HACCP Plan for Restaurant Template: How to Create One (Free Sample PDF)

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

A HACCP allergen control program is important to maintain food safety.

The FDA has identified that allergic reactions to foods can range from simple itching to severe cases where the body develops respiratory problems called anaphylaxis.

As such, food authorities have established allergy policy regarding allergens such as their declaration in the food packaging. As a food manufacturer, you have to create a safe food processing course for your consumers. A step toward this goal is having an HACCP Allergen Control Program.

A HACCP allergen control program is critical for maintaining food safety by managing allergen risks effectively.

Identifying potential allergens and preventing cross-contamination are primary goals of an allergen control program.

Proper labeling and documentation are essential components of an allergen control program to inform consumers and comply with regulatory standards.

Supplier review and process flow diagrams are key elements that help in the identification and management of potential allergen contamination points.

Employee training on allergen awareness and control is vital for the successful implementation of an allergen control program.

Production scheduling and thorough cleaning protocols help minimize the risk of allergen cross-contamination in manufacturing facilities.

Regular updates and reviews of the allergen control program are necessary to accommodate changes such as new suppliers or formulations.

Building an effective allergen control program is essential not only for regulatory compliance but also to protect consumers from potential allergens.

FoodDocs' HACCP software is designed to streamline the creation of allergen control programs using comprehensive data and resources.

An allergen program is one of the crucial prerequisite programs of a HACCP plan as it involves critical control points. In America alone, about 50 million people are allergic to some types of foods. Studies have shown that at least 1 in 13 children has a food allergy which can be related to more than one allergen. To date, the most common food allergy is considered to be related to peanuts.

Most allergens are part of everyday raw materials, their use and contact with them can sometimes be inevitable. As such, a HACCP Allergen Control Program is an essential tool to uphold food safety in your organization. In this article, we will share the things you need to know when it comes to allergens and making an effective allergen control program.

Protecting allergic consumers is a critical duty of any food business. An effective allergen control program, as part of your HACCP plan, prevents unintended allergens from ending up in products and ensures all allergens are properly declared.

The stakes are high: undeclared allergens have become one of the leading causes of food recalls globally. In this comprehensive guide, we’ll cover how to build a robust allergen control plan, include a handy checklist/template, and answer common questions to help you manage allergens confidently.

An Allergen Control Program (or Allergen Control Plan) is a written, systematic approach that food manufacturers and restaurants use to identify, control, and prevent food allergens from causing harm. In practice, this program outlines how you handle allergenic ingredients from the moment they arrive (receiving and supplier info) through processing, packaging, and even cleaning procedures. It also covers how you inform consumers of allergens in your products (labeling). Essentially, an allergen control plan is a cornerstone prerequisite program to your HACCP food safety system, focusing specifically on allergenic hazards.

Why is this important? For one, food allergies affect millions of people. If an allergen ends up in a food unknowingly, the allergic consumer is at risk of serious reactions, even anaphylaxis. Regulators recognize this danger – that’s why laws require clear allergen labeling and controls.

Undeclared allergens are a top cause of food recalls in the US and abroad, accounting for nearly half of all recalls in recent years. Beyond consumer safety, failing to control allergens can mean regulatory violations, lawsuits, and damaged reputation.

Having a strong allergen control program protects your customers’ health and your company’s viability.

The main goal of an effective allergen program is to prevent any allergen from contaminating products that are not intended to contain them and inform your consumers if any of your products may contain allergens. An effective HACCP allergen control plan should meet the following goals in order to accomplish this aim:

Begin by cataloging every ingredient and raw material used in your facility and determining which ones contain any of the major allergens. This includes reviewing supplier documentation, formulations, and even potential sources of cross-contact during ingredient sourcing and delivery. The more accurately you identify allergens, the more precisely you can build controls around them.

Develop and implement strategies to avoid unintentionally transferring allergens to allergen-free products. This includes production scheduling, segregated storage, dedicated equipment or utensils, and validated cleaning procedures. Cross-contact can occur through surfaces, hands, air (in the case of powders), or rework, so your plan must address all these potential vectors.

Product labels must clearly reflect any allergens present, using legally compliant formats such as “Contains” statements or bolded ingredients. This requires alignment between recipe formulation, production, and packaging. Establishing a reliable label review process and managing label inventory effectively are key to preventing mislabeling, which is one of the most common causes of allergen-related recalls.

Staff should be trained not just on what allergens are, but how they apply to their specific roles—whether that’s receiving, storage, production, sanitation, or labeling. Reinforce training regularly, especially when new products, ingredients, or procedures are introduced. Well-trained employees are your first line of defense against mistakes that could lead to allergen cross-contact.

Allergen control is not a one-time setup. Keep records of all processes, including cleaning logs, label checks, training attendance, and supplier documentation. Set a schedule for regularly reviewing and updating your plan—especially when there are changes in ingredients, suppliers, equipment, or regulations. Documentation not only ensures consistency but also demonstrates compliance during audits or inspections.

Meeting these goals will not only help you comply with food safety regulations, but also demonstrate due diligence in keeping consumers safe from allergen hazards.

One of the first steps in allergen control is knowing which foods/ingredients are considered major allergens that you need to manage and declare. Different countries have different lists of major allergens:

Tree nuts (e.g. hazelnuts, cashews, almonds)

As the table shows, the U.S. FDA recognizes 9 major allergens that must be declared on labels (these are mandated by the Food Allergen Labeling and Consumer Protection Act and updates from the FASTER Act adding sesame). The U.K. and EU require labeling of 14 allergens, which include the U.S. list plus additional ones like celery, mustard, lupin, molluscs, etc.

It’s crucial to know which allergens are present in your ingredients. For instance, if you operate in the U.S., you’ll be focused on the Big 9, but if you ship products to Europe or serve customers in the U.K., you need to account for the Big 14. In practice, many companies just default to managing and labeling for the larger list to be safe.

Tip: Keep an updated Allergen Ingredient List in your facility. This could be a simple spreadsheet or binder section where you list every ingredient you use and mark which of the major allergens it contains (or if it’s derived from one). Include “contains X” label statements for each ingredient. This master list will be the foundation of your allergen control plan because it tells you what you’re controlling.

Part of an effective allergen risk reduction program on your HACCP plan is ensuring that the correct control measures are in place. An allergen control checklist is most helpful to achieve this goal by following some considerations for a food manufacturing facility.

Building a HACCP allergen control program involves several components, each addressing a point in your process where allergens need to be managed. Below are the key components and best practices for each:

Establish a dedicated allergen control team or designate a coordinator (often part of the food safety/HACCP team). This team is responsible for developing, implementing, and updating the allergen control plan. It usually includes management (to ensure company commitment), quality assurance/food safety personnel, and representatives from production and purchasing.

Training is vital for all employees, not just team members. Train your staff on:

Emergency Procedures: While prevention is the focus, train staff on what to do if there is an allergen exposure or a mislabeling is discovered (e.g., hold the product, notify supervisors immediately, etc.).

By having a trained team and workforce, you create a culture of allergen safety. Many facilities post reminders and have periodic refreshers. Remember, training isn’t one-and-done. Shedule refresher training at least annually or whenever procedures change. Document all training sessions (who attended, what was covered) as proof of your team’s expertise.

Your allergen control efforts start even before ingredients enter your facility. It’s critical to work with suppliers who are transparent about allergen information. Key actions:

By controlling allergens at the ingredient source, you eliminate surprises down the line. This step ties into your HACCP hazard analysis – every allergen that comes in should be identified as a potential hazard that you have controls for in the subsequent steps.

Once ingredients are on site, proper storage and segregation are fundamental to prevent accidental mixing or cross-contact:

By organizing your storage with allergen safety in mind, you greatly reduce the chance that an allergen will accidentally find its way into a product that shouldn’t have it. Segregation is a simple yet powerful preventative measure.

In the production area, careful scheduling and thorough cleaning are the main lines of defense against cross-contact:

Effective scheduling and rigorous cleaning go hand in hand. Many allergen incidents trace back to inadequate cleaning (a bit of allergen was left on equipment). So, treat cleaning for allergens with the same seriousness as you would cleaning for bacteria in a ready-to-eat product – it’s that important.

Cross-contact can occur through many little routes in a facility, so implement practices that block those routes:

These practices, while sometimes seemingly minor, build layers of protection. They ensure that even outside of main production and cleaning, you’re not allowing allergens to hitchhike on tools, people, or rework into places they shouldn’t be.

Even with all the cross-contact prevention, labeling remains a critical element. If a product does contain an allergen (intentionally or via unavoidable traces), the label must declare it clearly:

Ultimately, even if an allergen accidentally gets into a food, a correct label can protect consumers by alerting them. It’s your final safety net. So treat label control as seriously as any critical control point – double-check and document it every production run.

An allergen control program is only as good as its execution and maintenance. This means you need to document what you do and continuously improve:

During review, involve cross-functional staff (i.e., the people who do the receiving, mixing, cleaning, etc.). Their experience can identify practical improvements. For example, an employee might note, “We need a better way to mark opened allergen bags,” leading you to introduce a new tagging system. That kind of frontline experience is gold for refining your plan.

Finally, management support must continue for the allergen program. Leadership should sign off on the allergen policy and ensure resources (like cleaning time, testing kits, extra label stock, etc.) are available to keep the plan effective. Allergen control is an ongoing effort, not a one-time setup. When properly maintained, it greatly reduces the risk of allergic reactions and costly recalls.

Every facility’s allergen control plan will differ slightly, but most will contain common sections. Using a template can help ensure you don’t miss any critical components when drafting or updating your plan.

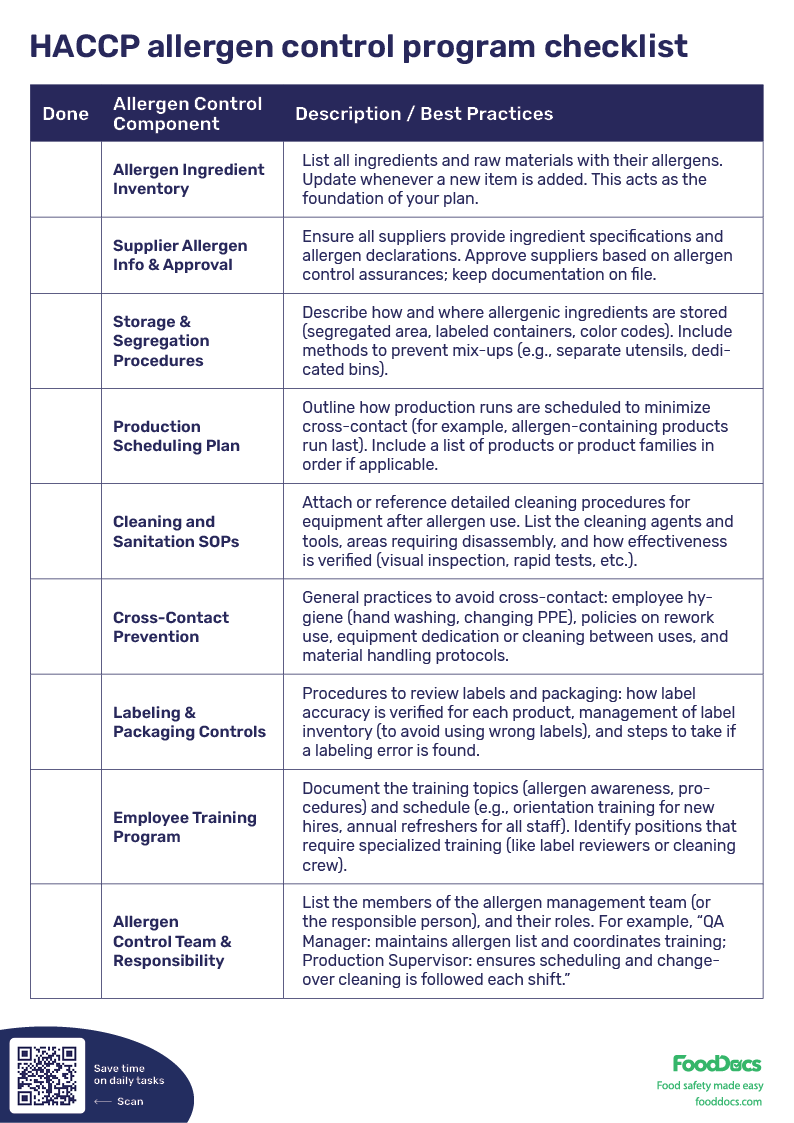

Below is an Allergen Control Plan checklist outlining typical sections and tasks:

| Done | Allergen Control Component | Description / Best Practices |

|---|---|---|

| Allergen Ingredient Inventory | List all ingredients and raw materials with their allergens. Update whenever a new item is added. This acts as the foundation of your plan. | |

| Supplier Allergen Info & Approval | Ensure all suppliers provide ingredient specifications and allergen declarations. Approve suppliers based on allergen control assurances; keep documentation on file. | |

| Storage & Segregation Procedures | Describe how and where allergenic ingredients are stored (segregated area, labeled containers, color codes). Include methods to prevent mix-ups (e.g., separate utensils, dedicated bins). | |

| Production Scheduling Plan | Outline how production runs are scheduled to minimize cross-contact (for example, allergen-containing products run last). Include a list of products or product families in order if applicable. | |

| Cleaning and Sanitation SOPs | Attach or reference detailed cleaning procedures for equipment after allergen use. List the cleaning agents and tools, areas requiring disassembly, and how effectiveness is verified (visual inspection, rapid tests, etc.). | |

| Cross-Contact Prevention | General practices to avoid cross-contact: employee hygiene (hand washing, changing PPE), policies on rework use, equipment dedication or cleaning between uses, and material handling protocols. | |

| Labeling & Packaging Controls | Procedures to review labels and packaging: how label accuracy is verified for each product, management of label inventory (to avoid using wrong labels), and steps to take if a labeling error is found. | |

| Employee Training Program | Document the training topics (allergen awareness, procedures) and schedule (e.g., orientation training for new hires, annual refreshers for all staff). Identify positions that require specialized training (like label reviewers or cleaning crew). | |

| Allergen Control Team & Responsibility | List the members of the allergen management team (or the responsible person), and their roles. For example, “QA Manager: maintains allergen list and coordinates training; Production Supervisor: ensures scheduling and changeover cleaning is followed each shift.” | |

| Monitoring & Verification | Explain how each control is monitored and verified. e.g., “Sanitation supervisor signs off cleaning checklist and performs allergen swab tests monthly,” or “Warehouse manager audits storage area weekly for segregation compliance.” | |

| Documentation & Record Keeping | Note what records are kept (cleaning logs, training records, label check logs, etc.) and where they are stored. Ensure it’s clear that records are retained (and for how long, e.g., “keep allergen records for minimum 2 years”). | |

| Plan Review & Update Policy | State that the plan will be reviewed annually and whenever changes occur. Include a log table of revisions (date, changes made, approved by) to track updates over time.You can use the above as a template outline. |

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

For a more formal template, industry organizations like the International Dairy Foods Association (IDFA) provide allergen control plan templates, and regulatory bodies like the FDA have guidance documents with examples. Tailor the template to your facility’s needs: for a small bakery, the plan might be a few pages covering the basics; for a large manufacturer, it could be much more detailed with separate appendices.

Checklist usage: Consider turning the critical points into a checklist for daily/weekly use. For example, a Daily Allergen Control Checklist for a manager might include items like:

This operational checklist helps ensure the written plan is executed every day.

By having a clear template and checklists, you create a system that is easier to follow and audit. It moves allergen control from concept into routine practice, which is ultimately what protects consumers consistently.

Following this guide and continuously improving your approach will help ensure your HACCP allergen control program significantly reduces the risk of allergen-related issues.

Always remember: the goal is to keep your consumers safe and confidently enjoy your products without worry. An effective allergen control plan, executed daily, is how you achieve that safety and trust.

From the hospitality to the healthcare industry, food businesses must have an effective allergen control program as a prerequisite for their HACCP plan. To build one, a thorough assessment of the whole production process from ingredients to distribution is a must.

At FoodDocs, we help you build your HACCP allergen control program to strengthen your food safety credibility by using the most efficient HACCP software.

This development by FoodDocs guarantees an effective allergen program in just an hour or less. Learn which areas are critical points when it comes to allergen contamination and their potential risks.

You can try FoodDocs' full suite of food safety management software with a free 14-day trial or book a personalized demo to see how we can support your allergen control program needs.

Scheduling consultation with a chemical representative is not typically part of an allergen-control plan. An allergen-control plan focuses on managing food ingredients and processes – things like retaining ingredient labels, training staff, segregating allergens, cleaning equipment, and labeling products are common components. Bringing in a chemical sales rep isn’t relevant to controlling food allergens, so that would be the least likely element. (This question often pops up in food safety quizzes, where the incorrect option is a giveaway – in this case, consulting a chemical rep has nothing to do with allergen management.)

In the United States, 9 major allergens must be declared and controlled: milk, eggs, peanuts, tree nuts, soy, wheat, fish, crustacean shellfish, and sesame. These are often referred to as “the Big 9” allergens. In the U.K. and European Union, 14 major allergens are recognized, which include the U.S. ones plus others like celery, mustard, lupin, molluscs (shellfish like clams and snails), and sulphites. No matter where you are, you should identify which of these allergens are present in your ingredients and make sure they are part of your allergen control plan. Also, remember that any ingredient derived from those (e.g., gelatin from fish, whey from milk) counts as an allergen source and needs control and labeling.

Yes, in effect. While laws might not ask for a document literally titled “Allergen Control Plan,” food safety regulations in many countries require you to manage allergens safely. For instance, in the U.S., the FDA’s rules under the Food Safety Modernization Act (FSMA) consider allergens a hazard that must have preventive controls – failing to address allergen cross-contact or mislabeling can lead to regulatory action. USDA-inspected facilities are expected to control allergens as part of their hazard analysis and sanitation controls. In the U.K./EU, food business operators must comply with allergen labeling laws and general food safety principles (HACCP), which include preventing cross-contamination (cross-contact) of allergens. Additionally, major third-party audit schemes (BRCGS, SQF, etc.) explicitly require an allergen management plan. So, if you’re in the food industry and you handle any of the major allergens, you are effectively required to have an allergen control program – whether by regulation, by audit standards, or simply by liability and consumer safety expectations.

You should review your allergen control plan at least once a year, typically as part of your annual HACCP plan reassessment or internal audit schedule. However, do not hesitate to update it more frequently if changes occur. If you introduce a new product or new ingredient, or switch to a new supplier, or if an allergen incident/near-miss happens, update the plan right away to address any new risks. Regular reviews ensure the plan stays effective as your operation evolves. Many companies keep a “revision history” section in the plan to log updates. Frequent, small updates are a sign of a living document – that’s a good thing! It shows you are actively managing allergen risks as things change, rather than set-and-forget.

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

Get a clear and complete breakdown of the most common Critical Control Point examples in HACCP for biological, chemical, and physical hazards.

Discover the key details of critical limits in the context of the food safety industry's HACCP program. Get real-life examples and tips for...