HACCP Plan for Restaurant Template: How to Create One (Free Sample PDF)

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

Writing a HACCP plan is a crucial step in keeping control of food safety in the food industry.

If you're looking for a summary table of the most important information and don't need a more comprehensive HACCP document, check out our free HACCP plan template below. You can also download the HACCP Plan eBook if you want to read about it first.

Either way, we've got you covered with our HACCP plan example template. All you need to do is click on the editable cells and input your specific information to customize it according to your business operations.

| Critical Control Point (CCP) | Potential hazards (P) Physical (C) Chemical (B) Biological |

Critical limits | MONITORING | Corrective action | Verification procedures | Record-keeping procedures | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| What | How | Frequency | Who | |||||||

| Cooking | (C) Unwanted allergens | No undeclared allergens in food | Check storage of food; allergens must be separated daily; Check labels of food deliveries daily; Check personnel hygiene daily; Check availability of separate utensils and equipment for allergen special orders daily; Check product allergen declarations; Check implementation of allergen controls daily |

Visual check | Daily | Manager | Recall food that is suspected to have undeclared allergens; Dispose of food that has been exposed to cross-contact during storage; Re-train staff who are not practicing good personal hygiene; Dispose of food that is exposed to an allergen during cooking |

Chemical analysis of raw materials and finished products that do not contain the allergen; Conduct internal audits; Records of third-party audits |

Yearly audit; Results of Laboratory analyses |

|

| Cooking | (B) Multiplication and survival of spore-forming and toxin-forming bacteria: Staphylococcus aureus Clostridium perfringens Clostridium botulinum Bacillus cereus | Internal temperature 176˚F for 10 minutes is achieved | Check and record cooking temperatures following the required minimum temperatures using a calibrated thermometer | (1) Check the internal temperature of cooked food; (2) Use food probe thermometers that are properly calibrated |

(1) Every batch; (2) Weekly |

(1) Staff; (2) Manager |

(1) Continue cooking until required temperature of 176˚F for 10 minutes is achieved; (2) Re-calibrate food probe thermometers |

Manager must maintain record of cooking temperature and calibration; Manager confirms weekly that food probes are used, properly maintained, and calibrated |

Cooking temperature log; Calibration record |

|

| Chilling | (B) Multiplication and survival of spore-forming and toxin-forming bacteria: Staphylococcus aureus Clostridium perfringens Clostridium botulinum Bacillus cereus | Chill food down from 135°F to 70°F within 2 hours (Record starting time); Then from 70°F to 41°F or lower within 4 hours; (Record finish time and temp); Total chilling time may not exceed 6 hours. |

Marking starting time for the processed food; Avoid recontamination; Cover food during cooling |

(1) Check the internal temperature of chilled food; (2) Use food probe thermometers that are properly calibrated |

(1) Every batch; (2) Weekly |

(1) Staff; (2) Manager |

(1) Continue chilling until the required temperature of 70˚F / 41˚F is achieved; (2) Re-calibrate food probe thermometers; Review chilling procedure |

The manager must maintain a record of chilling temperature and calibration; The manager confirms weekly that food probes are used, properly maintained, and calibrated |

Cooling temperature log; Calibration record |

|

Thank you for downloading our free template!

Want to create a full HACCP plan in 1 hour?

How about a digital Food Safety Management System in 15 minutes?

In this article, we also cover how to make a comprehensive HACCP Plan in just 1 hour or manually write the HACCP Plan with step-by-step instructions.

Or if you're tight for time right now, download our free How to Write a HACCP Plan eBook to read later.

Several hours of thought processes and physical inspections may go into making this food safety management plan. Building a comprehensive and accurate HACCP plan shows your committed approach to food safety for your consumers.

A HACCP plan can help prevent any unacceptable health risks and the occurrence of any severe illness as a result of consuming your finished products.

In addition to being a mandate in many countries, making a HACCP plan ensures that your business or manufacturing plant only serves and produces safe food items free from hazards. If you are a new food industry player, the biggest question you might have is probably:

Let's start with a high-level view of what's going to be involved and outlined in detail later in this article. Before writing the HACCP plan itself, the process involves preoperational steps. These preparatory steps include:

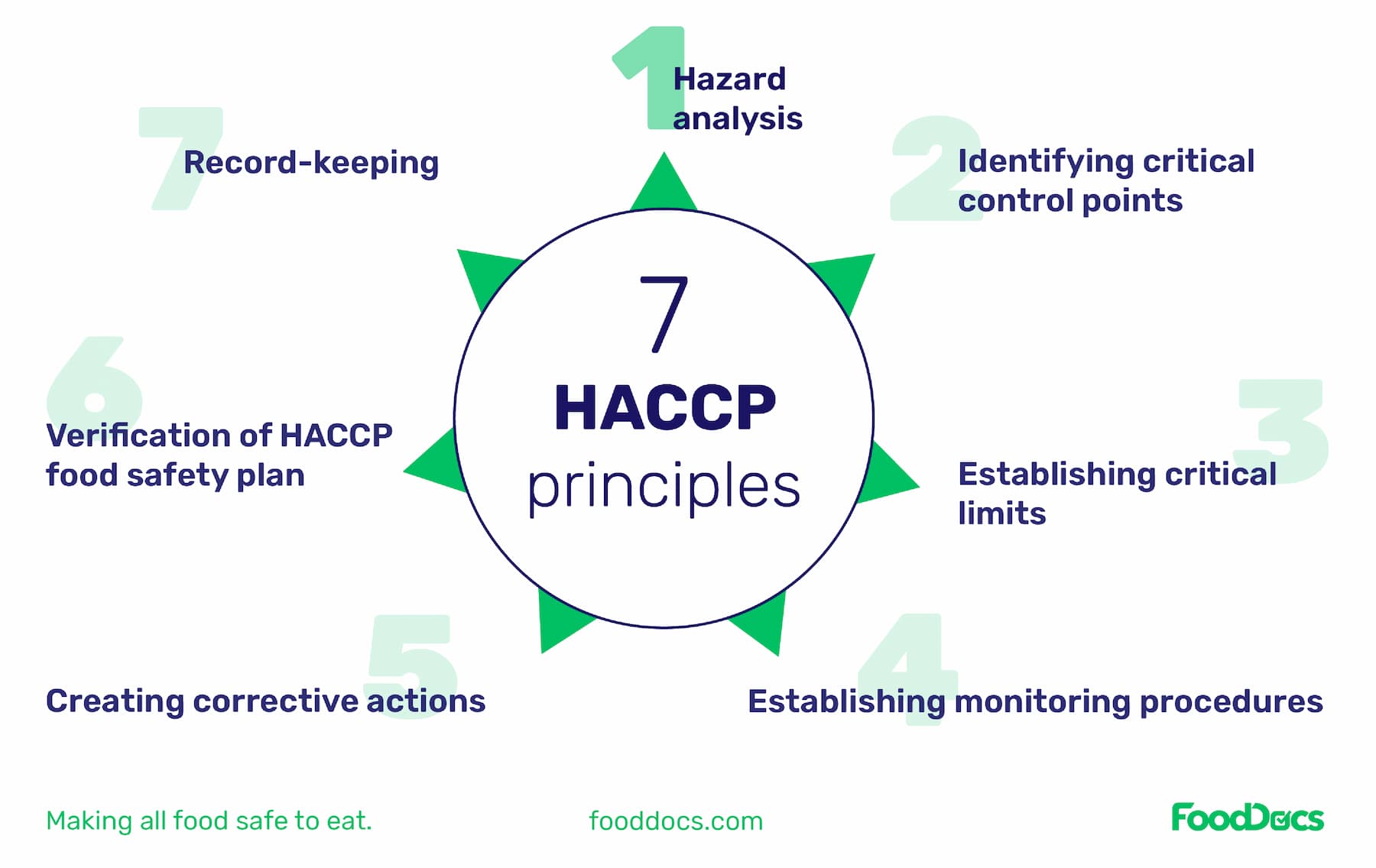

Once you've done that, you can move onto the step-by-step process of writing a HACCP plan which are based on the seven principles of HACCP.

The 7 steps of writing a HACCP Plan are:

A HACCP plan is an internationally recognized food safety management system that addresses the hazards in your food operations by carefully identifying them and assigning preventive measures.

Charles C., an ISFQN Moderator, shared in the International Food Safety and Quality Network forum that a HACCP system is larger in scope than a HACCP plan; the HACCP system is the implementation of the developed plan.

This food safety system aims to prevent any foodborne illness and other adverse health consequences of poor food employee practices from occurring. We also invite you to read more about the HACCP definition. Writing a HACCP plan involves several subsequent steps that you need to follow to achieve the system's best advantages.

Behind every effective HACCP system is a well-designed HACCP plan.

Creating a HACCP plan needs preparation and the correct mindset. It’s a written plan that properly addresses the food safety risks of your food business, which requires focus and adequate knowledge about food safety and related manufacturing operations.

Making your own HACCP plan in-house promotes a sense of ownership and a general understanding of your food operations. In case of problems, you can resolve unexplained system failures if you know your plan in-depth.

While making a HACCP plan from scratch can be tedious, some food companies seek the advice of independent experts such as food safety consultants from regulatory agencies in the food industry.

Thank you for downloading How to Write a HACCP Plan eBook!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Now, let's go into the preparatory and process steps to create your HACCP plan.

The first step to creating a HACCP plan is to check your prerequisite programs. These programs are foundational to your eventual HACCP plan and ensure the basic conditions of the manufacturing process and service.

They address minimum quality standards regarding sanitary design principles, general food safety and hygiene practices, employee health, proper environmental conditions, and proper employee training.

Guaranteeing that your food business or manufacturing plant implements and maintains basic prerequisite principles and sanitary conditions ensures that low-risk that low-risk health hazards are controlled to safe levels.

Some basic prerequisite programs that can easily address low-risk food safety concerns may include:

Before building a complete HACCP plan, you need to lay out important information about your products and food operations and establish a working team for the task. These preliminary steps are explained below.

1. Build your HACCP team

Who is responsible for creating the HACCP plan?

Tasks divided by HACCP team members

Tasks divided by HACCP team members

The people who are responsible for creating the HACCP plan are key company employees from each department in your food business. Building a HACCP plan is not the sole responsibility of a food business manager.

Before you can put up a plan, you will need to build your HACCP team. Your team must consist of people who know how to make a HACCP plan or its basic principles.

An efficient HACCP plan team will include members from any position responsible for your food production process to offer expert advice from their fields.

Having a team of purely quality control personnel or just a food manufacturing plant manager may lack the necessary information regarding equipment's technicalities. Similarly, a team composed entirely of only food engineers may lack expertise in quality control aspects.

Some of the members who will be tasked with establishing your HACCP system may include representatives from the quality assurance, engineering, manufacturing, logistics, and managerial departments.

Each representative must have substantial information about how the business operates. They will be responsible for raising both safety and quality concerns about the HACCP system concerning their departments and contribute to addressing them.

2. Identify your product's intended use and general food group

A HACCP plan is a food safety management system specific to a food business. It sets out food safety standards, rules, and preventative measures for operating to produce safe food products.

As such, it is important to identify the nature of your business, products, and target market to become the basis of your HACCP system. Below are some of the most important information that you need to provide for your HACCP plan:

Describing the product you are analyzing gives your team an idea of what hazards may be involved.

Your product description becomes more useful if the details become very specific.

The sample description of general food groups

Information such as the chemical and physical parameters of the raw materials and the finished product's titratable acidity level, moisture level, water activity, salt concentration, product formulation control, and chemical composition will contribute to hazard identification and their analysis.

This information may also include specifications from suppliers, including minimum enteric pathogen load.

3. Identify target consumers

Your team will also be responsible for identifying which market segment your product is made for. This step is particularly essential if your product is intended for niche consumers, which refers to those who have intolerances or weak immune systems.

These groups include infants, pregnant women, the elderly, and individuals with special diet needs.

Example of the market segment

4. Develop a block-type flow diagram of your food service operations

This commodity flow diagram is a simple outline of the whole production processing method of your food operations, from receiving the raw materials to the distribution procedures of the finished safe products.

Your simple schematic diagram describes the process steps needed to produce a specific product which means all inward and outward flows of processes must be included.

Your process flow diagram must be accurate and comprehensive. Every processing line must have its flow chart. Differences in equipment design and process steps may render different conclusions in a HACCP plan.

Free flow chart template from FoodDocs

We emphasize this importance because this flow chart will be your basis for later steps in knowing how to write a HACCP plan. Process flow charts differ depending on the type of product you are trying to analyze. The process of making a sandwich is very different from the pasteurization of milk.

Build your own flow chart using our free template tool (click on the link below the image) or save time and generate a flow chart automatically with all other required HACCP Plan parts with our HACCP builder.

5. Verify all preparatory steps

Traditionally, this step calls for an on-site monitoring & verification procedure for your commodity flow chart. We suggest applying the whole comprehensive verification activities to all of the mentioned preparatory steps.

All of these verification steps are vital to preparing your whole food business in making a HACCP plan the traditional way. Check for any spots in the preparatory plan that may have been missed during any activity of verification.

Need help preparing for your HACCP plan-making phase and its verification? The USDA has provided a guidebook for small to very small businesses that want to comply with HACCP requirements.

After completing all the mentioned prerequisite steps, you are ready to write a HACCP plan. These steps apply the seven major principles of a HACCP food safety program known throughout the food industry.

In this section, we will apply these principles to restaurant businesses, food processing plants, or retail food stores to answer the commonly asked question: "How do I write a HACCP plan?"

The key to making a comprehensive HACCP plan for a restaurant, or any food business for that matter, is the attention to detail and proper execution of each HACCP principle.

Below are the HACCP writing stages and accompanying HACCP plan examples you can use for inspiration.

So without further ado, what is the first step in developing a HACCP plan?

A HACCP plan aims to control potential hazards in food to an acceptable level before they cause significant harm. To do this, you must accurately identify all of the potential food safety hazards in your operations — in other words, conduct a hazard analysis — before proceeding to the next steps in a HACCP plan.

Hazards are any material that can contaminate food and harm customers. These potential hazards may be classified as:

They must be listed for further hazard analysis and identification of the point they would most likely occur.

In hazard identification, list the hazard's likelihood of occurrence, the duration of illness, and the level of risk of damage as an assessment for illness caused in addition to their proper identification.

After identifying and analyzing the hazards, control measures needed to control the hazard must be added. You must identify each preventive and control measure, whether it's a CCP with a YES or NO based on hazard risk assessment.

Free Hazard Analysis Template from FoodDocs

Hazards are quite specific to the type of food you are producing and the operations you are using. Some of the most common, unsafe food safety hazards in a restaurant or food service setup that can cause foodborne illness to consumers may come from:

Safe food products can only be produced if your team properly performs hazard identification and analysis. This step is vital for setting up control measures in your operations.

Use our free Hazard Analysis template to help you map out and present all identified hazards in your food establishment.

Hazard Analysis Template from FoodDocs (highlighted: CCP decision)

Identifying which among your controllable processing steps is a critical control point is also a mandatory element in knowing how to make a HACCP plan. From your previously analyzed hazards and designated preventive measures, your HACCP team must identify which steps are critical control points.

A critical control point is any step in your operation where measurable controls and critical limits can be applied to control specific hazards to an acceptable level. Learn more from our well-explained article on what is a critical control point.

Critical control points are your company's main defence against hazards. Evaluation of control measures can be done using established scientific literature surveys or decision tools such as a HACCP decision tree or a food risk assessment matrix.

In each step, one or multiple hazards may be addressed and must be listed under a food operation for evaluation. CCPs must be consistently applied to every batch of food products you serve.

Examples of CCPs may include the following for a restaurant business and other food establishments:

HACCP plan template (Highlighted: Critical Control Points from Hazard Analysis)

These critical control point examples may be more specific for some food businesses. Some operations, such as microbiological testing products, physical and chemical measurements, and analytical testing, may be applied to verify the effectiveness of CCPs in controlling hazards that may cause severe health effects.

A concrete example of a CCP in a restaurant is cooking beef patties. Undercooked beef patties have been related to causing severe illnesses in consumers due to the unwanted multiplication of pathogens.

Unwanted pathogen growth is caused by the prevalence of pathogenic microorganisms in a batch of undercooked beef patties. These biological hazards can be inactivated through adequate cooking of beef patties.

In this scenario, the proper cooking step to the correct internal temperatures can be considered a CCP since there will be no further processing after this step. Food preparations such as assembling the cooked patties and applying packaging materials will not be able to further eliminate pathogen growth.

The CCP ensures that cooked beef patties, including other raw meats, are free of microbiological pathogens and safe for consumption.

Read more about whether to choose a HACCP Decision tree or a risk assessment matrix for your operation's food safety.

HACCP plan template (Highlighted: Critical Limits)

Identifying the risk level and likelihood of occurrence of a food safety hazard in combination with CCPs leads to establishing critical limits. These acceptable limits are the lowest and highest tolerable values and control factors for your critical control for safety.

Critical limit deviation may lead to the production of a non-compliant product or hazardous foods and cause severe health effects. Staying within the critical limit range is an essential criterion for food safety.

For a restaurant HACCP plan, typical critical limits are usually related to the:

to become compliant

Critical limits can be science-based facts for regulatory standards such as the minimum and maximum limits for raw meat's internal temperature for a thermal process. Breach of critical limits may lead to the production of unsafe food and unacceptable health risks.

A good example of setting critical limits is when storing foods away from ambient temperature or the temperature danger zone. High-risk foods must be stored using hot or cold holding procedures as a control measure.

The general method of storage rule is for any safe food product to not stay for more than two hours in temperature ranges between 41°F to 140°F (5°C to 60°C) or microbial pathogens may spoil the food. For cold holding at 41°F (5°C) or lower, the critical limit would be 41°F (5°C). For improper storage beyond this point, corrective actions for deviations must be applied to the non-compliant product.

HACCP plan template: (Highlighted Monitoring procedures)

To ensure that the CCPs and other control measures do their intended purpose, your HACCP team is tasked with establishing CCP monitoring procedures and has the responsibility for oversight of production.

These monitoring activities aim to record a sequence of observations for CCPs and will serve as documentation after the food operations in appropriate monitoring logs. They can serve as proof that your HACCP food safety plan is working.

Examples of monitoring activities on essential food preparation steps may include physical and chemical methods with appropriate logs. Monitoring forms or logs are composed of several parameters that need to be filled by the person with the position responsible for daily record review. These parameters vary in frequency of continuous monitoring.

Each CCP will need a corresponding monitoring form to determine any concerns, such as loss of control in their critical limits. A good monitoring form must be comprehensive and flexible. Some components of a monitoring record may include:

The complexity of monitoring procedures may depend on these factors as well.

For a restaurant food business, monitoring techniques will require you to create logs for the following activities:

How to log Cooking Temperature with the FoodDocs app (Critical limit monitoring)

How to log Cooking Temperature with the FoodDocs app (Critical limit monitoring)

The responsibility for monitoring must be clearly communicated to employees in charge of food safety and quality control. Employees must undergo an effective training program to familiarize themselves with the monitoring procedures. Parameters that need to be included in monitoring records and the appropriate critical limits must be clear to avoid producing unsafe food.

Monitoring records must clearly represent what occurred during food preparation as proof of HACCP compliance. Any critical point unaccompanied by a monitoring procedure may introduce a chance for cross-contact product contamination.

A HACCP plan is a systematic approach to food safety, but that doesn't mean it's a zero-risk approach. This means there may be lapses in the system, especially if there is due maintenance in the operations or other unforeseen circumstances. Monitoring procedures can reveal a trend towards loss of control, which is when corrective actions are needed.

Corrective actions aim to gain control over the operations again and address the remaining food safety risk with little to no compromise to the food products.

Corrective actions are meant to maintain food safety when a critical control point fails to control a hazard. In establishing corrective actions for deviations, an employee must be assigned to conduct the task and audit why the corrective action was applied.

An example of a corrective action procedure in a restaurant setup would be if a thermometer failed to read the correct temperature of the food for consumption. The inadequate cooking step will encourage the multiplication of pathogens.

The first corrective action may be to prolong the cooking time and use a different thermometer to address this. After the process, ensure the calibration schedules for all thermometers to prevent similar instances. Calibration schedules must always be followed to ensure consistently accurate records.

HACCP plan template (Highlighted: Corrective Actions)

Learning how to write a HACCP plan means knowing that this food safety system is based on scientific studies and facts and that all steps must undergo verification. This step aims to ensure that all procedures work and achieve their targeted functions when needed. The initial validation step can be in the form of internal audits.

Verification and validation of your system is not a one-time thing. An aspect of verification is the commitment to food safety that ensures your HACCP system is still effective and does not need to be revised. External audits, frequent reviews, and health inspections from regulatory agencies are occasionally conducted to validate your system.

Your verification procedures include product testing, CCP evaluation, in-house plant observations, revision of operational limits, and review of monitoring records.

HACCP plan template (Highlighted: Verification Procedures)

A HACCP plan is a system that requires extensive documentation. Every monitoring, revision, deviation, corrective action record, sampling system, layout, employee training record, certificate, calibration record, and verification report must be properly documented.

Individuals responsible for record-keeping are required to keep all these documents for a minimum of 2 years for future verification and reviews.

HACCP plan template (Highlight: Determining Record-keeping Procedures)

Proper documentation is key proof that your food business has successfully implemented your HACCP plan and that your team is performing their assigned tasks. If a known hazard occurs in your operations, your record will prove to regulatory agencies that you applied control measures to bring the hazard to an acceptable level.

A great way to create a HACCP plan accurate record-keeping system is to have sets of templates for all your procedures. This lets you easily add new information and tailor the forms to your food business.

Use our free monitoring log templates from our food safety template hub.

FoodDocs is the only digital solution that offers an AI-powered HACCP plan builder. In just one hour, you'll get a comprehensive and working HACCP plan — based on your specific business operations — that you can start using quickly in your HACCP system. No more long hours of meetings and revisions.

And, if needed, you can fully customize the HACCP plan and make updates as your operations change or based on an inspector's or auditor's feedback!

The smart HACCP system includes the most important components of a food safety plan by getting your answers to basic questions during the setup process.

Our solution cross-references the information with our digital food safety knowledge library and uses artificial intelligence to generate the template. Some of the food safety questions include:

What is your business type?

What raw materials are used?

What kind of food do you sell?

How big is the volume?

What duties do you have in your business?

As seen in the example of the HACCP plan above, our digital solution can generate the most important information for you. What's even greater is that you can customize the information to fit your business better.

Our system generates a customizable HACCP plan template based on your answers to a few questions about your business. This helps us identify the necessary procedures and forms related to your food business and tailor the HACCP plan for you.

Here is an example of the contents of a HACCP plan template you will get when you sign up with us at FoodDocs.

In addition to the AI-powered HACCP Plan builder, FoodDocs also offers an all-in-one food safety monitoring and traceability system. Check out the two-minute FSMS explainer video below:

A HACCP plan is an important food safety management document to help food business owners prevent loss of control over food safety and protect their consumers from any foodborne illness by establishing basic conditions of safety.

Food safety teams write a HACCP plan to identify and analyze food hazards and establish operations that will control or eliminate these potential hazards.

Every food business needs a safety plan with proper control measures to produce safe food products. The HACCP program is considered one of the standard plans in the food chain and has been adopted by different countries and organizations worldwide for educational programs on food safety. Several HACCP-based food safety plans are present in the food industry.

HACCP ensures that a food business does not have unsafe operating conditions that will continuously affect the production of wholesome foods. It aims to create conducive and sanitary conditions for food production.

Below is an example HACCP plan to help you visualize what it would look like and how can our team at FoodDocs help you:

HACCP plan example from FoodDocs

HACCP plan example from FoodDocs

The likelihood of causing any severe illness or a foodborne outbreak is low with a comprehensive HACCP plan. With a working HACCP plan, less end-product testing and post-analyses would be required for product safety and wholesome foods would be ensured.

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

Get a clear and complete breakdown of the most common Critical Control Point examples in HACCP for biological, chemical, and physical hazards.

The HACCP allergen control program is one of the crucial prerequisite programs of an HACCP plan. These are the key components and goals of using one.