Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

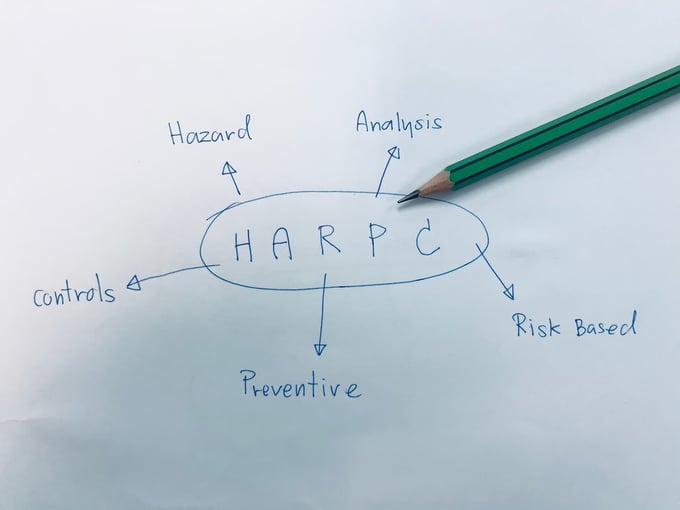

HARPC stands for Hazard Analysis and Risk-based Preventive Controls.

Under the Preventive Controls Rule of the FDA FSMA law, all food businesses are required to have a HARPC system which is a science-based risk assessment and preventive control system for all the potential food safety hazards in your operations.

Non-compliance to the HARPC system may merit sanctions from the FDA such as suspension of work permit, criminal charges, or import alert status.

WHAT WE'LL COVER:

HARPC stands for Hazard Analysis and Risk-based Preventive Controls, focusing on preemptively managing food safety hazards.

Under the FDA FSMA law, HARPC is mandatory for all food businesses, requiring science-based preventive measures.

Non-compliance with HARPC may lead to severe FDA sanctions, including suspension of work permits or criminal charges.

The HARPC program enhances food safety by focusing on hazard prevention rather than reaction to food safety incidents.

HARPC’s scope includes a wide range of potential hazards, from biological to radiological, that could impact food safety.

Risk-based preventive controls under HARPC require scientific justification and must effectively manage identified food safety risks.

Regular verification and reanalysis are crucial under HARPC to ensure the ongoing effectiveness of food safety measures.

Maintaining comprehensive and accessible records is vital to meet HARPC standards and facilitate audits and inspections.

The success of food businesses relies heavily on the quality and safety of their products. The food industry has put much emphasis on producing safe food products and controlling the potential risks of hazards to cause foodborne illnesses.

Proof of this is the number of food safety management systems available for all parts of the entire supply chain. The United States government has even initiated one of the well-known food safety management systems in the food industry for consumer protection that is the Hazard Analysis and Risk-Based Preventive Controls (HARPC) system.

The HARPC program follows the main principle of the FSMA law which is to shift the focus of the food industry into preventing hazards from occurring. This program targets the prevention of food safety problems even before they happen through a proper analysis approach and the establishment of preventive measures. All food businesses may benefit from the HARPC program and can help in becoming compliant with food safety laws.

With all these food safety programs, a newcomer in the food industry may become a bit confused. If you are this type of food handler, then this article is for you. We will walk you through some of the most important information and principles of HARPC.

HARPC or Hazard Analysis and Risk-based Preventive Controls food safety system is a program mandated by the FSMA that requires any food processing facility to have a science-based risk assessment for the identification and prevention of potential hazards in their operations. The HARPC food safety program was established following the Preventive Controls rule of the FSMA.

Under this rule, food establishments within the jurisdiction of the Food and Drug Administration (FDA) are required to have a minimum acceptable level of safety standards for the production of any food for consumption.

The HARPC food safety management system is a fairly new program that contains requirements for the identification and analysis of potential food safety hazards in your operational processes. This system includes hazards that can naturally occur or those which can be unintentionally introduced into your operations. Included in the system is the establishment of regulatory standard limits and corrective action procedures in addition to the process of preventive measures for food safety.

Despite the recent introduction of the HARPC system into the food industry, its principles and requirements are not that new from the other food safety systems. If you are looking for the quickest way to become FSMA compliant, and in turn, satisfy all HARPC requirements, try our Hazard Analysis Critical Control Point (HACCP) food safety program plan builder at FoodDocs.

In a way, HARPC is a system of approach to food safety with a broader range. It contains additional tasks to maintain food safety throughout your food business by apprehending food hazards before they cause any severe illness. This system is a government agency mandate and must be properly documented for audits.

To understand the main principles of the HARPC food safety management system, here is what the acronym stands for:

The system aims to accurately identify hazards that may be present in your operations and potentially inflict risk to consumers. These hazards may become from your food ingredients, hygiene practices, actual processing operations, storage, packaging, and even during distribution.

Included in the process is assessing the occurrence of these hazards such as the risk of food contamination as well as the degree of damage they can cause.

To properly identify the potential hazards in your food establishment, having general knowledge about them is a must. Below are some of the most common hazards present in the food industry.

These hazards are composed of pathogenic and unwanted microorganisms that can cause any foodborne illness to consumers. These pathogens may be bacteria, molds, yeasts, parasites, and viruses.

Biological hazards also include the natural toxins related to some pathogens. Some microbial pathogens are naturally present in food materials and require proper processing techniques to be controlled.

Biological hazards may be considered as clear signs of improper food hygiene practices as well as the occurrence of cross-contamination during food preparation. The majority of the recorded foodborne illnesses are the result of pathogenic microorganisms and their related toxins.

These hazards include chemical inorganic toxins, pesticides, chemical or drug residues, unapproved food and color additives, adulteration hazards in foods, or harmful by-products that result from overprocessing.

Chemical hazards can cause systemic or acute effects on consumers depending on their nature. Some examples of common chemical hazards include non-food grade lubricants, pesticide contamination, cleaning chemicals, or paints.

Chemical hazards can also be present as a result of too much addition of additives or overprocessing using thermal cooking. Chemical hazards are usually undetectable through visual observations and may need chemical testing.

This type of hazard is a new addition to the food safety system. Radiological hazards result from the ability of radiological contaminants to adhere to food materials. These contaminants can adhere to the food material through the water used for irrigation or washing, air, and most commonly soil.

Radiological hazards are common in plant or crop materials since their source of nutrients in the soil and water. The effects of these hazards do not necessarily show immediately but they can accumulate over time to dangerous levels.

Common examples of this type of hazard include strands of hair, shards of glass or metal, insect parts, soil in food, and the like. Physical hazards are the most easily detectable hazards that can be resolved through visual observations. These hazards can become precursors of biological hazards such as in the case of insect parts or rodent hairs. In addition, sharp hazards can cause injury upon ingestion.

In addition to these major hazards, the HARPC system is also concerned with food allergen controls about the major allergens in the industry. The HARPC system also aims to identify whether these hazards are intentional adulteration of foods or acts of terrorism and food fraud or if they are unintentional to prevent them from happening occurring again.

Similar to the provisions of the Product Safety Rule, all food businesses, whether domestic or foreign, are required to establish risk-based preventive controls. This set of controls must be conceptualized based on their effectiveness to regulate or eliminate food safety risks from hazards from your operations, especially for critical operations.

Instead of a critical limit, the proposed preventive controls must be established and have a scientific basis to prove their appropriateness. In choosing which process steps require preventive controls, the HARPC food safety team must assess the degree of damage a hazard from this step causes and use it as a basis for preventive controls.

All justifications and analyses of the implemented preventive controls must be documented. In addition to the establishment of preventive controls, a food recall plan must also be available. Recall plans must be tailored to scenarios of limit breaches for every process control system in place.

Contrary to other food safety systems, the HARPC program also applies preventive controls to other food production processes.

Below are some of the common preventive controls you could apply in your food business:

The main difference between HARPC and HACCP is that HACCP takes a reactive stance on food safety, focusing on identifying, preventing, and controlling hazards to maintain safety. In contrast, HARPC adopts a proactive approach, aiming to identify, control, and prevent potential and foreseeable risks that could lead to illness when consumed.

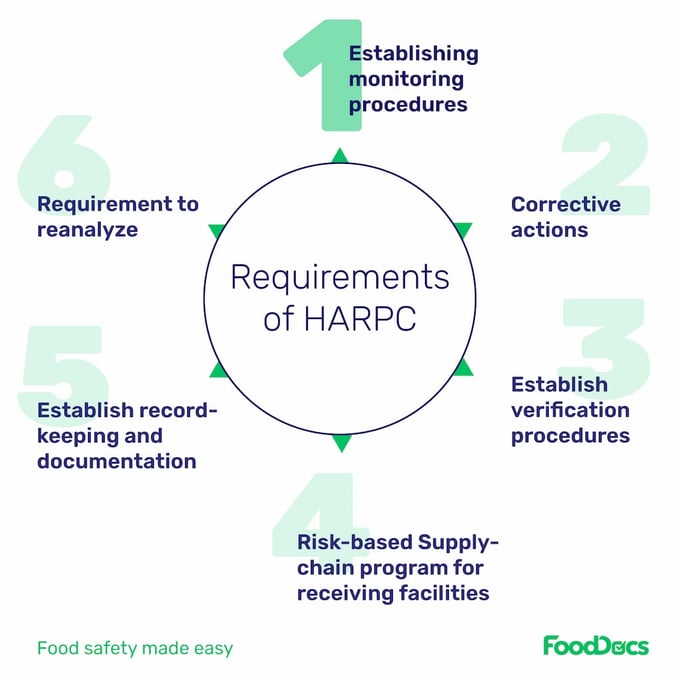

The principles of HARPC go beyond Hazard analysis and the establishment of risk-based systematic approach preventive controls which are the first and second principles. The HARPC system is also concerned with making sure that these preventive controls are properly working as well as emergency actions in the case that hazards persist.

Below are some of the other principles related to the application of HARPC:

As mentioned, it is not enough to have preventive controls in place. During the formulation and establishment of HARPC preventive controls, your tea must also be able to come up with monitoring techniques to observe if the controls are effective. This aspect tells your food business that preventive controls must be measurable. If the preventive control you have is impossible to observe, then there is no point in applying it.

Monitoring activities can be in the form of taking logs and routine inspections. To do this, you must have a monitoring form that contains all of the necessary information required to evaluate the performance of your preventive controls. In compliance with the FSMA, the HARPC system requires you to have these comprehensive documents.

Luckily, we can provide you with customizable monitoring forms for a wide range of preventive control activities for your operations. Our free monitoring form templates are part of our FSMS software that helps you ensure food safety in your operations. Also, we recommend visiting our food safety template hub and check out several free monitoring form templates you can customize for your operations.

The HARPC system requires food businesses to establish corrective actions in case the preventive controls become occasionally ineffective. A written document of which, when, and how these corrective actions will be applied must be provided by the food business. In addition, these corrective activities will also be applied if new preventive control is being tested or whenever there is doubt on their effectiveness.

The official HARPC mandates suggest a set of mandatory components when making the required corrective actions for any type of establishment related to food production.

To know whether all the steps of your HARPC plan are working, routine and effective verification activities must be conducted. This principle aims to evaluate if the whole HARPC plan is working as intended, starting from hazard identification, up to recordkeeping requirements.

Verification procedures aim to prove that preventive controls and corrective actions are working. After inspection, these steps must be evaluated if they must be retained, revised, or removed. It is also part of verification activities if the identified hazards are still significant and if they are still being controlled.

Verification requirements are very important when it comes to complying with the HARPC mandates. Audits also require these documents to be well-arranged and presented when asked for the evaluation of your HARPC system.

The HARPC food safety management program is an interconnected system that involves all parties of the food supply chain. This aspect is most evident in the sense that HARPC requires suppliers to be able to present proof that their raw materials are free from food safety issues as a part of supplier verification activities. In addition, it does not require additional risk-based preventive control measures for receiving raw materials if the supplier has its own approved HARPC system.

Your raw material receiving section must create a supply chain preventive control program that will verify the eligibility of your suppliers. Included in this assessment are the evaluation of supplier performance and process controls and documented HARPC system. To fulfill this task, your receiving team must come up with verification activities targeting the effectiveness of the supplier's HARPC. In addition to document requests, an on-site audit inspection may be done to ensure compliance for process manufacturers.

To facilitate a chain system, your food business must present to potential suppliers your written supply-chain controls program and set of requirements. These action steps can be your basis for supplier approval.

This step emphasizes the legal requirement of the HARPC system and the FDA FSMA for food businesses to have a well-established documentation system of all control systems, hazards, recall plans, and certifications related to food safety. The recordkeeping requirement is an amendment to the previous conditions of the FDA which only mandated food companies to compile any accurate record for traceability. Under this new amendment, food establishments are required to keep documents about the following process steps:

Under the HARPC system, an additional requirement is mentioned which mandates food processors to reanalyze their establishment's food safety protocols. Reanalysis is required for events such as when major changes are applied to the manufacturing process which might introduce new hazards or increase the potential occurrence of previously determined hazards. Additionally, when raw materials are substituted or product formulation has been revised, reanalysis of your HARPC system is required.

Whether or not there are any major changes in your food business, you are required to reevaluate your HARPC system every three years. If there are no significant changes and no revisions are required for the current HARPC system, this decision must also be justified in the documentation process.

These documents are mandated to be maintained for not less than 2 years. Your HARPC plan records must be clear enough to give auditors a quick yet comprehensive glimpse of your whole operations and your commitment to food safety. Under the FSMA law, all of these documents must be available upon request by the food agencies.

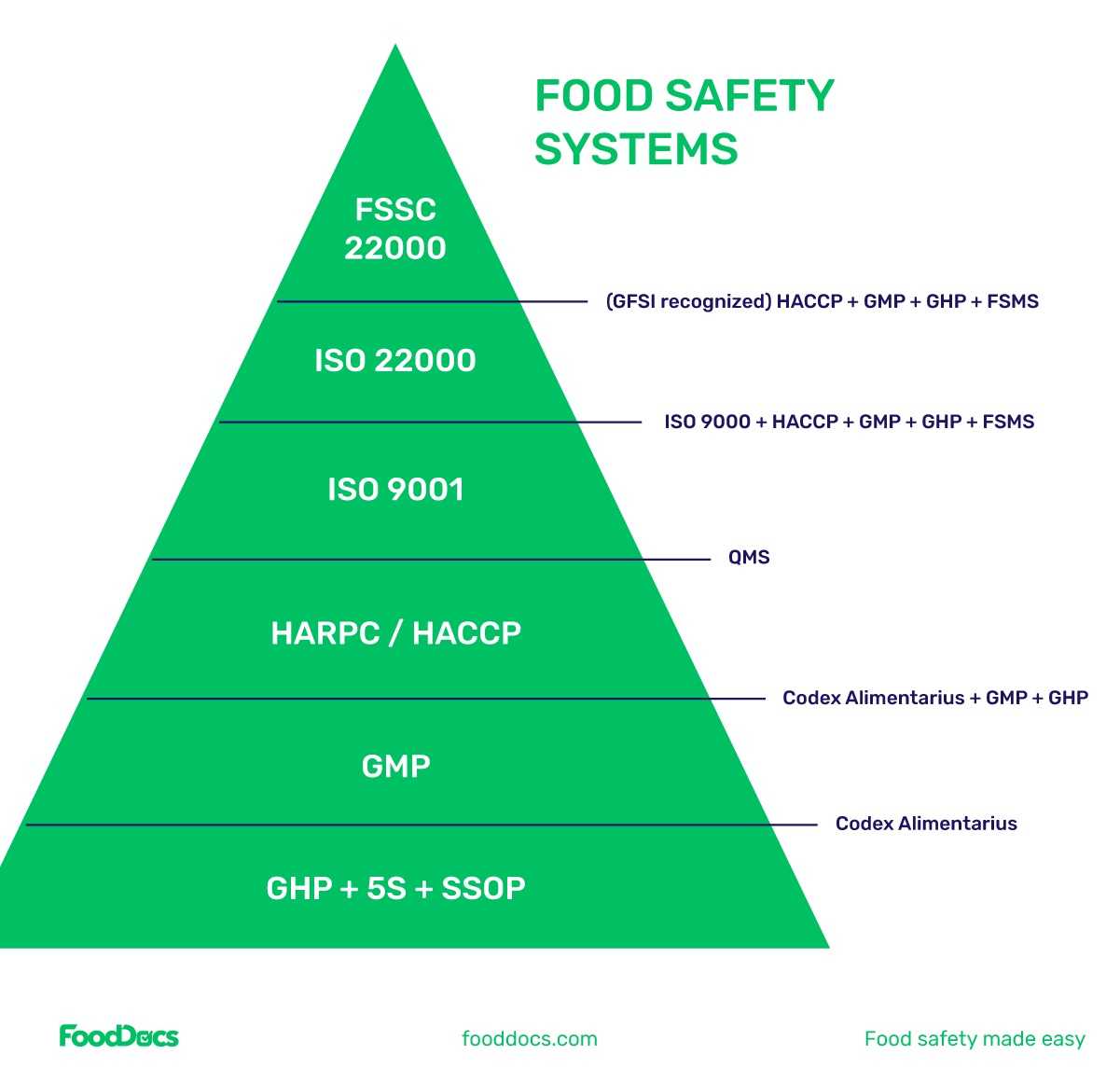

In the food industry, food safety management systems are categorized according to their level of stringency and requirements. Each level may be a prerequisite to the next one or an entirely different system that requires a different set of documents.

Below are the major categories of food safety standards with their core differences.

These programs include Good Hygiene Practices (GHP), the 5S system, and the Sanitation Standard Operating Procedures (SSOP). These processing activities are fundamental steps and operating conditions in maintaining a certain level of food safety to provide wholesome food. General practices are not very technical and may involve preliminary steps regarding how to be more organized at work, the principles of food hygiene, or how to properly maintain cleanliness in the human food facility.

1. Seiri (Sort) - emphasis on the removal of unnecessary materials or tasks to achieve your goals.

2. Seiton (Set in order) - create a storage system for organizing all your tasks and related materials.

3. Seiso (Shine) - regularly maintain cleanliness in the working area.

4. Seiketsu (Standardize) - establish standard operating procedures for your team to maintain uniformity and consistency in the quality of work.

5. Shitsuke (Sustain) - ensure that the system is followed by establishing assessments for the whole team.

The Sanitation Standard Operating Procedure or SSOP is a compilation of practices in maintaining sanitary conditions for equipment and the facility environment. The related documents in this program include instructions on how to properly clean food contact surfaces and other specific directions.

Also known as the GMP, these processing practices are considered prerequisite programs to the succeeding food safety management systems. The principles of GMP encourage food manufacturing businesses to adjust their processing operations towards a more food-safe condition. The GMPs create a system for the proper design of food processing facilities, behavior, monitoring, and manufacturing processes in your business.

The recommended practices under the GMP are based on the minimum standards set out under the Codex Alimentarius which is the compendium of international standards for safe manufacturing practices in the food industry.

This category pertains to the different management systems recognized in the food industry. It includes the Food safety plan requirement, HACCP, HARPC, and other systems. Food safety management systems commonly target foreseeable hazards in your food processing operations and aim to control them using preventive measures. These systems also require monitoring and verification procedures to know the effectiveness of the chosen system.

Food safety management systems help to ensure detailed analysis of the processing operation and proper documentation procedures. Such is the aim of HARPC. Although some of the principles of HARPC and the other management systems overlap, the HARPC system is regarded to have a broader scope. As such, the HARPC system is not regarded as a replacement to closely related food safety systems, but rather an upgrade. What sets food safety management systems apart from higher categories of management systems is that they are the base requirement to acquire the minimum standard for food safety.

This program aims to establish and implement quality management systems in your food business. A company is granted a certification of ISO 9000 when it has successfully developed and implemented effective documentation of quality system elements to maintain safe and quality productions. Unlike the food safety management systems, acquiring an ISO certification is not mandatory.

This certification system is considered as the highest degree of an efficient FSMS. To gain certification, it requires a company to apply the most stringent food safety regulations and food safety policies to control safety hazards regardless of their significance in the process. The ISO 22000 certification integrates the principles of all food safety policies to ensure the higher food safety quality system there is.

The Food Safety Certification 22000 is a certification scheme based on the standards of ISO22000. This scheme is an internationally recognized certification system that combines the standards of ISO 22000, ISO 22003, and some prerequisite programs. Requirements to pass this system aim to provide programs for managing food safety and producing safe products for your consumers. What sets this system apart is that it is recognized by the Global Food Safety Initiative (GFSI) which is a private organization that monitors different auditing bodies. The GFSI sets out top-tier standards of recognition for food safety audits.

The HARPC system is a part of the FSMA law which makes it mandatory to be implemented by all types of food facilities that report under the FDA. Under the system, food establishments must have science-based preventive controls that aim to control foreseeable food safety hazards and the risk level that they come with.

The majority of all the food businesses in the United States of America are required to establish their own comprehensively documented HARPC food safety plan. As of September 17, 2016, approximately 1 year after the establishment of the Preventive Controls Rule, food businesses under the FDA are required to submit the necessary documents related to HARPC. Failure to comply may result in receiving an FDA alert letter and may be considered as an offense to the law and merit prosecution.

According to the FSMA law, food establishments will be exempt from implementing a HARPC system given that they belong to the following categories:

In addition to these 6 major exemptions, food establishments that only act as receiving facilities or storage areas for raw agricultural commodities are not required to have a HARPC system in place.

The FDA will make a formal request from your team to show and submit all your HARPC documents and you must be ready to provide them accordingly. If the FDA finds that your requirements are lacking or you are not able to present anything at all, it can impose several sanctions such as:

Additionally, compliance would also mean that your HARPC plan must be updated every 3 years. Should there be any significant changes to your operations or revision of ineffective controls, your HARPC plan must be updated sooner.

A HARPC system requires several hours of identification and analysis of hazards, evaluation, monitoring, and verification procedures which will also require reanalysis over and over. In addition, this requirement is time sensitive and may affect your safe food production process permit if the food agencies find out that you are operating without being compliant yet.

Hiring a food safety consultant may speed up the process by a bit but not as much as a digital solution would. At FoodDocs, we can help you become FSMA HARPC compliant in just 1 hour.

Our system offers a HACCP plan builder which can satisfy all the requirements of the HARPC as well. The HARPC system weighs heavily on your documentation process and what would be the best way to complete them, rather than a machine learning software that contains knowledge from the best food safety experts.

Using our HACCP plan builder, you get all the relevant guidance documents for your HARPC compliance: hazard analysis, suggested preventive controls, monitoring forms, process flow diagram, and the like.

The results we provide you with will be based on your answers to a few straightforward questions which mostly deal with the nature of your food business. Through these questions, we can evaluate which local and international legislations apply to your food business.

Some of the questions include information on your:

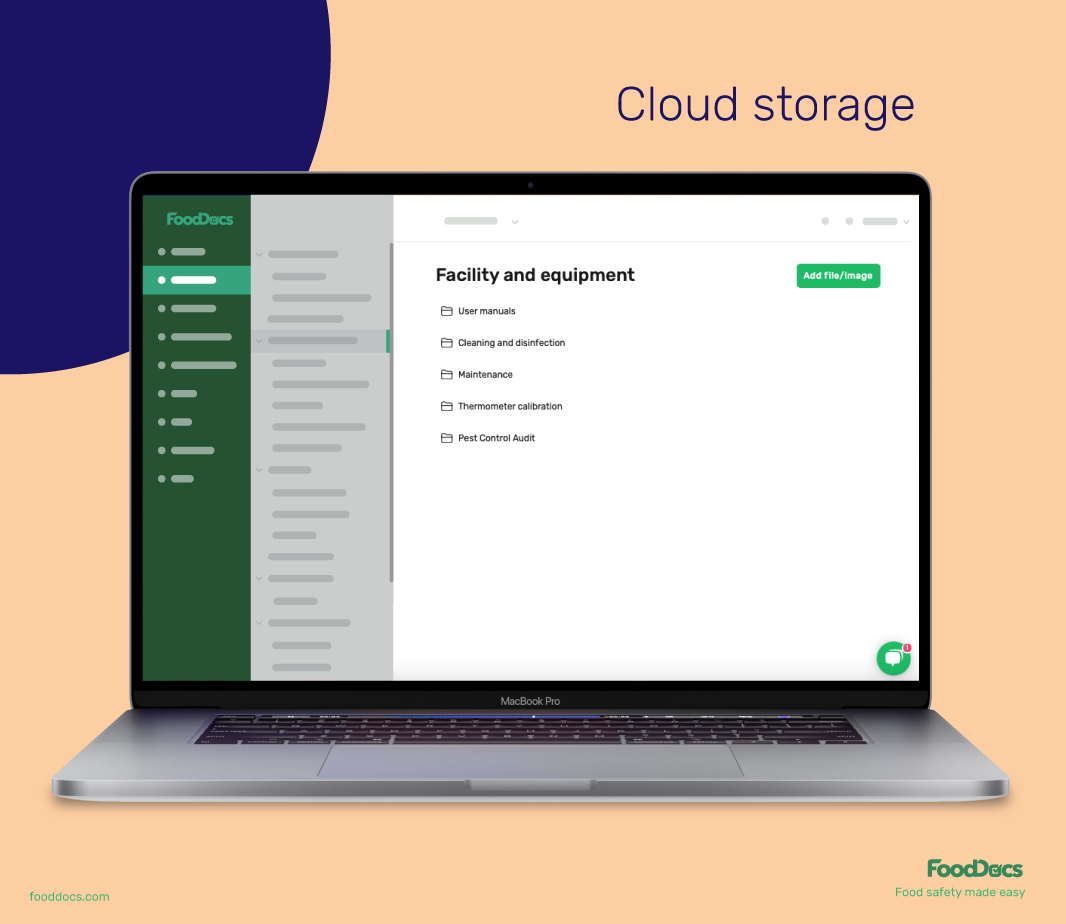

As emphasized by the FSMA law, the HARPC system is quite big on documentation procedures. At FoodDocs, we store all of your details in our app for ease of accessibility and safe-keeping.

This feature will help you save up on physical space in your office and easily access all the information you need with just a few clicks. You can choose to download all the documents we will generate for you, print them, and hand out copies to all the team members of your HARPC system.

Our solutions do not just stop there. We can even accompany you through your food HARPC implementation journey and continue throughout your everyday operations. Our system offers a monitoring system for your operations that can notify you if there are observations needed to be executed or if any standards are breached.

This is in addition to the array of free monitoring form templates we offer your food business. Our mobile app can become your partner in achieving food safety standards.

What's even greater is that our HACCP food safety management system software is customizable to help you accurately tailor all documents to your food manufacturing process.

Sign-up with us now and try our services using your free 14-day trial. That's more than enough time for you to get your business HARPC-compliant!

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...