HACCP FLOW CHART TEMPLATE FOR FREE

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

Key takeaways

-

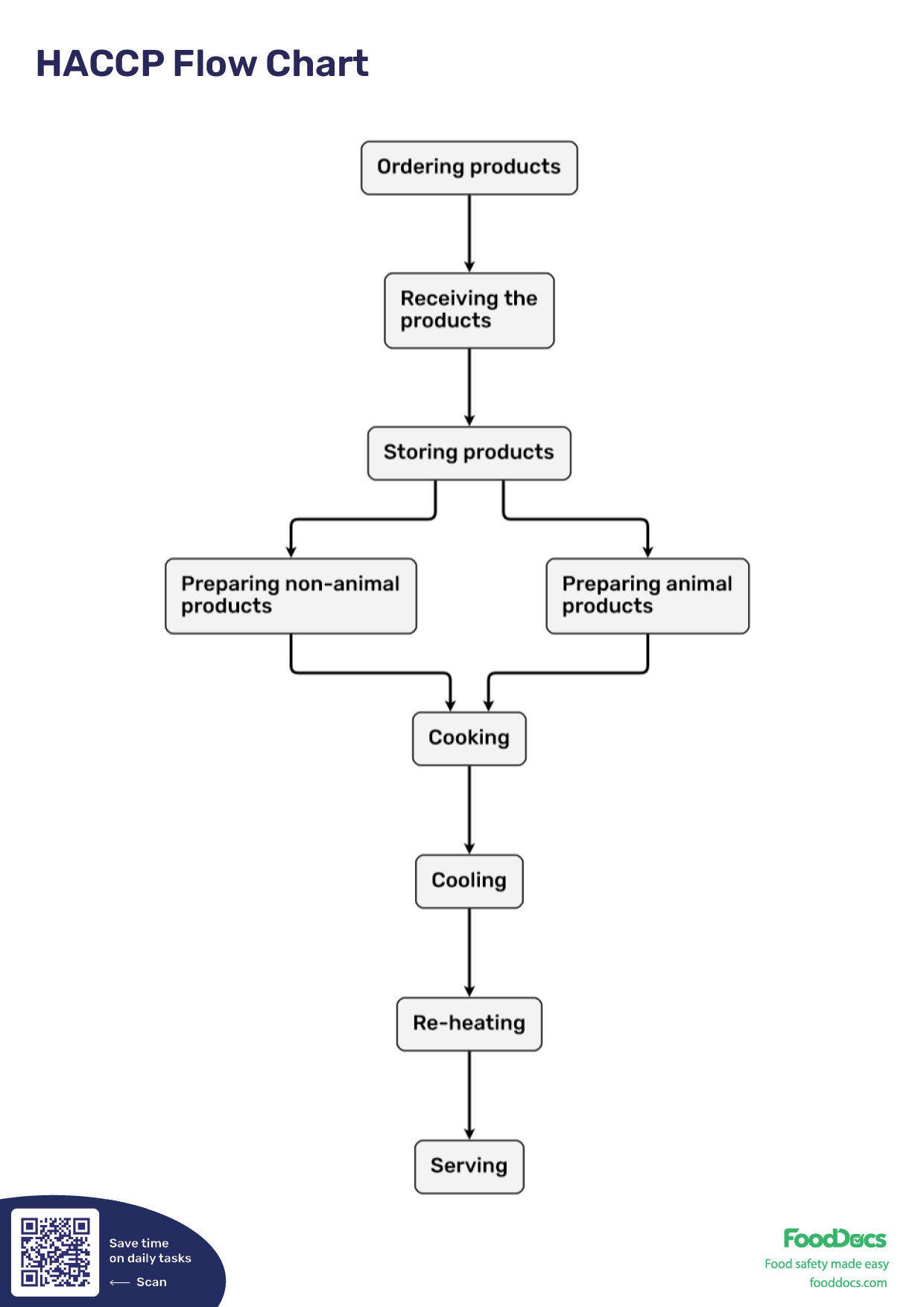

A HACCP flow chart is a graphical representation of the entire manufacturing process of your food business.

-

A HACCP flow chart represents the flow of food materials in your food business starting from receiving any raw material to serving your finished products.

-

HACCP food safety system requires a detailed and comprehensive food flow chart to properly identify the associated hazards in your manufacturing process.

- To create a HACCP flow chart in five steps, define all processes in your company, list all HACCP process steps, define (critical) control points, define control measures, and verify your HACCP flow chart.

- Some key times when you need to revise your flow chart are at least once a year, if there's been any change(s) to your HACCP processes, whenever you start to use new food ingredients, when you introduce new food operations (e.g., food delivery), and upon receiving post-audit revisions.

- A food flow chart is also useful even if not for HACCP food safety program purposes. Food processing plants and other establishments benefit from having an accurate record of your entire standard operation process which can help you easily identify at which point do errors usually occur.

-

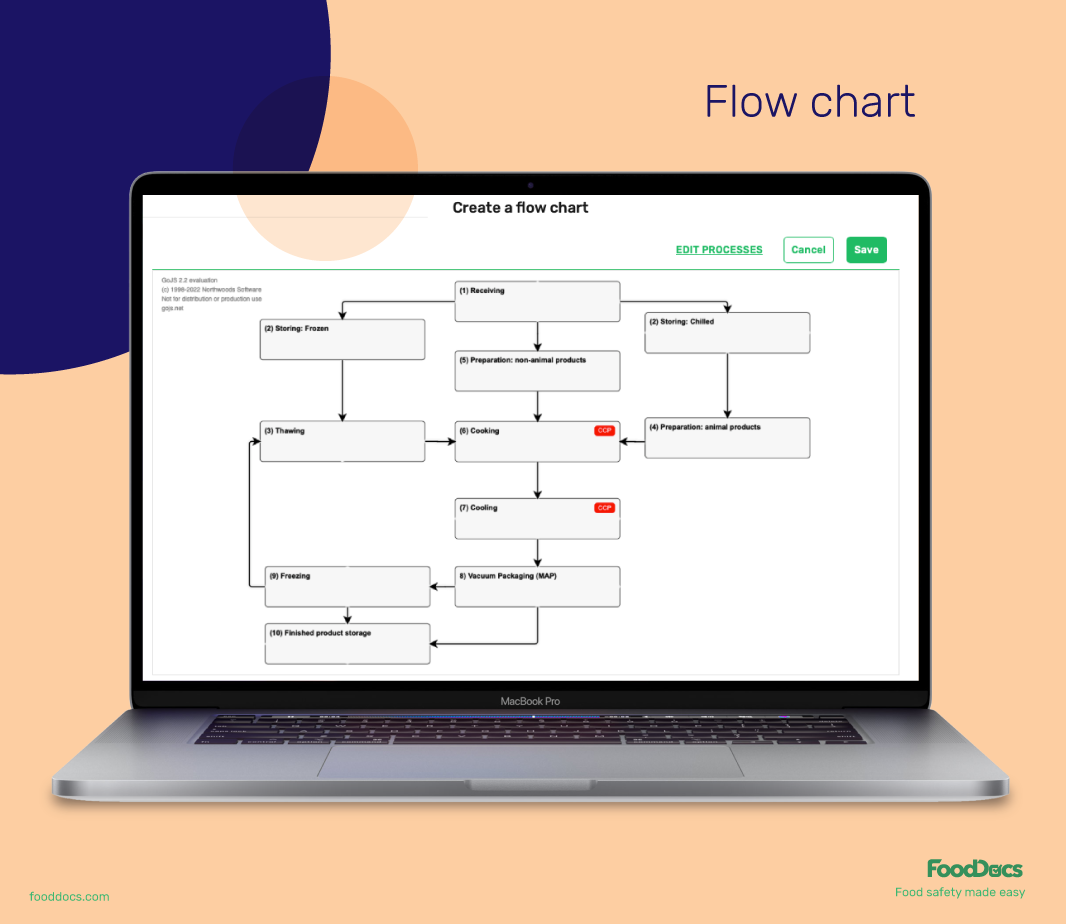

FoodDocs digitizes food safety, including necessary Flow Chart documentation required for compliance.

What's a HACCP flow chart?

A HACCP flow chart uses simple symbols to represent each part of your food process. Rectangles are used for steps like cooking or cooling, diamonds for decision points such as “Was the temperature reached?”, and arrows to show the sequence of steps. It visually connects everything from raw ingredient intake to the final point of service or sale.

Every food business in the food chain has its own unique and complex food operations to come up with for its product. These operations describe the everyday activities of a business and are comprehensively analyzed in a HACCP plan. This step is done by building a HACCP flow chart or otherwise known a

This diagram is a graphical representation of all your processes and is usually considered a critical tool and the most difficult part of a HACCP plan. It will be used as a basis to map out the potential hazards in your operations to prevent any adverse health effects of foodborne diseases which may originate from your processes.

Making a flow chart of your operations may seem easy, but it has a lot of technicalities in itself and requires much attention and a firm commitment to preventing any food safety issue. A food restaurant owner may turn to food safety professionals or food safety chart software to create their flow charts.

Once you do it yourselves, it just seems too complicated to create. After all, an actual flow diagram document is a great and solid foundation of a comprehensive HACCP plan. In this article, we briefly go through what a flow chart sample is and how to create it the quickest and easiest way.

Also, feel free to use our HACCP flow chart template. Just replace the words on the form where applicable and download or print it out.

If you want to take the easiest way and let the software do the job for you, sign up for HACCP builder software and see how machine learning creates the flow chart sample automatically together with all other compliance documents.

Feel free to check our entire food safety template hub containing all the documents that are important and most wanted parts of your HACCP plan. Just change the wording by clicking on the words and then print them out.

Is a HACCP flow diagram mandatory for food businesses?

Most food businesses, including restaurants, processors, and institutional kitchens, are required by local or federal authorities to include a process flow diagram as part of their HACCP plan. Agencies such as the FDA and USDA expect this as part of compliance checks. It is the last part of the preliminary steps before applying the HACCP principles such as hazard analysis.

Your health hazard identification and hazard analysis stage will be based on this document. Depending on your country's legislation regarding the requirement of a HACCP food safety system, it may be required to have a restaurant operation flowchart as part of your HACCP plan. In case you need to be HACCP certified, you will definitely be required by law to have it.

A food flow chart is also useful even if not for HACCP food safety program purposes. Food processing plants and other establishments benefit from having an accurate record of your entire standard operation process which can help you easily identify at which point do errors usually occur.

What tool should I use to make a HACCP process flow chart?

The traditional way of making a HACCP flow chart is manually mapping the whole process by hand and inputting it through applications such as MS Word and the like.

To date, there are a lot of common tools and software that you can use to create a detailed flowchart design. Whatever format or tool you decide to use, make sure that it is flexible.

Revisions and improvements are very common especially in the food business similar to what happened during the Covid-19 pandemic. Remember that flexibility is a criterion you must always consider.

Some examples to use when creating a HACCP flow chart for restaurants and other food businesses:

- Pen & paper: Perhaps the most basic quality tool to make a HACCP food flow diagram. It is allowed to create your flow process chart on paper, even in the 21st century. It's not the most convenient way, but when you're not very technical, go the traditional way. This method is also a great way to make an initial draft. In terms of flexibility, this method is great. Although, a flow chart from scratch can be tedious and hard to make.

- Microsoft Office solutions: Excel, Word, and Powerpoint are reasonably good for creating a commodity flow diagram. All the elements needed to make a food flow chart are in these applications. It just takes time and skill to find them and use them to make a flow diagram. Flexibility-wise, this is also a good choice. The downside to this is that you have to make everything from scratch. This means that all ideas must come from your restaurant employees.

- Design tool: design tools such as Creately, Miro, Draw, etc. are widely available on the internet. This solution is an advanced way of making a food flow chart and can be customized in more ways than one. Despite this, the level of technicality far exceeds using Microsoft Office solutions.

- Food safety software: Some HACCP software companies such as FoodDocs include an automatic HACCP plan builder that creates a flow process chart automatically and is customizable at any time using basic editing options. Using our software, you do not have to come up with all the ideas by yourself. Our expert-guided AI will help you build your detailed flow chart in minutes.

8 Key elements to include in a HACCP flow chart

To build a clear and complete HACCP flow chart, make sure you include the following elements. Each one helps ensure that your hazard analysis is based on a full understanding of how food moves through your operation.

- All ingredients and raw material receiving steps: Start by showing where raw materials enter your facility. This is important for tracking potential biological, chemical, or physical hazards from suppliers and establishing traceability.

- Processing stages such as thawing, cooking, or cooling: These are the core transformation points where food safety risks are highest. Identifying these stages helps you apply the right critical control points, such as cooking temperatures or cooling times.

- Holding, packaging, or plating steps: These stages are often overlooked but can introduce contamination or allow time-temperature abuse. Including them helps monitor food safety between prep and service.

- Rework and return flows, if applicable: If you reuse ingredients or redirect food (such as cooked leftovers), mapping these flows ensures they’re controlled and don’t bypass food safety procedures.

- Waste or by-product outputs: Identifying waste points helps clarify the end of your process and prevents confusion between food intended for service and what should be discarded.

- Final service or delivery stages: The last step in the chart should reflect how food reaches the customer. This helps assess risks during transport, hand-off, or self-service.

- Arrows that show the direction of flow: Clear arrows show the order of operations and make the chart easier to follow. This is especially helpful for new staff or during audits.

- Control points and critical control points clearly labeled: Labeling CPs and CCPs ensures the flow chart connects directly to your HACCP plan. These points are where monitoring and corrective actions must occur.

This checklist helps ensure no steps are missed and that your chart is complete before moving on to hazard analysis.

How to create a HACCP flow chart (in 5 simple steps

STEP 1. Define all processes in your company

As already described, you should document all HACCP process steps you have in your food business, nothing more or less. This flow chart step starts from receiving until the food is delivered to the end-users.

Avoid including steps that do not directly relate to food production, such as cleaning, sanitation, or testing procedures.

Examples of the flow of food in the food business:

- Picking herbal products

- Ordering/buying products

- Receiving products

- Storing products

- Thawing/defrosting

- Cleaning dirty vegetables

- Preparing non-animal food

- Preparing animal food

- Cooking Cooling

- Freezing

- Re-storing

- Re-heating

- Drying

- Packaging/labeling

- Transporting food

- Serving Food donation

Despite repeatedly mentioning that you need to indicate all processes involved, there is no need to point out non-processing steps. Steps like cleaning and sanitizing, inspection, audits, testing, etc. do not have to be added to the flow chart. Focus only on the steps that your raw materials go through before becoming a finished product in your menu.

Because a HACCP plan is process and process-specific, your food flow chart must be the same as well. You will be required to make separate flow charts for all your products if they undergo different processing methods. This makes it harder if you have a wide variety of products with different manufacturing processes.

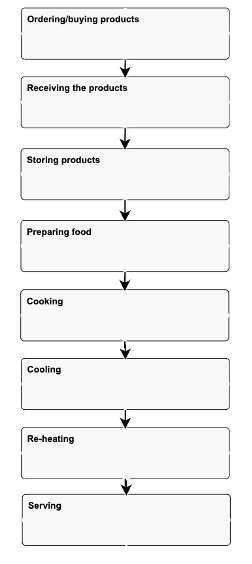

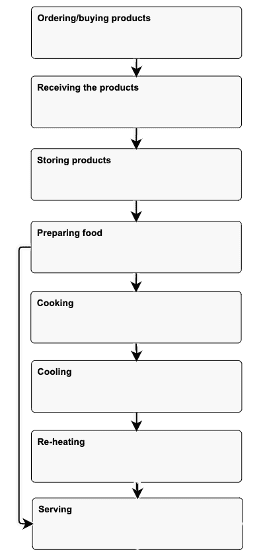

STEP 2. List all HACCP process steps

After defining the previous steps, list all your processes according to your facility's real-life situation. Include alternate process flows if applicable. For example, if some products are served raw while others are cooked, list both paths.

It might seem that there is only one simple option, but usually, there are several ways that HACCP processes can change for the location.

For example, after preparing the food, it can go directly to serving without being cooked. Make sure that all arrows are properly used and will not cause confusion. Before proceeding to the next chart step, verify your restaurant operations flowchart if all information is correct.

Apply revisions where they are needed. Add or remove connector objects wherever you see fit.

See below how the flow process chart changes:

STEP 3. Define Control Points and Critical Control points.

Depending on the region, you sometimes need to validate and mark your HACCP flow chart, whether your process steps are Control Points (CP), or Critical Control Points (CCP). You may need to list each step of the HACCP process and note down all possible hazards for each step.

Evaluate the possible hazards of each step separately based on their severity and likelihood of occurring. Some steps can have a single hazard, whereas others can have more than one.

The customizable restaurant flowchart we will provide you is the essential foundation of your entire restaurant operation and can be edited to put your specific operations or any additional step.

Defining CP and CCPs is an important job and a prerequisite to tasks such as establishing critical limits, corrective actions, and monitoring procedures further down your HACCP plan.

If this all sounds too complicated for you, we have put together a great article about the most common critical control points for food businesses. Feel free to read more about this topic to know which steps can be considered critical control points and how to use automation tools.

When using FoodDocs HACCP builder software, the whole HACCP flow chart template will be created by the software. If you want to apply any revisions, you can easily edit all sections yourself according to how you want them to be.

STEP 4. Define control measures

The next flow chart step is to define and mark which control measure must be monitored, whether measuring the adequate time, internal temperature, moisture level, or quality.

Because the flow chart we generate for you is based on general knowledge from established businesses with a solid foundation, there will be instances that you would have to specify which measures need to be controlled specifically.

Do not worry because this is an easy task and will only take a few clicks to finish. The process will still be way faster than making a flow diagram on your own. Other specifications such as which process step is a critical control point or a control point may be specified on your end.

Step 5. Verify your HACCP flow chart

After completing your process flow diagram together with the whole HACCP plan comes the verification procedure. You must verify that your flow chart accurately reflects real kitchen operations.

To do this:

- Conduct a walk-through of your kitchen using the flow chart as a guide

- Involve your HACCP team or food safety lead to confirm accuracy

- Update the chart immediately if anything is missing or out of order

Your chart should also be reviewed and signed during every major HACCP plan update.

One of the best things about using our process flow chart template, aside from automatically generating the actual chart for you, is that it is highly customizable and you can edit everything at any time. There will be situations when you will need to do so.

These key times when you need to revise your flow chart and merit a future verification step are:

1. At least once a year as an update or to apply revisions.

2. Whenever there has been a change to any of your HACCP processes, like installing new equipment or removing existing equipment from the process.

3. Whenever you start to use new food ingredients for new dishes in your food menus, that can have an important impact on the production process. For example, food components containing an allergen.

5. When you introduce new food operations in your restaurant business such as food delivery.

4. When revisions from an auditing firm require you to change your processes.

Things can be very variable especially in the food business. Covid-19 has also made the food sector leaner, so the more flexible your HACCP flow chart is for modifying, the better.

Feel free to try HACCP builder software that helps you to create and modify your editable restaurant flowcharts at any time so you can focus on what you really need to, which is to manage your business.

Who creates and verifies the flow chart?

A HACCP flow chart should be created and verified by a small team of people who understand the full scope of your operation. Each role plays an important part in making the chart accurate and effective.

- Food safety manager or kitchen supervisor: This person is responsible for food safety compliance and often leads the HACCP plan. They ensure the flow chart meets regulatory standards and reflects company policies.

- Chefs or prep team members who know each step of the process: These team members bring firsthand knowledge of how food actually moves through the kitchen. Their input ensures that no step is missed or misrepresented on the chart.

- Quality assurance personnel, if available: QA staff help identify risks, verify control points, and ensure the chart is reviewed with a safety-first lens. They often catch gaps that others might overlook during the mapping process.

This team approach ensures the flow chart is not only technically correct, but also practical and reflective of real-world practices. Verification should always include a walk-through to confirm that the chart matches daily operations.

When should you update your flow chart?

Your HACCP flow chart should be updated:

- At least once a year, during your HACCP review

- When adding new equipment or menu items

- After changes in suppliers, ingredients, or allergens

- When a new service method is introduced, such as delivery

- After an audit that identifies a missing or incorrect step

Keep a copy of each version, including the date of review and the names of people who signed off.

How FoodDocs can make using a digital HACCP flow diagram even easier

Making a HACCP plan requires a lot of time and technical experience and skills. If you are from an existing food company, you know how tedious writing a HACCP plan can be.

FoodDocs digitizes food safety for every critical area of a food business's Monitoring and Traceability systems. It also automatically creates a HACCP plan (as well as any other compliance standards) in less than an hour, which includes a Flow Chart.

With FoodDocs, you can:

- Easily customize it according to your business when needed. All you've got to do is drag and drop the boxes to the required locations and change the content accordingly.

- Create an unlimited number of flow charts based on your various product groups (e.g., main courses, desserts, marinated products, etc.).

And with the mobile app, team members will receive smart notifications so that staff never forget a task related to your food flow process.

This reduces the administrative burden while ensuring compliance and maintaining high food safety standards in your facility.

Before allocating budget to hire a food safety consultant, get your own HACCP plan and flow chart in just 1 hour.

The HACCP plan that we build for you covers all stages including accurate identification of hazard and different stages of hazard analysis, established preventive measures, procedures for monitoring, corrective actions, critical limits, and comprehensive verification procedures.