Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

At first glance, quality assurance vs quality control sounds like it’s going to cover the food industry’s great debate.

It’ll be anything but! In fact, quality assurance (QA) and quality control (QC) in food businesses work together to create and bring nothing but high-quality food products to market.

We’ll get into the nuances below, but as necessary parts of effective quality management:

WHAT WE'LL COVER:

Sources even trace the roots of quality management, QA, and QC back to the late 13th century, when craftsmen organized themselves into unions called guilds. The responsibility of guilds was to develop rules to ensure high-quality products and services.

Sound familiar? According to the American Society for Quality:

Inspection committees enforced the rules by marking flawless goods with a special mark or symbol. Craftsmen themselves often placed a second mark on the goods they produced… Inspection marks and master craftsmen marks served as proof of quality for customers throughout medieval Europe.

In that same spirit, some of the most renowned certifying bodies expect continuous improvement when it comes to food safety culture and quality.

So let’s get into the differences between quality assurance and quality control, and learn how you can elevate both for your food business.

Quality control in the food industry refers to the operational activities used to verify that food products meet defined quality and safety requirements before they are released to the market.

Food quality control focuses on product-level checks, such as inspections, testing, monitoring of critical control points, and verification of specifications during or after production. The goal is to detect deviations, defects, or non-conformities and take corrective action before unsafe or substandard products reach consumers.

Quality assurance in the food industry is a system-based approach focused on preventing quality and safety issues by controlling how food is produced.

Rather than inspecting finished products, quality assurance establishes the processes, procedures, standards, and training needed to ensure food products are consistently produced according to regulatory, safety, and quality requirements. In food businesses, QA typically includes programs such as GMPs, SOPs, HACCP, internal audits, and continuous improvement activities.

The difference between quality control and quality assurance is one of processes versus products. QC relates to the validation process that ensures products are meeting the existing agreed upon quality requirements. QA ensures that staff have followed all standards, methodologies, procedures, and techniques to be able to consistently create products that are defect-free.

To use an alternate definition, quality assurance exists to prevent defects while quality control exists to identify (and correct) them.

Here's a table to help visualize these distinct differences more clearly:

| Criteria | Quality Assurance | Quality Control |

|---|---|---|

| Which comes first | Begins before the initiation of the production process | Activated after production is complete |

| Goal | Designed to prevent any defects and ensure standard adherence (i.e., proactive defect prevention) | Aimed at defect identification and rectifying post-production defects (i.e., defect detection and correction of defects) |

| Approach | Takes a proactive stance on enhancing processes to avoid issues | Reactive process focused on remedying detected issues |

| Focus | Emphasizes consistent methods and procedures for quality | Focuses on examining finished products against standards |

| Responsibility | Responsibility is distributed among all team members | Typically handled by specialized quality control personnel |

| Orientation | Geared towards continuous process betterment | Concentrates on identifying past defects to rectify |

| Duration | Maintained throughout the duration of the project or process | Generally implemented at or near the production cycle's end |

While the principles of food quality control remain the same, how quality control is applied differs between food processing and food manufacturing environments.

In food processing, quality control often focuses on:

In food manufacturing, quality control typically involves:

Both environments rely on quality control to confirm that food products meet defined requirements before distribution.

Under the broader quality management umbrella, quality assurance involves many moving pieces that work together as and with quality control to deliver safe, high-quality food products.

Example in food manufacturing:

A quality assurance team establishes standardized operating procedures for ingredient receiving, sanitation, and production changeovers. By training staff and auditing adherence to these procedures, QA helps prevent contamination and quality deviations before production begins.

Quality assurance is only as good as its pre- and well-defined SOPs. Standard operating procedures are an integral part of your HACCP prerequisite program help to ensure consistency and outline the protocols and steps that teams need to know throughout the entire food production process.

The prerequisite programs required for a food safety program have been traditionally based on current Good Manufacturing Practices. GMP guidelines provide quality assurance teams with a blueprint for maintaining consistently safe and sanitary food production environments, which ultimately prevents contamination, bad hygiene, and foodborne illness.

HACCP is a proactive process and systematic approach to identifying, evaluating, and controlling hazards and critical control points throughout the food production process. Quality assurance teams will conduct internal and external audits on a regular basis to ensure that they're maintaining standard compliance. And if they're not, taking corrective actions to address any non-compliance issues.

As strict as food safety quality is, industry standards not perfect, and neither are the everyday people trying to adhere to them day in and day out. That's what makes continuous improvement strategies a key component of quality assurance.

These strategies can involve regular internal food safety audits, scheduled team trainings, and frequently evaluating and analyzing your food safety system's data to identify areas of improvement.

Quality control demands similar things to what we described above such as maintaining GMPs and implementing a HACCP Plan, as well as team education and training.

Example in food processing:

A quality control team monitors cooking temperatures and cooling times during daily operations. When measurements fall outside established limits, corrective actions are taken immediately, and affected product is evaluated before release.

But there are a few other key components of quality control that teams should know:

Once your business has landed on an approved supplier list, sourcing high-quality ingredients and raw materials is foundational in food product quality control because it directly influences the safety, taste, and nutritional value of the final product.

This step is crucial as it ensures that the food product meets regulatory quality standards and consumer expectations from the outset. Failing to do so could result in spoilage and contamination, which would have negative impacts both financially and health-wise.

Using the highest quality ingredients still requires staff to monitor CCPs throughout the production process to ensure food quality and consistency, especially where hazards are present. Monitoring CCPs will help food businesses prevent, eliminate, or deduce those hazards to acceptable levels. Common monitoring tasks include checking temperatures, chilling, allergens, and more.

Monitoring and documentation go hand in hand. Without proper documentation, maintaining food safety and quality only gets harder to accomplish. Keeping monitoring and in-process documents that record things such as process time, batch size, product weights, moisture levels, pH levels, and product appearance will keep your business compliant and make it easy to verify what steps staff have or haven't taken to ensure food safety, and to implement the necessary corrective actions.

With January 2026 ushering in the deadline for food businesses to meet FSMA compliance, there's no better time than now to start levelling up your quality management action plan with an emphasis on recalls.

Food traceability plans should include clear procedures for the withdrawal of products, communication strategies for stakeholders, and methods for investigating and correcting the root cause of the recall, demonstrating a commitment to consumer safety and regulatory compliance.

In case of a recall, your quality control team should have the ability to quickly and easily get the recall information into the hands of governing bodies.

Despite the undeniable benefits of quality assurance and control in the food industry, maintaining high standards consistently presents a series of challenges. Some of the most frequently highlighted ones are:

Not every food business has the luxury of having designated quality control teams. You can argue that teams share more responsibility when it comes to quality assurance activities, but quality control tasks are typically limited to qualified individuals.

That said, you hear stories all the time of companies using QA a QC synonymously or combining the two roles into one. In these cases, having limited resources could put your ability to manage quality at risk.

So it's best to be clear with your business what the scope of your responsibilities are, and how to address anything that falls outside of it.

The price of a comprehensive product quality management software, according to DocXellent's Chief Customer Officer Amy Sinyei Rodrigues, ranges from an average of $15,000 to $50,000 per year.

That's excluding the budget for qualified staff or additional requirements such as data migration, development support, integrations, and software validation.

Depending on a company's financial health, the price points of some QMS softwares might be outside of their budget. Especially during a time when many companies are being more fiscally conservative.

Depending where you're sourcing raw materials and ingredients (and from whom), supply chains can experience volatility. This could be for a number of reasons including economic trends, geopolitics, and weather conditions.

Because of supply chain volatility, it's important to diversify your list of approved suppliers to help lessen the risk of having all your eggs (or other food products) in one basket should something go wrong.

Giving your business more access to approved suppliers will also allow you to continue putting quality first, as opposed to potentially settling for lower quality products or suppliers.

Regulatory requirements vary from product to region to country. Regulations also span a range of topics including certifications, food safety, allergens, product labeling, and traceability. Failing to comply with these regulations can result in fines, recalls, or legal actions.

Despite changes to food industry regulations seeming to creep up more quickly than we expect, adapting existing food safety programs to meet updated compliance requirements doesn't happen overnight.

Fortunately, governing bodies typically gives businesses sufficient time to meet compliance. For example, if you're striving for FSSC 22000 Version 6 compliance, you have until March 31, 2025 to complete the upgrade audit. FSMA 204 is another upcoming change surrounding new traceability requirements which has a deadline of January 20, 2026.

The food industry's digital transformation is happening whether you like it or not. In many ways, and in long run, advancements in technology are a net positive for the food industry.

In the International Journal of Business Administration, researchers Jan Frick and Piotr Grudowski highlighted Quality 5.0 as a paradigm shift toward proactive quality control.

Quality 5.0 “is the fifth evolution of quality management principles, reflecting the transformative impact of emerging technologies and holistic quality concepts on industrial processes" through advancements in artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies enable businesses to gather and analyze real-time data.

By monitoring and analyzing data from various sources, including sensors, cameras, and other connected devices, Quality 5.0 can identify potential defects or quality issues before they occur, allowing manufacturers to take corrective action proactively... By shifting from a reactive to a proactive approach, Quality 5.0 can lead to more efficient production, higher quality products, and improved customer satisfaction.

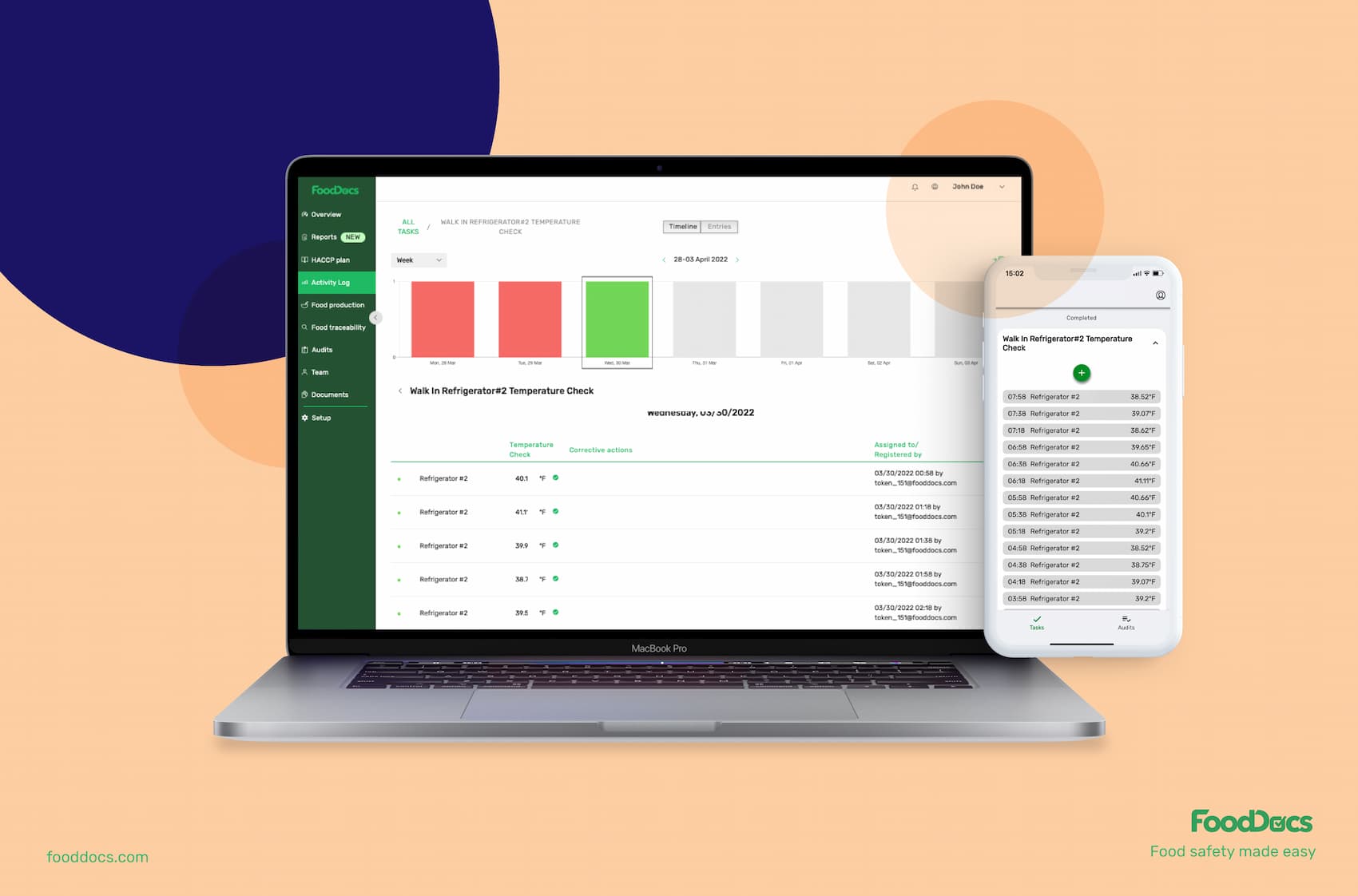

Companies are using quality management software to monitor CCPs and remove paper from the compliance equation. They're also leveraging smart sensors that integrate with food safety software to support quality control activities that would otherwise add hours to their workload every week.

As a result of this increase in practical real-time data, businesses are able to improve upon and optimize their operations to not just grow their business, but grow their business safely, because they have a better finger on the pulse of their food safety and quality.

All of that sounds good, but the challenge remains: change management is hard. The entire organization requires buy-in, from entry level workers all the way up to the leadership team.

At the end of the day, it's important to overcome these challenges — or at least have a roadmap to move in that direction.

In order to strike the right balance between quality control and quality assurance, it's helpful to be aware of where they sit within a quality management program. Remember: quality assurance is a broader term, serving as a prerequisite for quality control. You can view QA as a "setup" where the system and parameters are defined and then QC ensures the system is functioning as designed.

Being successful at quality control is dependent on a properly designed, agreed upon, and implemented quality assurance program.

Despite quality assurance coming first in the QA and QC relationship, both are required to fulfill regulatory compliance.

Ultimately, companies need to bake both quality assurance and quality control into to the foundation of the food business — from the raw materials to the finished goods. Neither can be an afterthought without the risk of future quality-related defects, recalls, or worse, foodborne illnesses.

Food safety software can provide savings as well as invaluable support for both quality assurance specialists and quality control professionals. The proof is in the proverbial pudding.

For example, in the journal Sustainability, researchers studied the impact of digitalizing their food quality control processes. Their original, paper-based system led to consistent waste in a few areas:

These inefficiencies were costing the business time, money, and employee satisfaction. However, after digitalizing the quality control process, the line quality control (LQC) team saw improvements such as:

On top of other improvements, researchers concluded that "[the] annual economic savings due to this reduction in paper use have been estimated to reach nearly £7000. This also has associated a significant reduction in environmental impact related to the production of the paper as well as its waste management.

Here's how FoodDocs can help you in similar ways:

Food safety software can significantly improve the efficiency and consistency of quality testing. Automating things like routine temperature checks and maintaining live dashboards of key metrics like all in-process monitoring tasks, the best food safety software facilitates data-driven decision-making processes. It also simplifies data management and makes it more accessible, reducing the risk of errors and improving accuracy.

When we talk about balancing QA and QC, improving quality and access to data is one of things that will help break down departmental silos, foster collaboration, and set clear benchmarks for quality management performance.

By standardizing testing methods and data reporting, food safety software ensures consistent interpretation of data across the organization.

By standardizing testing methods and data reporting, food safety software ensures consistent interpretation of data across the organization.

Food safety software can use predictive analytics to track potential quality control risks. Monitoring risk factors and triggering alerts when certain conditions are met will help teams manage risk more proactively. Early risk detection will also help teams to reduce product waste, improve safety, and meet customer expectations and customer satisfaction.

FoodDocs links risk detection with corrective quality control measures. When our food safety software recognizes a risk, you'll get a suggested corrective action notification and be able to correct it and mitigate the risk.

FoodDocs links risk detection with corrective quality control measures. When our food safety software recognizes a risk, you'll get a suggested corrective action notification and be able to correct it and mitigate the risk.

Food safety software can have built-in regulatory compliance standards. This alleviates the need to manually check each product against laws and guidelines. It can also provide audit trails, generate reports for health authorities, and maintain a real-time database of compliance information.

FoodDocs handles the creation and maintenance of reports for food safety authorities. The food safety software's reporting function removes the hassle of preparing these documents manually and minimizes human errors that can result from manual entry.

FoodDocs handles the creation and maintenance of reports for food safety authorities. The food safety software's reporting function removes the hassle of preparing these documents manually and minimizes human errors that can result from manual entry.

"Everything we use FoodDocs for, including our own record-keeping, helps ensure we always maintain best practices," says Michael Worbanski, Gruppo Terroni's Human Resources and Operations Safety Specialist. "FoodDocs makes the inspections easier for us because all the data is stored in one location."

Like a great harmony, quality assurance and quality control are two different but equally important parts of the food safety song.

Knowing their nuances will only help you more effectively integrate them effectively into your quality management program and enable your food business to deliver nothing but the highest quality products and services to customers.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...