Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Handwashing is one of the most effective ways of helping reduce the occurrence of foodborne illnesses.Let's answer this question right up front before getting into more details (and free handwashing resources) below:

Food workers can wash their hands in a designated handwashing sink or an approved automatic handwashing station. However, employees may not clean their hands in sinks used for food preparation, dishwashing, or any other service-related activities.

One of the fastest ways of spreading contamination in any kitchen is through a food handler's hand. Unclean hands can unknowingly transfer pathogens from one place to another and become the source of a foodborne illness outbreak.

A very slight contact of unclean hands with a clean utensil can contaminate the utensil and cause indirect cross-contamination in food.

WHAT WE'LL COVER:

In fact, there are several infections, foodborne and not, that can be transmitted when proper handwashing is not followed. Every food business must require proper and frequent handwashing for their foodservice employees as part of their approach to food safety, but where can a food worker wash her hands?

Handwashing is a basic part of food hygiene. The Center for Disease Control and Prevention (CDC) mentioned that proper handwashing education can reduce the number of people who get sick with diarrhea by 23-40% and diarrheal illness in people with weakened immune systems by 58%.

To fulfill the intended objectives of handwashing, food handlers must be aware of how and when to properly do it. Food handlers must also learn about the basic principles behind the operation. Of course, an additional minimum requirement for handwashing is to provide areas for it.

Handwashing is a simple solution and the key to avoiding the spread of foodborne illness-causing pathogens in a food establishment. Many reports have already proven that proper handwashing significantly reduces the risk of foodborne illnesses. In fact, the CDC has put so much value on this operation that they estimated that at least 1 million deaths per year can be prevented if everyone washed their hands routinely. It is the best defense against food contamination.

Food workers are known as one of the main carriers of harmful pathogens. Not only can they transmit harmful bacteria from one point to another, but they are also sources of these pathogens. Bacteria such as Staphylococcus aureus, a known potent pathogen are considered an indicator of poor food hygiene and naturally live on different human body parts – mostly the skin.

Food handlers hold more than the foods that they prepare. Every food handler also touches food contact surfaces, doors, utensils, aprons, and other objects at different given times in a shift. As part of food hygiene practices, food handlers are required to wash their hands before, during, and after food service.

Handwashing, although a seemingly easy task, requires proper execution to be effective. Pathogens can work their way underneath the nails of food handlers as well as in between fingers and the wrist. A food establishment must supply warm running water for handwashing. Additionally, handwashing tools such as a brush, soap, and disposable towels. As such, certain steps are recommended to ensure that this operation is effective.

Although there are more related steps to handwashing, 6 steps of handwashing for food handlers are well-emphasized in any food establishment:

After washing their hands, food workers are expected to handle any raw and cooked or ready-to-eat food. Touching anything else in between may increase the risk of cross-contamination. Handwashing must always be paired with regular and correct practices for cleaning utensils, equipment, and food contact surfaces. With both operations regularly executed, the risk of causing contamination to food that could lead to foodborne illnesses is significantly reduced.

We've mentioned the 6 basic handwashing steps. In addition to these basic steps, there are more specific tasks that must be done to ensure that handwashing is effective. When washing your hands, all corners must be lathered with soap. When necessary, you can also use a soft brush to dislodge dirt. A brush can be necessary when food workers are handling ingredients that stick to their hands such as flour when kneading dough.

Specifically, we encourage you to wash your hands using these easy steps:

Notice in this set of handwashing routines that all corners of the hands are rubbed with soap and washed. Microorganisms can work their way around and grow underneath the nails of food handlers. In addition, some people forget to include the wrists when washing their hands. These areas are all significant points where pathogens can stay and potentially recontaminate the hands.

Additionally, take note that food handlers must only use a clean towel or tissue to dry their hands. Using a hand drier increases the risk of recontaminating the hands of food handlers. They must also avoid touching the faucet with their recently cleaned hands, rather use a clean paper towel to ensure that the hands would not get any pathogens from the faucet.

To help your team remember every step for proper handwashing, use one of our food safety posters at FoodDocs.

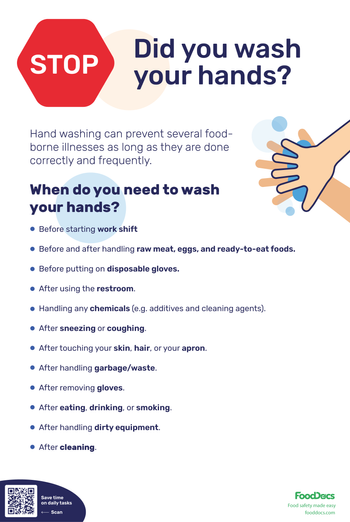

Downloadable handwashing poster from FoodDocs

Downloadable handwashing poster from FoodDocs

All food handlers must wash their hands for at least 20 seconds. This amount of time is enough to cover all areas mentioned in the previous section as well as ensure that any residual dirt is removed. Alternative to manually counting your handwashing time, the CDC recommends silently singing the song "Happy Birthday" twice in your head. This set of songs is long enough to cover the whole handwashing process.

Frequent handwashing can help food handlers minimize the risk of causing foodborne illnesses, but when is it really necessary to wash your hands? Generally, food handlers must wash their hands after handling anything besides the food they are preparing. Handling anything, even a pen or wiping your hand on your apron can contaminate a food handler's hand.

Specifically, here are some common scenarios that will require you to wash your hands:

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

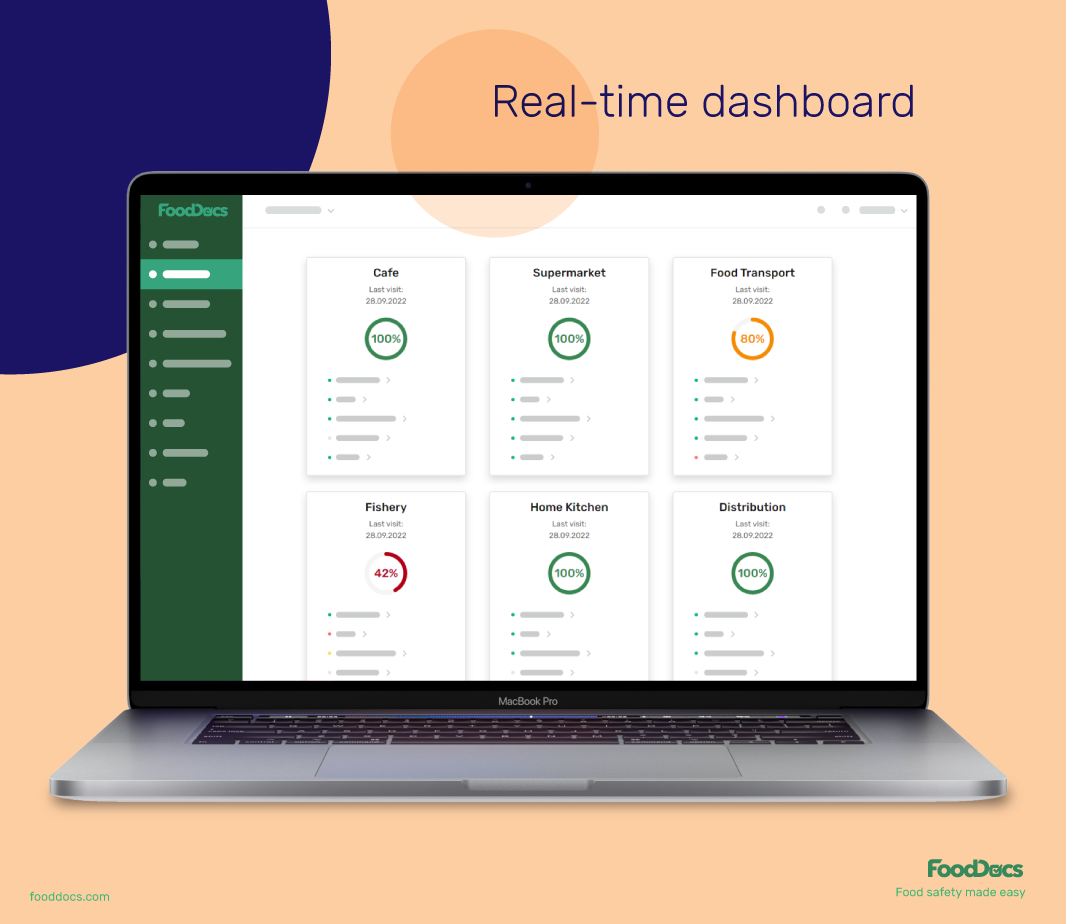

Handwashing is a basic part of food hygiene and is required to be performed regularly. To achieve this, every food safety team's food safety management system must be effective and constantly working for your team. FoodDocs offers a smart, digital solution for this.

Our digital Food Safety Management System (FSMS) is powered by artificial intelligence that can significantly help your team become efficient by implementing an intuitive notification system. With this feature, food handlers are alerted of any food safety task that needs to be done. We've also got a step-by-step guide on how to choose food safety management software.

And just in case you thought that Google knew everything...

The FDA Food Code 2017 provides several regulations regarding handwashing and related operations. As per the Food Code, all food handlers are required to wash their hands on a sink that is dedicated to handwashing only. Other sinks may be present in a kitchen area such as for janitorial operations, food preparation, and handwashing.

As such, following rules on the placement, number, and required handwashing tools are provided by the FDA Food Code. Under the Food Code, handwashing regulations apply to the following:

Specifically, the FDA recommends every state in the US to adopt the following regulations:

Remember that handwashing sink regulations may vary depending on the approved food safety laws and regulations being implemented by your local authority. As such, it would be most convenient to consult them for any specific instructions such as the placement of your sink, which can significantly affect the design of your kitchen.

As a general rule, food handlers are only allowed to wash their hands using a dedicated handwashing sink. These sinks must be placed conveniently near food preparation and service areas. Food handlers are not allowed to use sinks that are dedicated to preparing foods, nor sinks used for janitorial operations. Similarly, handwashing tools such as brushes, soaps, and other utilities cannot be used for other areas of the kitchen.

In deciding where should handwashing sinks be located, always consult your local health authority. In the US, 1 handwashing sink is required to be located inside a food preparation area where it must be conveniently accessible for food handlers. Additionally, handwashing sinks must also be available either inside or adjacent to a toilet room.

Commercial or regular kitchens are required to have separate sinks for handwashing as well as for washing equipment and utensils. There are set separate food regulations for the use of a warewashing sink and utility sink.

In the UK, hand basins are required for proper handwashing procedures. The UK is quite clear when it comes to regulations on hand basins. At least 1 hand basin must be available for every 25 people in the food establishment. Hand basins must be clearly designated and given proper labels for the proper identification of users. Hand basins for food preparation must never be used for other operations other than the indicated.

Food hygiene regulations consist of very broad topics. One of the most important food hygiene regulations would have to be handwashing. This operation must always be part of the food safety program and training provided by the food safety manager to the employees.

Other food safety tasks such as proper cooking, storage, regular cleaning, and an overview of your sales and progress must still be kept in place and monitored. What if there was a smart and more efficient way to lift the burden of monitoring your food safety tasks from your shoulders?

At FoodDocs, we have considered these concerns and have come up with the best solution. Using our digital Food Safety Management System, your team will never forget any food safety tasks and will always be able to do them on time with proper monitoring.

With the help of our digital solution, you can get the following features that can significantly help you maintain a high level of food hygiene:

To help managers improve food safety compliance efficiency and effectiveness, our digital FSMS was built with the following features:

Our digital FSMS was built to make food safety compliance accessible and easy to follow for all food businesses. The best part is that using our digital FSMS, you can get a comprehensive system in just an average of 15 minutes. Our process would only require you to answer a few basic questions about your business. After completing the questions, our system will automatically generate a digital FSMS based specifically on your food safety tasks!

In addition to a digital FSMS, we can also help you easily generate the most important documents for food safety compliance such as your HACCP plan. With artificial intelligence and smart software, we can help you digitize all of your existing documents, including your layout plan. Our built-in customizable HACCP plan template can be used to redesign your floorplan layout. You can now easily decide where to put handwashing sinks and other necessary sanitation equipment.

Interested in experiencing our services? We offer a free, 14-day trial that you can use to explore our digital FSMS product and discover the convenience and efficiency that we provide.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...