Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

A HACCP program is a food safety system that controls hazards with critical control measures.

The purpose of a HACCP program is to identify, evaluate, and control food safety hazards so that food is produced, handled, and distributed safely and consistently.

This preventive approach focuses on controlling risks before they cause food safety incidents, rather than reacting after problems occur.

Hazard Analysis Critical Control Point (HACCP) is a prominent phrase in the food industry. This program has long been applied in manufacturing companies to minimize and control potential risks in the production chain to protect the welfare of consumers. In this article, we will learn about the HACCP food safety program and discuss an effective example.

WHAT WE'LL COVER:

A HACCP program is a standard food safety management system composed of critical control measures and monitoring procedures to ensure that food safety is a top priority and is always upheld.

The Food and Drug Administration explains that an HACCP food safety program is made to prevent food safety issues from arising in the first place.

The first HACCP food safety program was conceptualized in 1960 by NASA. It aimed to provide astronauts with food that is safe for consumption in space without the risk of foodborne illness.

HACCP programs use the Critical Control Point system to determine which steps are most prone to risks. They also establish risk-based preventive controls, standards, and monitoring procedures to ensure that your food business's raw materials and finished products will not cause foodborne diseases.

HACCP programs can be applied to retail stores, processing plants, and food service businesses.

What's more, building a correct HACCP program is critical to developing a comprehensive monitoring system, as it identifies all key areas that require monitoring.

If you want a HACCP program built specifically for your business, use FoodDocs' HACCP plan builder. You can create a program within one hour and set up your monitoring system immediately.

Several hours of brainstorming, evaluation, and documentation go into creating a good enough HACCP program.

Food safety programs cannot be completed without ensuring a sanitary environment and minimizing the risk of hazards.

HACCP prerequisite programs guide the proper design of facilities, help with guideline implementation, and allow for the verification of standards and processes.

Here are some of the most common HACCP prerequisite programs:

GMPs involve methods, equipment design, facilities layout, and ingredient handling practices for producing processed foods. This prerequisite program also includes the minimum sanitary design principles for producing safe and wholesome products.

They are a part of food quality control that ensures products are consistently produced and controlled while minimizing contamination. They also include adequate and effective training for company employee practices.

Read our comprehensive article about GMPs from here.

SSOP is a set of guidelines that aim to maintain certain sanitary conditions in manufacturing and provide a daily monitoring guide for their maintenance. This prerequisite program prevents the production of hazardous foods by ensuring that food handlers know how to clean and sanitize food areas.

This prerequisite program aims to implement four basic principles: deny entry, shelter, food, and destruction.

The most important aspects of these programs include training personnel in terms of hygiene and proper behavior in the manufacturing facilities. These programs include orientation and regular reminders on using protective gear, operating machinery properly, and keeping the environment clean.

Importantly, setting up a monitoring system is key to ensuring compliance with HACCP prerequisite programs. With the help of FoodDocs' smart Food Safety Management System software, you can build a monitoring system based on these essential programs.

The system built by our software will help you monitor compliance parameters for the prerequisite program you want to implement. This will make HACCP system implementation faster and more efficient.

A HACCP program ensures the food items and finished products your food business produces are always safe for consumption. Here are some of the main purposes of a HACCP food safety program:

Once again, by implementing an HACCP food safety program, food businesses aim to prevent, reduce, or eliminate hazards before they can compromise the food product's safety.

Building a monitoring system based on this program can help your team secure compliance for your business more efficiently. That's because the HACCP program will help you understand which areas require close monitoring.

With FoodDocs' smart software, you can get the best of both worlds. Not only can our system create a comprehensive HACCP plan template for you, but it can also set up a monitoring system based on that HACCP plan. With this advanced solution, you can rest easy that your monitoring system covers all critical areas identified by your HACCP plan.

For food businesses, the purpose of a HACCP program goes beyond theoretical hazard control.

In practice, a HACCP program helps food businesses:

By embedding food safety into daily processes, HACCP supports both regulatory compliance and operational consistency.

A HACCP program is made by following five preparatory steps and seven main principles.

Below, we discuss these steps and principles to help you write your HACCP program.

The members of an effective HACCP food safety program team must consist of independent experts in the specific process being evaluated. This means they must have a specific responsibility to play in the processing as much as in developing the HACCP program.

In other words, the team must consist of people from varying production fields to ensure that all aspects are covered.

A full description of the product should be made, including relevant safety information such as food composition, physical/chemical structure, packaging, durability, storage conditions, and distribution method.

The product's intended use must be clear. It's important to identify what must not be done, mixed, or prepared with the materials. Similarly, product consumers must be identified. This includes those not allowed to consume the product due to allergy or vulnerability to severe illness.

This process flow diagram will serve as a complete guide to how the product is made from start to finish. It will also serve as the backbone of the HACCP food safety program in determining the critical control points.

After mapping a flow diagram, the team must ensure that all inflow and outflow of resources are considered by conducting an on-site inspection and verification.

Once these preparatory steps are covered, your team is ready to make the main content of the HACCP program.

A HACCP program consists of seven key principles. These principles cover all areas of your food production process.

Principle 1) Conduct hazard analysis

After satisfying the preparatory stages, the team is tasked to list important health hazards and the entire processing flow. These hazards can be chemical, biological, or physical hazards and are identified as anything that can cause harm to the consumers when ingested. The team must also identify which among the listed hazards can cause significant problems if not controlled.

Principle 2) Establish Critical Control Points (CCP)

After hazard analysis, the HACCP team must establish controllable processing steps to prevent the spread of the identified hazards. A critical control point involves food operations that prevent the multiplication of pathogens through the cooking process and proper heating times.

Other CCPs include chemical methods for testing ingredients for chemical residue and analytical testing of physical contaminants such as glass.

Critical operations aim to control identified hazards to safe levels. The creation of CCPs depends on meeting specific criteria, such as the absence of a subsequent step that can manage the hazard.

CCPs can be determined using tools like decision trees or risk assessment matrices.

Principle 3) Establish Critical Limits

Although deviations in CCPS are unwanted, they can be set to tolerable limits. The team must create minimum and maximum critical limit guidelines to critical control points, which dictate the tolerable safe levels for these points. Loss of control or breach of critical limits may cause an imminent threat and unacceptable health risk to public safety.

Principle 4) Monitoring procedures

A HACCP food safety program must consist of continuous monitoring procedures to ensure critical control points are being controlled. These monitoring procedures will also be used for traceability purposes. Examples of monitoring activities include microbiological and chemical measurements for the presence of potential hazards.

Procedures for monitoring are always accompanied by control factors, such as food temperatures and water activity during a thermal process like drying. The complexity of the monitoring depends on the type of CCP and hazards being controlled.

Ideally, food handlers need a continuous monitoring procedure to ensure that all products are food safety compliant. The problem is that sampling is sometimes impossible when the process is ongoing. As such, batch-basis monitoring procedures are often used.

Principle 5) Determine corrective action procedures

Critical limit deviations are sometimes inevitable despite establishing control points, especially if regular maintenance procedures are not observed. As part of an effective HACCP food safety program, the team must develop appropriate corrective actions to address minimum or maximum critical limit deviations. The approach may differ in each situation.

Principle 6) Establish verification procedures

After the successful implementation of the HACCP program, regular verification of its effectiveness and efficiency is important. This addresses whether the program is still fit for the current processing method layout and results in the production of safe food products.

Principle 7) Documentation and record-keeping

A successful HACCP program relies on a strong traceability system, which is based on keeping detailed and accurate records. Therefore, part of putting this program into action involves maintaining complete files of all documents related to the process.

Here is a standard HACCP program example normally used in the food industry:

HACCP program template from FoodDocs

You can handle all preparatory steps and principles of an HACCP program with the help of FoodDocs' built-in HACCP plan template builder. Using our software, you can get a comprehensive HACCP plan template specifically based on your operations. You can skip all five preparatory tasks and allow our software to do all the hard work.

A HACCP program is designed to:

However, a HACCP program is not:

HACCP works effectively when it is maintained, reviewed, and updated as processes, products, or risks change.

Monitoring in an HACCP program is a systematic process of observing and recording specific information to ensure that a CCP is under control. involves regularly measuring or observing critical control points to verify that they operate within established limits and that the food safety plan is followed. Here are four key elements of a monitoring system for an HACCP program:

Remember, monitoring is a proactive and ongoing activity that plays a crucial role in ensuring the safety of food products. It provides real-time information about critical control points, allowing for prompt intervention when deviations from critical limits are detected.

This means establishing a monitoring system is the next step after building an HACCP program. You can do both tasks with the help of FoodDocs' smart software.

With the help of our intuitive software, you can build a HACCP plan template and immediately establish a detailed monitoring system based on this plan. Our system saves you significant time in building two of the most essential food safety systems for complying with food safety regulations.

A company's performance is just as good as its approach to food safety.

Establishing a good HACCP program assures your consumers that they will receive quality and safe products. However, implementing an effective program requires learning the basic principles and steps to create a working HACCP program example.

While food businesses always have the option to seek expert advice for building an HACCP program, there is a better, faster, and more efficient solution.

You can simply use FoodDocs' smart HACCP plan template builder to fulfill all the integral parts of an HACCP plan and the most essential criteria for food safety.

With our customizable HACCP plan template builder, you can get the following HACCP plan parts:

In addition to the major parts of an HACCP program, we can help you set up your prerequisite plans, such as pest control, waste control, and allergen management plans. Plus, all parts of the automatically generated HACCP plan template can be customized by adding business-specific information.

The cherry on top? FoodDocs helps you achieve all this in just an hour.

After complying with the food safety regulation of setting up an HACCP plan, FoodDocs can also help you establish a monitoring system specifically based on this plan. From the hazard analysis and critical control point information generated from our HACCP plan builder, our smart Food Safety Management System software creates a detailed list of monitoring tasks for your operations.

Customizable monitoring tasks from FoodDocs software

The customizable monitoring system consists of useful monitoring tasks, such as the following:

These monitoring tasks are specifically based on your operations and can be further improved through customizations. You can incorporate unique tasks into each monitoring form and personalize them to fit your operations perfectly.

In addition, you can also create monitoring tasks from scratch. You can choose to create a detailed form or a checklist and create the monitoring task for your team.

What's more, all automatically generated monitoring tasks come with detailed instructions. You can also upload your version of the instructions to train your team and help them remember how tasks are done accurately.

Remember, building a monitoring system based on a HACCP program is the most accurate way of ensuring that your entire operation is covered and protected. This activity ensures that the monitoring system you set up covers every critical point of your operation and is equipped with the necessary controls.

With the help of FoodDocs' smart software, you can do these two things simultaneously while ensuring efficiency and accuracy. Our software leverages artificial intelligence to make your HACCP plan and monitoring system as comprehensive as possible.

This means with the help of FoodDocs' smart Food Safety Management System, you can save time manually building your monitoring system while ensuring accurate tasks.

Start your journey to more advanced and secure food safety by building your HACCP program and food safety monitoring system with our free 14-day trial.

Do you still have questions about what a HACCP program is? Check out our answers to frequently asked questions on this topic.

The Pillsbury Company helped develop the first HACCP program in the 1950s and was the first food production company to implement it. The project was a collaboration between Pillsbury Company and NASA to produce safe food for the first US space expedition. Read more about the history of HACCP here.

The main purpose of a HACCP program is to properly identify potential hazards in a food production business and set up appropriate controls to keep these potential hazards at acceptable levels. The program is applicable throughout the food chain process, from raw material production to finished product distribution. It also helps reduce the need for end-product testing to ensure food safety.

The last process step of an HACCP program is the record-keeping and documentation procedures. This process includes collecting the HACCP plan, monitoring records, employee training records, verification reports, layout, and all other food safety documents. Recordkeeping allows you to store proof that your establishment complies with food regulations and regulatory standards.

The most important part of an HACCP program implementation is the proper hazard identification and analysis. This step sets out the succeeding procedures in an HACCP program. Improper analysis of hazards can lead to inaccurate critical control points and ineffective monitoring procedures.

The responsibility for HACCP lies with the entire food production team, but a designated HACCP team and a trained HACCP coordinator are typically appointed to oversee the implementation, maintenance, and reassessment of the HACCP system.

Describing the product and its use before developing an HACCP plan is essential for understanding the specific hazards associated with it and its intended use. This information helps identify critical control points and implement effective measures tailored to the product's unique characteristics.

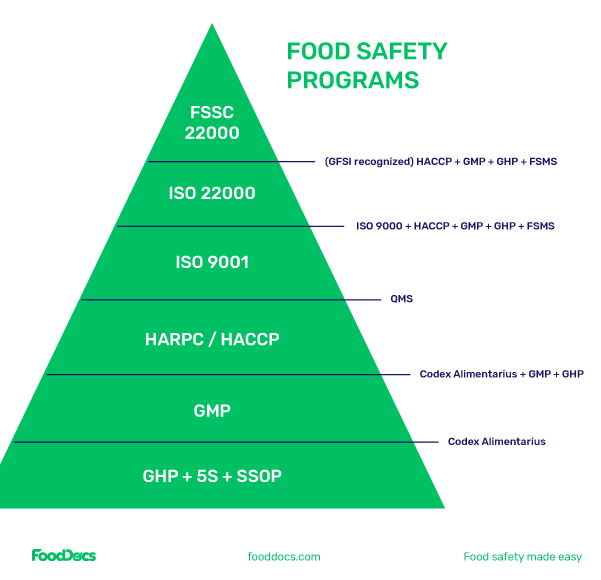

HACCP is not a stand-alone program; it is often integrated into a broader food safety management system. While HACCP focuses on identifying and controlling specific hazards in the production process, it can be part of a larger framework that includes prerequisite programs, a monitoring system, and regulatory compliance.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...