Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Food traceability is an integral system that supports food safety by making the production process transparent.

Let's start by acknowledging the elephant in the room: food traceability is incredibly challenging in a number of ways. From implementation to tracing logs (particularly if you're using paper) to good old potential for human error.

And because recalls are common occurrences in the food industry, the FDA's Food Safety and Modernization Act (FSMA) in the United States, for example, is one way to get businesses to comply with traceability regulations.

Tracing food properly means being able to show where came from, what was done to it (if anything), and where it went. All so that businesses can quickly identify and remove (potentially) contaminated food from the supply chain to prevent outbreaks and protect public health.

Our goal with this article is make food traceability clearer for you.

WHAT WE'LL COVER:

Before we jump into traceability as a whole, it's important to clarify some related terminology:

A food traceability system is composed of three parts that help you to create a:

When all's said and done, these three steps of traceability often take a painstakingly long time for food producers. That's why, as you'll see, we created an easy to use food traceability software.

A food recall involves withdrawing a food product from sale or use, or amending its label, at any stage in the supply chain as a precautionary measure. It is the industry's duty to efficiently eliminate the recalled food from the market.

When a recall occurs, it's initiated in one of two ways:

One way is from the supplier, who's required to send food recall data to the FDA, for example, including the ingredient and batch number for the affected products. The process typically looks like this:The other way is from the customer, to whom the producer has sent a product that needs to be recalled. The process typically looks like this:

With FSMA 204 requiring that you provide necessary recall data to the FDA within 24 hours, it's easy to see how much a paper-based traceability system can put your company at risk.

With this foundation, let's jump into this food traceability guide.

Traceability in food safety is the ability to track the journey of a food product and its ingredients through every stage of the supply chain. For individual businesses, food traceability means being able to track items one step backward, while it's a work in progress, and one step forward.

Ideally, tracking food products and their ingredients enables everyone in the supply chain to help connect the production, processing, and distribution stages.

Internal traceability processes in the food industry require documenting all processes, including the receiving procedure for raw materials, food preparation, packaging, and food distribution.

The main objective of traceability is to have a transparent overview of the product's state and safety throughout its production.

The concept of traceability in food systems can be divided into two categories:

In case of problems such as a foodborne illness outbreak or contaminated products, traceability records are used to identify the source of problems quickly. The records for foods are also used to determine the potential size of the problem and plan corrective actions accordingly.

The traceability system acts as an integral part of a defense plan for food manufacturing companies and food service businesses.

Generally, there are four types of individuals who are responsible for food traceability to varying degrees, depending on the size of your business and operational needs:

Food and beverage businesses can benefit from implementing a traceability system more than just in terms of inventory control and management.

Traceability is a vital part of a food business' preparedness plans against food safety events, such as complaints and foodborne diseases.

It covers several aspects of food production and food safety regulations.

Aside from convenience, the capabilities of production traceability ensure a company's compliance with regulations related to food safety.

Generally, all food and beverage manufacturers and businesses will benefit from establishing a food traceability system for continuous improvement. Several countries have food regulations for establishing a traceability system to help reduce food safety risks.

In the UK, Regulation (EC) No. 178/2002 requires food and beverage industry businesses to establish a comprehensive traceability system to protect consumers from hazardous risks in the supply chain.

In the US, the FDA provides an additional requirement under the Food Safety Modernization Act Food Traceability Final Rule.

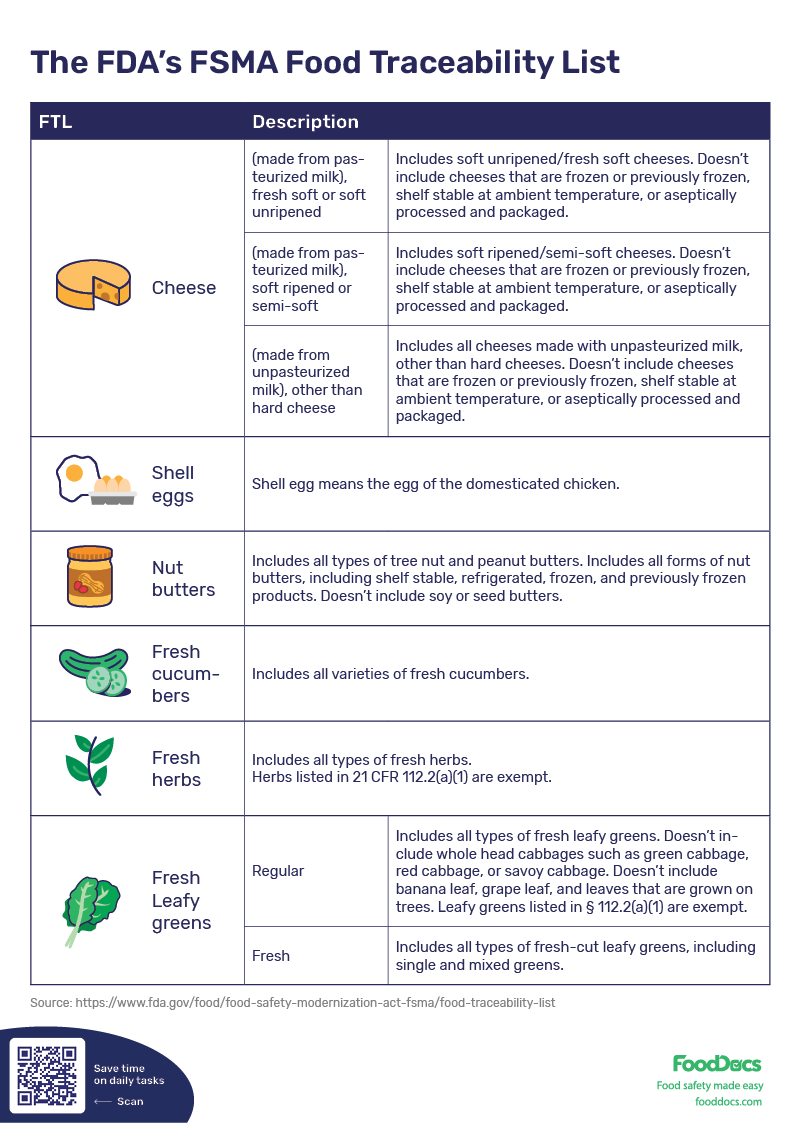

FSMA 204 requires any food manufacturing business or food producer that is handling, packing, holding, and distributing foods included in the food traceability list to establish traceability recordkeeping.

The Food Traceability List includes food ingredients that were assessed to cause significant impacts based on the risk-ranking model used under the FSMA.

The foods under the Food Traceability List were evaluated based on the following factors:

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Businesses in food production and service equipped with the proper food traceability procedures are more likely to be prepared to address problems and provide higher customer satisfaction.

In a food recall, food companies with a comprehensive supply chain mapping can immediately remove affected products from the market. The enhanced traceability can protect more consumers from buying the product.

Read our food safety tips to prevent contamination of foods in your business that may lead to food recalls.

An effective product traceability system can significantly contribute to the success of a company's approach to food safety.

The system for tracing food must be able to capture the necessary information that will be vital in case of problems. The information will be used as standard reference data by food inspectors in a standardized approach.

Product traceability requires the following essential information and legal requirements:

These parts are just some of the common features of a traceability system. The collected detailed requirements must be clear to understand the root cause of the problem. The product information will be used to analyze the situation to resolve recall issues or for food safety incident management.

In addition to a free food traceability template, check out other free templates from our list to help you comply with food production regulations.

The quality and comprehensiveness of your traceability requirement records can determine the efficiency of any traceability activity and help in making informed decisions. All records must be maintained until the product is out of circulation in the market.

Records on product requirements and the entire production flow must be consistently organized for easier access and faster action in case of problems and legal requirements.

Most recent product development cycles promote the use of digital solutions and relevant traceability tools that can compile all the necessary traceability information in one application.

Use one of the best food traceability software such as FoodDocs. Log information about your products, operations, suppliers, and end-users using our two-in-one Traceability system. This system also helps your team by automatically computing expiration dates based on the shelf-life information of each product you log in your recipe book.

Plus, our system features smart solutions such as a notification system that alerts employees of a product's shelf-life status and expiry dates.

You can also perform efficient batch tracking and shelf-life monitoring using our smart Food Safety System with traceability features.

Especially now that the demand for transparency has significantly increased as part of food safety trends, traceability has become more important. Effective food safety practices and complete records of the movement of ingredients and products offer valuable information for business owners, food safety agencies, and consumer protection.

A traceability system in the food chain can help food businesses comply with their commitment to protecting consumers and show that food safety is important. In addition, an accurate traceability program can help businesses protect their assets by ensuring that no food goes to waste as they track every product's shelf-life.

The level of complexity of supply chain transparency can determine the usefulness of a food traceability program. Investment in technology and smart software programs is the trend and more efficient solution in the current food industry.

Learn more about ensuring food safety for customers from our detailed article on food safety guidelines.

In the U.S. food industry, at least 492 food recalls were issued from 2021 to 2022. In 2023, FDA food and beverage recalls alone totalled 232. In such cases, traceability systems significantly contributed to identifying affected products and rapidly removing them from the market.

In one of the most comprehensive updates of the U.S. food safety laws, a rule that strengthens the traceability system of the U.S. food supply chain was enforced.

In the U.S. FDA's pursuit of faster and more effective tracking of the food movement, the FSMA Food Traceability Final Rule was established in November 2022. The FDA traceability rule emphasizes the technical level of standards for food traceability record requirements and strict guidance on traceability for food businesses handling foods that are listed in the Food Traceability List.

The rule also requires producers to maintain a traceability plan detailing the procedures performed by the business to collect the necessary product information. According to the rule, food businesses must maintain paper-based or electronic records of the information and be readily available upon request by the food safety agency.

The food traceability process in food manufacturing is used to monitor and manage the movement of food products and their ingredients at various stages of the production and distribution process. It helps ensure consumer safety and product quality standards while providing transparency to them.

Food traceability in manufacturing industries or production businesses is a critical component as they produce foods in large batches. Addressing recalls or customer complaints can take a while and cost more without a properly working traceability system.

Complete traceability in manufacturing typically captures information about the ingredient source, production information, inventory, and regulatory compliance. Additional recordkeeping requirements may vary from one food process manufacturer to another.

The recorded information provides several benefits for manufacturers, specifically in improving operational efficiency.

Such systems can streamline operations by automating data collection and sharing, reducing manual record-keeping, and improving production efficiency.

To help you understand the importance of a food traceability system, we listed examples of traceability contributions in cases of outbreak cases.

Food traceability systems are extensively used by health and safety agencies such as the Centers for Disease Control and Prevention (CDC). One of this agency's main tasks is to investigate cases of outbreaks and assist in analyzing the events that violate government regulations.

In 2020, a multistate outbreak of Salmonella linked to onions occurred, which affected at least 1,127 people across 48 states. In this case, inspectors were able to trace the cause of the outbreak to be linked to the supplier of the raw materials. The company was able to recall the affected products one week after the outbreak was detected.

A similar multistate outbreak involving raw tuna also occurred in previous years. The outbreak affected 25 states and sent approximately 425 customers to the hospital. Using records, the CDC and FDA were able to identify that the source of the outbreak was tuna, which was a common ingredient in all of the implicated restaurants.

Upon detection and conclusion of the source, the agencies established a strict screening process for all imports of similar raw materials from foreign suppliers.

With the help of food traceability, food agencies can immediately address concerns and minimize the potential damages of an outbreak. The availability of records also allows businesses to issue an immediate recall to protect consumers from further problems.

FoodDocs software makes traceability logging and recalling easier, saving lots of time for you and your kitchen team. Our software is built so you can log your traceability within seconds, saving time on repetitive activities, and making the whole traceability process easy to trace in case of recall.

Here’s how FoodDocs can help:

Setting up an internal traceability system is a continuous task and requires serious commitment from your food safety team. Using FoodDocs' smart Food Safety Management System equipped with a two-in-one Traceability System fulfills all traceability and production needs.

With our Traceability System, you can create traceability logs with just three clicks. Enter all product information, including:

All essential information needed to track the movement of your ingredients and products and for recalls is conveniently presented in one custom food traceability software.

Managers can also attach monitoring tasks to each traceability information, such as receiving temperature tasks, to further support product information.

In addition, food handlers can log traceability information through our Food Safety App, which is accessible through any mobile device.

Ensure that all of your recipes are organized in one cloud storage with the help of our Digital Recipe Book. With this feature, you can log all recipe information, including the following, to our system:

The information logged into our Digital Recipe Book is also used to automatically calculate batch production and expiration dates of products automatically. Use this smart solution to ensure food handlers have access to proper food preparation and reference for the correct business processes.

Once you log individual product or ingredient shelf-life information in our Digital Recipe Book, you can receive intuitive alerts about shelf-life reminders.

Based on the date and production time stamps you enter or what our system computes automatically, food handlers will receive smart notifications when a product is nearing its expiry date.

With this feature, you can access accurate data for labels and ensure that all food ingredients and products are optimized before spoilage and reduce food waste. Never let any food go to waste with our Shelf-Life Tracker.

![]()

With the help of our comprehensive food traceability software system, you can ensure that all ingredient and product information is well-organized and can be accessed easily in case of future recall events or inspections. Use our software for food manufacturing, service, or retail to achieve food safety compliance with food industry standards.

You can either show the system information or print the data in an organized sheet for easier analysis. At FoodDocs, we aim to make food safety more accessible and easier to understand with AI-powered solutions. Show your commitment to food safety by using our smart software.

The automated setup of your smart Food Safety Management System takes only an average of 15 minutes. Our system can generate the necessary digital documents based on your business operations using artificial intelligence and a machine-learning program.

Start using our smart solutions to keep track of your products and food safety. Book a demo to get a quick overview of how you can trace and manage your production with ease.

Food traceability refers to the ability to track the movement of food products and their ingredients throughout the entire supply chain, from production or cultivation to consumption. It involves documenting and recording information about a food product's journey at each stage of production, processing, distribution, and sale.

The production traceability definition refers to the ability of a food business to track the flow of its materials and products along the manufacturing process and production chain.

The Food Traceability Rule is one of the major provisions of the FSMA. It requires business owners who receive, handle, manufacture, store, pack, and deliver food items listed in the Food Traceability List to maintain traceability information. The information will be used in case of a critical tracking event in the supply chain.

Traceability is a system that allows food businesses to monitor the movement of products in the supply chain and secure safety. On the other hand, recall or product recall is an activity wherein a food business voluntarily or forcibly removes food products at any point of the supply chain to control a food safety issue.

Discoverability.

In one sentence, it would mean the ability to follow a product through the supply chain.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...