Why Is Food Safety Important In Healthcare? Healthcare Leaders Guide

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Cooking does more than just make food tasty. It can save a life!

Cooking might just be the most common and essential method in a kitchen. This step is regarded to be a critical control point for food service establishments. Cooking through the application of heat may be done through baking, frying, roasting, boiling, and other methods.

Each method is used to come up with a different and unique food product that you may use to attract consumers. Regardless of which method you choose in your establishment, every cooking method has a very important objective in maintaining food safety.

Aside from achieving the desired texture, flavor, and aroma from cooking, heat application aims to reach a safe food internal temperature.

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

The internal temperature of food refers to the temperature reading at the center of the thickest part of raw material being cooked. Heating the center of the thickest portion of the food ensures that the food is thoroughly cooked and that all parts have received adequate heat treatment.

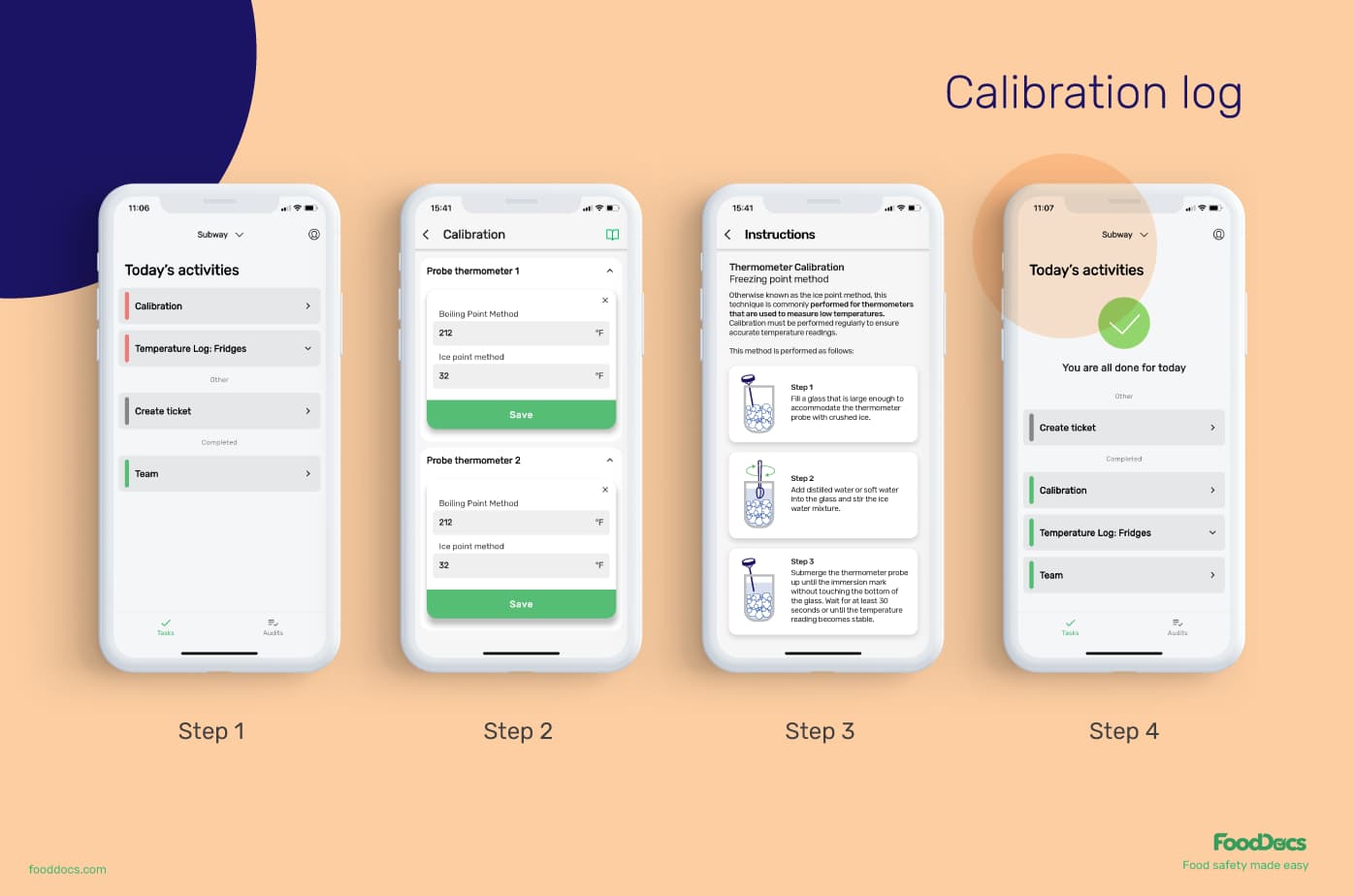

The center portion of food is the farthest location from the exterior portion and, therefore, takes the longest time for heat to reach. Accurate reading of the internal temperature is essential in cooking as it can determine the final characteristics of a food product and its safety. To achieve the targeted internal cooking temperature, a properly calibrated food thermometer must be used at all times. You can get a convenient calibration log and easily explained calibration instructions from the FoodDocs app.

The target safe cooking temperatures may vary depending on several factors. These factors may include:

WHAT WE’LL COVER:

In cooking, reaching the minimum internal temperature means effectively eliminating the potentially harmful bacteria on the raw material. Proper temperatures for cooking are first established based on the optimum heating conditions to kill target pathogenic microorganisms.

The application of heat is one of the most effective methods to inactivate different types of pathogens. Up to a certain point, warm environments can help pathogens grow, but when increased to a significantly high level, heat can eliminate pathogens.

Thorough cooking is essential to keep customers safe, as foods naturally contain microorganisms. Some of these microorganisms can be considered beneficial, whereas some are considered pathogenic. Pathogenic microorganisms cause foodborne illnesses when consumed and are therefore considered biological hazards and can harm public health.

Depending on the type of food being cooked as well as its source, the target pathogen may vary. Some of the most significant pathogenic microorganisms include Salmonella, Escherichia coli, and Norovirus.

Harmful bacteria and other microorganisms can also be introduced at any point in the food processing system. Without proper food safety practices, pathogens can get contaminated through cross-contamination.

Cooking and reaching the target internal temperature is often considered the last step to controlling foodborne pathogens and preventing food poisoning.

Cooking makes raw materials, such as raw meat, edible and safe for consumption. The length of time needed to cook a food material and reach the desired internal cooking temperature highly depends on the type of meat or raw material you are using.

Cooking foods to the correct internal temperature also makes them stable at room temperature. Although they can withstand the temperature danger zone with less risk, proper storage conditions are still required.

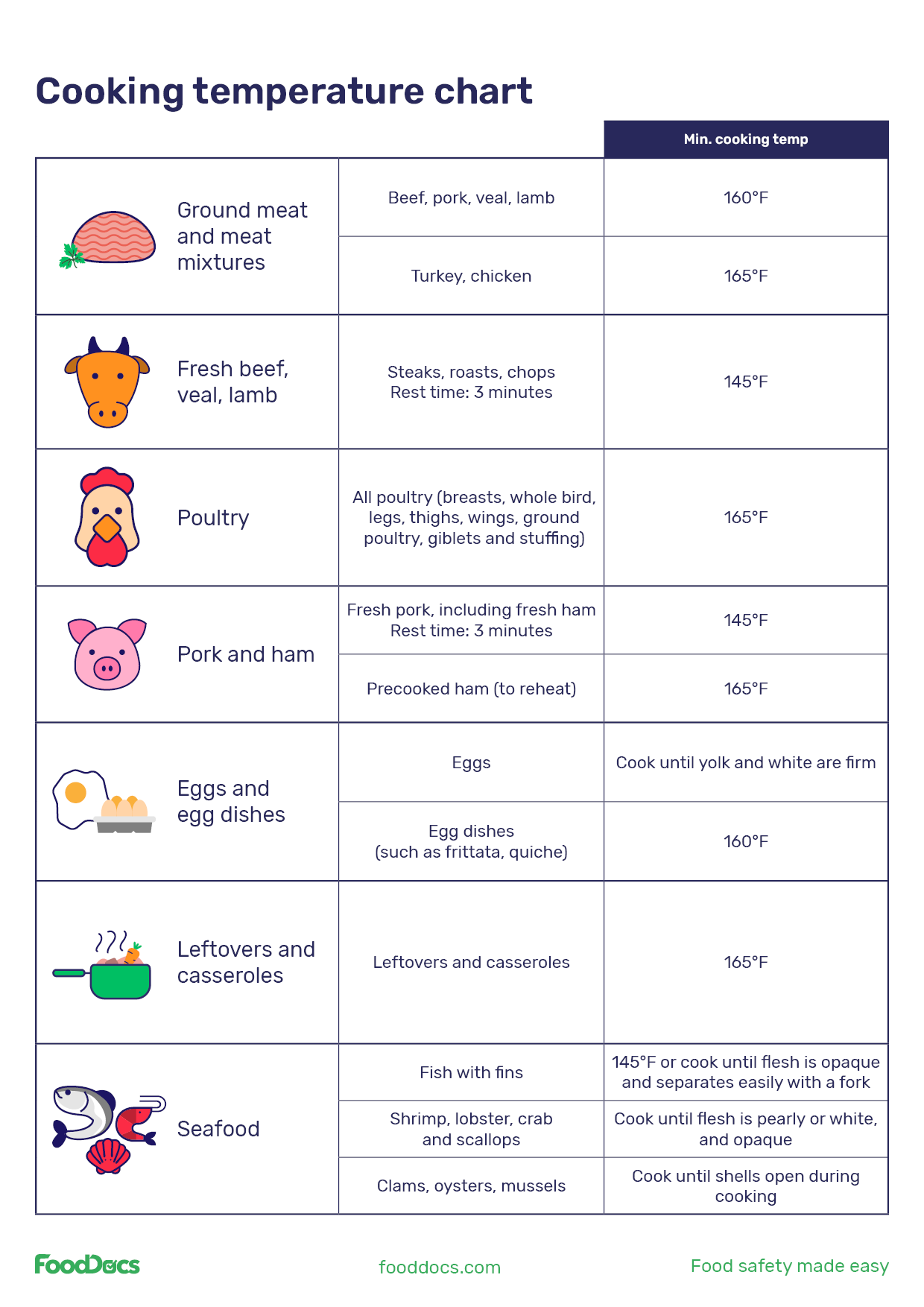

To help you understand the proper cooking temperatures for different types of food, here is a short list and explanation:

Cooking temperature chart

Beef is a widely used type of meat, whether in households or in restaurants. Some restaurants offer beef, venison, and lamb in different degrees of doneness. At a minimum, the safest internal cooking temperature for these types of meat is 160°F (71°C). This level of cooking will give the meat medium to medium-well doneness with a slightly pink center while still retaining its springy texture.

Beef is often associated with the pathogen E.coli, which has caused several cases of foodborne illness outbreaks in the past. In fact, one of the biggest outbreaks recorded in the US was caused by a strain of this dangerous bacteria. At 160°F (71°C), this pathogen, along with other dangerous pathogens linked with beef, is eliminated.

Despite this guideline, some people have a personal preference for consuming beef and other meats slightly undercooked. Meats, such as beef and veal, are more popularly served as medium-rare for their texture, juiciness, and overall flavors. To achieve this doneness, the raw meat must be cooked to an internal temperature of 140°F (60°C).

When serving undercooked foods, the quality of the raw beef, as well as the preparation methods, must comply with the highest standards. The USDA has recommended a lower safe temperature for beef, which is at 145°F (63°C), with a three-minute rest time before carving.

Cooking different types of meat may sound confusing, we suggest using our cooking temperature charts as your guide:

Another popular type of meat is pork. This meat comes in chops, roasts, or cubes and is very versatile when it comes to restaurant dishes. Unlike beef, pork has less myoglobin which is the pigment in the blood that gives the meat a red color.

According to the USDA, the safe cooking temperature of pork can be reduced to 145°F (63°C), provided that it will have a three-minute resting time before being cut.

Pork has been implicated in many different pathogenic outbreaks, including Staphylococcus aureus, Clostridium perfringens, Salmonella, Listeria, and the parasite Trichinella spiralis.

Need a guide for cooking different cuts of pork and hams? Use our Pork Temperature Chart and Ham Cooking Temperature Chart.

Poultry meat includes chicken, turkey, goose, and game birds. To maintain food safety, raw poultry and poultry products must be cooked to an internal temperature of 165°F (74°C). A few degrees below the target temperature increases the risk of causing foodborne disease.

This type of meat has been linked to many foodborne illness outbreaks because of the pathogens, Salmonella and Campylobacter. Unlike pork and beef, cooking poultry has less room for errors.

When cooking whole raw poultry meat, a chicken, for example, the thermometer must be properly inserted into the breast part. This area is the thickest part of a chicken.

Use our Chicken Temperature Chart as a guide for cooking different parts of poultry meat and alternative heating combinations. Here are some other guides for cooking poultry and game meat:

Eggs and related products must be cooked to a minimum temperature of 160°F (71°C). Much like poultry meat, eggs may have the risk of causing foodborne illnesses when not properly prepared or cooked.

As such, cook egg-containing foods to the target internal temperature at all times.

Unlike other types of meats, fish and other seafood tend to overcook faster at very high temperatures. In terms of quality, seafood must achieve an opaque appearance without being rubbery. To hit the sweet spot between safety and quality, fish and other seafood must be cooked to an internal temperature of 145°F (63°C) for a few minutes.

Fish and other seafood are commonly associated with pathogens such as Norovirus, Vibrio, and Salmonella. Several pathogenic microorganisms can be transmitted through water, and seafood can become carriers.

Leftover dishes and cold, cooked food that needs to be reheated, including sauces and gravies, must be thoroughly reheated before serving again. Foods that may have already had contact with other objects, such as utensils or food handlers, have an increased likelihood of being contaminated.

Food that needs to be reheated should be heated to a minimum internal temperature of 165°F (74°C). When reheating, remember to stir the food occasionally to ensure that the heat is evenly distributed. Once leftover foods have been reheated, do not refrigerate them again for later serving.

Ground meat requires thorough cooking. Since this type of raw material has already gone through the grinding process, potentially present pathogens may have already spread throughout the material. More surface area of the product has been exposed after grinding.

As such, the minimum cooking temperature for ground beef, pork, and veal is 160°F (71°C), whereas ground poultry must be cooked to an internal temperature of 165°F (74°C).

Reaching the target internal temperature is the combination of a regulated application of heat, time, and constant monitoring. As previously mentioned, the internal temperature of food can be achieved through different methods of cooking. The main objective is to apply heat and evenly distribute it up to the center of the food.

To do this task, food handlers must first be aware of the target internal temperature. Every type of raw meat has a designated target internal cooking temperature. During cooking, food handlers must have a properly calibrated food thermometer that will be used to measure the internal temperature of the food.

Depending on the type of meat and its thickness, reaching the internal temperatures for meat may vary. In addition, the state of the food before cooking will significantly affect heat distribution. Ideally, you must cook raw material at ambient temperature. Frozen and refrigerated foods will need to be thawed before cooking. Constant monitoring throughout the cooking time must be performed.

Some foods will require rest time to allow equal heat distribution of the surface temperatures throughout the food.

The quickest way to tell if the internal temperature has not been reached is to use a calibrated food thermometer. This method will give you an accurate measurement of the current internal temperature of the food being cooked.

Some types of food, such as beef and veal, are purposely served undercooked. This means that they can be served with a slightly pink center while still being safe for consumption. While color is a good indicator of the level of doneness, it does not necessarily translate to safety.

Did you know that consuming undercooked food requires strict food handling preparations and a consumer advisory from the food establishment?

For some types of meats, such as poultry, consuming them undercooked has a significant risk of causing foodborne illness. As such, a pinkish center or even slight undercooking can be dangerous.

A properly calibrated food thermometer is key to acquiring accurate temperature readings. Calibration is done to ensure that a food thermometer is accurately presenting the actual temperature of food.

Thermometer calibration is a regular task for food businesses to maintain food safety. The calibration method may vary depending on the intended use of a food thermometer.

The two main calibration methods for food thermometers are:

Thermometer calibration (boiling point method) poster

Thermometer calibration (freezing point method) poster

Using a single thermometer for a very broad range of temperature readings may cause the tool to lose its accuracy faster.

In addition to general routine, calibration must be done at these particular events:

All calibration processes and information must be recorded as proof of food safety compliance, for example as a thermometer calibration log. Irregular and improper calibration of thermometers can result in food safety issues such as undercooking foods and causing foodborne illnesses.

Measuring the internal temperature of foods is achieved through the use of a food thermometer. This kitchen tool comes in different forms. You can have a conventional bimetal thermometer, a digital thermometer, or even an infrared thermometer.

Regardless of which type of thermometer you have, using one is the best way to measure the internal temperature of foods. Remember that as a food device, this tool needs to be regularly calibrated to ensure accurate readings.

Follow these steps to properly measure the internal temperature of foods:

For some thermometers, the equilibration of temperature readings may vary depending on the manufacturer's instructions. Always have a proper cooking temperature chart as a guide for the proper and safe temperatures needed for a particular dish.

In addition to properly cooking foods to the correct internal temperature, food handlers must be aware of particular food safety practices to keep the presence of pathogenic microorganisms to a minimum. While achieving proper internal meat temperatures is key, this operation can only be effective if the microbial load is not very high.

At exceedingly high microbial loads, pathogens can spoil food very fast or make cooking parameters insufficient. Additionally, cooked foods will no longer be processed, as such, their storage and environment must be kept clean at all times.

As such, follow these few safe food tips when preparing and handling food products:

To ensure that your food business is safe from causing foodborne illnesses, always follow the 4 C's of food safety. In addition, always ensure that you have a comprehensive and intuitive food safety management system (FSMS).

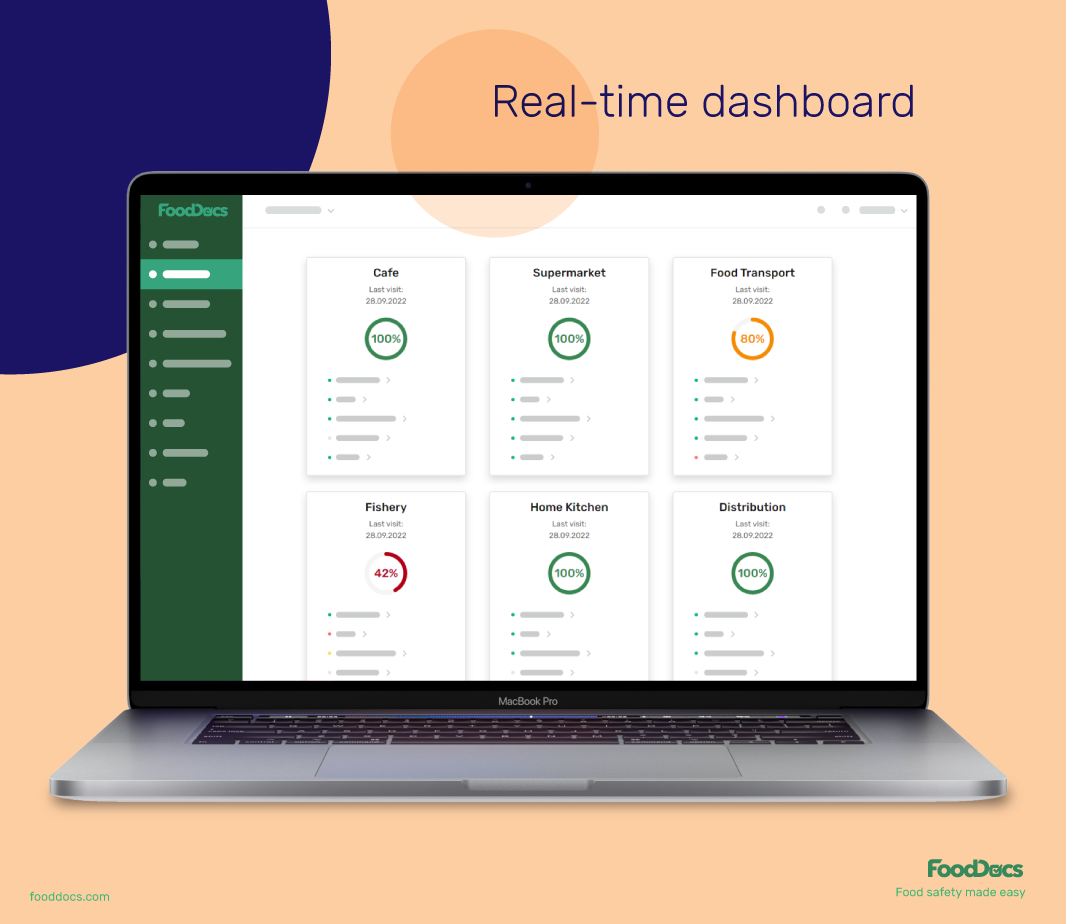

At FoodDocs, you can be sure at all times that essential tasks, such as cooking foods to the correct actual temperature, are always food safety compliant. Use our digital Food Safety Management System to implement a digital monitoring system that is built based on your business profile in just 15 minutes.

Cooking and monitoring the internal temperature of foods are regular tasks in any food business. Day-in and day-out, food handlers will have to measure cooking temperature, and every accurate reading must be recorded. Your monitoring logs will serve as proof of your compliance with food safety regulations.

Monitoring food internal temperature is a repetitive task that can sometimes drift along with other food safety operations. Despite this, forgetting to monitor internal temp for foods may lead to significant food safety issues.

Our goal is to help you ensure easily that monitoring tasks are done on time and effectively every day. With our digital solution, you can be sure that food handlers will know when to monitor internal temp and how to properly achieve accurate results.

When you use our monitoring solution, you access the following benefits:

Using these features, you can save a significant amount of time in training and actually performing all food safety tasks.

In addition to features that can help food handlers effectively and efficiently fulfill food safety tasks, our digital Food Safety Management System can also help managers improve efficiency in other business aspects:

In addition to our many valuable features, switching to our digital platform can become your first step towards sustainability. Our digital FSMS can help you switch from a paper-based monitoring system to a completely digital one in just 15 minutes.

The whole process of switching to our digital FSMS would only require you to answer a few basic questions about your everyday operations. Using artificial intelligence and a machine-learning program, our system will generate the food safety system tailored for you.

We understand how the everyday operations of a food business can sometimes be repetitive but still essential. Our digital solution can help you easily fulfill these tasks and give you more time to focus on other aspects of your food business.

The good news is you can start your digital monitoring system now by using our free, 14-day trial.

Need a few more information on the internal temperature of foods? Here are some frequently asked questions about this topic.

Unsafe internal temperature refers to the core temperature below the recommended range. A few degrees below the recommended internal cooking temperature for a type of food may increase the risk of allowing a pathogen to survive.

In terms of storage, the unsafe internal temperature may refer to the temperature danger zone, which is from 40°F to 140°F (5°C to 60°C). Foods must constantly be held either higher or lower than this temperature range as it is the optimum temperature for the multiplication of bacteria and other pathogens.

Foods such as different types of seafood, pork, beef, and lamb are recommended to be cooked to an internal temperature of 145°F (63°C) for around 15 seconds.

The USDA has recently announced that pork's recommended internal cooking temperature is lowered to 145°F (63°C), provided that the meat will be allowed to rest for three minutes before carving. The resting time will allow the residual heat to thoroughly cook the food while resting.

The USDA generally recommends that steak can be free from pathogenic contamination when cooked to a minimum internal temperature of 145°F (63°C) with a three-minute rest time. A restaurant offering undercooked steak must provide a consumer advisory to protect consumer.

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...

Boost your retail food safety with essential practices and digital tools to protect customers and your brand. Plus a free Retail Food Safety Leader...