Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

The HACCP program was built to create crumb- and pathogen-free foods for astronauts. Here's what it looks like today.

Creating a HACCP plan isn't an easy task. It is time-consuming and requires a lot of paperwork. However, thanks to technology it is possible to get a HACCP within 1 hour with HACCP plan software. It wasn't always like this.

The HACCP program started like any other program, with a pen and a paper as an approach to food safety. HACCP was drafted to resolve food safety issues for a world-changing project in space. The history of HACCP goes back to the 1950s and has since revolutionized food safety.

Aside from being mandatory, causing foodborne illness outbreaks or related food safety concerns will soon result in the closure of a food business. The prevention of such cases is the aim of the development of the HACCP system.

If you're a food business owner, you may have always heard about what HACCP is, but where did it come from? Below we outline the history of HACCP.

The now internationally known food safety management system Hazard Analysis Critical Control Point or HACCP was first made as a systematic approach to help space explorations in the early 1960s.

The National Aeronautics and Space Administration (NASA) together with the help of the Pillsbury Company created the first concept of the HACCP program. The initial objective of this project was to develop foods with the highest level of food safety for traveling space.

The main driving idea was that astronauts cannot get sick in space as this can significantly put their lives at risk. As such, the risk of any foodborne illness from hazards must be removed. Both institutions formed groups to create a crumb- and pathogen-free product that can withstand space travel and have a significantly longer shelf life by identifying all critical failure areas.

To achieve their main objective, they used the critical control point system of the U.S. Army Natick Research, Development, and Engineering which was normally used for ensuring the quality of medical supplies.

The original HACCP program had only three principles as prescribed steps for HACCP at that time. Soon after the success of the application of HACCP, Pillsbury continued the innovation and implemented it in its operations and food facilities for safe food production. Similar to the success of NASA's project, the company successfully implemented the program in their operations and resolved their issues with finding glass contaminants.

Soon after the successful application of HACCP by Pillsbury, the concept of HACCP was presented to the world through the National Conference on Food Protection in 1971 to further protect public health. After this, Pillsbury started conducting classes with the Food and Drug Administration (FDA) inspectors.

The FDA then used HACCP to address the challenges with food safety on low-acid canned food regulations. During this time, HACCP was used to employ a preventive approach in controlling food safety hazards and risks from production to the human consumption of food products.

HACCP did not go unchanged. Several revisions and petitions were filed to improve it. In 1983, the World Health Organization (WHO) Europe officially endorsed its use. The program soon gathered even more recognition from other organizations such as the National Advisory Committee on Microbial Criteria for Foods (NACMF). This organization pushed the movement to encourage food companies to adopt the HACCP program and aid in the establishment of resources on the principles and implementation of HACCP in 1985.

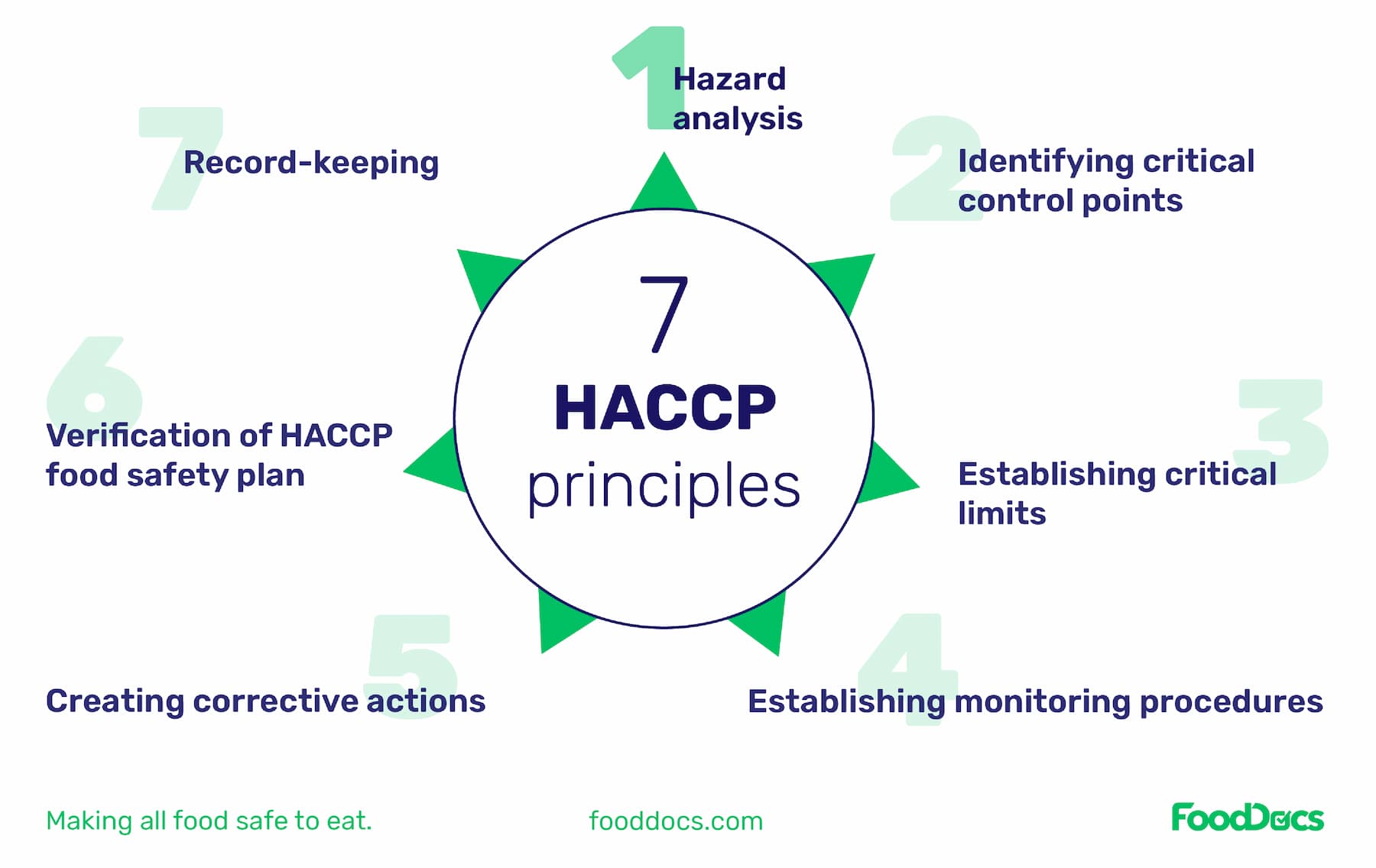

In this duration, some of the most significant improvements occurred for the HACCP program. After years of careful studies, the NACMF presented a report in 1992 that contained all the 7 major principles of HACCP and 5 preliminary steps which we know as of today. These principles and preliminary tasks include:

Principle 1. Conduct Hazard Analysis

Principle 2. Determine critical control points (CCPs)

Principle 3. Establish critical limits

Principle 4. Establish monitoring procedures

Principle 5. Establish corrective actions

Principle 6. Establish verification procedures for the effectiveness of your HACCP system

Principle 7. Establish record-keeping and documentation procedures

One of the biggest supporting movements that this publication garnered was its adoption by the Codex Alimentarius Commission, the committee responsible for all implementation of food regulations built by the joint FAO/WHO Standards Programme. This committee is also responsible for establishing a uniform program for food safety management standards for the industry.

In terms of mandating the application of HACCP in every food plant, it was not until the incident called Jack-in-the-Box in 1993 occurred that most food agencies and every regulatory authority required HACCP. This incident affected more than 700 people across the US. Around the same time, the UK has also been facing food safety problems, particularly from the effects of Bovine Spongiform Encephalopathy (BSE).

It was these high-profile cases of foodborne illness outbreaks that prompted the food industry to encourage HACCP implementation even more. In 1990, the EU made having a HACCP plan a legal requirement, whereas the USDA imposed the Pathogen Reduction/HACCP Systems rule for the production of safer meat and poultry products. Soon after these mandates, the foodborne illnesses were significantly reduced by 20% in the US alone and food safety practices have been deeply rooted in the food processing industry.

As part of the history of HACCP, the International HACCP Alliance was established in 1994. This group has the main objective to ensure that HACCP application was uniform throughout the food chain. The alliance provides three different services:

The alliance is now known as an international authority in providing certification, accreditation, and any training program to understand and verify HACCP implementation. They also provide information on regulatory compliance with food safety standards, good manufacturing practices, and prerequisite programs for safe production in different food production systems.

What started as a hazard analysis plan created by a team of food scientists in the late 1950s has now developed into one of the most accurate and esteemed food safety management systems in the world. HACCP is a standardized tool and a strategic plan for every business in the food industry that validates, through following the HACCP procedures, that all food cooked, served, and consumed, is safe to eat.

As a regulatory requirement by almost all food safety agencies, food safety teams consisting of food handlers for every manufacturing plant and other production facilities must become familiar with how to make a HACCP plan. This task alone is not easy. There is a lot at risk in implementing an inaccurate HACCP plan. As such, several hours and focus go into making it. From the drafting, writing, and revision of the plan, a lot goes into making a HACCP plan.

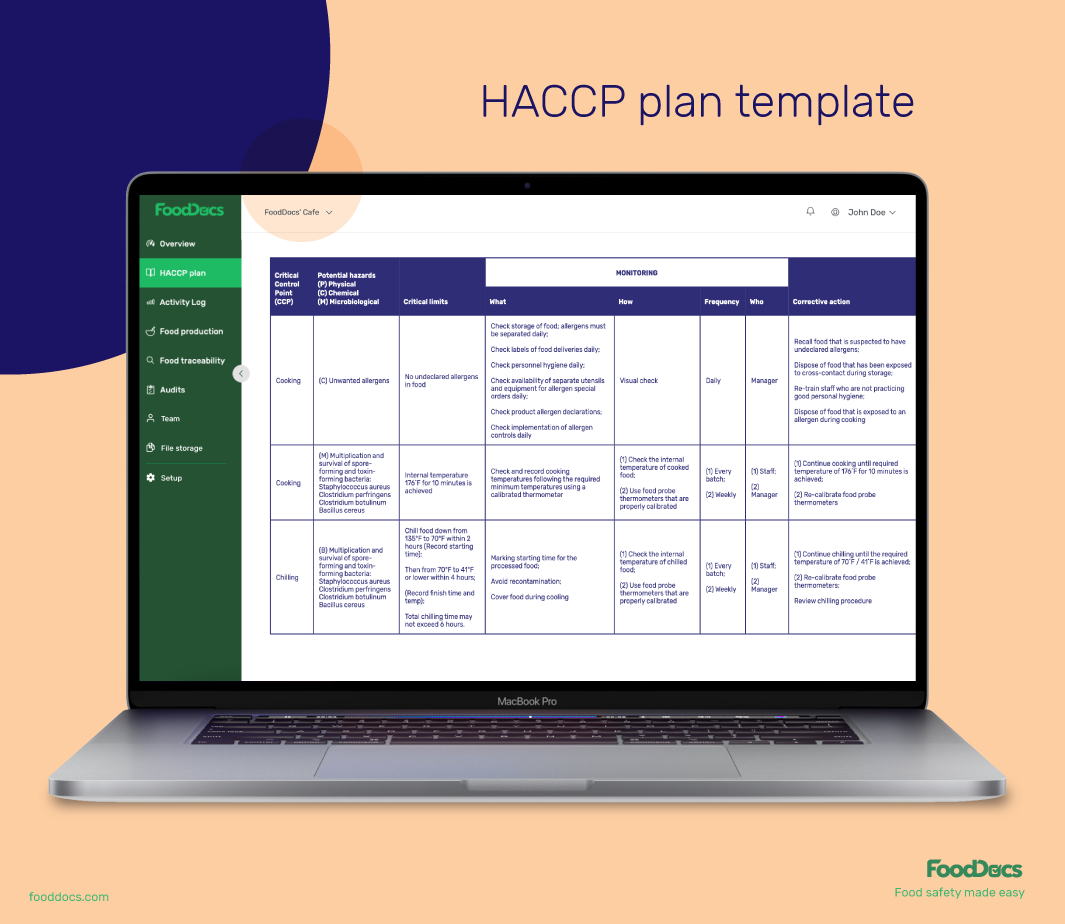

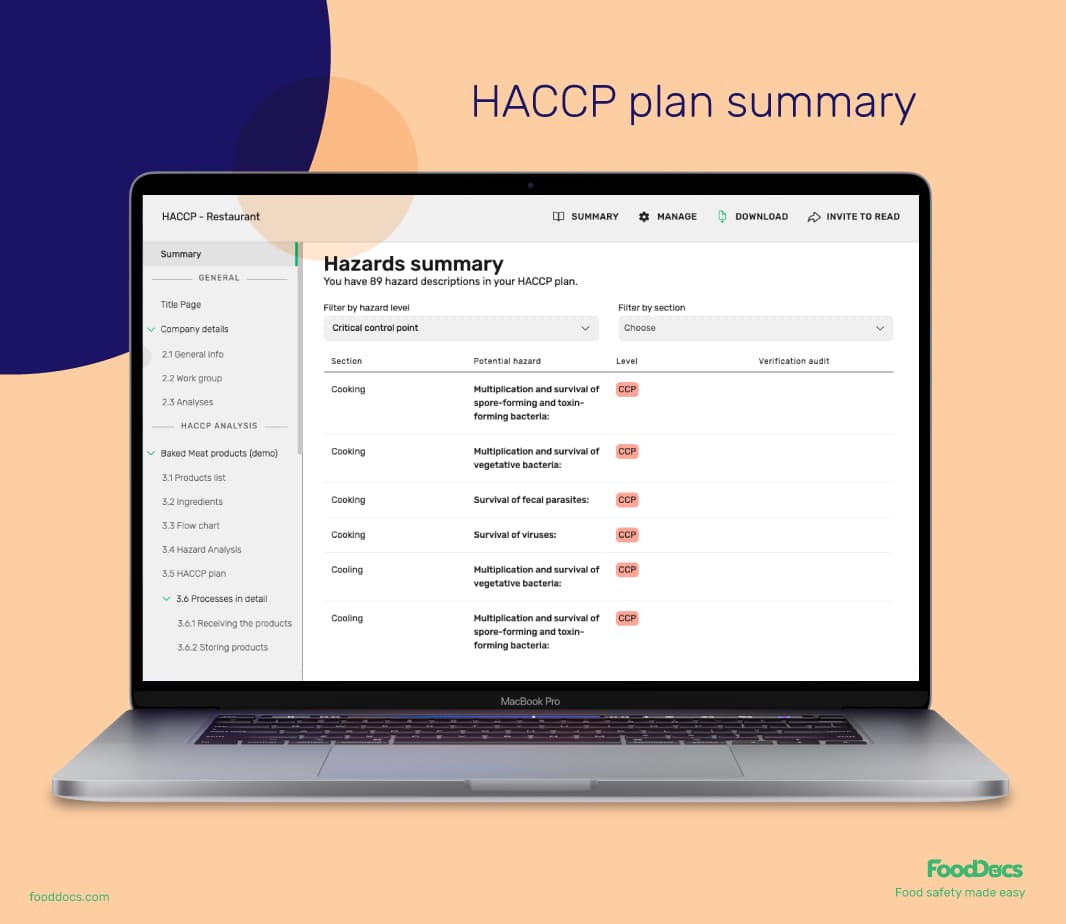

In 2020, a group of food safety experts formed a ground-breaking innovation that soon started revolutionizing food safety and the implementation of HACCP. A digital HACCP software was produced by FoodDocs which allows easy access to a comprehensive HACCP plan for every food business. This system automatically creates a HACCP plan fit for the customer's food business operations by using AI-powered technology. With such an innovation, more and more food businesses have propelled their businesses toward compliance with HACCP requirements.

In addition to these important dates, here are some quick answers to additional questions about the history of HACCP:

In the US, the USDA adopted the HACCP program in 1996 and released their first rules but it was only by the power of the Food Safety Modernization Act 2010 for most food processing plants.

In the UK, the mandatory implementation of HACCP for all food establishments is under the EC Regulation 852/2004 on the hygiene of foodstuffs.

A. Pillsbury®

B. General Mills®

C. Yum Brands®

D. Kraft Foods®

In the 1970s and after the successful implementation of HACCP for the Apollo program, the Pillsbury Company was the first ever food business to adopt and implement the HACCP program.

AI-powered HACCP builder, FoodDocs is on a course to change the future and shake up the existing food safety industry, and further increase consumer confidence in food safety.

In a climate where businesses and business models need to change overnight, a digital HACCP plan comes with many crucial benefits. Aside from automatically generating a comprehensive HACCP plan in just 1 hour, a digital HACCP plan can be customized anytime.

In 2021, HACCP plan software is finally revolutionizing food safety. The core of this revolution does not lie with the next generation of smart sensors, but with the first and most important step of them all, creating your HACCP plan. With the help of technology, we have come a long way from waiting on food safety consultants to opening our dream businesses.

Now, you can simply answer simple questions about your food business and watch as our AI HACCP plan software compiles your HACCP plan and other food safety documents that:

You do not need prior food safety knowledge to switch to a digital HACCP plan and you can get your fully customizable HACCP 500 times faster than making it the traditional way. Apart from a super speedy start, saving all your food safety data in one place comes with another massive benefit: all your data is always and immediately available for upcoming audits, and nothing gets lost.

This is not where the technological magic ends. On top of allowing food businesses to get a HACCP plan in 1 hour, we also provide them with a top-notch traceability system that allows users to track the entire food supply chain quickly and accurately and prevent further problems such as vulnerability to food fraud.

Accurate tracking is not only extremely important in preventing the spread of contamination, but also in everyday life. Consumers demand increased transparency when it comes to the source of their food and is becoming more environmentally focused when shopping. They are more interested in the sources of the ingredients from their favorite restaurant and takeaway meals come from. All of this brings food traceability systems into the limelight and helps make FoodDoc's ultimate goal possible which is to ensure all food is safe to eat.

Get a comprehensive HACCP plan that is specifically fit for your operations in just 1 hour. You do not need to take too much time or hire a food safety consultant to make your HACCP plan. The plan that we automatically generate for you at FoodDocs accomplishes all principles of HACCP plan-making and ensures that all food safety hazards in your operations are well identified and analyzed. Our built-in HACCP plan builder guarantees to help you get HACCP compliant even with very minimal food safety knowledge. Our system promises expert-level services and results that will allow your team to save time and focus more on managing your food business.

With more and more businesses switching to a digital HACCP plan, we can safely say that starting a food business will be completely different in 5 years and that the technological revolution started right here, at FoodDocs. Start your HACCP compliance journey with us at FoodDocs and avail of our free, 14-day trial.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...