Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Different food safety hazards cause different reactions and foodborne diseases. As part of a food manager's responsibility, food handlers must be trained well to properly identify and address these physical, chemical, and biological hazards promptly and is part of a larger food safety program.

The first step to making sound strategies on how to address these potential hazards is to familiarize food workers with them. Each food safety hazard has the potential to cause any foodborne illness or injury with varying degrees of potential damage.

Food safety hazards are any substance or material that causes foodborne illnesses or food-related injuries, whether mild or severe, to consumers when ingested. Naturally, where there is food, there is a food safety hazard. Some hazards are naturally present in food or even food handlers. Despite this fact, food safety hazards can be controlled or even eliminated. Proper food safety and hygiene practices are keys to this task. To do this, your team must first identify the present food hazards.

The main 3 categories of hazards that make food unsafe include:

Each type of hazard represents a group of harmful factors that can contaminate food production at any point. They can be introduced through cross-contamination or through other external factors connected with the food supply chain.

The point of entry for hazards starts at the farms where raw materials are produced and ends until the finished product reaches the table of the consumers. Detection, analysis, and strategies for the handling of each type of hazard will significantly vary depending on their nature.

Food hazards can naturally be present or synthetically introduced to food materials. They can be easily prevented from causing further damage by early detection and properly placed food safety precautions. Most foodborne illnesses are widely known to be caused by biological hazards, but in reality, physical and chemical hazards can equally bring the same effects. In this section, we will be discussing each hazard, common examples, ways to prevent them, and notable cases of food-related issues.

These hazards are often detected as actual objects or any foreign material that can cause injuries when ingested and can sometimes become precursors of other types of contamination. These objects in food can be sharp, hard, and rough and can easily cause cuts, bruises, or choking. Some physical hazards, although not likely to cause injuries, can bring about other hazards such as bacteria and viruses.

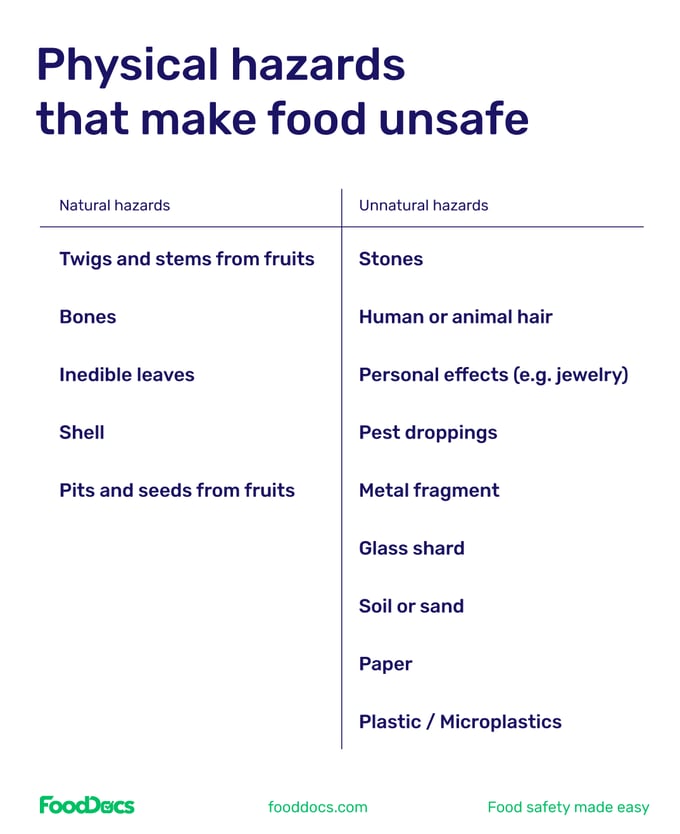

Physical hazards can either be natural or unnaturally present in foods. Natural physical hazards include pieces that are part of the food being processed. On the other hand, unnatural physical hazards are foreign objects introduced to the food from the surrounding environment.

Here are a few common examples of physical hazards that can normally be seen in a food production process.

By comparison, physical hazards are easier to spot than biological or chemical hazards. They are significantly bigger and some physical contaminants in food businesses distinctly stand out from a batch of food. Regardless of this fact, physical contamination is a widespread problem in the food industry. In the US alone, the presence of foreign materials has been declared as the leading cause of food contamination and recalls for only the first half of 2019. During this year, the majority of the detected foreign materials included metal, rubber, and plastic. This report also noted that the cases of physical contamination in the first half of 2019 were significantly higher than that of the whole of 2018.

Here are some notable cases of food recalls due to foreign materials:

As mentioned, unlike pathogens and chemicals, physical contaminants are significantly larger and some pieces can be readily seen. Despite this, it does not mean that physical hazards can be taken lightly. Some contaminants such as common pest droppings and hair would be hard to detect from a bag of raw materials. To effectively prevent physical hazards from entering the food supply chain, here are a few tasks that you can implement in your food business:

Practice good manufacturing practices. These practices involve basic food safety and hygiene tasks such as wearing proper attire during production, avoiding wearing jewelry, keeping all loose items close, keeping nails neatly trimmed, and using a hairnet in the kitchen area.

Thorough inspection. During raw material receiving, food handlers can be properly oriented on how to spot field contaminations such as stones, twigs, chunks of soil, and others. Although a simple solution, the preparation process such as prewashing or cleaning raw materials also helps significantly remove physical hazards.

Advanced inspection systems. Machines such as magnets, metal detectors, or more advanced and artificial intelligence-powered detection systems can significantly and efficiently help food handlers remove physical contaminants.

Identify and remove potential sources of physical hazards. Pests are perhaps one of the greatest sources of physical contaminants. Hair, droppings, nibbled foods, or damage to products can easily work their way into your kitchen. Clean areas that can serve as hiding places for these pests and implement proper food waste management and pest prevention programs.

Read more about physical hazards.

These hazardous agents include different types of microorganisms such as bacteria, molds, yeasts, viruses, and parasites that can cause foodborne illnesses and are collectively known as pathogens. Biological hazards can either be naturally present in foods or introduced through contamination. They differ from beneficial microorganisms in the sense that they can harm consumers and potentially cause death in severe cases. Naturally occurring pathogens in foods or in food handlers can also be transmitted to other foods in a phenomenon called cross-contamination.

Different food items have an affinity to some microbiological hazards. Some are even considered high-risk foods because of their significant likelihood of getting contaminated. That is, particular pathogens are more often seen in one type of food than in others. This is the case for Salmonella bacteria in foods made from poultry meats and eggs. Other pathogens generally come from very common sources such as E.coli bacteria in contaminated water and Staphylococcus aureus on the skin of food handlers.

Here are a few more common biological hazards examples that have been reported to cause significant foodborne illnesses:

Each year, at least 600 million cases of foodborne illnesses occur in the world. Among these cases, at least 420,000 lead to death. The majority of these cases, if not all, are caused by contamination of food by microorganisms that have stemmed from inappropriate or inadequate food handling practices. Over the years, biological food contamination has prompted revolutionary changes in the food safety policy of different countries.

Below are some significant cases of contamination of food by biological hazards:

Despite the natural presence of some biological contamination in food materials, these hazards can be controlled. Established food safety and hygiene practices are keys to preventing these hazards from multiplying. Below are a few methods that every food business owner can do to control biological hazards:

Read more about biological hazards.

Chemical hazards are natural or synthetic substances that can cause significant health problems when ingested or inhaled. These hazards can be part of a food product or a chemical introduced into the system either as food additives or accidentally. Natural chemical hazards are usually part of raw food such as natural toxins produced by some animals. A popular example would be the scrombrotoxin from fishes that have high levels of histamine. Another example is the toxins that some mushrooms may have.

Chemicals that are generally safe but used in excess can also be considered a form of food poisoning. Preservatives such as sulfites are commonly used as an antifungal agent for bottled juices but only at regulated levels. In excess, this chemical can trigger allergic reactions and can sometimes be fatal. Other chemical hazards can come from machines such as oils or residues of cleaning agents. In addition, chemical hazards can also be an indication of temperature abuse such as in the case of acrylamide. This chemical is a by-product of cooking foods at an excessively high temperature.

Chemical hazards, like biological hazards, are hard to detect without proper testing. They can originate from various sources and dangerous products and can significantly harm consumer health.

This list includes some of the most common chemicals that can be associated with food products:

Chemical food poisoning is a substantial food safety risk to public health. Therefore, contact with food should be very limited and monitored. Exposure to some chemical hazards can cause long-term effects which can lead to chronic illness.

The effects of these hazards on humans may depend on the number of chemicals consumers may have been exposed to. In 2015, a consulting firm estimated that the effects of chemical hazards have resulted in more than 1 million illnesses, of which 56,000 deaths occurred worldwide.

Here are some food-related issues caused by chemical contamination in food businesses in the past:

From 1998 to 1999, one of the first recorded intentionally caused foodborne outbreaks occurred. At least 107 people fell ill due to pesticide-contaminated salt from a restaurant. The salt was found to be highly contaminated with methomyl, a very toxic pesticide.

In 2010, the Dallas County Health and Human Services reported the occurrence of acute onset of illnesses among the customers of a restaurant. The case was pinned as a chemical poisoning event which was later speculated to have originated from the served iced tea. The tea was found to contain hydrazoic acid which forms sodium azide, a toxic chemical, upon contact with water.

One of the biggest food safety controversies involving chemically-tainted foods is the case of dairy products contaminated with melamine in China. In 2008, a Chinese company made headlines as authorities unveiled that the milk powder from an ice-cream maker introduced to the market is the culprit for widespread chemical poisoning. At least 300,000 people fell ill from unknowingly consuming the contaminated products. Of these victims were 6 infants who eventually died.

Read more about chemical hazards in food.

All three types of hazards that make food unsafe can be efficiently prevented using a clear, and comprehensive food safety management system (FSMS). This management system must include directions for proper food handling techniques, personal hygiene practices, and monitoring control procedures for all food safety operations.

FoodDocs' digital Food Safety Management System does all of heavy lifting for you, making it easy to maintain compliance and monitor these food safety hazards for a safer daily operation.

Switching to our digital platform won't even take too much of your time. In just an average of 15 minutes, our system will automatically set up a digital FSMS built based on your food safety operations. By answering a few questions about the type of food service you offer and the nature of your operations, our system, powered by artificial intelligence, uses this information to automatically tailor a digital FSMS to fit your food business.

The main features of our system are automatically generated digital monitoring forms and checklists for your food safety operations. These monitoring forms can be further customized to accommodate unique tasks or modify suggested operations.

This provides flexibility to your digital FSMS. These monitoring forms can also be set to auto-fill settings and our system will automatically input data based on the previous information logged. This saves your team a significant amount of time and would only need to verify data entries.

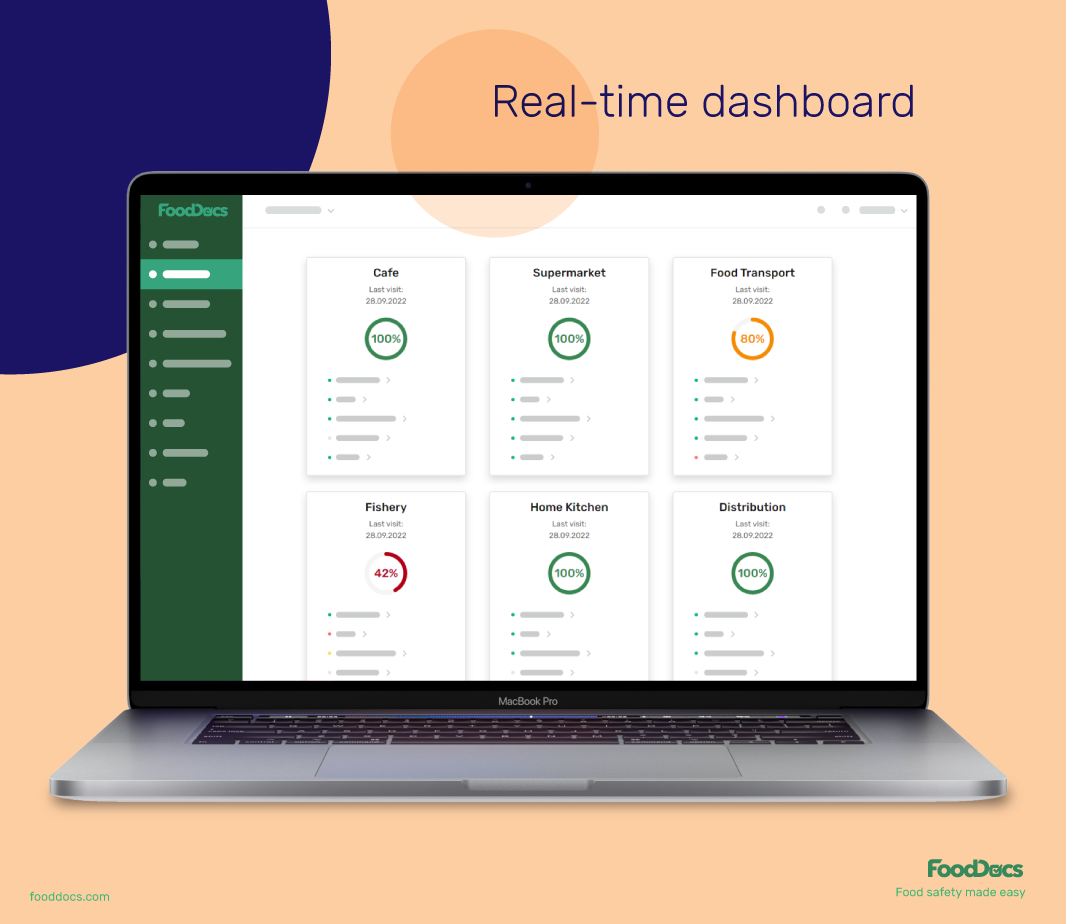

Never forget any food safety task with our smart notification system. Using our mobile application, our system sends out notifications for any food safety task that is due to be done. You can also create a more efficient workflow and save at least 20% of your time from supervising using our real-time dashboard.

This feature collates your everyday information and shows areas that would need more attention for improvements. You wouldn't even have to worry about where to store all of the data you generate. You will also get cloud storage for your food business where you can store and arrange all information with easy access.

Our system was built by food safety experts for food handlers. You can get the expertise of a food safety consultant and ensure a high-quality digital FSMS that can help you stay compliant all the time. With artificial intelligence, our system can incorporate and cover all significant food safety hazards related to the nature of your food business.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...