Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Chemical hazards in food can cause long-term and chronic illnesses in humans when not properly controlled.

Foods are made up of chemical compounds that make up their taste, color, smell, and nutritional quality. In the food industry, other chemical substances are added to food products to enhance or preserve their quality.

All unnaturally present chemicals in food are required to be declared in the food labeling. Undeclared and unintentionally present substances can be considered chemical hazards in food.

Simple preservative materials, such as sugars, salts, and nitrites, are all considered chemical substances. What makes such materials hazardous for the consumer is when they are unintentionally added or present in excess. Chemical hazards can enter the food system at any point in the cycle.

They can be naturally absorbed by foods when being grown, or introduced because of poor food handling. Food handlers must know what are chemical hazards to understand how to control their presence and reduce any concern for chemical exposure.

Learn to identify which chemicals can be considered a chemical hazard in the food industry with this article. Read through our content and find out some of the most common chemical hazards in food and the most efficient digital solution to prevent food safety hazards from contaminating your products.

WHAT WE'LL COVER:

Chemical hazards definition refers to chemical substances that are unintentionally present in foods. They can also be naturally present in foods but are at harmful levels for human consumption.

When consumed, chemical hazards can cause adverse health effects to humans. The results can range from acute to chronic illnesses, depending on the type and amount of chemical hazards in foods. Food handlers are responsible for reducing the customer's risk to chemical exposure.

In the food industry, chemicals are always used. Chemicals don't always have negative effects on humans. Some substances only become harmful when misused, mishandled, or added in excessive amounts against food safety standards.

A chemical hazard in food is any substance with a chemical nature that can harm the consumers. A wide range of chemical hazards is present in the food industry. Workplace chemical hazards can be equipment lubricants, additives, chemical toxins, veterinary medicinal products, by-products of animals, and agricultural chemicals or plant protection products (e.g., pesticides).

In some cases, chemical hazards are produced by biological materials, such as the food itself, as a defence mechanism.

Hazardous chemicals in food are also sometimes used as an indicator of overprocessing of foods. By-product chemical substances, such as acrylamide, can form when products high in sugar and proteins are heated excessively.

This type of hazard in food can cause long-term effects on consumers, as compared to foodborne illnesses caused by biological hazards. Some chemical hazards can lead to birth defects, cancers, or severe sensitivity to chemicals.

Chemical hazards are defined as any substance that can enter the food supply chain and cause negative effects on consumers. Different types of chemicals can be considered hazardous. On the other hand, chemical contamination is the event wherein a chemical hazard enters the food supply chain.

During food handling, if an employee accidentally adds an unknown food additive to the food, that occurrence is called chemical contamination. In this case, an example of a chemical hazard is the unknown additive. Direct contact with harmful chemical hazards can have negative effects on food handlers.

Every food business is open to chemical hazard contamination. There is a wide variety of chemical hazards. The cleaning agents, machine oils, and hand sanitizers in your kitchen can become a chemical hazard when improperly handled.

The Codex Alimentarius has identified a hazardous chemical list and provided food safety guidelines and standards for at least 250 food additives and 250 agricultural chemicals. This list of food additives and chemicals acts as a comprehensive guide for food handlers.

Chemical hazard examples in food products can be any of the following categories:

This chemical hazard list is non-exhaustive. Countless other harmful substances are present in the food industry. The concern for chemical exposure is a priority for any food business. The dangers of chemical hazards can often lead to serious diseases and put the lives of consumers at risk.

A food business must always have practice controls for the different types of chemical hazards that will ensure a safe working environment.

All previously mentioned categories of chemical hazard examples are very common in the food chain industry. Some harmful chemical substances can enter the system during the harvesting of raw materials, whereas others can contaminate the food during preparation. Some chemical food safety hazards may also enter the production line through accidental contamination or unintended contact with food.

Some examples of chemicals in food are usual household items that, when ingested, can cause severe adverse effects on human health.

Here are 10 examples of chemical hazards in the food industry:

Some chemical substances only become hazardous when the maximum established limits by federal agencies are breached. Legal limits of chemical food safety hazards are based on scientific studies and years of collected data from the food industry. They are established to prevent the severe reactions that chemicals in food can cause.

Different countries may have different enforceable standards and requirements of food laws for chemical hazard limits and occupational exposure limits. These limits also apply to imports of food from other countries.

The reasons for establishing limits may also depend on the tolerance of a population or the criticality of a particular hazard. A food safety model or plan for controlling chemical hazards may be based on the lifestyle of a nation.

Some known hazardous chemical substances are often associated with a food product. When a food business uses a product that is prone to a chemical hazard, monitoring for these chemicals is a must.

Whether when receiving food ingredients from suppliers or for everyday operations, monitoring documents and food safety tasks are keys to keeping chemical food safety hazards away from your food products.

Chemical hazards are all around us. They can be found in the soil, water, and food that we eat. What makes this type of hazard dangerous is when excessive human exposure occurs.

In this section, we discuss some of the common sources where chemical hazards may be found. Take note of which source is closest to your food business for establishing chemical hazard internal controls:

One of the fastest routes for chemical hazards is through the drinking water system, especially when growing food ingredients and foods of animal origin. When the water used for irrigating crops and other food ingredients is contaminated, the raw ingredients can absorb them along with other environmental factors and extraneous materials.

Foods, such as vegetables, absorb water from the soil as a source of energy. If the drinking water contains chemicals, then there is a possibility that it will get absorbed by the food.

Most veterinary drugs and agricultural solutions used by animal food manufacturers are applied through water systems. The lack of proper control and monitoring of environmental factors can lead to high levels of food contamination. Animals and animal products can carry chemical hazards when exposed to high levels during growing.

Similar to the water supply, chemical substances can also enter food ingredients through the soil as a significant environmental factor. The best example of this route is seen in the case of green tea leaves. This plant is a known organism that detoxifies the soil. This plant has been studied for removing environmental contaminants from the soil.

Several studies show that the green tea plant can absorb heavy metals from the soil. Without proper control of agricultural treatments and monitoring conditions, the final product can carry heavy metals up to when the customer steeps the tea. Proper and controlled processing can reduce hazardous chemicals to acceptable levels.

This category of chemical hazard source involves several different ways of contamination. One is through chemical release or migration from food contact materials. Some studies have shown that inappropriate packaging materials for sensitive foods can cause chemical migration or the transfer of toxic chemicals from the packaging to the food.

Another way for a chemical hazard to contaminate food is through the sanitizers used for cleaning surfaces and equipment. Chemical manufacturers of sanitizers usually recommend safe concentration levels for chemical sanitizers in the food chain industry. Using beyond the recommended amount increases the risk of chemical hazard contamination.

In addition, any harmful chemical substance can also enter the food system through the equipment used in the kitchen. Aggressive use of coated pans may scrape the equipment, which can then mix in with the food being prepared along with foreign materials such as iron shaving.

This is also the case with oils used as a lubricant for equipment joints. Harmful industrial chemicals can cause diseases when collected by the body.

All raw food ingredients are made up of chemical compounds. Some foods require specific processing parameters to remove hazardous chemicals in food. A good example of this type of food product is beans and legumes.

Beans naturally contain lectin, which is an active substance and hazardous material that prevents the body from absorbing other nutrients from the food. In high levels, lectins can cause digestive problems, such as abdominal pain, vomiting, and nausea. Lectins can be easily removed by soaking the beans for several hours.

Another widely known food that naturally contains chemical hazards in the form of natural toxins is cassava. This food item contains cyanogenic glycoside, which is a very strong chemical hazard to humans. This type of hazard can cause severe reactions, such as digestive problems, but can be easily removed through thorough washing and adequate cooking.

Some of these naturally occurring hazards may also transfer to animals when ingested. Complete animal foods that are contaminated with hazardous substances may infuse into the meat of the animals. They can either cause adverse animal health effects or carry over the hazards from animal food production and affect public health.

In some references, allergens are also considered chemical hazards. For example, gluten-containing flour can cause adverse health effects on consumers. This is the reason for discovering the use of gluten-free flour in the industry.

Improper or excessive processing can also form chemical hazards. This way is very common for processes involving very high heat. Methods such as baking, frying, and roasting are operations that can form carcinogenic compounds when cooking foods rich in starch and proteins.

Cooking foods such as potatoes can form acrylamide as a by-product. Processing-induced chemicals develop when the food is cooked for too long and the oil used for frying is repeatedly used without replenishment. The cooked foods will then contain the hazardous chemical which can affect customers when ingested.

Identifying the most common locations and points, where chemical contaminants can occur, are important components of risk analysis that will help your team control the hazards significantly. Combined with the severity and likelihood occurrence analysis, food handlers can create critical control measures to protect consumer and worker health from chemical hazards.

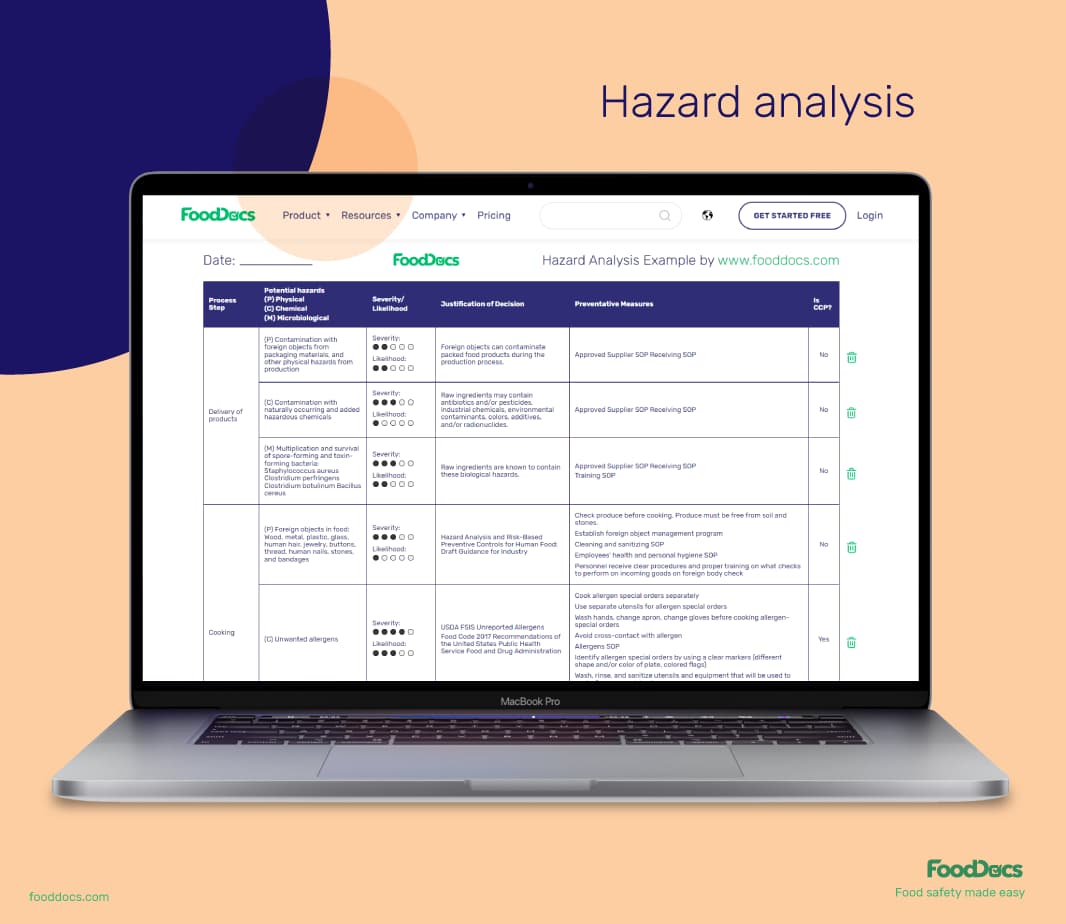

Identify and analyze hazards using our free HACCP Hazard Analysis Template. Use this free tool to list and analyze chemical hazards according to the parameters of a risk assessment matrix.

If you want an automatically generated comprehensive hazard analysis table and a customizable HACCP plan, use our digital HACCP plan builder. In an average of 1 hour, you can get a digital HACCP plan based on the operations of your food business.

Some hazardous substances are very hard to remove, whereas others can be easily reduced using proper processing. The key is to understand the nature of a chemical hazard.

There are two main options when a food handler detects a chemical hazard in food.

The first method is for food ingredients that naturally contain chemical hazards as previously discussed. When handling foods high in chemical hazards, food employees must carefully follow established control measures.

For example, the toxic substance glycoalkaloids in potatoes can be removed through peeling, boiling, and frying. Without these operations, the risk of causing foodborne illness to consumers is significantly high.

The next method for handling foods contaminated with hazardous chemicals is to hold the food ingredient or products. The product must undergo appropriate chemical hazard analysis to determine if legitimate factors, such as the levels of the present hazard, are unsafe for human consumption.

If the products will be disposed of, proper documentation must be done.

Information, such as the following must be documented:

Foods contaminated with chemical hazards must be properly separated from wholesome foods to avoid cross-contamination.

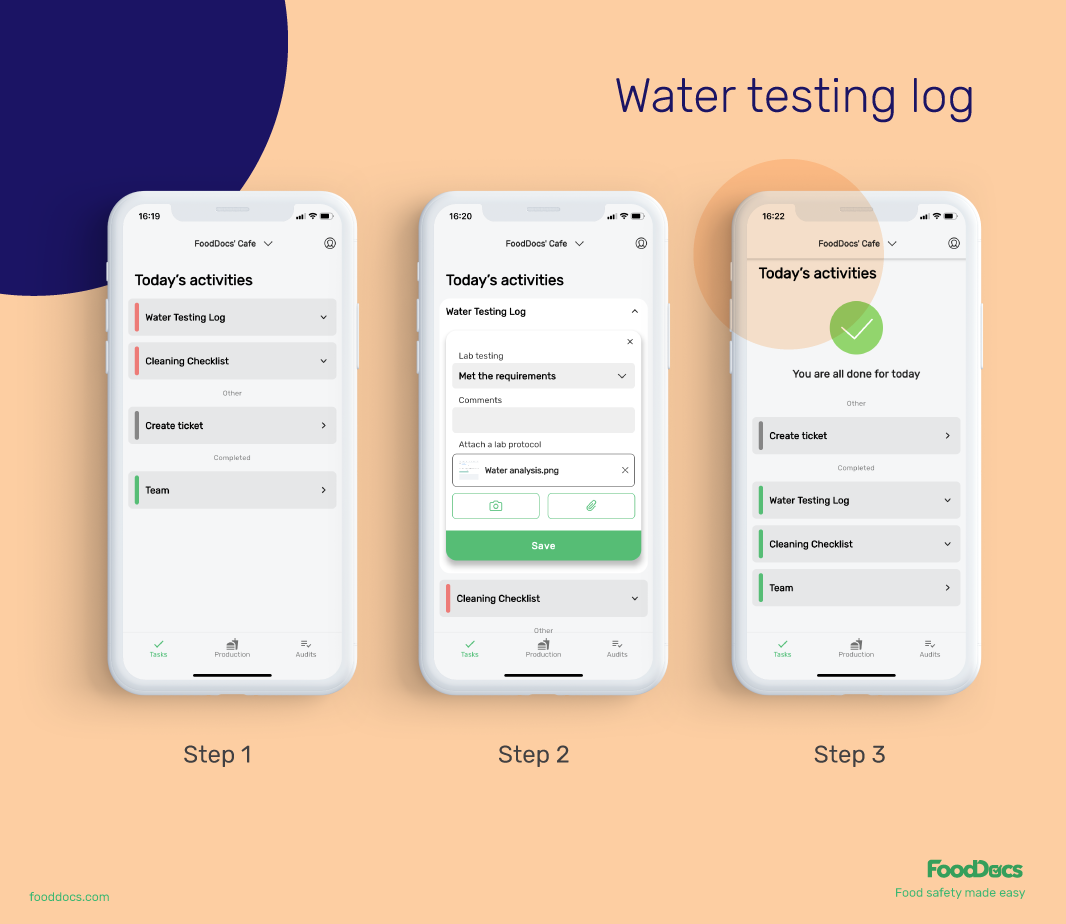

In cases like this, a recall and traceability system would significantly help your team. Use FoodDocs' digital Food Safety Management System, which features a traceability program. Using our mobile application, you can track the status of an affected food product batch and determine any distribution channels that it may have gone to. Get this and more features when you use our digital solutions.

Chemical hazards in foods can cause both acute and chronic foodborne illness or food poisoning. Unlike biological and physical hazards, chemical hazards can cause long-term illnesses in humans.

Some chemical compounds are cumulative, or will only show negative effects when high amounts are stored in the body. On the other hand, other effects of chemical hazards can show symptoms within minutes and will require immediate chemical emergency.

Some immediate symptoms of chemical reactions can be observed as the following:

Chemical hazards can enter the body through ingestion, inhalation, or direct skin contact. Different effects may show depending on how a customer or food handler was exposed. Absorption through skin may have less severe effects than exposure to chemicals through inhalation or ingestion. Cumulative exposure to chemical hazards can worsen the negative effects.

In more serious cases, chemical risks from exposure to chemicals can also cause other toxic effects, such as severe allergies or sensitivity to chemicals, cancer, and even birth defects among pregnant women. Direct exposure to high amounts of chemical hazards will require immediate medical care.

Customers with weakened immune systems are more prone to the dangerous effects of chemical hazards. It is part of the responsibility of food handlers to protect consumers from such hazards.

Food safety agencies, such as the Centers for Disease Control and Prevention (CDC) and European Food Safety Authority (EFSA), offer assistance and guidance for cases of chemical poisoning in food. Food safety agencies also establish proper handling procedure for food additives.

Problems involving chemical hazards can negatively affect your company's brand and be costly if legal actions are taken against your team. They can cause a variety of damage both to your company and to your customers.

Test and train food handlers on their knowledge about food safety with our free food safety quiz tool.

Proper food handling is very important in preventing chemical hazards from reaching your food and customers. Simple ways such as labeling all materials can prevent accidents, such as accidental contamination.

Chemicals are important components of any food business, whether for cleaning or preparing food. While chemicals can be hazardous when improperly used, they help maintain your food facility and protect your products from food spoilage.

Follow these key food handling procedures to prevent chemical hazards and contaminants from polluting your food products:

You can use informative visual aids, such as posters, checklists, and schedules based on established food safety standards, to guide food handlers on using chemicals.

Handling chemical food hazards is an essential part of a food handler's proper food safety training. During a training program, the food handler must understand the dangers of chemical exposure and how to handle situations with chemicals. Risk communication is the job of a food safety manager.

Access free tools for monitoring chemical safety from our food safety template hub.

As previously mentioned, early and proper hazard analysis is essential in protecting consumers from chemical hazards. Hazard analysis requires great knowledge of food safety standards on permissible exposure limits and a comprehensive risk assessment.

The larger the involvement of a food business in different areas of the food chain, the more extensive the hazard analysis and level of controls should be.

If your food business also handles sourcing food raw materials, risk managers must be aware of common food safety policies and other matters of food safety for chemical hazards. Hazard analysis is the first step to making a food safety plan that will ensure minimal levels of chemical contaminants in your food operation. It is also a requirement to determine the feasibility of controls for your food business.

The fastest way for you to conduct a chemical hazard analysis is to use our free Hazard Analysis Template. Using our free tool, you can easily insert information and select the level of risks associated with a hazard and its potential severity. You can print out the generated table any time you want.

If in case you have very little knowledge of matters of food safety and chemical hazards, what you need is a more intuitive solution. Use our built-in digital HACCP plan software to automatically analyze the most critical chemical hazards in your operations.

Using artificial intelligence and a machine-learning program, our smart software can automatically generate a comprehensive hazard analysis table for your food business. Our system uses stored information from businesses with similar operations and creates a relevant potential hazard analysis for you.

In an average of 1 hour, our system can give you a detailed breakdown of the hazard's risk assessment including the following information:

What makes this automatically generated hazard analysis summary even better is that you can customize it according to the nature of your business. If an analyzed hazard is more severe for your operations, you can simply adjust the analysis with a few clicks.

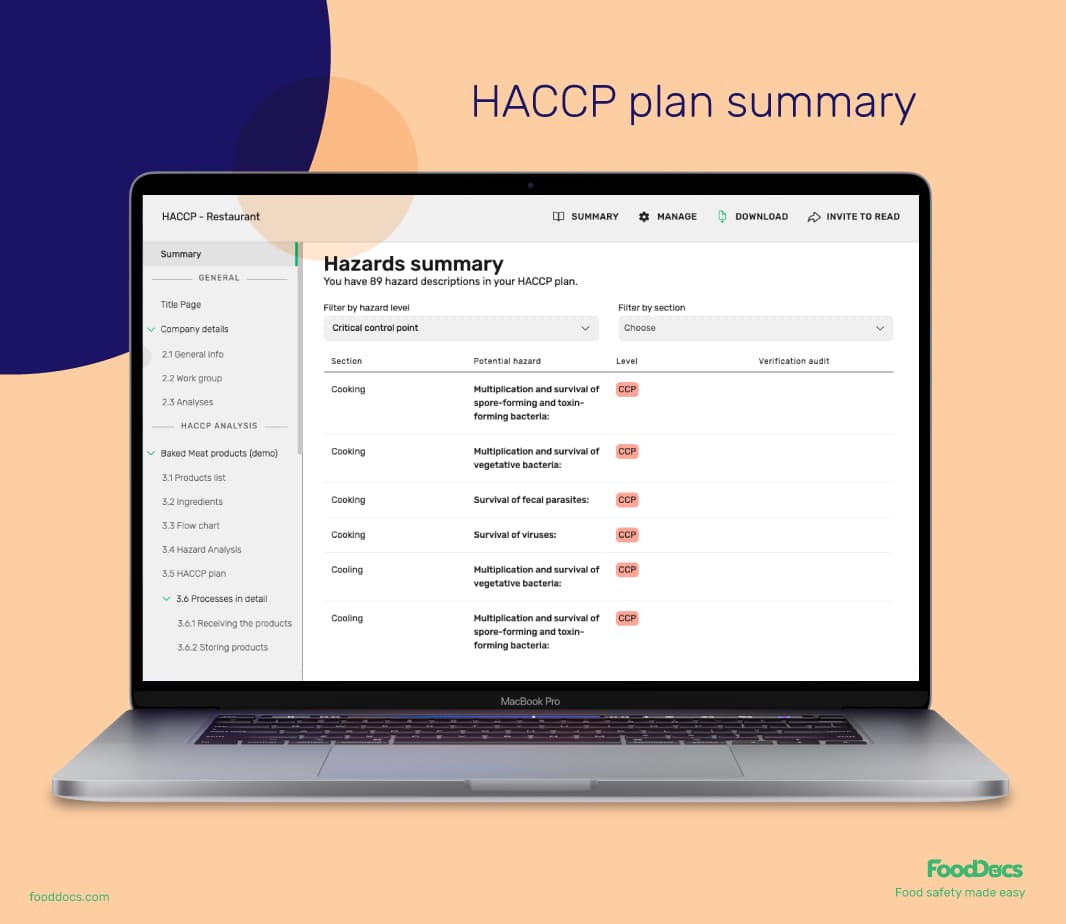

This step is just the first part of our digital HACCP plan builder! In 1 hour, our system will also generate a comprehensive list of the following food safety plan components:

.jpg?width=1065&height=924&name=HACCP_template%20(1).jpg)

With our smart software, you can save a significant amount of time by analyzing the hazards in your business and creating a comprehensive HACCP plan. You can skip all the steps of a HACCP plan-making procedure, let our system do the heavy work, and jump right into establishing your plan.

Our system also accommodates customizations. Use this easy feature to apply suggestions and revisions from food safety inspectors when improving your HACCP plan.

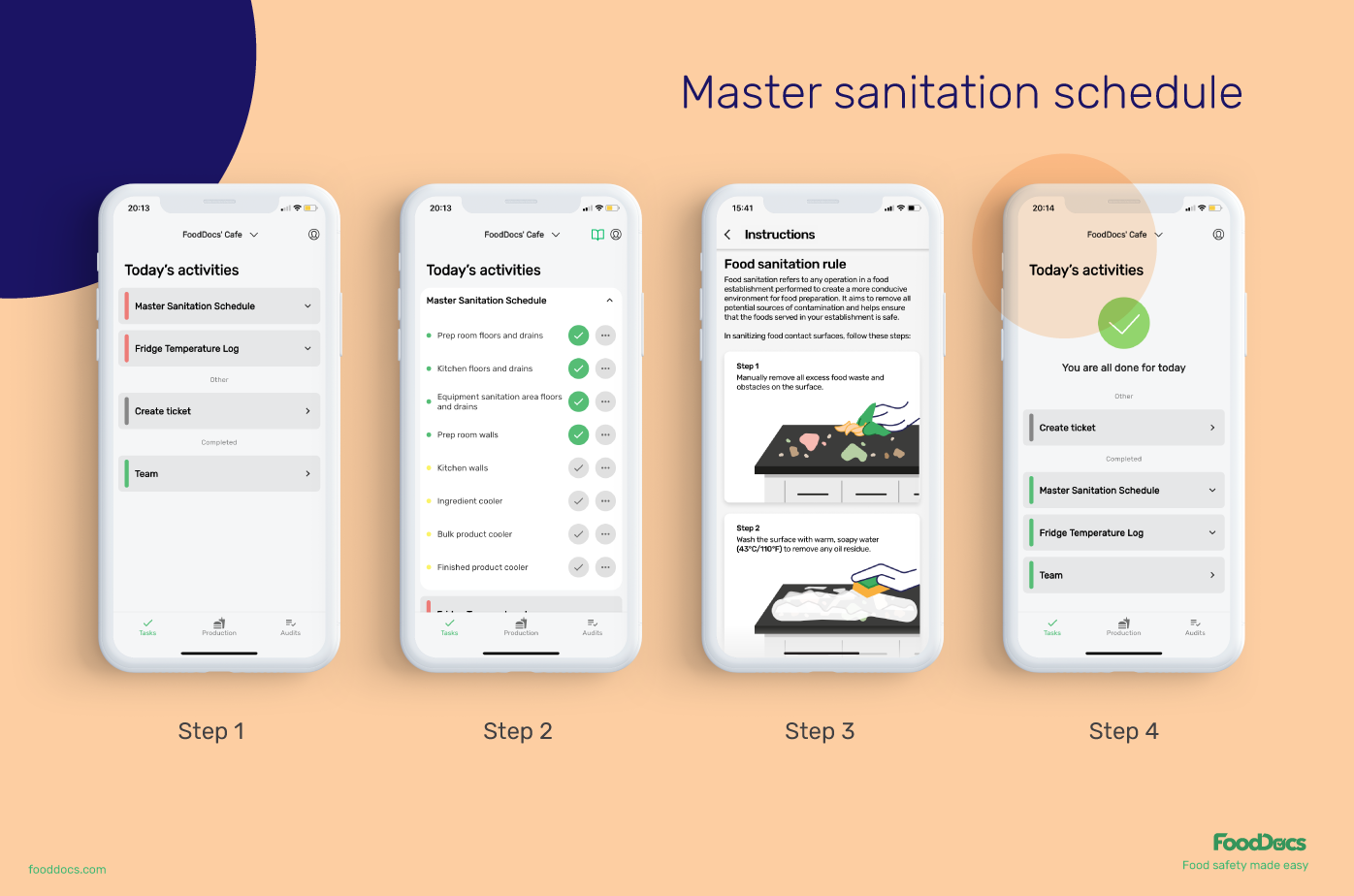

After generating your digital HACCP plan, your team must maintain control of chemical hazards by regularly monitoring all of your daily operations. All identified points with a high risk to chemical exposure must be closely monitored to prevent chemical hazard contamination.

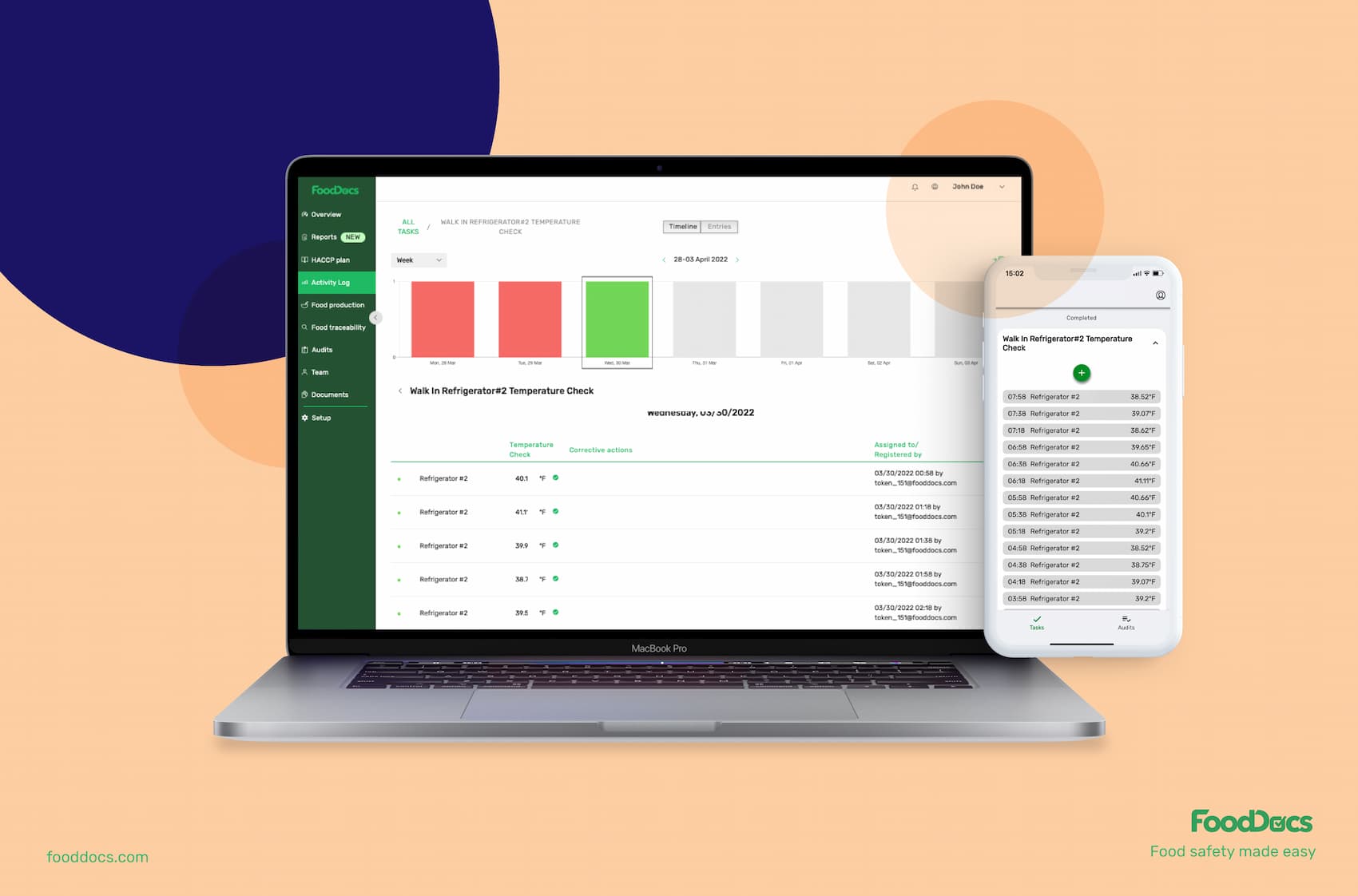

Our smart solutions can go beyond just generating a digital HACCP plan for your food business. You can also use our digital Food Safety Management System Software to control all types of hazards in your food business.

When you use our smart solution, you can automatically get a digital Food Safety Management System in an average of 15 minutes. After generating the system, you can immediately implement it for everyday use.

Our digital food safety system can provide the following features for your team:

In addition to smart monitoring log solutions, our system also offers a real-time dashboard that can help risk managers and business owners analyze the food safety situation at just a glance. Use this feature to save time on manually managing your team all the time.

Use our digital solutions that combine the expertise of a food safety consultant and the power of technology in one. Become more sustainable by leaving the pen-and-paper monitoring system behind and using our digital platform.

Maintain consistent compliance with food safety standards and protect your customers from potential hazards with our digital Food Safety Management System.

Use our free 14-day trial to get the full experience of our system now.

Need more information about what are chemical hazards in foods? Here are some of the most frequently asked questions about this topic.

Chemical hazards in food safety refer to any foreign material that is chemical in nature that causes health problems when ingested or inhaled. Chemical hazards can contaminate foods and be ingested by customers, which can cause severe reactions, such as food poisoning.

They are any (non-biological) substance with a chemical nature that can enter the food system. Chemical hazards can come from the environment as a natural contaminant or from processing-induced reactions, such as excessive heating.

The most effective method in preventing chemical hazards in a food facility is to practice good personal hygiene. When handling hazardous chemicals, food workers must always wear proper protective equipment and wash their hands to avoid cross-contamination.

Chemical hazards can cause harmful effects, such as poisoning, chronic illnesses, or acute foodborne disease when consumed or inhaled. They are toxic substances that can put the health of customers at risk when the permissible exposure limits are exceeded. Depending on the type of chemical and its level of activity, the effects may significantly vary.

Immediate risks of chemical hazards involve vomiting, skin rashes, and nausea. In more serious cases, chemical hazards can cause cancer, birth defects, or death in immunocompromised individuals. The level of risk from chemical hazards may vary.

Chemical hazards examples in food can come from natural toxins, environmental pollutants, agricultural products, veterinary drugs, and chemicals used for food processing.

Not all chemical hazards are always visible. A majority of them can only be detected through chemical analyses.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...