What is Food Defense and How to Create a Food Defense Plan in 4 Steps

All food businesses reporting under the FDA must establish a food defense plan. Here's what it is and how you can create a food defense program in 4...

A food safety plan is a food company's main defense against the risks of foodborne illnesses. Are you adept enough to make one on your own?

Compliance and maintenance of food safety is a multi-faceted task. Fulfilling the requirements of food safety requires several layers of operations as it covers all corners of your food production and services. These operations are all laid out in a documented food safety plan. When opening a food business, aspiring food business owners are obliged to understand what this plan is and how to get it. Establishing a food safety plan is at the top of the list that needs to be fulfilled when starting your own food business. It is an integral document that illustrates a food company's approach to food safety for the protection of public health against potential hazards.

Whether a requirement of the presiding federal food safety agency or not, having a food safety plan ready can help address the problem of foodborne illness outbreaks worldwide. Despite this, establishing a food safety plan involves several technical steps that may require the expertise and advice on food safety requirements of a food safety consultant.

Need a food safety plan fast, and are you on a budget with both monetary and time resources? Find out from this article how to build your own food safety plan in traditional and more advanced ways.

WHAT WE'LL COVER:

A food safety plan is a unique set of documents that identifies the food safety hazards and illustrates appropriate control methods, critical limits, and corrective actions to minimize them for an individual business. This plan is designed based on a food company's nature of food service operations and covers the entire food chain. It includes control procedures for raw material production or receiving up to the distribution of foods.

A food safety plan ensures that a food business is operating under safe conditions to protect the general public health and prevent hazardous foods from entering the market. Food safety plans are derived from the principles of the Hazard Analysis Critical Control Point (HACCP) system. It uses the main components of the HACCP system while incorporating a wider scope.

The main objective of a food safety plan is to minimize the risk of potential hazards that may cause bacterial food poisoning or related injuries. A food safety plan is a critical set of documents for any food business.

Making a food safety plan is based on the risk-based principles of a HACCP program. A food safety plan consists of documents detailing all the related operations of a food business and the necessary preventive controls.

Every food business must at least have an established food safety plan to operate fully. As such, it is important that you know how to make one and understand the importance of each step.

Below, we describe all the steps on how to write a food safety plan:

To create a food safety plan, you need a team composed of representatives from the different departments of your food business. In some countries, such as the United States, a food safety team must be headed by a Preventive Controls Qualified Individual (PCQI). This individual does not have to necessarily be one of your employees and can be an outsourced food safety consultant who can develop food safety plans.

A PCQI is an individual who has garnered a certification of competency from adequate job experience and a food safety training program accredited by the Food and Drug Administration (FDA). The food safety plan leader will facilitate the plan-making process and its implementation. This individual must have adequate problem-solving skills and have passed the necessary assessment requirements.

After building your food safety team, draw a detailed block-type flow diagram that clearly outlines all of the steps in your operations and real workplace setting. It is critical that you include every operation involved in your operations as this will determine the robustness of your food safety plan.

The flow diagram does not need to be professionally drawn. All it needs to be is a complete representation of your operations. Every step will be evaluated and analyzed for the establishment of preventive controls.

Create your own HACCP plan flow chart using our free tool.

With an established team and illustrated workflow, your team now has to create a comprehensive food safety plan.

3.1 Hazard analysis. The first step to making a food safety plan is to identify all potential food safety hazards and the sources of contamination related to your operations. All steps of your food production process must be analyzed for the presence of food safety hazards.

Unlike a HACCP plan, a food safety plan also considers other types of hazards, including radiological hazards and "economically motivated adulteration." Regardless of whether a hazard will require preventive control or not, it must be mentioned.

In addition to identification, this step includes the evaluation of each hazard. Descriptors such as the type of hazard, its likelihood of occurrence, its potential for contamination when uncontrolled, and if it will require a preventive control.

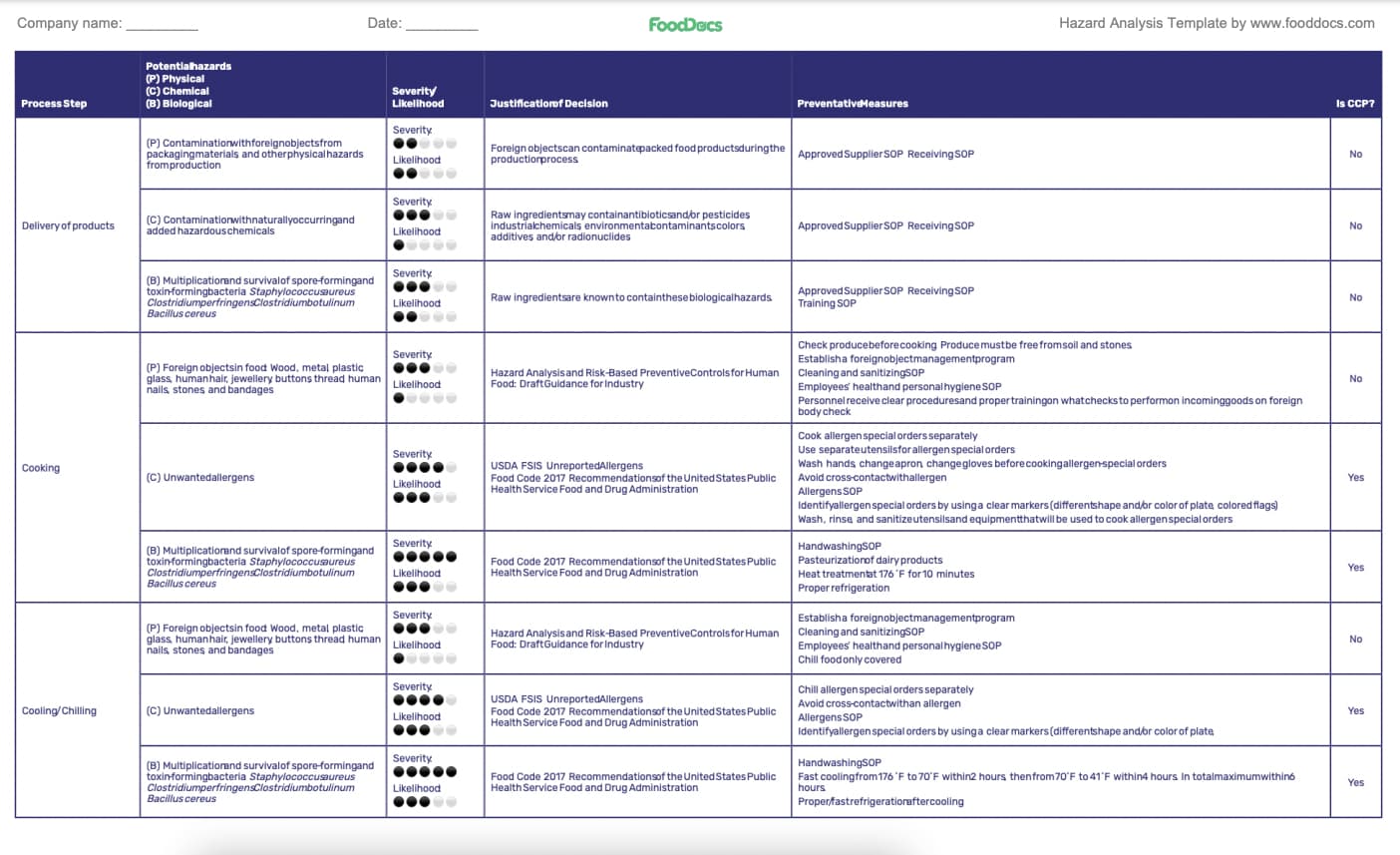

FoodDocs Hazard Analysis Template

Use our free Hazard Analysis Template to clearly present all of the potential hazards in your food business.

3.2 Establishment of preventive controls.Preventive controls refer to operations that must be implemented to maintain or eliminate a hazard at least to acceptable levels and create safe food items. These controls are implemented based on an identified hazard that is most likely to result in foodborne illness or injury when not properly controlled. Some preventive controls include hygienic practices or manufacturing practices, such as the following:

Risk-based preventive controls do not necessarily have to be considered Critical Control Points (CCP). They also include operations that are not final actionable steps for controlling a hazard as opposed to CCPs in food processing.

The most common type of preventive control is Process Control. This type of control includes operations that can eliminate a hazard or reduce it to an acceptable level. It includes cooking and chilling. Other types of preventive controls may include:

3.3 Monitoring procedures for preventive controls.Monitoring procedures include written steps to evaluate if preventive control effectively controls the levels of hazards to food safety. Monitoring procedures require specifications such as parameters to control, monitoring and audit frequency, steps of monitoring, and personnel in charge of monitoring.

Monitoring record sheets are proof that your food safety plan is effective and copies of action taken for control. They can also be used to evaluate whether your food safety programs must be revised or if it is efficient enough to be retained.

Monitoring procedures must be consistently performed to ensure the safety of food during manufacturing. When done on time and breaches of food safety are detected, food handlers may immediately apply corrective action procedures. Failure to monitor preventive controls increases the risk of causing foodborne illnesses.

3.4 Corrective action plan.In case of non-compliance, operators of food facilities must have a corrective action plan in place. This plan lays out the necessary contingency procedures to gain control of hazards that were not effectively controlled.

Corrective actions aim to achieve what preventive controls may have failed to do or at least salvage the products. A corrective action plan also includes procedures on how to evaluate processed products to ensure control of food safety. After the evaluation, food handlers must also identify the root cause of the non-compliance to avoid its reoccurrence.

All operations under a corrective action plan and its application must be properly recorded to serve as a reference in case of customer complaints.

3.5 Verification procedures.Verification activities are continuous operations. These procedures aim to ensure that the food safety plan is working as intended and that the correct information is captured from the monitoring system.

Verification procedures include periodical and everyday verification of records. The food safety supervisor is in charge of verifying all food safety documents and alerting team members of non-compliance or inconsistencies.

All documents related to the food safety plan must be subject to proper recordkeeping procedures. Improvements or revisions to the food safety plan must also be properly recorded. Building a food safety plan requires careful assessment of your entire food process. The whole planning requires time and extensive documentation to complete.

In the U.S., food safety authorities do not require any particular format for a food safety plan. As such, it is best to coordinate with your local food regulatory authority to identify any specifics required for your food safety plan.

In other countries, such as Canada, Australia, and the UK, a food safety plan is based on all of the principles of the HACCP system. You can use our customizable HACCP plan template builder to satisfy regulatory requirements for making a food safety plan in your location.

In the U.S., a food safety plan is different from a HACCP plan, whereas, in other countries, they are referred to as similar programs. A food safety plan in the US covers a broader scope of topics and includes monitoring preventive controls other than critical control points.

In particular, a HACCP plan is a documented program of a systematic approach to the analysis of hazards and the establishment of critical control points for their elimination. This food safety program is required by the United States Department of Agriculture (USDA) for all raw and cooked meat businesses and poultry products, as well as the FDA for juice and seafood businesses.

While a food safety plan is based on the risk-based principles of the HACCP system, it has a few discrepancies from the latter program. The FDA produced a summary table comparing the two plans.

FDA's Comparison of HACCP and Food Safety Plan

After reading this comparison, questions such as "Do I still need a Food Safety Plan if I already have a HACCP plan?" The FDA clarifies that while the HACCP plan satisfies the majority of the regulatory requirements of a food safety plan, your team may still need to incorporate additional information, such as the supply-chain program, which is not normally a part of the HACCP plan.

Do you have no idea how to make a HACCP plan? We've got you covered! Using our built-in HACCP plan template builder, you can get your customizable HACCP plan ready in just 1 hour. All you need to do is answer a few basic questions about your operation, and our software will do the rest.

Find out more about our digital solution at the end of this article!

Food safety regulations require all food businesses, including food service establishments, food retailers, and food processing plants, to have a food safety plan in place. This document is an essential part of your approach to food safety and the protection of public health.

Where the HACCP plan is a voluntary system for operations not concerning beverage and seafood production, as regulated by the FDA, all food businesses are required to have a HACCP-based food safety plan. Every food business must have a complete set of documented procedures detailing the analysis of hazards and preventive controls set in place.

A food safety plan with complete compliance requirements to the Hazard Analysis and Risk-based Preventive Controlsfor Human Rule is composed of the following sections:

The primary purpose of a food safety plan is to protect customers from the risks of foodborne illnesses and related injuries. It allows a food business to operate safely while serving quality products to its consumers. A food safety plan can help improve the totality of the food business, as safety affects other aspects of the food industry.

Particularly, a food safety plan is important for any food business by serving the following benefits:

A food safety plan can affect the performance and other aspects of your food business. It can help you optimize operations while securing profit and customer loyalty. Establishing your own restaurant food safety plan example prepares you for any food safety issues and ensures the stability of your food processing operations. Compliance with food safety requirements is a necessary task to work in the food industry.

The most important aspect of any food safety plan is proper identification and hazard analysis. This basic step determines the succeeding principles to be applied in making a food safety plan.

When food safety hazards are left unidentified, your team will not be able to apply preventive controls, and the risk of foodborne illnesses becomes significantly high. In addition, inadequate hazard analysis may lead to undermining the effects of a hazard, and similarly, inadequate preventive controls may be established.

Different types of food safety hazards can be found in all areas of the food supply chain. The food safety team must carefully assess which hazards are present in every step of your food processing methods to produce safe products.

A food safety system requires a thorough verification and reanalysis once every three (3) years or as needed. Food safety is dynamic, and Federal regulations are constantly changing. As such, your food safety plan must change accordingly.

An approximate time of three years is enough to capture any significant change in food safety regulations. In addition to a routine reanalysis, your food safety plan can also be subject to improvements and revisions in case a food safety auditor points out any non-compliance with your operations.

All revisions and previous versions of your food safety plan must remain properly documented to serve as a reference for your food safety team.

Building a food safety plan requires a significant amount of time, effort, and expertise. At least one of your team members must be knowledgeable enough to identify hazards, distinguish preventive controls, and discern discrepancies between plans.

For a newcomer in the food industry, this task is huge enough that it can sometimes be discouraging. In addition to building a food safety plan, your team must constantly improve it to remain compliant with the changing food safety regulatory standards.

What you need is a smarter solution to build your own food safety plan. At FoodDocs, we understand the woes of every food business owner. As such, we have come up with a digital solution that can help every food safety team to build a compliant food safety plan in just 1 hour!

Our built-in digital HACCP plan template builder is powered by artificial intelligence and a machine-learning program. Using these technologies, our system can automatically create a comprehensive and customizable HACCP plan specific to your food operations.

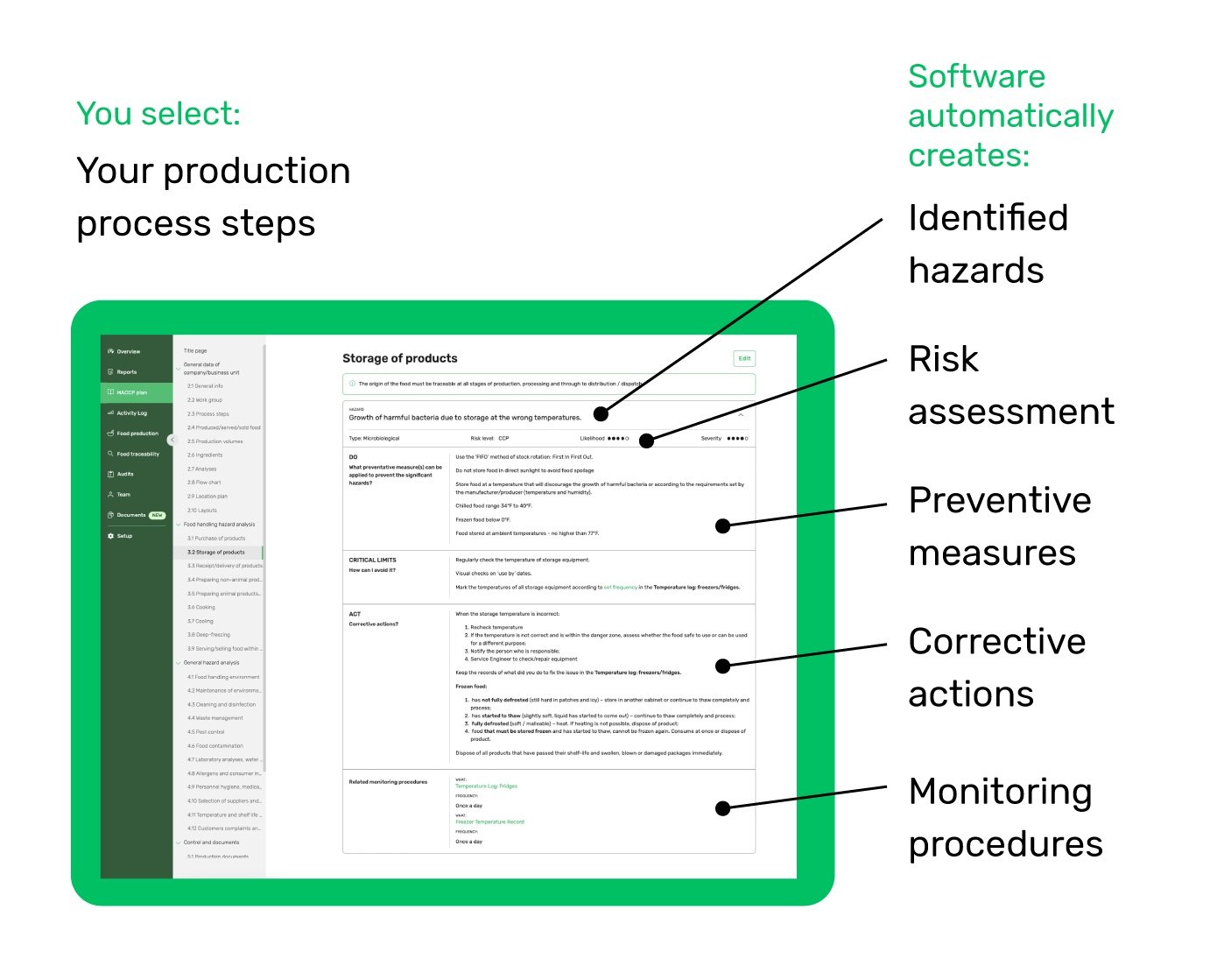

When you use our software, you can get the following components:

HACCP food safety plan in FoodDocs

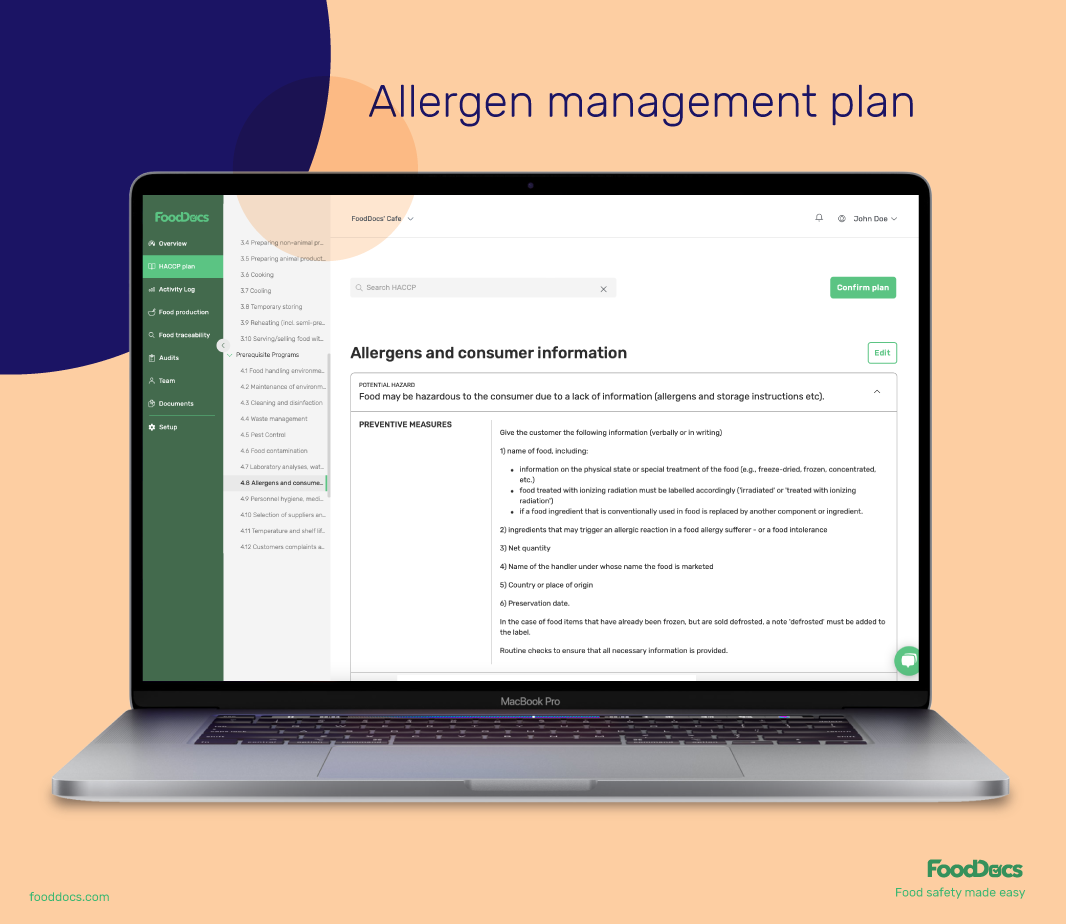

In addition to the main components of your HACCP food safety programs, our digital solution can also help generate the following for you:

Allergen management plan in FoodDocs

The HACCP plan that our system can generate for you satisfies the majority of the applicable requirements of the Risk-based Preventive Rule of the FDA Food Safety Modernization Act of 2011. Even more exciting for you is that you do not need extensive knowledge about food safety to get comprehensive HACCP food safety programs. Our system will cover all of the technical details for you.

Our digital solution promises a 500x faster process than manual documentation of your food safety plan. This software is also 15x cheaper than hiring a food safety consultant to help you make your HACCP plan.

In addition to the ease of making your digital HACCP plan, the food safety plan that our system can generate for you can be customized for any improvements. With this particular feature, you can incorporate suggestions from food safety agencies and apply compliance revisions. You also do not need to worry about storing your older versions, as you can download or share them with your food inspectors.

Our digital customizable HACCP plan builder can help you become compliant with the most stringent food safety standards in just 1 hour.

Use our system's free 14-day trial to build your HACCP plan now!

All food businesses reporting under the FDA must establish a food defense plan. Here's what it is and how you can create a food defense program in 4...

4 steps of food safety help prevent the spread of any type of contamination in a food establishment. See all the steps, the importance, and tips to...

All food businesses in Australia are required to follow the Food Standards Code and establish a Food Safety Program. Learn from the article, how to...