HACCP Plan for Restaurant Template: How to Create One (Free Sample PDF)

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

The HACCP decision tree and risk assessment matrix are used to analyze hazards in your process.A key element in the applications of food safety management systems in the food industry is to be able to identify and analyze hazards. These hazards cause foodborne illnesses to consumers and may negatively affect food manufacturing companies.

As a preventive approach to food safety, the HACCP system was designed to establish critical control points (CCPs) in addition to hygiene practices to prevent these hazards from occurring further down your operation steps. The verification of these CCPs assists with tools such as the HACCP decision tree and hazard matrix.

Key takeaways

The HACCP decision tree and risk assessment matrix are essential tools for analyzing hazards in food processes.

A key element in food safety management systems is the ability to identify and analyze hazards that cause foodborne illnesses.

The HACCP system is designed to establish critical control points (CCPs) to prevent hazards in food manufacturing.

Verification of CCPs is supported by tools like the HACCP decision tree and hazard matrix.

Critical control points require undivided attention from manufacturers to prevent critical limit deviations and ensure food safety.

A HACCP decision tree helps determine if a process step is a CCP to produce safe food products.

Hazard matrices visualize the likelihood and impact of hazards, aiding in determining CCPs.

Preventing food fraud is a shared responsibility, effectively managed by implementing a comprehensive food safety management system and traceability.

The successful implementation of critical control points requires undivided attention from the manufacturer to avoid a critical limit deviation of any standards to make food safer and avoid any consumer illness.

Because of the focus that food companies must dedicate to CCPs, these practices must be carefully considered. Some steps are maintained as safe through prerequisite food hygiene requirements, whereas some need more control processes and therefore need further examination.

Learn which is the best way to identify and establish CCPs to create a competent food factory and protect your intended consumers. Additionally, learn the best alternative to using a decision tree or a risk matrix in establishing CCPs with FoodDocs. Make this task easier without the need to consider all questions and numbers. Read until the end and learn this best method!

A HACCP decision tree is a tool used to determine which among your food processing operations are considered as a critical control point (CCP) or not to produce safe food products. Any controllable processing step of your whole food chain where preventive measures can be applied for the elimination of hazards can be considered as a CCP.

Some examples of CCPs may include correct cooking temperature, proper conditions of storage, monitoring the integrity of packaging material, and others. A HACCP decision tree helps you decide whether a process step requires the critical limit establishment and a focused set of monitoring procedures for the control of food safety.

A decision tree in HACCP consists of a set of questions designed to arrive at conclusions of whether a step is a CCP or not. The questions involved in a HACCP decision tree are always answerable by a yes or no. It is used to support the judgment of a HACCP team when identifying CCPs. A HACCP decision tree is used specifically for each type of hazard in the context of food production. It is considered a vital part of your HACCP plan documentation and implementation.

The standard decision tree developed by the Codex Alimentarius Commission, a group developed to establish international guidelines for food control systems for the protection of public health, is used as the basis for most decision trees. To protect your intended consumers, it is important to conduct all stages of hazard analysis and perform adequate actions such as the implementation of CCPs to control them.

The most obvious time to use a HACCP decision tree is during the conceptualization of your HACCP plan. After careful consideration of food safety hazards in your business, this tool is used for the establishment of critical control points before critical limit determination.

To be able to use a process decision tree approach, your team must come up with a comprehensive block type flow diagram of the processes of your whole food chain and have identified the most probable food safety hazards to occur in your processing for the protection of your consumer.

Your HACCP team is tasked to identify all food safety risks for a specific product, designate which operation are they most likely to occur, and which step is capable of controlling this hazard. Operation steps such as temperature control during the cooking process, inspection upon receiving of raw materials, and hazard control during storage can be considered as CCPs and passed through a decision tree.

Using an incorrectly structured decision tree can lead to inaccurately identified CCPs and unnecessary control standards. The HACCP decision tree is used to separate CCPs from other preventive measures such as prerequisite programs, control points, and others. The most common mistake is when new food companies often identify too many steps as CCPs.

All food operations are suggested to be subjected through a decision tree to check whether they are CCP or not. With certain considerations on food hygiene and safety prerequisite programs, some operations steps can be ruled out as CCPs.

Choosing whether to use a decision tree in HACCP-making is based on the decision of your team. Critical control point establishments can be done based on existing literature and similar cases, but a decision tree can help in this process. Here are a few considerations you need to know when using this tool:

A hazard or risk matrix is a visualization tool that is used to determine the likelihood of occurrence and degree of damage that a hazard can cause. This matrix is made up of rows usually depicting the extent of damage that risks can cause and columns for the likelihood of occurrence. These elements can be interchanged in terms of position.

A hazard matrix is used to evaluate a hazard. In turn, this tool can be used by your HACCP team to determine which operation can be considered as a CCP or which ones can be solved through simple prerequisite programs such as basic conditions and sanitary design principles.

A hazard matrix offers several advantages such as the following:

The extensiveness of a hazard matrix can be adjusted depending on the level of how specific does the team wants to evaluate the hazards. Depending on the targeted outcome, all mandatory elements can be expanded such as the risk level either ranging from level 1 to 3 or a range of level 1 to 5.

Labeling and the extent of these variables can greatly vary depending on the company using the hazard matrix. Here is a list of the likelihood variables commonly used for an extensive HACCP risk assessment matrix:

These frequency variables are plotted against different levels of severity that each hazard can cause if left uncontrolled. The levels are labeled as follows or depending on the company using the hazard risk assessment matrix:

Using a matrix with more variables has its advantages and disadvantages in the food manufacturing sector. On the one hand, a hazard matrix with a narrow cross-section would be too small to describe situations and properly categorize potential hazards, but it will be easy to understand by everyone.

On the other hand, a hazard matrix with more variables would clearly describe how important a specific risk is as well as the degree of control needed but it may be too complex for other team members. Choosing the number of variables for your hazard matrix would depend on the expertise and preference of your HACCP food safety team.

Both the HACCP decision tree and the hazard matrix can be used for the implementation of critical control points. They are both useful tools for the successful implementation of food safety controls for potential hazards and are considered parts of the management commitment to food safety. They enable better CCP application by food business operators. Despite this, their approaches are unique when compared with each other.

Here are some evident differences between the two approaches:

The decision tree and risk assessment matrix generally differ in their approaches to establishing CCPs. A decision tree evaluates specific steps based on specific hazards they can control, whereas a risk assessment matrix evaluates hazards and determines what level of operations they need.

| HACCP Decision Tree | Hazard/ Risk Assessment Matrix |

| Qualitative evaluation. Uses questions to evaluate steps. | Quantitative evaluation. Uses numerical scales to evaluate risks. |

| Evaluates operation steps for suitability of CCP | Evaluates specific hazards or risks and not the operation itself |

| Can be subjective | Objective approach |

| Tells whether an operation is a CCP or not | Designates level of operation to a hazard (CCP, CP, PRP, oPRP) |

The most basic decision tree as released by the Codex HACCP consists of 4 or 5 different questions. These questions are answerable by a yes or a no and will lead to a decision of whether a step can be considered as a CCP or not for the production of wholesome food. The use of a decision tree comes after hazard identification and analysis in your process operations.

Once hazard identification and their analysis are done, your team is tasked to apply the decision tree in every operation step of your HACCP flow chart from receiving up to the delivery of your finished product. Steps that have been identified to be focal points for the occurrence of hazards must be prioritized.

Your HACCP team is required to answer questions in order. Here are examples of questions commonly used in a decision tree:

The extensiveness of a decision tree to be used depends on the requirements of food manufacturing companies or authorities in food safety agencies. The more questions involved, the more complicated the decision tree gets.

Despite this fact, the justification for establishing a CCP becomes more detailed. After the implementation of a CCP, the next steps include critical limit determination and the establishment of corrective actions and monitoring procedures.

The first step in establishing a risk assessment matrix is deciding the complexity of your matrix. That is whether to use more or less variable scale points for the hazard's likelihood of occurrence and the damage it can cause. After deciding the type of matrix to use, you can follow these definitive steps:

Risk levels are the main determinant of what food safety control and preventive measures need to be used to eliminate a hazard or at least reduce it to an acceptable level. Action criteria for these risks can be prerequisite programs, critical points, operational prerequisite programs, and critical control points.

Did using a decision tree or a risk assessment matrix seem like a lot of work for you? If you felt like you would get confused with all the questions from a decision tree or all the levels from a risk assessment matrix, then we've got just the solution for you!

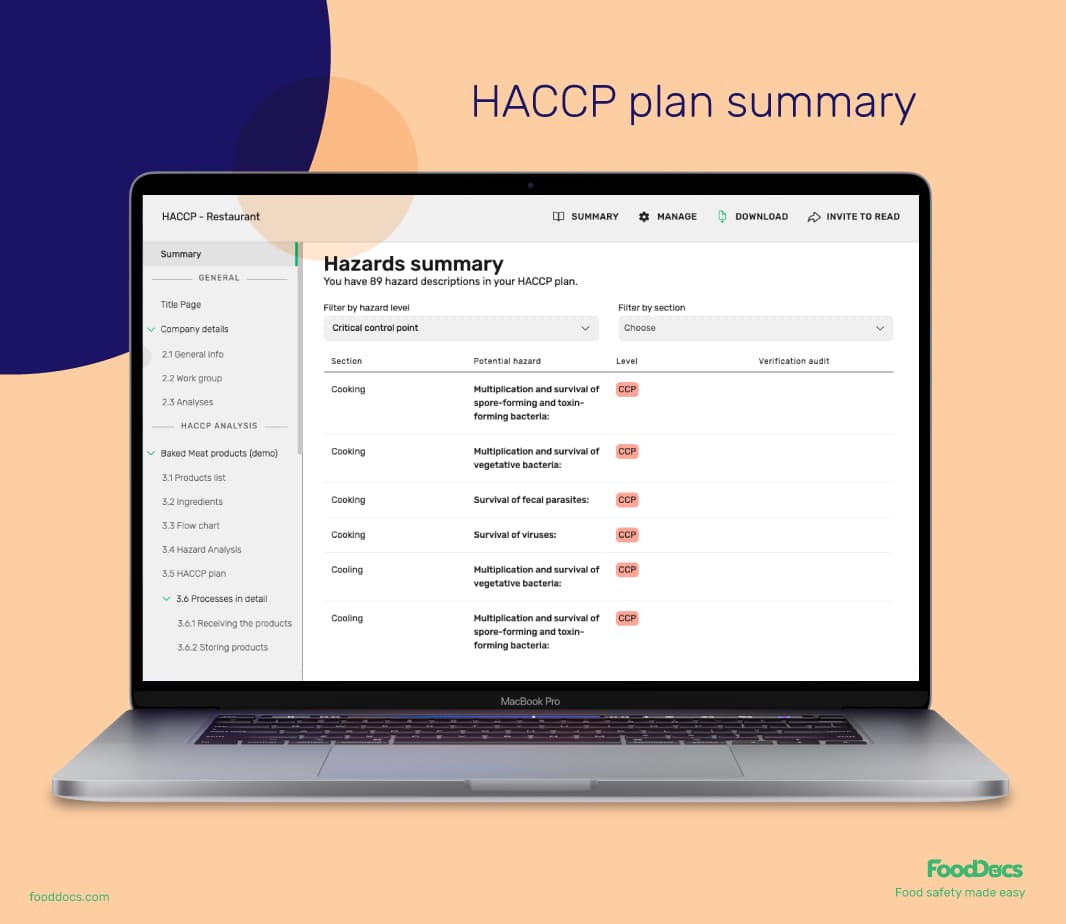

One of our most recent innovations at FoodDocs is establishing a hazard risk assessment matrix for you. We have designed a risk matrix that you can refer to for establishing your critical control points. As you answer the questions about your food business, our machine-learned system generates a HACCP plan for you.

Our system suggests which process steps in your food chain are considered as CCPs. Our suggestions are based on previous information provided by our customers in the same industry as your food business as well as knowledge from our food safety experts. Each of your process steps will be given a predetermined level of likelihood and severity and a corresponding control action.

With the globalization of the food industry at hand, faster, smarter, and more convenient solutions to making your HACCP food safety plan have become even more essential. These features are what make FoodDocs the best and only digital solution to your food safety requirements.

Our built-in HACCP builder that was designed by food safety professionals can complete all the necessary documents for a comprehensive HACCP plan and its successful implementation.

Our system tailors a HACCP plan that is fit for your food business by answering a few basic questions about your company. We automatically apply every HACCP principle to your answers and generate a food safety plan for you.

This downloadable HACCP plan will have a complete identification and analysis of hazards, appropriate preventive controls and CCPs, corrective action procedures, procedures for monitoring, and comprehensive verification procedures.

Concerning monitoring procedures, premade templates for monitoring records are also provided within our services. The complexity of monitoring forms can be adjusted as these are all customizable.

What makes our system even more reliable is that you can customize any section of your HACCP plan to fit your business. If you feel like a food safety hazard we have specified should have a higher level of severity in your case, you can customize the level with a few clicks.

In addition, our system allows you to add more process steps that may be new or very specific to your food business. Select the level of likelihood and severity of the hazard and you will automatically get a suggested action level. Use the risk assessment matrix we will provide as reference to what type of preventive and control action will you need.

Our food safety management system at FoodDocs also allows you to perform continuous monitoring of your operations through automated entries of your commonly performed activities. Our mobile application notifies you if monitoring records detect non-compliant results and allow you to take action swiftly. Critical limits monitoring can be as easy as just reading messages from your phone.

Let our system guide you into correctly establishing your critical control points and other documents for CCP monitoring and continue producing safe food. Ditch the manual decision tree and traditional risk assessment matrix by going digital with FooDocs. We would be pleased to help you build your HACCP plan.

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

Get a clear and complete breakdown of the most common Critical Control Point examples in HACCP for biological, chemical, and physical hazards.

The HACCP allergen control program is one of the crucial prerequisite programs of an HACCP plan. These are the key components and goals of using one.