HACCP Plan for Restaurant Template: How to Create One (Free Sample PDF)

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

A CCP is a step in your process where a control measure with clear critical limits is needed to control a hazard.

When you set out to start a food business, you might have heard the importance of a food safety plan and identifying all critical control points, but do you know the importance of these things?

As a food handling business, you are responsible for many things, including the emotional experience of a delicious meal, attracting customers with a versatile menu, and producing wholesome food for consumption.

To run a safe and successful food business, all requirements around food safety must be met to prevent the occurrence of any foodborne illness or any adverse health effects as a result of serving hazardous food.

WHAT WE'LL COVER:

1. What is a critical control point?

2. What are control measures?

3. Difference between CP, CCP, PRP, and OPRP

4. The most common critical control points

5. CCPs in the food industry

6. Digital solution

The initial steps to ensuring food safety are to conduct a hazard analysis and determine any critical control point in your whole food chain.

Identifying the potential hazards within your food handling process (ordering food, receiving food, storing food, etc.) is important to determine at which steps these food safety risks are most likely to occur. To address these hazards and produce safe food, critical control points along the manufacturing process are set.

In this article, we will be diving into the importance of critical control points and their contribution to a HACCP food safety plan.

According to the FDA, a critical control point is any process step where control can be applied for the prevention or elimination of any potential food safety hazard. A systematic approach and significant focus are being placed on a critical control point along your food production process. A breach or loss of control of the established parameters for this critical control point can cause adverse public health issues due to unsafe food.

The main prerequisite for assigning a critical control point based on the 7 HACCP principles is to identify the potential food hazards in each step. Food handlers are required to address all potential hazards that are reasonably likely to cause illness or injury if left uncontrolled. These hazards may include microbiological contamination, chemical contamination, or the presence of filth.

Examples of CCPs may include:

You need to carefully develop and document all your critical control points. A key purpose of accurately established CCPs is to serve as foundations for controlling food safety hazards. An accurate record of established CCPs is also one of the 7 HACCP principles and is essential for establishing a food safety management system when compiling your HACCP food safety programs.

It may be a bit confusing if you are new to these terms. Think of it this way, a critical control point is a step that when you forget to do, skip, or do not satisfy, would eventually result in lawsuits because of food safety issues. It does not get any clearer than that. End-product testing does not require any critical control point since not much can be done if the food product has already been processed.

A critical control point is considered a control measure and varies depending on the nature of your food manufacturing business, the type of food products you supply, and even the raw materials you use. A great example of varying critical control points per product is the measurement of internal temperature when cooking chicken or beef and storing vegetables.

To make chicken safe for consumption and remove the risk of Salmonellosis, your raw chicken must be cooked at around 165°F (75°C), whereas a slab of beef for roasting would only need 145°F (around 60°C-65°C).

Consider this scenario in a restaurant kitchen:

Cooking chicken to the required internal temperature is a CCP because undercooking could leave pathogens alive. If a chef forgets this step or miscalibrates the thermometer, the CCP failure could lead to Salmonella infection. That’s why monitoring and strict corrective action (like continuing to cook until temp is reached or discarding the batch) is critical.

On another note, maintenance of elevated temperatures may not be applicable for food services that deal with fresh produce such as vegetables. Critical control points for such businesses may be chemical testing for pesticide residue or the presence of microbial toxins, and others.

Learn more about what critical control points do not include.

A control measure is an action or an activity that can minimize or eliminate an identified potential hazard or reduce its likelihood of occurrence to an acceptable level. In other words, a control measure is any action, step, task, process, or procedure intended to address a food safety hazard. The term control measure is used because not all hazards can be prevented, but all of them can be effectively controlled.

Control measures are not necessarily considered critical control points. They can be simple steps such as proper hygiene, adequate testing, sanitation routines, pest control, or regular training.

The first step to understanding a critical control point in food preparation is knowing that control measures are categorized according to their nature, relationship to the process, and the level of risk to the consumer should the measure fail.

Examples of control measures include:

• Control Points (CP)

• Critical Control Point (CCP)

• Prerequisite Programs (PRP)

• Operational Prerequisite Programs (oPRP)

• Quality Control Points (QCP)

The responsibility for food safety is a key element in maintaining a good reputation in the food industry. This duty includes identification of hazards, the establishment, and monitoring of CCPs, and applying verification steps to ensure control of food safety. These little steps from purchasing ingredients to plating the food that helps reduce the risk of any health hazard and keep your customers returning to their favorite point of deliciousness.

In a HACCP food safety plan, other terminologies such as control point, prerequisite programs, and operational prerequisite programs may come up. To sort out any possible confusion surrounding these terms, let’s look into four main terms that you will come across when determining control measures and any critical control points for food safety.

Here's a comparison table that outlines the differences between Control Point (CP), Critical Control Point (CCP), Prerequisite Program (PRP), and Operational Prerequisite Program (oPRP):

| Aspect | Control Point (CP) | Critical Control Point (CCP) | Prerequisite Program (PRP) | Operational Prerequisite Program (oPRP) |

|---|---|---|---|---|

| Definition | Any step where biological, chemical, and physical hazards can be controlled. | A step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. | Basic conditions and activities necessary to maintain a hygienic environment throughout the food chain. | Measures and activities used to control the likelihood of high levels of identified risks in the manufacturing process. |

| Role in Safety | May or may not be critical in eliminating hazards but contribute to their prevention and reduction. | Critical in eliminating food safety hazards or reducing them to an acceptable level. | Control low and moderate risk levels and maintain sanitary conditions to prevent food safety issues. | Specific to control identified high-risk hazards, based on in-depth hazard analysis. |

| Example | Prewashing potatoes to eliminate physical hazards before blanching. | Cooking food to safe internal temperatures to kill harmful bacteria. | Proper employee hygiene, handwashing, pest control, and basic sanitary design. | Specific measures like a particular cleaning process for a piece of equipment identified as a risk point. |

| System | HARPC (Hazard Analysis and Risk-Based Preventive Controls) | HACCP (Hazard Analysis and Critical Control Points) | HACCP (As the foundation) | Varies based on food regulatory standards (country or industry specific) |

| Focus | General control of hazards, not necessarily critical points. | Specific critical steps where hazards must be controlled to prevent safety risks. | General maintenance of hygiene and operational standards throughout the food chain. | Focused on controlling specific hazards identified as high risk in the process. |

| Application | Used throughout the process wherever control can be applied. | Applied only at critical steps where failure to control a hazard could result in unacceptable health risks. | General application to support HACCP, not focused on specific steps but essential for overall safety. | Applied at specific points or for specific equipment/processes where identified high risks must be controlled. |

A Control Point is any step where any biological, chemical and physical hazards can be controlled. This term is generally used for processes that may or may not be critical in eliminating hazards but contribute to their prevention and reduction. An example of a control point may be prewashing potatoes to eliminate any physical hazard before blanching, which serves a different purpose. Control Point is a concert used in the HARPC food safety system.

One of the key HACCP principles, a CCP refers to the step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. If the potential hazard can be reduced or eliminated in another upcoming process, a control point is not critical. The clearest distinction between a CP and a CCP is that CCPs are the final step at which you can reduce hazardous contaminations to an acceptable level. The term CCP is based on the principles of HACCP.

Necessary basic conditions and activities that are needed to maintain a hygienic environment throughout the food chain. You can control low and moderate risk levels by putting robust PRPs in place. Prerequisite programs are simple regulations such as proper employee hygiene, handwashing directions, pest control, and basic sanitary design principles.

These programs promote sanitary conditions to prevent food safety issues and maintain clean facilities. As the name suggests, prerequisite programs are needed to establish a HACCP food safety plan with a solid foundation and are considered their basic framework. Examples of prerequisite programs for HACCP can also include quality assurance procedures, labeling, standard operating procedures, and recipes.

Common prerequisite programs may include:

Intermediate measures and activities used to control the likelihood of high levels of identified risks in the manufacturing process. Employing OPRPs depends on food regulatory standards and varies from country to country. Operational prerequisite programs are not general steps, but rather specific to control certain hazards. These programs are the result of in-depth hazard analysis.

To put a distinction between PRP and oPRP, prerequisite programs are usually general to the process and not focused on any particular step in the process flow. For example, cleaning and sanitizing are activities that can apply to all steps, rooms, and items.

If you want to figure out which control measures are appropriate to identify hazards in your food business, you should evaluate the risk levels using a critical control point decision tree diagram or a risk matrix or use digital solutions to food safety. Alternatively, you can use our free CCP tool to determine the type of operation needed to control a particular hazard. All you have to do is identify the hazard of concern, the likelihood of its occurrence, and the potential effect that it may have on your operations. Our free tool will then show the correct operation that you will need.

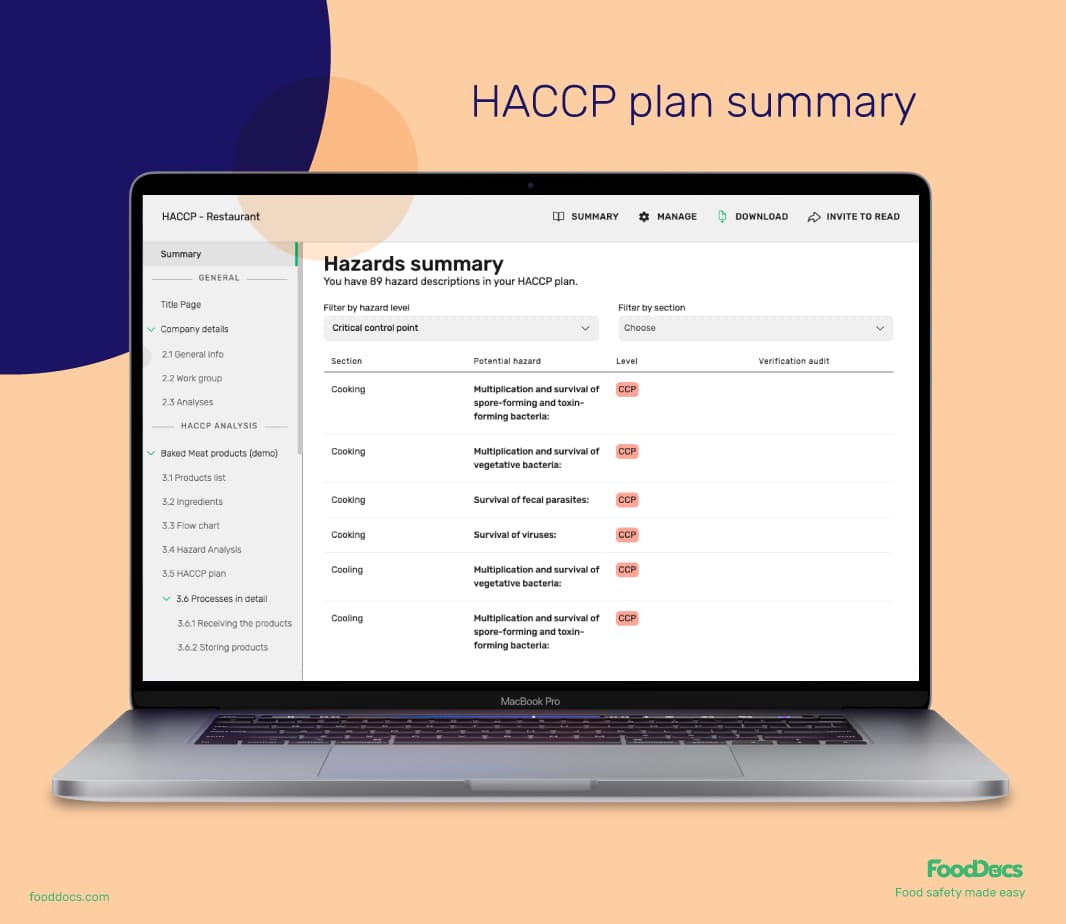

Want a faster solution? Our built-in HACCP plan builder can help you fulfill all components of a HACCP plan in just an average of 1 hour. Our built-in software automatically generates all of the most important documents of your HACCP plan, including the identification of CCPs. What's more is that you can customize the identified CCPs, add more operations, or modify them as an OPRP. Our system offers the fastest and most convenient way toward food safety and HACCP compliance.

Read more about OPRP and the differences between CCP and PRP here.

As you know by now, there are no generic CCP templates that fit all food businesses. Only you can decide what potential food quality hazard is applicable to your restaurant, burger truck, or café. Critical control points vary depending on the nature of the food establishment you have.

Different restaurants that prepare similar foods can still identify different hazards and have different CCPs and preventive measures. This can depend on the layout of the food processing facility, equipment, ingredients used, type of food produced, processes employed, etc. If you are unsure whether a certain step should count as a CCP, put it on the list for evaluation.

Accurate identification of CCPs is a job of your HACCP food safety team consisting of experts in the various fields of your process. A critical control point is always related to hazards and can vary in nature depending on the identified food safety risk. Food hazards can be biological which includes bacteria, fungi, viruses, and other pathogenic microorganisms; chemical, such as chemical toxins, preservatives, and pesticides; or physical which can be in the form of pieces of hair, glass, or metal shards.

Critical control points for biological hazards are usually dependent on the physicochemical properties of your food product. The growth of bacteria and other pathogens is affected by nutritional properties, acidity level, moisture level, water activity, salt concentration, smoke point, and others. In terms of chemical contaminations, CCPs can be based on the degree of processing, raw materials used, and added preservatives.

Lastly, CCPs for physical contaminants are mostly based on the origin of the raw materials and sanitation of the processing area and that of the supplier.

Here are some common critical control points and their basic principles that may apply to most establishments in the food industry:

Cold storage can be a CCP for different reasons. For example, if you offer raw meat to your customers, cold storage immediately becomes a CCP.

The principle behind using cold storage for storing and transporting fresh or raw products is that at low food temperatures, all biological processes are slowed down or even stopped. Such biological processes include enzymatic (e.g. browning in fruits and vegetables, and proteolysis in fishes and meats) and microbiological reactions.

Cold storage prevents the breakdown of the quality of your foods because it stops microorganisms from multiplying, sometimes even eliminating them, and prevents natural enzymatic breakdown occurs. Likewise, refrigerating precooked foods to prevent hazardous microorganisms from multiplying is another reason for using cold storage.

Fluctuations in temperature control keeping may help enteric pathogens to thrive by giving them time to recover and bringing the microbiological quality to unsafe levels and producing hazardous foods. In addition, drastic changes in surrounding temperature may sometimes cause softening of food tissues especially when they are frozen. During transport, if your food products are intended to be delivered within cold storage, this means that they tend to spoil if ambient temperatures are used.

Any specific heat process that is designed to destroy a specific microbiological pathogen at a specific time and temperature can often become a CCP. Thermal processing procedures are usually used for cooking safe food products such as canning, baking, and pasteurizing milk. Despite this, the principle of their use in a process can determine if they can be considered a critical control point.

Take canning and pasteurization as examples. In these processing methods, thermal processing is used not to cook the product, but to render them safe from microbial contamination. The factors affecting canning such as the time-temperature combination used for the process are determined by the target microorganism in low-acid foods which is Clostridium botulinum.

On the other hand, although a similar concept is at play, pasteurization time-temperature combinations are meant for killing the microbial pathogens Coxiella burnetti and Mycobacterium tuberculosis. All of these pathogens are known to cause severe human health hazards such as hospitalization and death. In some cases, their presence and other enteric pathogens have been the cause for a business to become closed. This is why microbiological testing for their presence is a standard in these food operations.

Skipping these processes or not adhering to the correct standards may cause food safety issues for your business, and therefore they are considered critical control points. In the case of baking, thermal processing is only needed to transform dough into bread. If the established parameters are not met, no significant food safety issue may arise. At most, the only problem may be underbaking or overbaking your food products.

In terms of chemical hazards, thermal processing limits can also be applied. For products that have the appropriate combination of proteins and carbohydrates, overprocessing can lead to the formation of acrylamide. This substance is a known carcinogenic agent and is formed when your product is excessively heated. As such, avoiding unacceptable levels must be followed.

When your finished product is pre-cooked and sold as hot food, it needs to be kept at 140°F (60°C)or above to prevent bacteria from multiplying while the food is on display or stored. The required temperature needs to be uniform around and within the food. This is a very common CCP for hotels, school cafeterias, and hot dog stands, among others.

The principle behind this is keeping your food away from the temperature danger zone which is 40°F to 140°F (4°C to 60°C) or the range of temperature where most enteric pathogens thrive. As a rule of thumb ready, it is not safe to eat products from food services that are not supposed to be outside this zone for more than 2 hours.

Food that has been cooked can be left out at room temperature until it cools down enough to be put into the fridge. The cooling must happen as fast as possible and different countries have different standards when it comes to the temperatures the food must reach within the first 2-4 hours.

The reason behind this CCP is that the longer your food takes to cold down, the more chance of surviving microorganisms to multiply increases. An abrupt temperature change will further hurt microorganisms and lessen their survival rate. The same principle applies to the thawing of foods. As you thaw your frozen foods, microorganisms that have survived will have the time to recover.

Read more about different critical control point examples.

This method can be considered as a critical control point for products that are considered high-risk. An example of high-risk products would be peanuts, corns, and other grains. If you are in the industry of peanuts and cereals, you are most certainly familiar with how important the levels of Aflatoxin are. This compound is a toxin produced by microorganisms under the genus Aspergillus. Aflatoxin is a highly regulated biological toxin because of its adverse effects on humans and animals and is most usually found in the mentioned products. As such, its detection during receiving is very important.

Food recalls in past related to this compound are recorded. Failure to detect breaches of acceptable levels may cause loss of control of safety, consumer complaints, human health hazards, and lawsuits. Raw materials are inspected and held in the storage warehouse before acceptance. Once proven clear of contaminants, they are accepted for use.

This step is commonly considered as a general critical control point to monitor, detect, and control physical hazards. Filth detection in a food processing facility can be done in many different ways. Aside from visual observations, another example would be sieving a sample batch of flour from your storage area. Using a specific size of sieve that will only allow the flour to pass through will prompt your quality assurance specialists and food safety supervisor if there are physical contaminants.

These contaminants are usually broken glass, pieces of metals, pieces of jewelry, and other sharp objects. Other methods can be done using a magnet or a metal detector to collect metal contaminants. These physical hazards can cause injury if ingested by consumers. The size of these filths is usually used as a physical parameter to determine the risk they have. Once they go undetected in inspection, they can easily work their way to the finished product.

During production, the specified amount of ingredients and raw materials are provided to your in-line employees. Preweighed ingredients are usually brought to the production and are ready for use. The product formulation control point is done by verifying the amount of these materials before use.

Exceeding or lacking the allowable or required weights and amounts, respectively, of certain products such as preservatives or other ingredients can lead to health hazards. If too little acidulant is added to your food product which is expected to have a low pH level, microbiological hazards may multiply in this condition and create a food quality hazard.

While allergen controls (e.g., dedicated equipment or cleaning protocols) are often considered PRPs, if a specific step is the last point to prevent a severe allergen hazard, it can be treated as a CCP.

Conducting a hazard analysis and identifying critical control points can be a time-consuming task. Not to mention that if you are quite inexperienced and your HACCP food safety team lacks specialization, there are chances that you might miss some critical control points. This fact may then lead you to hire a food safety consultant and can cost you quite a lot.

Luckily, those days are over. FoodDocs, your digital solution for food safety management system can determine the CCPs in your operations and processes smoothly and quickly. Our built-in software can automatically identify the CCPs in your food operation based on the nature of your business with just a few clicks.

You can even generate monitoring forms for different tasks such as thermal monitoring procedures, pest control, and other documents which can be used as a comprehensive verification procedure and control CCPs. We aim to make your lives easy and for food safety to be accessible to everyone.

One of the most effective ways to identify Critical Control Points is to use a decision tree, which consists of a set of questions designed to arrive at conclusions of whether or not a control measure is critical.

As outlined in our HACCP decision tree guide:

The standard decision tree developed by the Codex Alimentarius Commission, a group developed to establish international guidelines for food control systems for the protection of public health, is used as the basis for most decision trees. To protect your intended consumers, it is important to conduct all stages of hazard analysis and perform adequate actions such as the implementation of CCPs to control them.

When handling food, you need to analyze and describe which control measures can be applied for each hazard. Many preventive control measures are put in place to avoid food contamination from the production environment (e.g., staff, pests, water supply, etc.), but other measures aim to reduce or eliminate hazards directly linked to specific production processes. (These can lead to the establishment of CCPs or operational PRPs – more about these later.)

A critical control point is established after the hazard identification and analysis in your production process. Analysis of hazards is usually done by using established scientific studies, opinions from experts, and food laws and regulations. A lot of time goes into the identification and validation of which operations can be considered as CCPs.

After identifying which hazards are present, a critical control point can be evaluated for assignment. A method is considered a CCP if there is no other subsequent step that will minimize or eliminate the potential hazard present in the product. This means that the process must be successfully executed. A series of factors are considered before a process step is considered as a critical control point. This is why it is helpful to use a risk matrix or a decision tree diagram to identify the risk level of each step of the whole process and provide a detailed explanation and justification.

When conducting a hazard evaluation, consider the likelihood of exposure and the severity of the potential consequences if the hazard is not properly controlled. Severity is the seriousness of the consequences of exposure to the hazard (for example, the magnitude and duration of illness or injury and the consequences). You can use the following to evaluate the likely occurrence of a hazard:

If you choose to use a decision tree to determine the risks of each step in the process of food handling, remember that more than one step in a process can be involved to control a hazard, and more than one hazard may be controlled by a specific control measure.

As a rule, you need to determine which steps apply to your business and where the potential hazard could come from. Once you have identified all the hazards and their risk levels, you must ensure that you put controls and appropriate corrective actions in place for each one of them.

All of these tasks can easily be performed using our food safety software. You can keep records in our software system, set up your procedures for monitoring, and keep an eye on the records in the activity log. Using the features of our digital food safety system, you can leave the analysis to us and let us suggest which are the most important critical control points of your food processing plant.

Along with this suggestion, you can even generate your monitoring forms for each CCP, download them, and print them for the whole HACCP team. The best part is you do not have to wait long. The whole process of shifting to a digital food safety management system will only take 15 minutes.

Conducting a hazard analysis, identifying critical control points, and every other task involved in creating a HACCP plan is time-consuming and often expensive.

What if there is a way for you to do all these tasks with a method that is 500x faster and 15x cheaper? Our built-in food safety software at FoodDocs was developed to help you get through all the HACCP documents without breaking a sweat. Our HACCP program builder was designed to generate the most relevant hazards, critical control points, control measures, and validation activities fit for your business.

Some of the things we can do for you include:

Never worry again about how to identify CCPs for your HACCP food safety program with FoodDocs. Our system automatically ranks the hazards in your food operations based on our established risk assessment matrix. We automatically suggest the appropriate level of activity for each hazard.

Action levels vary as PRP, oPRP, CP, or CCP. Our suggestions are based on the knowledge of our food safety experts, related literature, and information from our customers in similar food businesses as yours. Through this combined information, you can be assured that all documents and data we provide are accurate.

In addition, we understand that some countries and food companies have specific critical control operations that are very unique. This is why we allow our customers to input new hazards and control measures in their HACCP plan. All you have to do is identify the hazard, input its level of likelihood and severity of potential damage, and we will automatically suggest which action level is most appropriate for this hazard.

Our services even come with a free 14-day trial enough for you to build your whole HACCP plan. Complete your HACCP plan within just 1 hour and download and print it for all of your employees. You can even invite food safety auditors to view your digital HACCP plan to save on printing it! Build your HACCP plan sustainably and efficiently.

Common CCPs include:

According to the National Advisory Committee on Microbiological Criteria for Foods (NACMCF), a Control Point refers to any stage where biological, physical, or chemical factors can be managed, whereas a Critical Control Point is a stage where managing these factors is crucial to prevent, eliminate, or reduce a food safety hazard to an acceptable level.

The HACCP team is tasked with identifying individuals within the organization who will be accountable for overseeing the Critical Control Points. These individuals must possess the requisite skills and knowledge to perform their responsibilities proficiently.

In the HACCP plan, it is essential to define the frequency of CCP monitoring, which should be determined by factors such as the severity of the hazard, the volume of production, the type of food being processed, and the equipment utilized. It is generally recommended that Critical Control Points be monitored at least once every four hours during continuous operations and following each batch processing to ensure food safety and quality.

When a CCP is not achieved (i.e., is out of control), the HACCP team must take prompt corrective measures to resolve the problem. This could include modifying processing parameters or discarding the product until it complies with safety standards. The corrective measures should be recorded and evaluated by the HACCP team to prevent any additional hazards.

Record-keeping and verification are important for CCPs because they help businesses maintain HACCP compliance and reduce food safety risk. For each CCP identified, you must establish critical limits, monitoring procedures, corrective actions, and verification steps, which are critical parts of HACCP principles.

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

Get a clear and complete breakdown of the most common Critical Control Point examples in HACCP for biological, chemical, and physical hazards.

The HACCP allergen control program is one of the crucial prerequisite programs of an HACCP plan. These are the key components and goals of using one.