HACCP Plan for Restaurant Template: How to Create One (Free Sample PDF)

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

A commercial kitchen layout can determine the workflow efficiency of a food business.

An appropriate and well-planned commercial kitchen layout can improve your operation's efficiency and promote cost savings. Although planning a layout may not be at the top of your checklist when planning to open a commercial kitchen, it is undeniably a priority for any food business.

Whether you are planning to build a commercial kitchen from scratch or rent a commercial space, building a conducive layout can help you maximize your operations.

Accidents, food wastage, and cross-contamination can all be significantly addressed with a careful consideration of the commercial kitchen layout. In addition, the speed and productiveness of your team can be improved if the kitchen layout is made to avoid bottlenecks and allow a seamless kitchen flow.

In this article, we will go through the following topics:

A commercial kitchen is a food business facility solely dedicated to preparing food for large volumes sent to smaller operating food businesses such as restaurants or smaller kitchens. Other food premises can rent commercial kitchens or opt for leasing options to prepare large batches of food. Commercial kitchens also work with ghost kitchens and catering kitchens, which are establishments that prepare food but are only available for pickup and delivery.

Commercial kitchens are typically complete when it comes to food preparation equipment and cooking facilities and can handle bulk preparations. Correct facilities follow strict food safety regulations, which include proper layout to minimize food safety hazards.

To fulfill operations and prepare large amounts of food, a commercial kitchen must have the following main areas and key components in no particular order:

Since commercial kitchens are mainly cooking facilities that focus on preparing food rather than serving them in-house, a common layout does not have a dining area. Some large commercial kitchens may also have an area where employees can change uniforms.

A commercial kitchen layout planner is a tool used to visualize and organize kitchen equipment, workstations, and workflow before physical installation.

Layout planners help food businesses:

While layout planners do not replace professional design or regulatory approval, they are commonly used as a planning aid to support informed layout decisions.

The layout for a commercial kitchen refers to the arrangement of facilities, restaurant equipment, and routines inside a commercial kitchen. The layout determines careful consideration of the machines' placement and the food handlers' particular kitchen flow.

A commercial kitchen layout must be flexible, efficient, and not prone to accidents. This layout will represent how your team executes a food service process while considering safety and organization. It brings the dynamic elements of a kitchen together to form a cohesive assembly with optimum output.

A kitchen's layout will depend on the available commercial kitchen equipment for use, the target preparation services, and the target number of employees the kitchen will accommodate. The layout will involve the following operations:

Based on these operations, the most optimum restaurant kitchen floor plan can be selected. There are many known layouts for a commercial kitchen, each with its advantages and disadvantages. The optimal layout for catering operations may vary from operations for retail food stores. Catering staff is expected to operate differently when compared with retail food service staff.

Some layouts for larger establishments consider storage requirements for washing up facility for employees and drying facilities for washed linens.

Before creating a commercial kitchen layout plan, several operational factors should be clearly defined.

These include:

Defining these elements in advance helps prevent layout changes later and ensures the final plan supports both operational efficiency and food safety requirements.

A layout plan created without these considerations often results in bottlenecks, unsafe workflows, or non-compliant designs.

Commercial kitchen layouts and design principles may vary depending on the intended production operations of the kitchen and the available space. Despite which layout is used for a commercial kitchen, the efficiency and safety of the operations are always priorities.

Below, we have listed the 6 most widely used commercial kitchen layout examples and highlighted which is the most viable option in different situations.

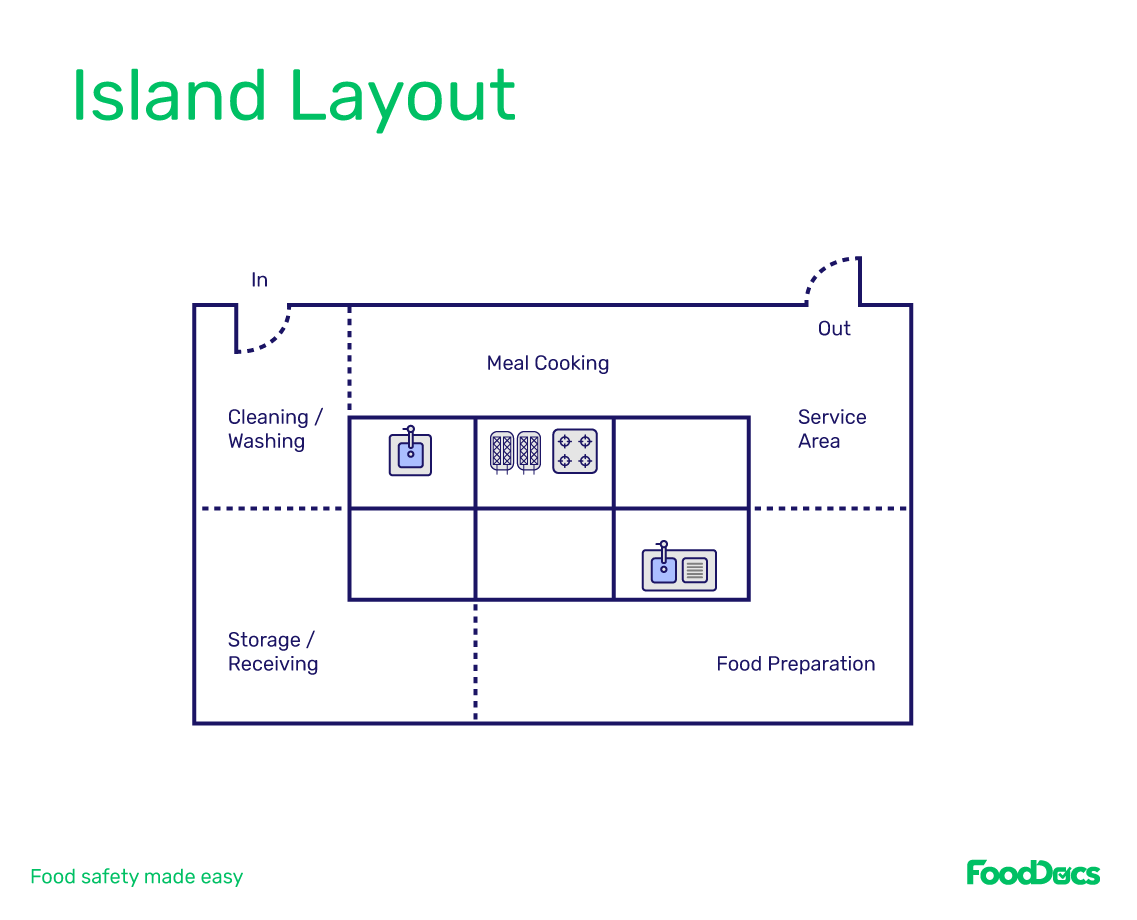

This kitchen configuration places the meal cooking section and commercial work table space at the center of the kitchen area. All machines and food equipment used for cooking, such as burners, commercial fryers, stock pot range, and baking stations, are collectively placed at the center counter space, with all other parts of the kitchen stationed around it. The food prep station and other sections of the kitchen are placed around the island in a circular flow.

The island design for a commercial kitchen plan promotes communication among the different parts of the kitchen and allows better supervision by the manager. Since the meal cooking area is the last step before delivery, all other areas revolve around this operation. Using the island layout requires an adequate amount of space to avoid obstruction between the different sections.

Commercial kitchen island layout

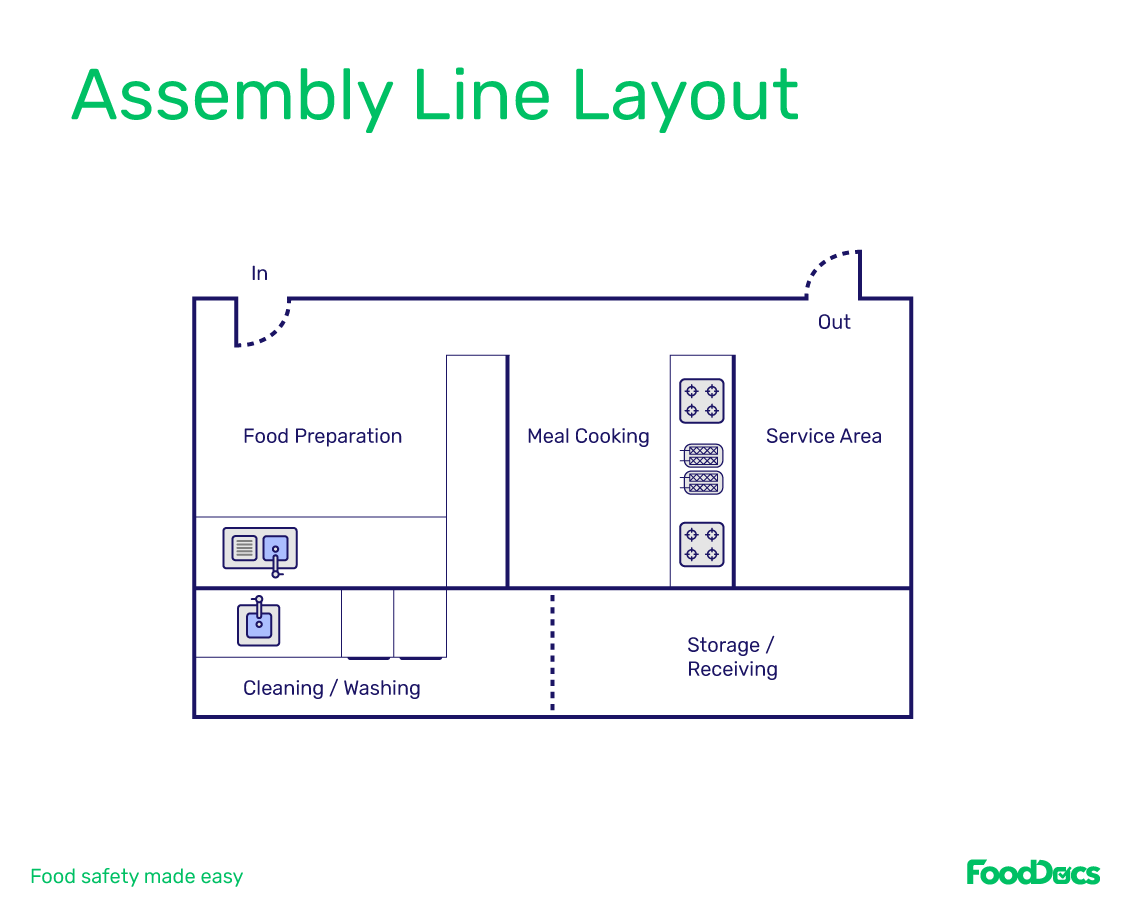

The assembly line configuration highlights the central preparation system of cooking a dish with a single line. This line consists of food preparation aspects, meal cooking, and service in a single orderly assembly. The configuration minimizes cross-contamination on surfaces for food preparation from unnecessary interaction once the product moves to the next station.

This common kitchen layout is ideal for the type of restaurant with repetitive operations, such as fast food type of restaurant or quick service facilities. All other operations besides food preparation, such as the bulk storage area and receiving bay, are placed beside the main assembly line kitchen layout. Such a configuration removes unnecessary interaction among employees. The delivery personnel will not have access to the preparation area.

Commercial kitchen assembly line layout

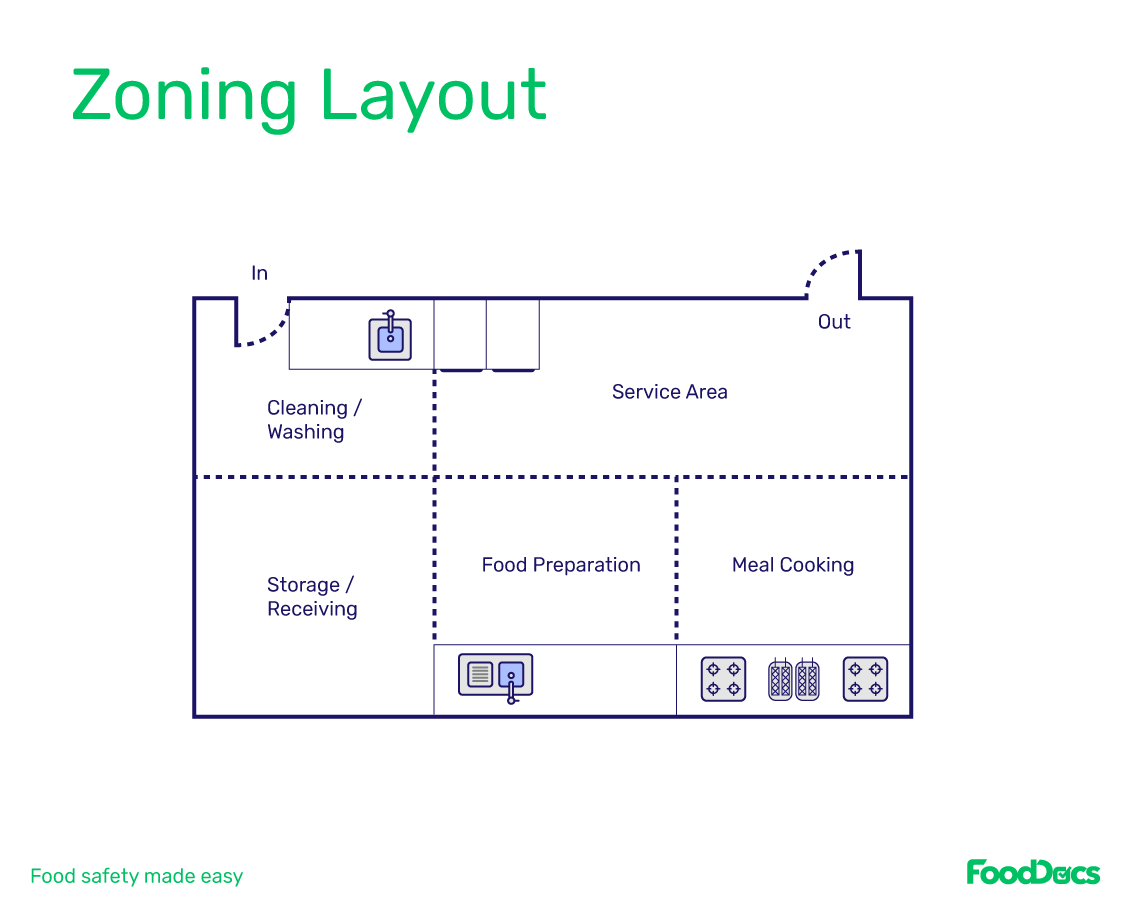

Zoning refers to the dedication of ample spaces for each main kitchen component in an organized manner. The zone-style layout is favorable for professional kitchens that accommodate multiple dishes at a time. The zone layout allows food handlers to focus on their tasks.

Commercial kitchen zoning layout

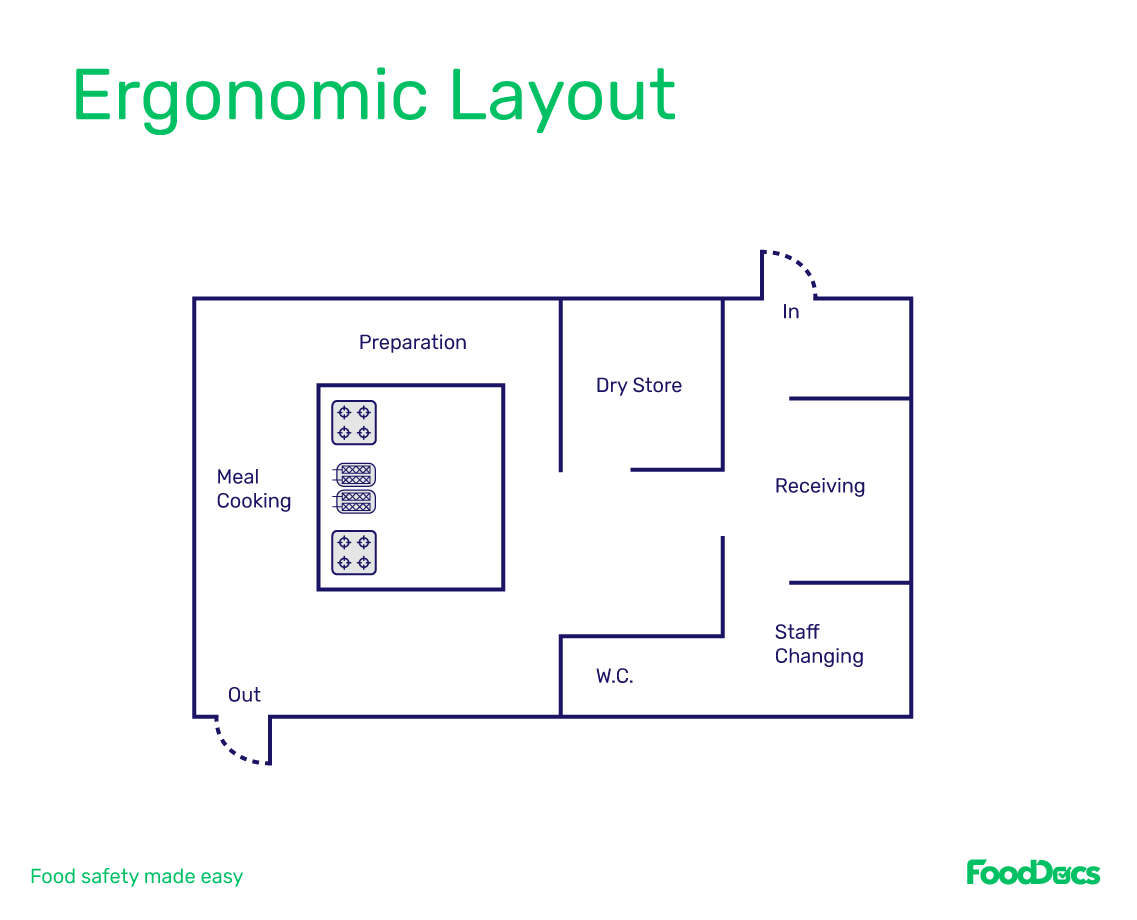

The ergonomic layout prioritizes the food handlers' ease of movement and comfort. This layout reduces the unnecessary space between closely related operations to minimize movement and save energy. Pieces of equipment and ingredient stocks are stored close to each other to speed up the food service process.

With items near the equipment and catering appliances intended for processing, food handlers would only require a limited space between prep tables to operate well.

Commercial kitchen ergonomic layout

5. Open layout

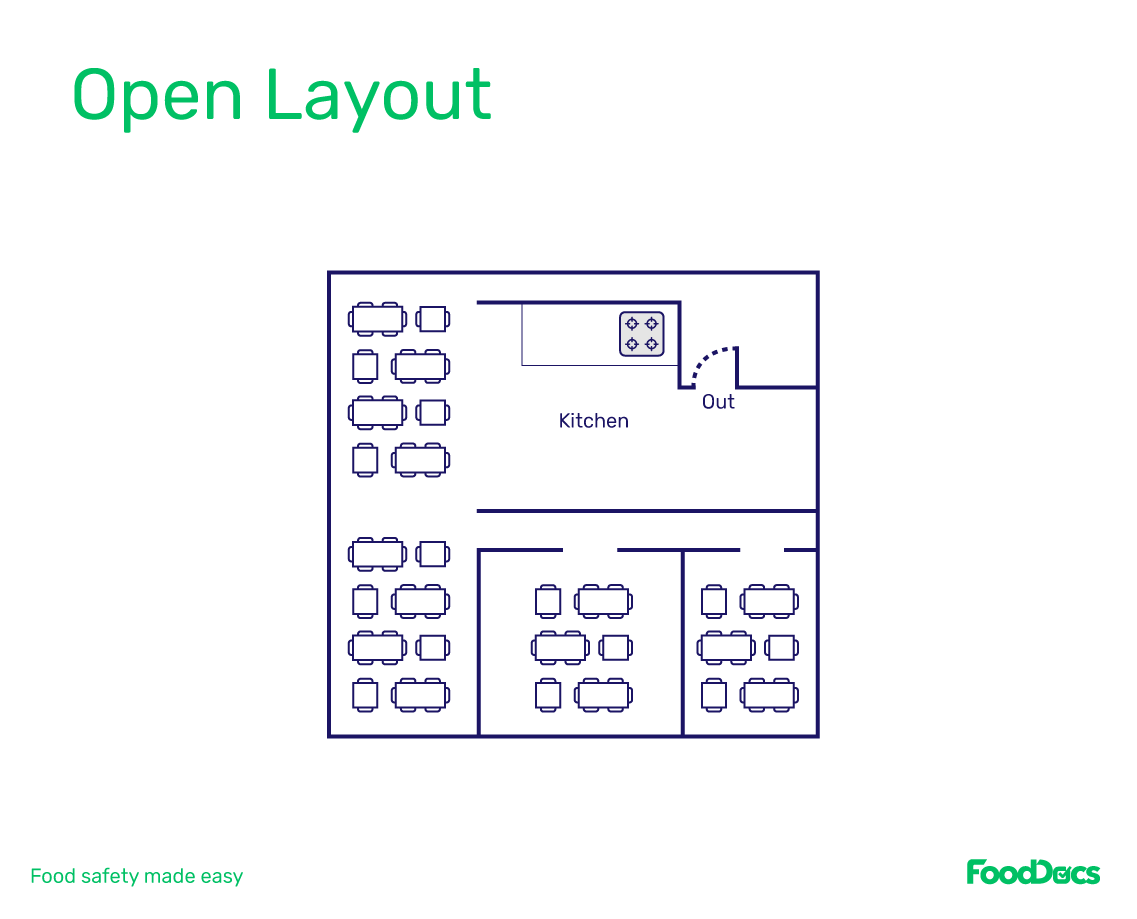

An open layout for a commercial kitchen is one where customers or the front-of-the-house section has visual access to the kitchen. This means that people from outside the kitchen can see the food service process happening inside.

This type of layout provides a unique dining experience, especially for larger facilities, and is increasingly becoming popular in high-end type of restaurant kitchen displays. In an open layout setup, insulation may be a priority to prevent the heat from the kitchen from transferring to the service area. The layout improves the speed of service with the short distance between the kitchen and the delivery area.

Commercial kitchen open layout

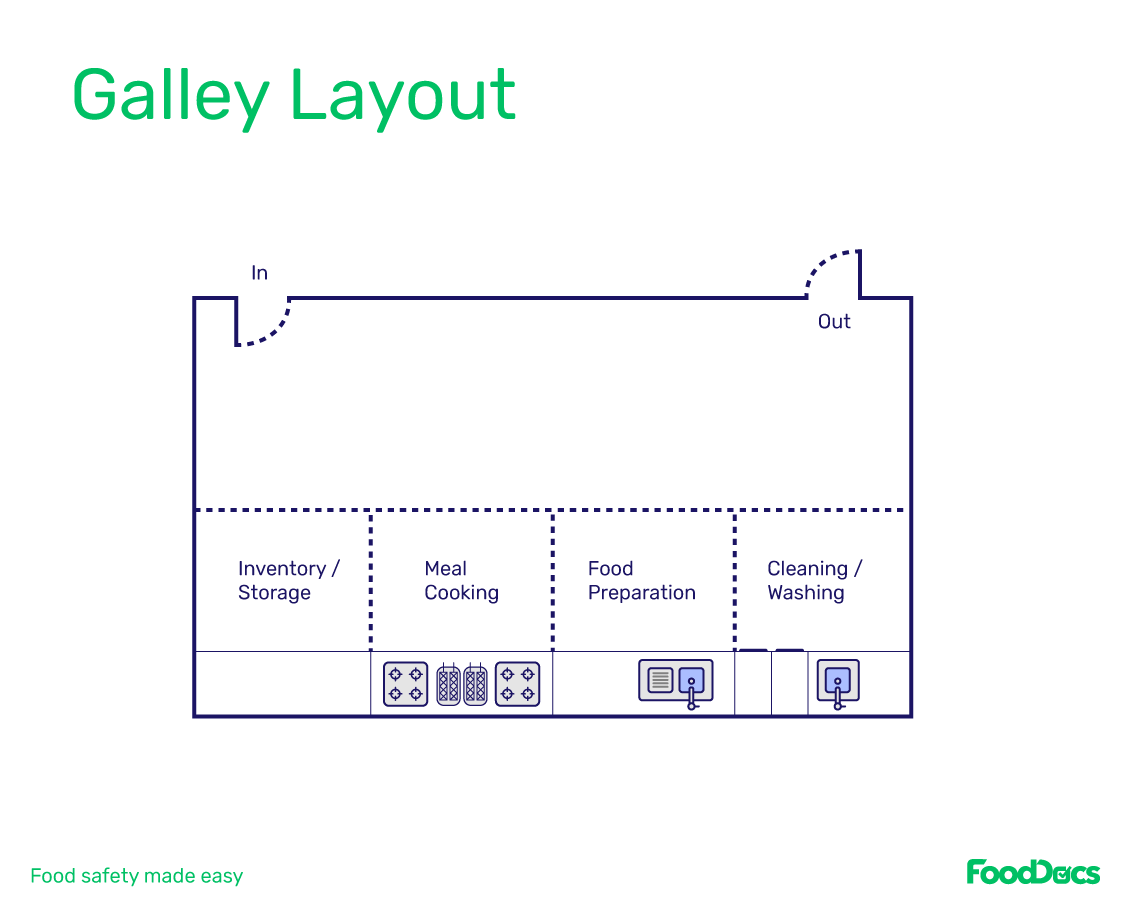

The galley layout is often a good choice for a smaller commercial kitchen with limited space and kitchen environment. It optimizes the space and kitchen functions by placing all stations within the food premises. The layout allows easy access to other sections by providing a common space for movement in the center of the kitchen of any type of restaurant.

Commercial kitchen galley layout

Choosing the correct kitchen layout can improve your operations and optimize your food service process through a conducive kitchen environment. It is a significant operation to ensure your business can work at its best. The wrong kitchen layout can lead to the unoptimized potential of the kitchen and translate as a wasted opportunity. Additionally, this can lead to a higher risk of accidents and increase food safety hazard occurrences in any type of restaurant.

Small commercial kitchens require layout decisions that prioritize workflow efficiency, food safety, and space utilization over idealized design.

In limited spaces, layouts are typically adapted rather than implemented in their full form. Common approaches for small commercial kitchens include:

For small kitchens, the most effective layout is often the one that:

Rather than choosing a layout type alone, small commercial kitchens benefit most from combining layout principles to suit their specific menu, equipment, and staffing levels.

A good commercial kitchen design or layout provides a significant advantage to food businesses. It is a key element in achieving optimum operations and boosting product output. A correct facility layout will reduce the likelihood of problems, such as accidents or downtime due to inefficient kitchen staff and machines.

In particular, a commercial kitchen layout can provide the following benefits to your operations:

The benefits of having a correct facility layout can only be achieved with an appropriate plan. The layout will depend on the operations that the commercial kitchen will target to accommodate. What you need is a versatile solution to building a commercial kitchen layout.

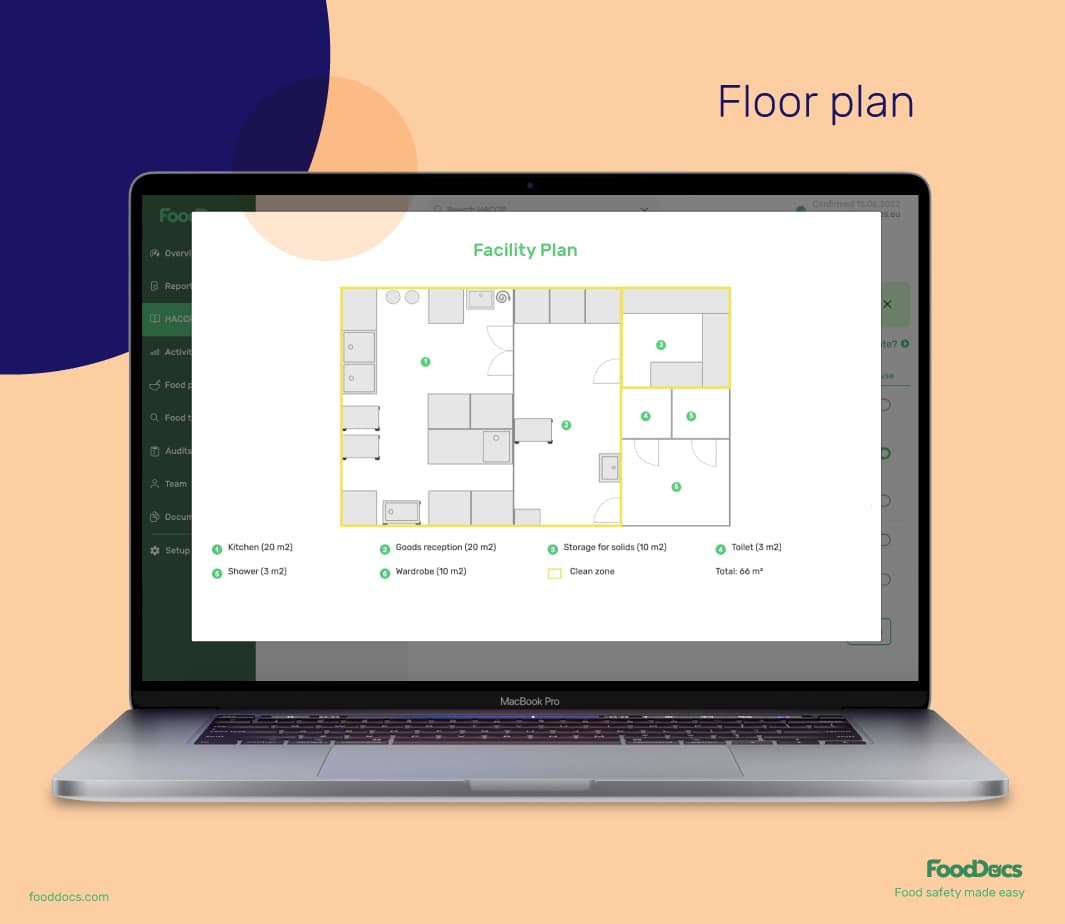

The FoodDocs digital HACCP plan builder features an easy way to create your kitchen layouts and food location plan. Our software can help you create your business layout as easily as using the drag-and-drop method in our application. Additionally, build plans for water and sewerage, equipment, and logistics plans with our software and get a complete HACCP plan with it.

Commercial kitchen layout design plays a direct role in food safety compliance.

An effective layout helps:

Regulatory authorities often assess whether a kitchen layout allows food to be handled safely and cleaned effectively. Poor layout design can increase food safety risks, even when procedures are in place.

For this reason, layout design is commonly reviewed as part of food safety management systems and inspection processes.

Designing a commercial kitchen and building a spacious layout requires several careful considerations and restrictions. Every country has its own regulations and public health laws regarding which facilities are mandatory for a commercial kitchen and which are less of a priority.

To help you logically build your commercial kitchen layout plan, use the following steps as a guide:

When designing a commercial kitchen layout, you must consider the following universal factors:

While considering these factors, build your commercial kitchen floor plan by involving your executive chef, appointed supervisor, and other key employees. As they are the ones working firsthand in the kitchen, they will have valuable input for the layout.

You can consult a commercial kitchen designer to help design your commercial kitchen layout while considering important regulations, such as standards for food storage. Use our digital solution at FoodDocs to effortlessly create your layouts in the most efficient way while considering the location of your food business.

The requirement for a fire door can be case-to-case in the US and UK food industries. In general, kitchen traffic doors are not required to be fire doors, whereas the doors that lead to the service area and waste disposal rooms must be fire doors.

Floor drains are vital for a commercial kitchen. A food business must have an adequate drainage system in the U.S. and under the FDA Food Code as well as the building health codes in the U.S. Similarly, the installation of a system that removes waste water quickly to prevent food contamination by bacteria is required by UK regulations.

There is no minimum size for a commercial kitchen. Despite this, the average size of a commercial kitchen is estimated to be 1000 square feet. This information is based on a recent poll to determine the elements that affect the start-up costs for a restaurant. Specifically, the average calculated size for a kitchen is 1,051 square footage.

At a minimum, every commercial kitchen must have two sinks: one dedicated sink for washing and rinsing food equipment and cooking tools and another solely for handwashing. The dedicated sink for warewashing is recommended to be a double or three-compartment sink to wash and sanitize food equipment properly. The dedicated pot wash sink must not be used for other purposes to avoid the accumulation of food waste.

Apart from food preparation sinks, a separate janitorial sink with hose connections is also recommended. This janitorial sink must be placed away from the food preparation area to prevent water droplets from contaminating cooked and raw products. All types of preparation sinks must have a regulator for water temperature. Correct water temperature in sink is essential for proper cleaning.

Depending on the size of your commercial kitchen, the number of dedicated sinks may increase. All preparation sinks must be properly labeled to dictate their purpose and avoid cross-contamination of products.

Building a commercial kitchen is almost similar to creating any other food business. The main difference is that a commercial kitchen least prioritizes having a service area since the establishment focuses on producing big batches for other food businesses.

A commercial kitchen would require a business plan that contains all of the necessary plans for the establishment, including:

In addition to the business plan, you would also need to procure food equipment and large machinery to operate high volumes of orders. In compliance with regulations, you would also need to secure licenses and permits, such as the following:

After securing licenses and permits for a food establishment, your commercial kitchen operations must have an established food safety plan to address food safety hazards. The most widely known and effective food safety plan is the Hazard Analysis Critical Control Point plan or HACCP plan. With the help of AI, you will get your HACCP Plan done within an hour.

Commercial kitchen planning also entails choosing the correct materials for your infrastructure and the equipment and utensils used for your food establishment. Based on prerequisite programs, kitchens must be built in accordance with minimum food safety standards. The materials used to build the kitchen must be hygienic, easy to clean, and will not attract accidents. This commercial kitchen design principle must be applied from the kitchen walls up to the smallest details, such as your electrical outlets.

Consider the following points for the design process of your commercial kitchen:

Designs and materials for building your commercial kitchen must always follow local and federal food safety regulations. Some laws may require particular material grades for safety, while others may be a bit lenient. The design of your commercial kitchen must always prioritize safety for both your employees and the food being prepared.

The difference in the description between businesses may entail differences in governing regulations. Below, we show some of the significant commercial kitchen layout regulations for the US and the UK.

In the US, waste management guidelines are provided under the FDA Food Code to prevent having a dirty kitchen. Some of the key items regarding waste management under this document include the following:

Similar food waste regulations concerning the kitchen layout are provided by the Food Standards Agency (FSA) in the UK. They are backed by other food safety laws, such as the Water Industry Act 1991. This law mainly identifies mishandling food waste and dirty items, including the uncontrolled discharge of fats, oils, grease, and other examples of food wastage, as a criminal offense.

The FSA provides regulations on managing food waste through a proper layout for food premises, such as the following:

The National Fire Protection Association (NFPA) provides codes and strict standards for food establishments in the US. Since the commercial kitchen environment is filled with fire hazards, regulations are strict. For example, commercial cooking equipment in a kitchen requires an individual protection system, as stated under NFPA 96. Under this code, all cooking equipment must have a hood or a duct system.

The code also specifies that high-risk food environments such as broilers, cold storage equipment, and dry storage space must have fire suppression systems. It also specifies the need for exhaust fans, grease containment, and the frequency of cleaning hoods.

In the UK, fire regulations require clear and properly placed fire exits, extinguishers, proper ventilation systems, and alarms to suppress any cases of fire within the kitchen environment. These restaurant fire safety measures must be clearly represented in the layout. Regulations also require that doors and other openings have the same fire rating as commercial kitchen wall surfaces.

In determining the layout of commercial kitchen, the safety of food handlers and the food being prepared are priorities. The kitchen environment must always include careful consideration of safe working conditions for every employee and how to minimize food safety hazards.

As a law in the UK, commercial kitchens are subject to establishing a HACCP food safety plan. This food safety plan identifies and addresses food safety hazards before they occur. Other laws that pertain to food safety in the UK include The Food Safety Act of 1990 and the General Food Law Regulation (EC) No 178/2002.

In the US, food establishments dealing with meat and poultry are mandated to have individually established HACCP plans. A comprehensive risk-based preventive program is required under the Food Safety Modernization Act for other food products prepared in a commercial kitchen. 2

To help you maintain compliance with food safety regulations, use our free resources from our HACCP plan template hub.

A complete and accurate layout or floor plan for a commercial kitchen is essential to your documentation and correct facility plans. Some food establishment owners hire experts to draft, visualize and implement the commercial kitchen layout as the task requires knowledge of safety regulations and even ergonomics.

Building a floor plan for your commercial kitchen can cost you a lot, even before you start your operations.

FoodDocs can help you automatically create your commercial kitchen layout and food location plans with our digital solution.

Instead of using the traditional way of building a food safety plan that takes months of preparation, verification, and implementation, you can create one ready for implementation immediately.

The solution can get the job done as easily through the following:

In addition to a floor plan, our digital solution can help you comply with other water and sewage systems regulations, equipment plans, and logistics. These plans use a similar drag-and-drop method to build a layout in minutes.

This digital solution is part of our main food safety software. FoodDocs strives to help food establishments effortlessly create food safety plans. Our digital HACCP plan builder was developed to automatically create a comprehensive digital HACCP plan with the following benefits:

Did you know that our system will automatically generate a HACCP plan with the following components based on your answers?

The entire process of making your digital HACCP plan can be done in just 1 hour. You can get a comprehensive plan normally done for months in just a few steps, and it can already be implemented immediately.

Our system aims to make all components of food safety accessible for all food premises. Allow our software to help you set up your commercial kitchen for success. The best part is that you can try the software for free for 14 days.

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

Get a clear and complete breakdown of the most common Critical Control Point examples in HACCP for biological, chemical, and physical hazards.

The HACCP allergen control program is one of the crucial prerequisite programs of an HACCP plan. These are the key components and goals of using one.