Pasteurization is a cornerstone of modern food safety.

Pasteurization plays a critical role in preventing foodborne illnesses.

Developed in the 19th century, this process involves heating food to a specific temperature to kill harmful microbes, then rapidly cooling it to prevent spoilage. It's especially vital for products like milk, beer, juice, meats, and more.

Before we dive in, don’t forget to download our pasteurization temperature chart for quick reference.

Key points covered:

-

Pasteurization is a process that heats food to a specific temperature for a set time and then cooling it in order to kill harmful pathogens.

-

French scientist Louis Pasteur is known as the father of pasteurization.

- Three key steps of the pasteurization process are heating, typically from 145°F (63°C) to 275°F (135°C); holding the food or beverage at a temperature for a set time to kill harmful microbes; and cooling or chilling to prevent remaining bacteria from multiplying.

- Pasteurization is effective against many harmful bacteria, including Salmonella, E. coli, Listeria, ampylobacter, and Mycobacterium bovis.

- Four types of pasteurization include Vat Pasteurization, High-Temperature Short Time (HTST) Pasteurization, Higher-Heat Shorter Time (HHST) Pasteurization, and Ultra-High Temperature (UHT) Pasteurization.

-

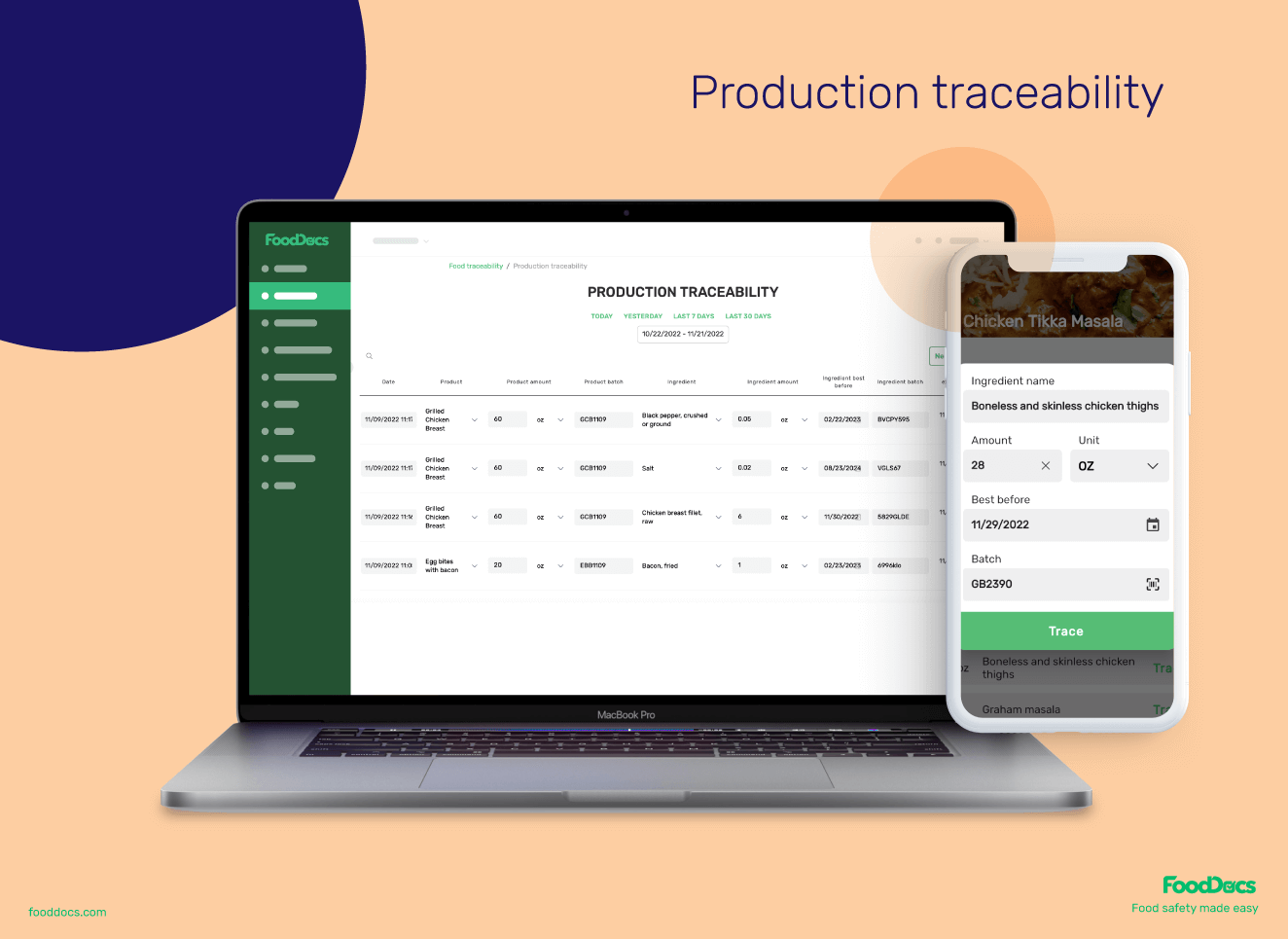

FoodDocs' digital Food Safety Management System can help food manufacturers who do pasteurization easily monitor and trace their products! implement their food safety plan and maintain compliance with it!

What is pasteurization?

Pasteurization is a process that heats food (typically liquids like milk, juice, and beer) to a specific temperature for a set time. This kills harmful microbes and prevents spoilage. The food is then rapidly cooled to maintain its freshness.

Though it doesn't sterilize the food completely, it does significantly reduce the risk of foodborne illness, making it safer for consumption.

Who invented pasteurization?

Louis Pasteur, a French scientist, is the father of pasteurization. In the mid-1800s, Pasteur developed this process while studying how to prevent spoilage in wine and beer. His work laid the foundation for modern food safety practices.

The term "pasteurization" itself is a tribute to his groundbreaking contribution.

Pasteurized vs unpasteurized

Pasteurization is a process designed to kill harmful bacteria in food, while unpasteurized products skip this step, offering a different set of risks and benefits.

Below, we break down the differences between pasteurized and unpasteurized foods in terms of safety, shelf life, nutritional content, and flavor.

Pasteurized products:

- Safety: Pasteurization significantly reduces the presence of harmful bacteria like Salmonella, E. coli, and Listeria, making the food safer to consume.

- Shelf life: These products typically have longer shelf life dates due to the reduction of spoilage-causing, harmful microorganisms.

- Nutritional content: While some believe pasteurization reduces nutritional content, the loss is minimal and outweighed by the safety benefits.

- Flavor: The process can slightly alter the taste, though modern techniques aim to preserve the original flavor as much as possible.

Unpasteurized products:

- Safety: Foods such as unpasteurized milk carry a higher risk of containing harmful bacteria, which can lead to foodborne illnesses.

- Shelf life: These products generally have a shorter shelf life, as the natural bacteria and enzymes are still active.

- Nutritional content: Some argue that unpasteurized products retain more of their natural nutrients and enzymes.

- Flavor: Many people prefer the taste of unpasteurized products, which can be richer and more complex due to the presence of natural microbes.

Here’s a side-by-side comparison of pasteurized vs unpasteurized to highlight the key differences:

| Feature |

Pasteurized |

Unpasteurized |

| Safety |

Low risk of harmful bacteria |

Higher risk of harmful bacteria |

| Shelf life |

Longer due to reduced spoilage |

Shorter, as natural microbes are still active |

| Nutritional content |

Slightly reduced, but minimal impact |

Potentially retains more natural nutrients |

| Flavor |

Slight alteration, but generally preserved |

Often richer, more complex due to natural microbes |

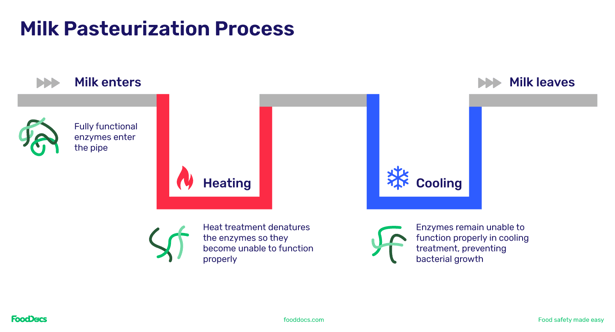

What are the 3 steps in the pasteurization process?

The pasteurization process generally involves three key steps:

- Heating: The food is heated to a specific temperature. This varies depending on the type of pasteurization but typically ranges from 145°F (63°C) to 275°F (135°C).

- Holding: The food is held at this temperature for a set time, ensuring that harmful microbes are effectively killed.

- Cooling: Also known as the chilling stage, the food is rapidly cooled to prevent any remaining bacteria from multiplying.

This three-step process is critical in ensuring that food remains safe without compromising its quality. That said, there are types of pasteurization (which we cover in a couple of paragraphs) that do drastically alter qualities such as nutrient density and flavor.

Individuals in the food safety industry sometimes include five additional steps leading up to the three key pasteurization steps we listed above. Using milk as an example:

- Chilling: Technically not part of the pasteurization process, chilling is helpful when working with milk in large volumes. This is because when you first get milk from a cow, the temperature is above ambient which increases the risk of bacterial spoilage. Reducing temperatures to between 35.6°F and 41°F (2°C and 5°C) helps stop the growth of bacteria.

- Pre-heating: Also referred to as regeneration, you heat the chilled milk to ~104°F to to make the separation of butterfat during standardization easier.

- Clarification: This part of the process helps remove foreign matter from the milk product, usually by using metallic filter tubes to strain the milk.

- Standardization: People prefer to consume different types of milk (e.g., skim, low-fat, high-fat). Standardizing milk fat fat helps ensure that whatever types of products you're producing are consistent in quality.

- Homogenization: During this process, milk fat globules are broken down into tiny droplets of fat so that the cream is less likely to separate. This helps keep the milk's fat evenly distributed.

What bacteria are killed by by pasteurization?

Pasteurization is effective against many harmful bacteria, including Salmonella, E. coli, Listeria, ampylobacter, and Mycobacterium bovis. These dangerous pathogens are responsible for serious foodborne illnesses, and pasteurization significantly reduces their presence in food.

A recent observational study of 48 human milk samples found that "holder" and "flash" pasteurization methods showed significant reduction in E. coli growth to 46.4% and 25.5 per cent, respectively."

The results support the idea that pasteurization is still one of the most reliable methods for controlling these bacteria in juice and dairy products.

According to the Centre for Food Safety:

Pasteurization systems are developed to achieve a 99.999% reduction of the microbial load by using the most heat-tolerant target pathogen Coxiella burnetii. The higher temperature is applied, the shorter the heat treatment time is required. The pasteurisation time and temperature combinations used are designed for killing harmful bacteria.

Which bacteria is not killed by pasteurization?

While pasteurization is highly effective, it doesn't kill all bacteria. Certain heat-resistant spores, such as those from Clostridium botulinum, can survive the process.

In the same resource above, food safety experts acknowledge that "pasteurization has its limitations. Some spore-forming bacteria like Bacillus may remain active after pasteurization, which could lead to food spoilage or even food poisoning if the pasteurized food is stored under improper conditions."

However, these spores are generally not harmful unless the food is improperly stored, which could allow them to grow. This highlights the importance of proper food handling even after pasteurization.

4 Types of pasteurization

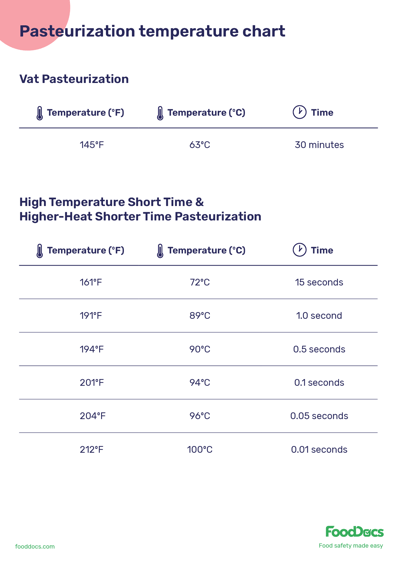

There are several types of pasteurization, each with its own temperature and time requirements:

- Vat Pasteurization: Heating food to 145°F (63°C) for 30 minutes. Commonly used for milk. It's also known as Low-Temperature Long Time (LTLT) pasteurization.

- High-Temperature Short Time (HTST) Pasteurization: Heating to 161°F (72°C) for 15 seconds. This is the most common method for milk and fruit juice.

- Higher-Heat Shorter Time (HHST) Pasteurization: Similar to HTST but at higher temperatures, typically 192-212°F (89-100°C) for a few seconds.

- Ultra-High Temperature (UHT) Pasteurization: Heating to 275°F (135°C) for 2-5 seconds. Used for products needing a longer refrigerated shelf life, like cream and milk.

In "Handbook of Farm, Dairy and Food Machinery Engineering", authors write:

Compared to sterilization, pasteurizing is a comparatively low order of heat treatment, generally at a temperature below the boiling point of water. The general objective of pasteurization is to extend product shelf-life by inactivating all non-spore-forming pathogenic bacteria and the majority of vegetative spoilage microorganisms, as well as inhibiting or stopping microbial and enzyme activity. To be effective, pasteurization is frequently combined with another means of preservation such as concentration, acidification, chemical inhibition, etc.

5 Most popular pasteurized foods

Methods for the most popular pasteurized foods include:

- Milk: Pasteurized primarily using HTST at 161°F (72°C) for 15 seconds.

- Eggs: Often pasteurized in their shells at around 140°F (60°C) for 3.5 minutes.

- Juice: Pasteurized using HTST or UP methods, depending on shelf-life requirements.

- Chicken: Rarely pasteurized, but some processes use temperatures around 158°F (70°C) for a few seconds.

- Beer: Flash pasteurized at 140-158°F (60-70°C) for a short time to maintain flavor.

Pasteurization temperature chart

Refer to our general pasteurization temperature chart for a detailed breakdown of internal temperature time combinations. You can also download the chart for easy access during your food safety operations.

Thank you for downloading our free template!

Want to create a full HACCP plan in 1 hour?

How about a digital Food Safety Management System in 15 minutes?

GET STARTED FREE

Check out our other food-specific pasteurization temperature charts, which you can download for free:

How to use food safety software for easy monitoring during pasteurization

If you work in the dairy industry or another part of the food manufacturing industry that pasteurizes food, check out FoodDocs' Food Safety Management software.

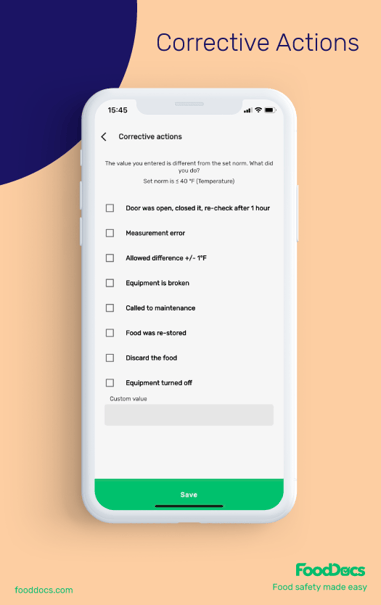

It makes monitoring temperatures — hot, cold, and everything in between — more easy and accurate. In addition to daily pasteurization temperature logs, the food safety monitoring system also includes cleaning checklists (for pasteurization tanks), receiving logs (for traceability), and more!

- Smart notifications: Temperatures that are out of the acceptable range during the pasteurization process will reach your relevant team members instantly. They'll be able to complete the suggested corrective actions according to your company’s standards, so they can avoid food safety incidents and stay compliant.

- Batch-based monitoring with traceability: Complete traceability logs and attach monitoring tasks to the same pasteurized product batch right away. Log hot or cold temperature checks to the prepared batch during the preparation process. This ensures necessary traceability and visibility in case of a recall or customer complaint and will help you ensure high-quality food safety.

- Control by verifying tasks: You can choose to verify the monitoring task entries. Assign it to yourself or a supervising team member to ensure that your staff complete their pasteurization-related activities according to food safety requirements.

Digitize your food safety system with FoodDocs and start your 14-day free trial today!

FAQs about pasteurization

Here are some common questions related to pasteurization:

What is killed by pasteurization?

Pasteurization kills harmful bacteria like Salmonella, E. coli, and Listeria.

What is pasteurization at 72 degrees Celsius?

This refers to High-Temperature Short Time or HTST pasteurization, where food is heated to 161°F (72°C) for 15 seconds.

What is the legal temperature for pasteurization?

The legal temperature varies by product but is often 161°F (72°C) for pasteurized milk.

Why is the temperature of pasteurization at 60 degrees Celsius?

Some foods, like egg products, are pasteurized at lower temperatures to prevent coagulation while killing bacteria.

How do they pasteurize milk?

Milk is typically pasteurized using the HTST method, heated to 161°F (72°C) for 15 seconds.

Is pasteurization food safe?

Yes, pasteurization is a proven method for reducing foodborne diseases.

What is the pasteurization process?

The pasteurization process involves heating food to a specific temperature to kill harmful microbes and then rapidly cooling it.

Why are people against pasteurization?

Some people believe pasteurization reduces the nutritional quality of food, though this is largely debunked. Regardless, Canada prohibits the sale of raw milk products. In the U.S., 30 states allow the sale of raw milk while 20 states explicitly prohibit it.

Is pasteurization just boiling?

No, pasteurization uses controlled temperatures that are lower than boiling to kill microbes without affecting food quality.