitoring must also be present. Food safety management systems help document these practices and serve as proof of compliance with food safety laws and regulations. The proper implementation of a comprehensive FSMS ensures that cross contamination is kept at a minimum level or completely excluded from your operations.

As a food business owner or food safety manager, we know that your best interest is concerning public safety and providing a satisfactory eating experience to consumers. To achieve this, your operations must be free from any contamination, whether it be from cross contamination or other sources. To ensure your continuous compliance with food safety laws and regulations with very little effort, switch to our digital Food Safety Management System.

At FoodDocs, we understand the necessary practices, procedures, and documents needed to maintain compliance with food safety laws. As such, we have developed digital solutions to improve the efficiency of your food safety operations while maintaining compliance every day.

Using our digital solution, you will be able to enjoy the following features and benefits:

In addition to solutions for food employees, our digital Food Safety Management System can also help managers improve everyday operations.

Our machine-learning system generates a comprehensive FSMS for your food business based on your response to our basic questions. These inquiries help us understand the nature of your food business and generate your very own FSMS. This digital solution can help you switch from a traditional FSMS to a completely digital platform in just 15 minutes.

We base all of our suggested documents and procedures on the combined expertise of our food safety experts and the information of our customers who are in the same line of business as yous.

In addition to our digital FSMS, we also offer at FoodDocs a built-in customizable HACCP plan template builder. Similar to our digital FSMS, this software creates a food safety plan that is tailored to your food business within an average of 1 hour. This plan provides you with a comprehensive identification and analysis of food safety hazards in your operations that can potentially cause cross contamination.

Achieve and maintain compliance with us at FoodDocs. What is even greater about our system is that you will only need an average of 15 minutes to switch to a completely digital FSMS. In case you are not that familiar with the digital platform, our team offers efficient customer support and is available upon your request.

Remain compliant with food safety laws and regulations by using our digital FSMS. Ensure that all your food handlers know the importance of food safety and the consequences of breaches such as cross contamination to your business and public health. Explore FoodDocs now and set up your digital FSMS using our free 14-day trial.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...