Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Whether a restaurant or a retail food store, food safety hazards will always be present. While it is impossible to run a food business without the risks from food safety hazards, they can be effectively addressed with preventive measures. The most well-known and widely adopted program in the food industry to do this task for food manufacturers is the Hazard Analysis Critical Control Point (HACCP).

This food safety plan is internationally recognized as the systematic approach to prevent the risk of potential hazards from causing serious foodborne illnesses to the public by producing safe food products.

HACCP plan making is composed of several steps and no one ever said that making one would be easy. HACCP compliance involves several hours of planning, writing, and revising to fit your food service operations and comply with the relevant food safety laws and regulations in your area.

Key takeaways

The traditional method of HACCP compliance involves extensive planning and consulting, whereas digital tools can streamline and speed up the process.

Achieving HACCP compliance involves completing a 12-step process, including preliminary tasks and establishing critical control points

A HACCP compliance checklist helps ensure all necessary steps are covered, including preliminary tasks, principle implementation, and ongoing verification.

FoodDocs' HACCP plan software can significantly reduce the time and cost involved in achieving compliance by automating the creation of HACCP plans.

Being compliant with the HACCP standards can save food companies from serious food safety issues. Of the 48 million reported cases of foodborne illnesses that occur in the US each year, more than half are associated with food service establishments.

Food safety violations such as the presence of any health hazard, depending on the degree of seriousness, can cause closure or other issues such as lawsuits or fines. These issues can cost any food business its customer connection and fail.

Food safety issues negatively affect your brand image and appeal badly to consumers. HACCP compliance opens several doors to HACCP compliant companies for international trade associations.

HACCP compliance in the food industry means completing all conditions of the HACCP food safety plan as a legal requirement by government agencies and passing comprehensive verification activities. Compliance with the HACCP system means having a well-studied and verified preventive approach against loss of process control for any food safety risk and maintaining an acceptable level.

Following a HACCP plan means that a food business performs its raw material production, receiving, processing, storage, and distribution most safely and with proper sanitary conditions. Examples of these operations include analysis of storage requirements, proper cooking temperature for thermal process, cleaning of food contact materials, ensuring safe temperatures for delivery, assessment of commercial food equipment, and even accurate documentation process.

Every food business in the US and the UK is required to either establish a HACCP system or a risk-based preventive control system based on the principles of HACCP as an international standard. HACCP aims to perform the accurate identification of hazards that make food unsafe.

It also aims to critically analyze food safety hazards to create a preventive strategy before they occur. In this way, food businesses can protect the public from foodborne illnesses and related injuries. A standardized set of requirements in the form of 7 principles and prerequisites have been established by the National Advisory Committee on Microbiological Criteria for Foods (NACMCF) and adopted worldwide in the 1990s.

As a legal requirement to become HACCP compliant, food businesses must implement a plan that contains a written strategy based on the 7 principles of HACCP. In addition to these principles, at least 5 preliminary steps and a few prerequisite programs must be satisfied to ensure basic conditions of safe processing and food quality.

All mentioned components are part of a HACCP plan and must be verified by a food safety agency concerned with the nature of your food business (e.g. USDA for meats and poultry).

The traditional way of making a HACCP plan consists of several hours of planning, testing, revisions, and consultations just for an initial plan. Each principle must be carefully considered and analyzed to become effective once implemented.

The HACCP-making process must be backed up by written proof that the established points and limits can indeed address a particular food safety hazard. A common practice in the food chain is to hire a HACCP consultant to increase the chances of satisfying the standards of food safety agencies.

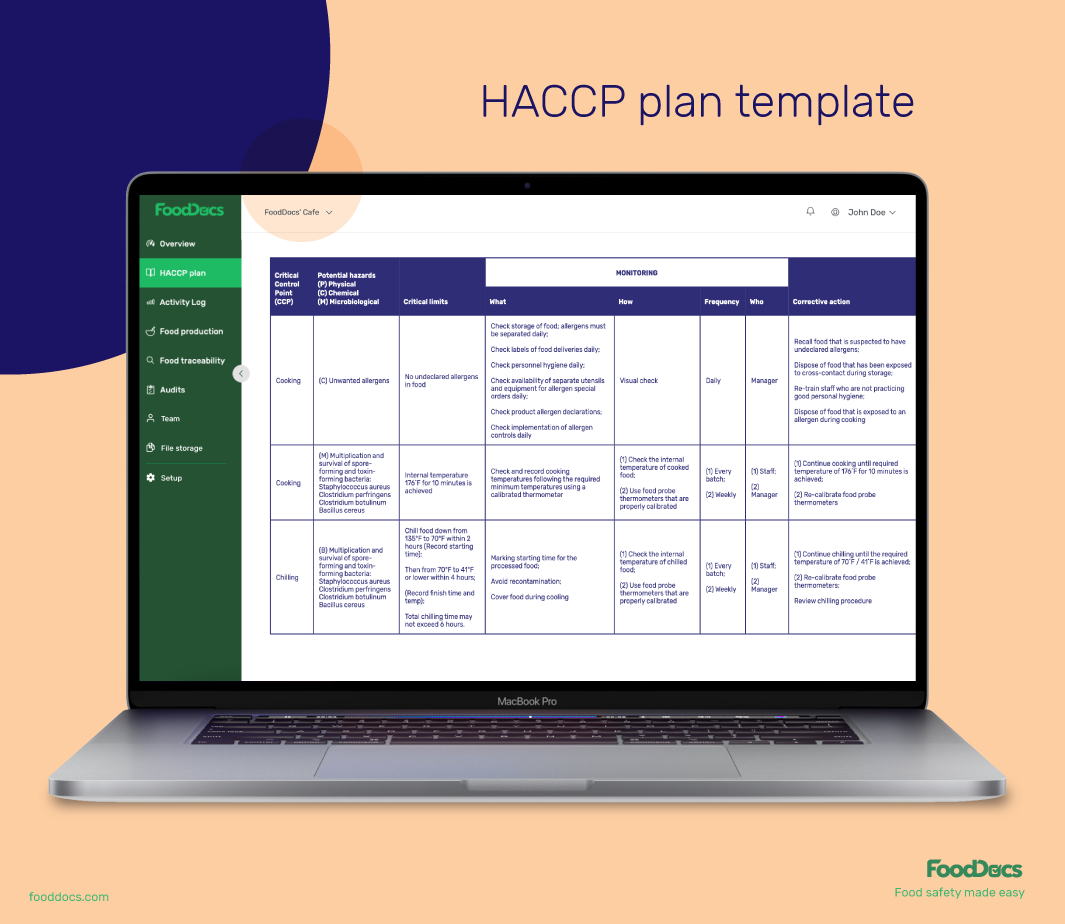

In recent times, the food industry has embraced the innovations brought by artificial intelligence for the assurance of food safety. The first-ever smart, built-in HACCP plan builder developed by FoodDocs is proof of this innovation. Food businesses can now get a comprehensive HACCP plan automatically generated by a system in just an average of 1 hour.

The whole process would only require you to answer some questions regarding your food business. These questions include the nature of your operations, the number of customers you expect each day, the target market, and the most common ingredients you use.

Such innovations help cut the hours of planning and the cost of hiring a top-tier food safety expert in HACCP to help you. Our software automatically considers the location and the nature of food business operations.

A sure way toward HACCP compliance is comprehensively completing the 12-step process involved. These steps include the preliminary tasks and the 7 main HACCP principles. In addition, ensuring that your HACCP plan follows all relevant food safety laws and regulatory requirements increases your chances of becoming compliant. A key to achieving compliance objectives is to layout a strong foundation of food safety practices.

The process of becoming HACCP compliant involves several steps that need to be fulfilled to ensure the safety of food. Among these steps are the prerequisite programs, preliminary steps to making a HACCP plan, and properly establishing the 7 main principles of HACCP.

As a verification task to help you check your team’s progress here are some of the major points that you have to fulfill for your HACCP compliance journey:

For the traditional way of making a HACCP plan, the mentioned preliminary steps can take hours or even days of meetings. Using a digital HACCP plan builder, you can skip all of these preliminary tasks as the software can do all of them for you.

A HACCP plan is built around 7 main principles. These principles systematically address the potential food safety risks in your food business. Below are the main principles of a HACCP plan.

Once your team checks out all of these boxes, you are ready for HACCP compliance verification procedures. Other documents such as foods safety checklists and monitoring forms for food safety management procedures can contribute to your HACCP compliance.

These procedures for monitoring help control hazards such as the multiplication of pathogens and even physical hazards in your operations. They may include checklists and monitoring templates for cleaning procedures, microbiological testing, analytical testing for chemicals, end-product-testing, and some aspects of food storage.

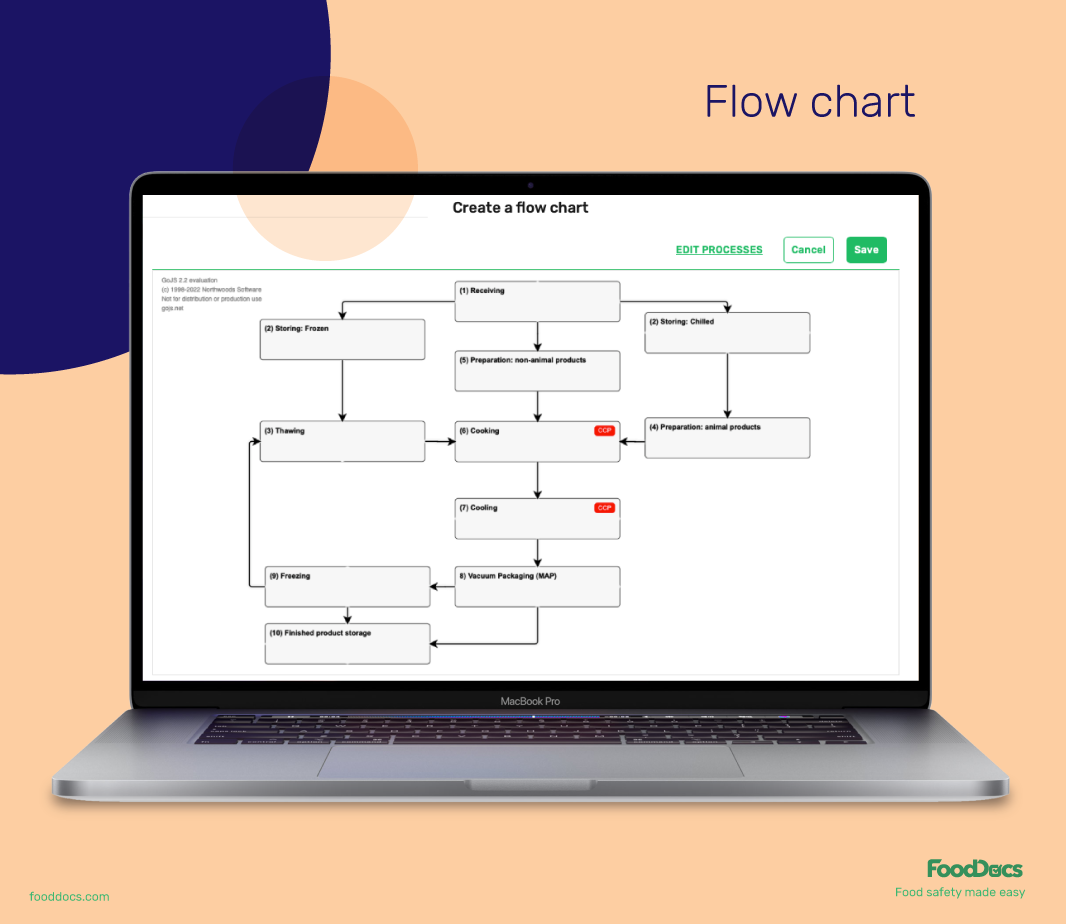

For a faster solution to your HACCP compliance journey, you can use FoodDoc’s innovative built-in HACCP plan builder. In just an average of 1 hour, you can get a complete HACCP plan with other important documents including a flow diagram of your food production process. You can easily tick all of the boxes in this compliance checklist once you finish answering our questions and generating a digital HACCP plan for your team.

Achieving HACCP compliance is the step before getting HACCP certified. Being HACCP compliant refers to the observation of food businesses of the HACCP requirements which aim to prevent the effects of potential hazards from causing foodborne illnesses. On the other hand, being a HACCP-certified food business means attaining certification from award-giving bodies as recognition of compliance with HACCP implementation.

A HACCP certificate is granted to food businesses that have passed a HACCP audit conducted by a qualified auditor or third-party experts and have proven that they have full control of food safety. The certification process ensures that the HACCP plan is properly implemented and effective.

HACCP certification aims to verify the previously granted HACCP compliant status. The main difference between HACCP compliance and certification is that the certification provides proof that your food business has a working HACCP food safety program.

Both processes help food safety and regulatory agencies determine whether a HACCP plan works in practice and is capable of protecting public health from unsafe food. The first step to becoming HACCP compliant is ensuring that your HACCP plan is complete, accurate, and applicable to any of your food operations. You can get a HACCP plan with these characteristics in just an average of 1 hour when you choose to use FoodDoc’s built-in HACCP plan builder.

Achieving the status of HACCP compliance means that your team has properly implemented your HACCP plan. The following question usually is, “What is the next process step?” The journey of food safety compliance does not stop with the approval of your HACCP plan. Another challenge on food safety compliance is how to implement it and ensure that is properly being executed every day to produce wholesome food. The maintenance and verification tasks of the CCPs on a HACCP plan determine the status of your approach to food safety.

Perhaps the most effective way to ensure that your HACCP plan is being properly implemented and is working for your food operations is to constantly monitor it. Do not worry, we know how important it is to have the right and easy tools for ensuring food safety. Therefore, we offer a HACCP Plan with a food safety monitoring system at FoodDocs that you can implement in a matter of minutes.

Failure to properly implement your HACCP plan or if inefficiencies are detected, would merit for your team to reevaluate your HACCP plan once again. A regularly conducted internal audit or verification schedule can identify which areas need to be reevaluated and which ones are efficiently working. These audit records can become relevant documentation of your HACCP compliance.

Passing a HACCP compliance evaluation significantly depends on the accuracy and effectiveness of your HACCP plan. Although it sounds simple, a lot of food businesses fail to pass this evaluation process on their first try. This reason is why most food businesses rely on hiring a HACCP expert or consultant to help them make a plan.

A few drawbacks with this practice are that your food safety team can become too dependent on the expert and may lack involvement during the process. Employees and the food safety manager must know the whole HACCP plan inside and out. In addition, although very helpful, hiring a HACCP expert is not cheap.

A study published in the Journal of Food Science estimated that developing HACCP food safety systems can range from $6,000 to $87,000. This estimate depends on the extensiveness of the plans and if your team decides to hire a food safety expert to help you.

An alternative to the traditional method is to use the first-ever built-in automatic HACCP plan builder from FoodDocs. With our HACCP plan builder, you can get a complete HACCP plan with a comprehensive essential foundation in just an average of 1 hour.

Hesitant to switch to a digital platform? Our built-in HACCP plan builder guarantees to automatically provide you with the following components for your HACCP plan:

You can get all of these in just an average of 1 hour by answering a few questions about your food business operations. With the help of artificial intelligence, our HACCP plan builder automatically creates a plan based on your daily operations. The whole process is 500x faster and 15x cheaper than making your HACCP plan the traditional way.

In addition, our system accommodates changes to your HACCP plan to further tailor it to your operations. You can easily click on the different fields of your digital HACCP plan and customize sections. With our digital HACCP plan builder software, you can skip all of the preparatory steps and get your whole HACCP plan done easily. With such a comprehensive HACCP plan, compliance with the food safety agency requirements is guaranteed to become more efficient and attainable.

Start making your HACCP plan and become HACCP compliant by starting the free 14-day trial, no credit card is needed. During the free trial, you can see how easy the program is and create a HACCP Plan. If you are ready to download or send the HACCP Plan to your local authority then you can just purchase the annual membership and wait for the verification of your HACCP Plan.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...