HAZARD ANALYSIS TEMPLATE

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

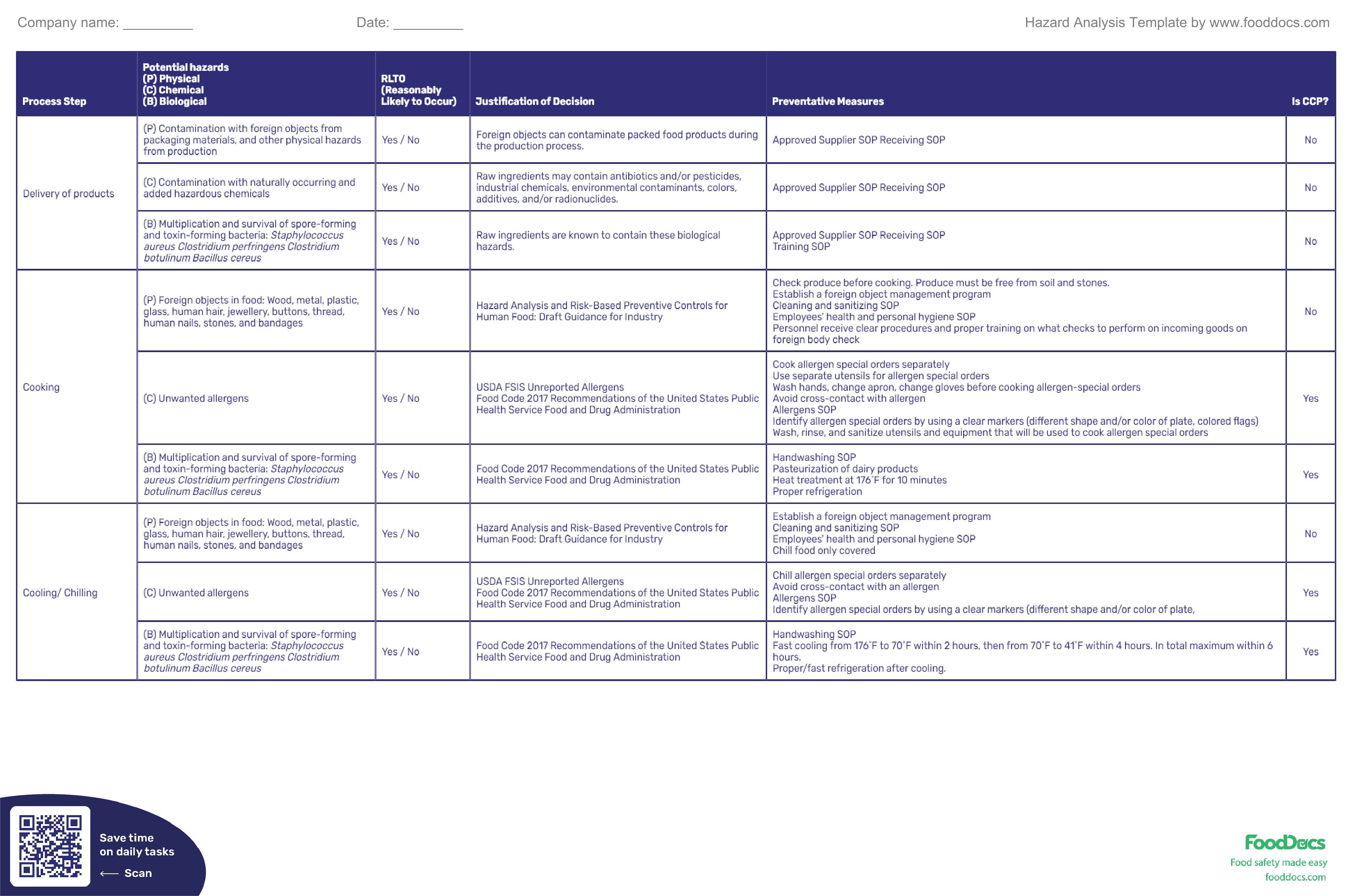

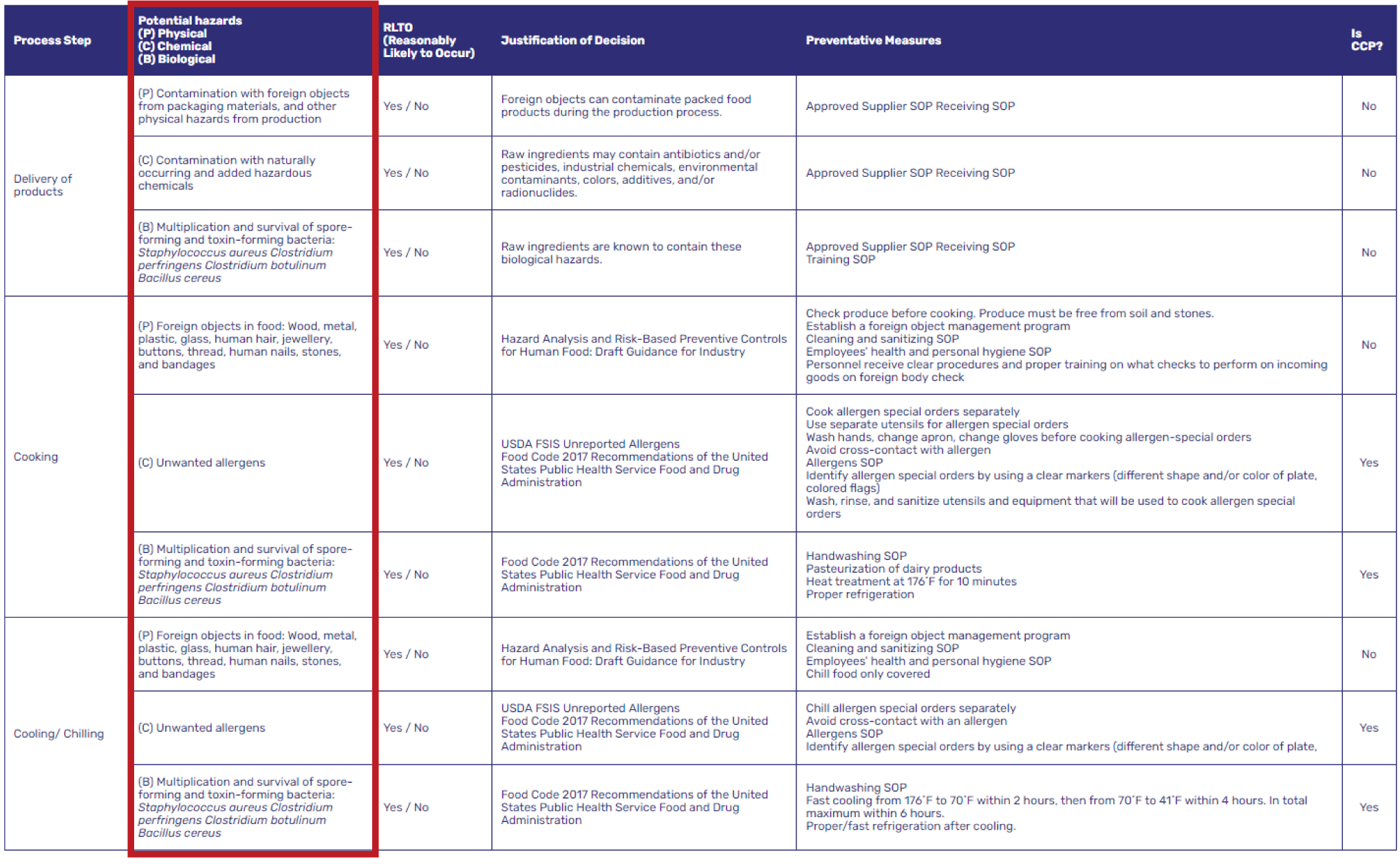

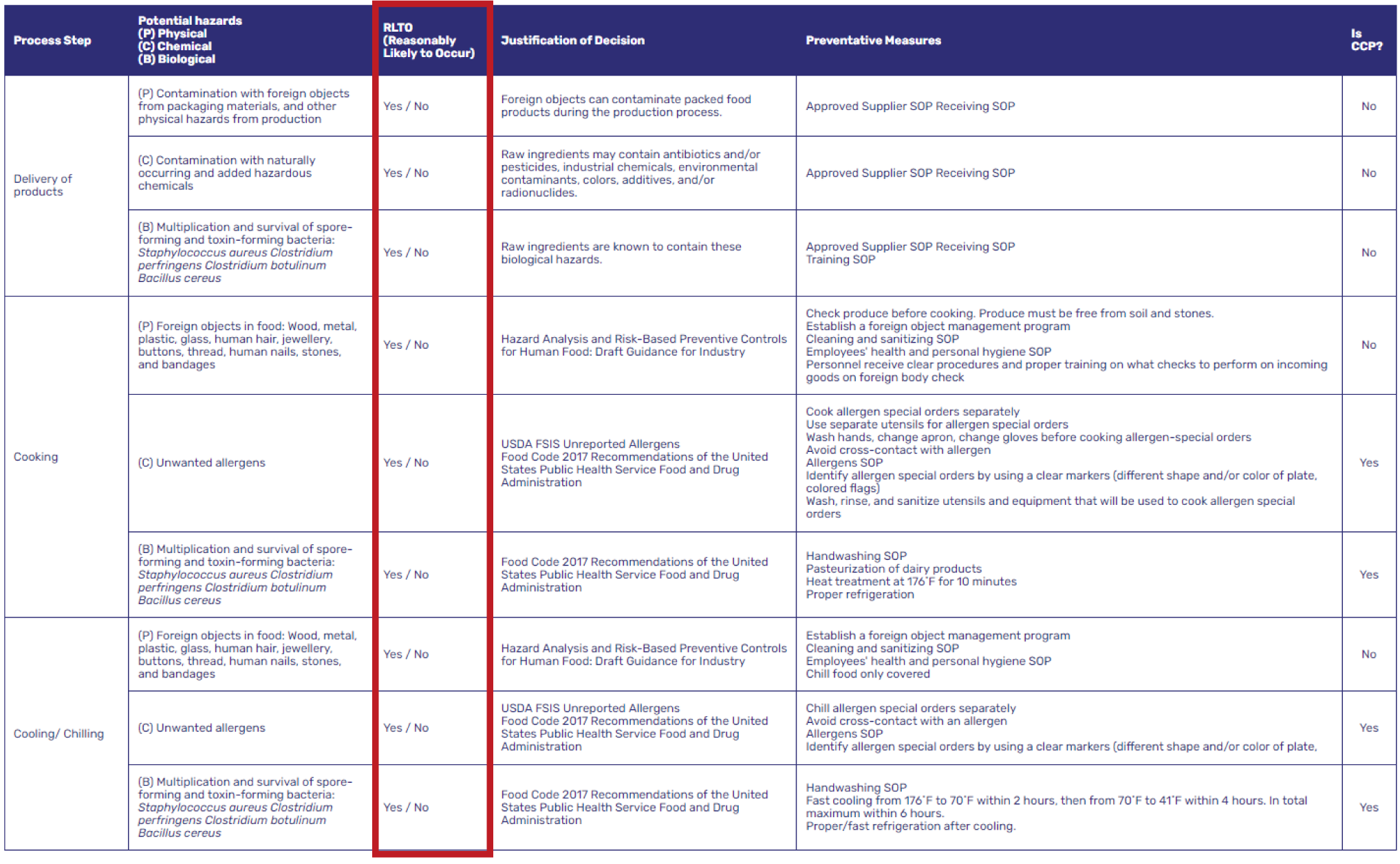

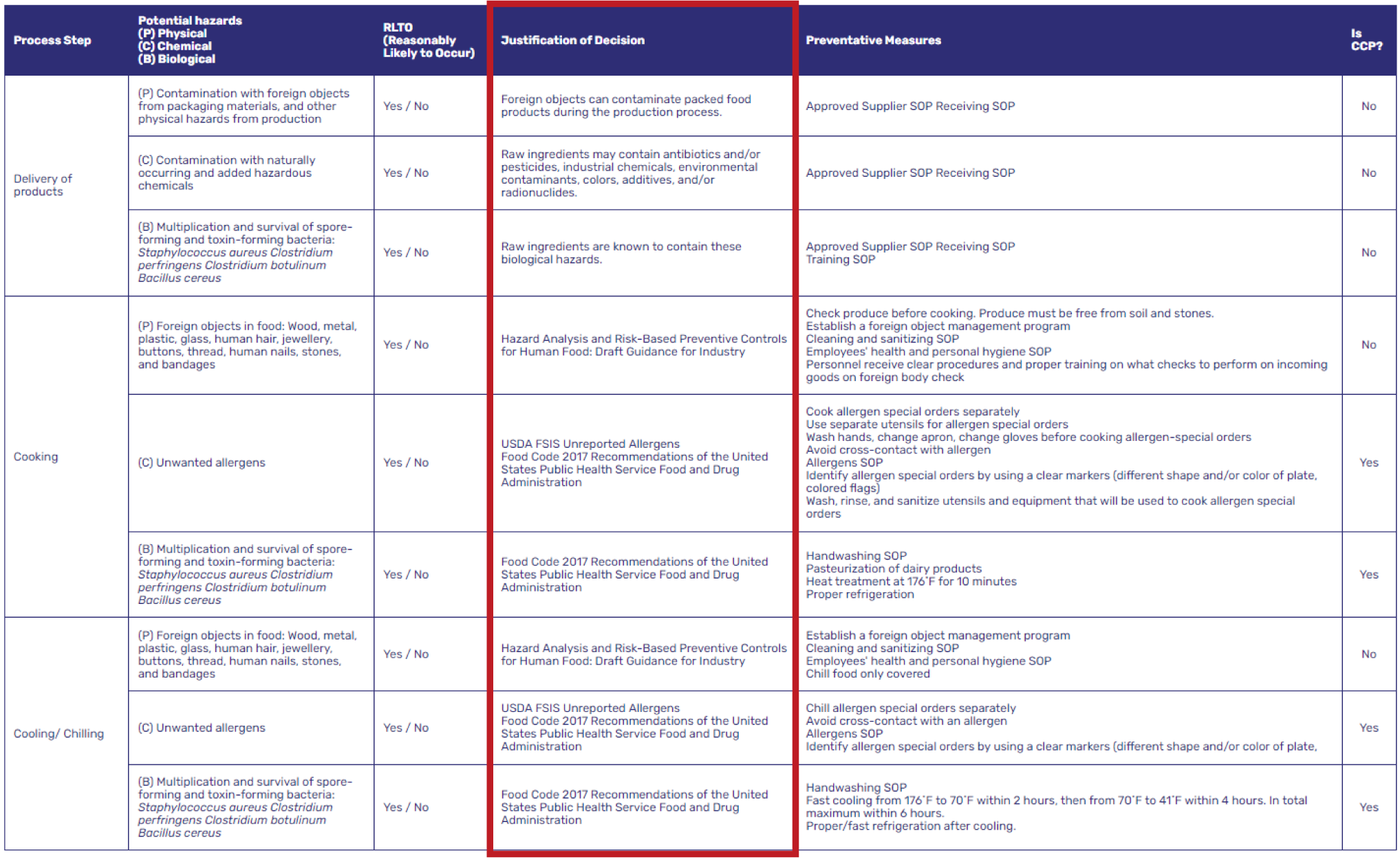

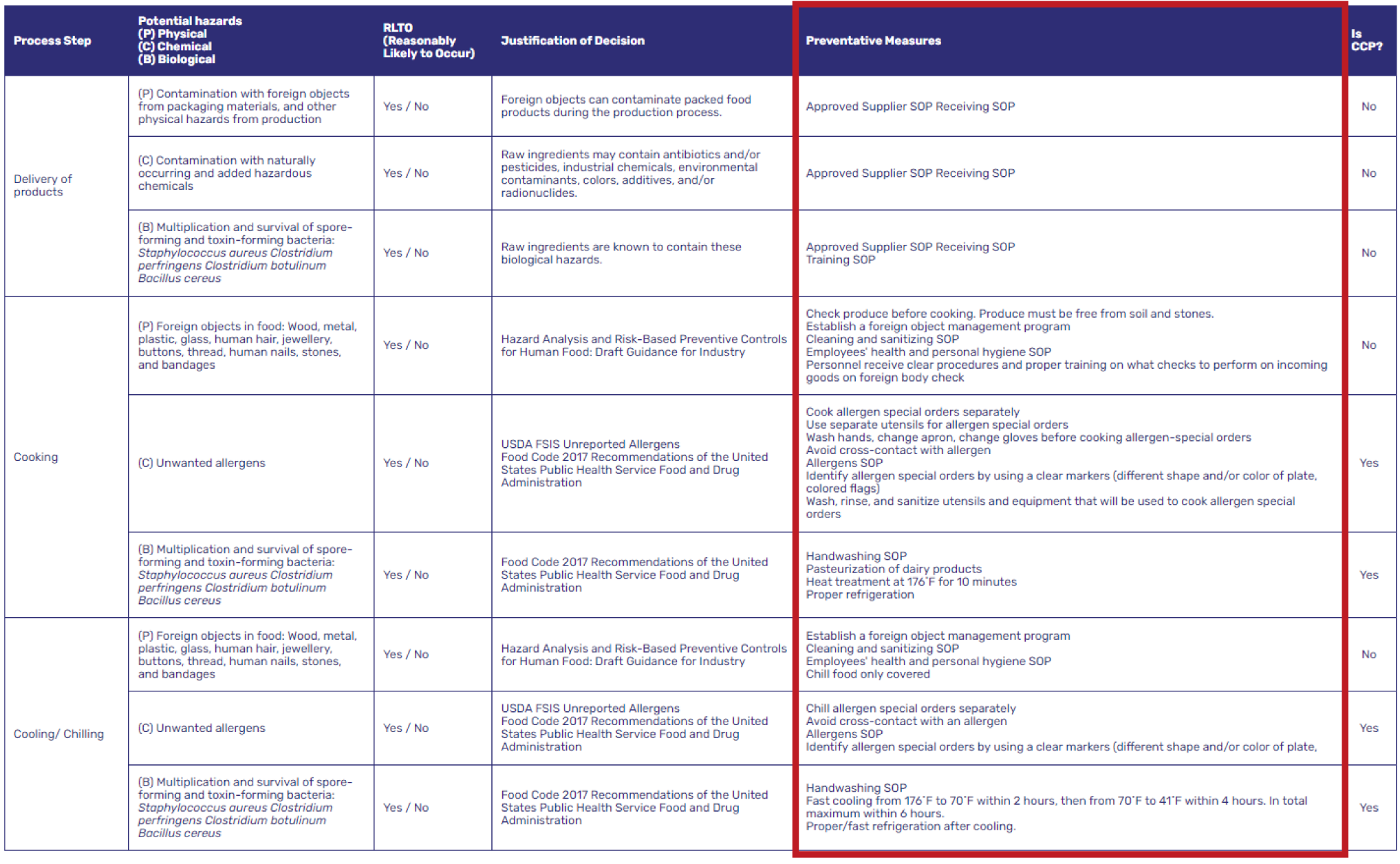

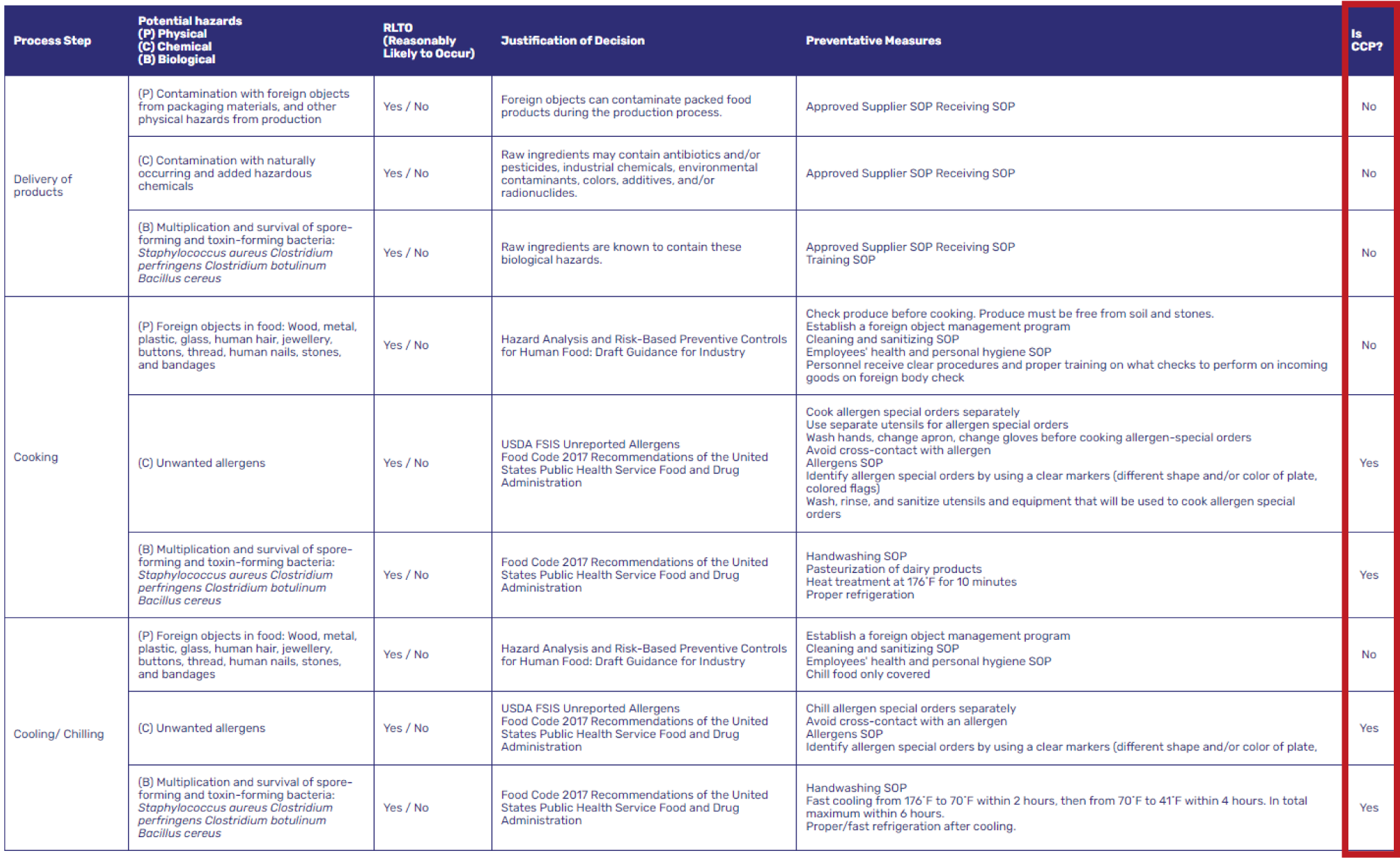

| Process Step | Potential hazards (P) Physical (C) Chemical (B) Biological |

RLTO (Reasonably Likely to Occur) | Justification of Decision | Preventative Measures | Is CCP? | |

|---|---|---|---|---|---|---|

| Delivery of products | (P) Contamination with foreign objects from packaging materials, and other physical hazards from production | Yes / No | Foreign objects can contaminate packed food products during the production process. | Approved Supplier SOP Receiving SOP | No | |

| (C) Contamination with naturally occurring and added hazardous chemicals | Yes / No | Raw ingredients may contain antibiotics and/or pesticides, industrial chemicals, environmental contaminants, colors, additives, and/or radionuclides. | Approved Supplier SOP Receiving SOP | No | ||

| (B) Multiplication and survival of spore-forming and toxin-forming bacteria: Staphylococcus aureus Clostridium perfringens Clostridium botulinum Bacillus cereus | Yes / No | Raw ingredients are known to contain these biological hazards. | Approved Supplier SOP Receiving SOP Training SOP |

No | ||

| Cooking | (P) Foreign objects in food: Wood, metal, plastic, glass, human hair, jewellery, buttons, thread, human nails, stones, and bandages | Yes / No | Hazard Analysis and Risk-Based Preventive Controls for Human Food: Draft Guidance for Industry | Check produce before cooking. Produce must be free from soil and stones. Establish a foreign object management program Cleaning and sanitizing SOP Employees' health and personal hygiene SOP Personnel receive clear procedures and proper training on what checks to perform on incoming goods on foreign body check |

No | |

| (C) Unwanted allergens | Yes / No | USDA FSIS Unreported Allergens Food Code 2017 Recommendations of the United States Public Health Service Food and Drug Administration |

Cook allergen special orders separately Use separate utensils for allergen special orders Wash hands, change apron, change gloves before cooking allergen-special orders Avoid cross-contact with allergen Allergens SOP Identify allergen special orders by using a clear markers (different shape and/or color of plate, colored flags) Wash, rinse, and sanitize utensils and equipment that will be used to cook allergen special orders |

Yes | ||

| (B) Multiplication and survival of spore-forming and toxin-forming bacteria: Staphylococcus aureus Clostridium perfringens Clostridium botulinum Bacillus cereus | Yes / No | Food Code 2017 Recommendations of the United States Public Health Service Food and Drug Administration | Handwashing SOP Pasteurization of dairy products Heat treatment at 176˚F for 10 minutes Proper refrigeration |

Yes | ||

| Cooling/ Chilling | (P) Foreign objects in food: Wood, metal, plastic, glass, human hair, jewellery, buttons, thread, human nails, stones, and bandages | Yes / No | Hazard Analysis and Risk-Based Preventive Controls for Human Food: Draft Guidance for Industry | Establish a foreign object management program Cleaning and sanitizing SOP Employees' health and personal hygiene SOP Chill food only covered |

No | |

| (C) Unwanted allergens | Yes / No | USDA FSIS Unreported Allergens Food Code 2017 Recommendations of the United States Public Health Service Food and Drug Administration |

Chill allergen special orders separately Avoid cross-contact with an allergen Allergens SOP Identify allergen special orders by using a clear markers (different shape and/or color of plate, |

Yes | ||

| (B) Multiplication and survival of spore-forming and toxin-forming bacteria: Staphylococcus aureus Clostridium perfringens Clostridium botulinum Bacillus cereus | Yes / No | Food Code 2017 Recommendations of the United States Public Health Service Food and Drug Administration | Handwashing SOP Fast cooling from 176˚F to 70˚F within 2 hours, then from 70˚F to 41˚F within 4 hours. In total maximum within 6 hours. Proper/fast refrigeration after cooling. |

Yes |

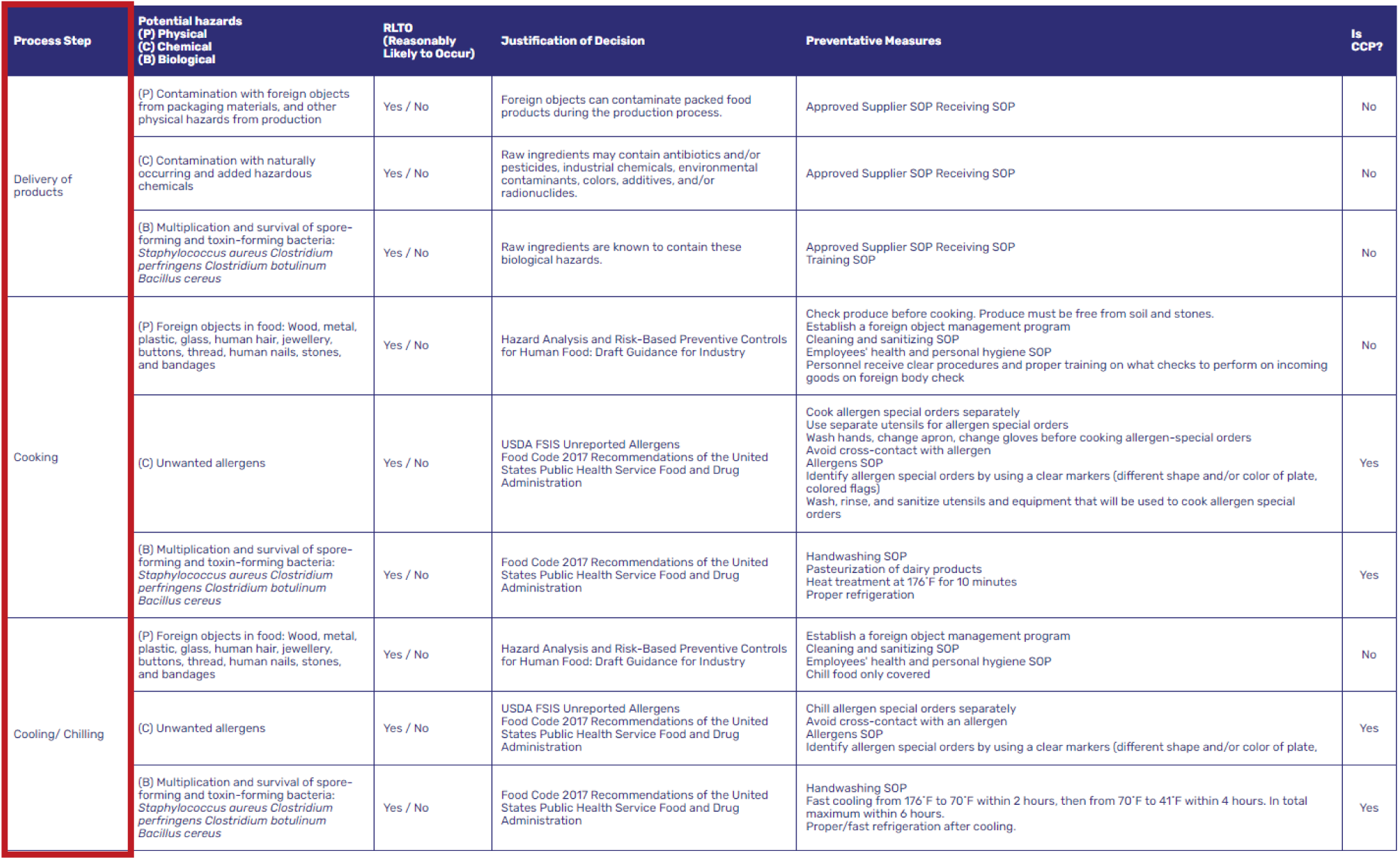

| Process Step | Delivery of products | |

| Potential hazards (P) Physical (C) Chemical (B) Biological |

(P) Contamination with foreign objects from packaging materials, and other physical hazards from production | |

| RLTO (Reasonably Likely to Occur) | Yes / No | |

| Justification of Decision | Foreign objects can contaminate packed food products during the production process. | |

| Preventative Measures | Approved Supplier SOP Receiving SOP | |

| Is CCP? | No | |

| Process Step | Delivery of products | |

| Potential hazards (P) Physical (C) Chemical (B) Biological |

(C) Contamination with naturally occurring and added hazardous chemicals | |

| RLTO (Reasonably Likely to Occur) | Yes / No | |

| Justification of Decision | Raw ingredients may contain antibiotics and/or pesticides, industrial chemicals, environmental contaminants, colors, additives, and/or radionuclides. | |

| Preventative Measures | Approved Supplier SOP Receiving SOP | |

| Is CCP? | No | |

| Process Step | Delivery of products | |

| Potential hazards (P) Physical (C) Chemical (B) Biological |

(B) Multiplication and survival of spore-forming and toxin-forming bacteria: Staphylococcus aureus Clostridium perfringens Clostridium botulinum Bacillus cereus | |

| RLTO (Reasonably Likely to Occur) | Yes / No | |

| Justification of Decision | Raw ingredients are known to contain these biological hazards. | |

| Preventative Measures | Approved Supplier SOP Receiving SOP; Training SOP |

|

| Is CCP? | No | |

| Process Step | Cooking | |

| Potential hazards (P) Physical (C) Chemical (B) Biological |

(P) Foreign objects in food: Wood, metal, plastic, glass, human hair, jewelry, buttons, thread, human nails, stones, and bandages | |

| RLTO (Reasonably Likely to Occur) | Yes / No | |

| Justification of Decision | Hazard Analysis and Risk-Based Preventive Controls for Human Food: Draft Guidance for Industry | |

| Preventative Measures | Check produce before cooking. Produce must be free from soil and stones; Establish foreign object management program; Cleaning and sanitizing SOP; Employees' health and personal hygiene SOP; Personnel receive clear procedures and proper training on what checks to perform on incoming goods on foreign body check |

|

| Is CCP? | No | |

| Process Step | Cooking | |

| Potential hazards (P) Physical (C) Chemical (B) Biological |

(C) Unwanted allergens | |

| RLTO (Reasonably Likely to Occur) | Yes / No | |

| Justification of Decision | USDA FSIS Unreported Allergens; Food Code 2017 Recommendations of the United States Public Health Service Food and Drug Administration |

|

| Preventative Measures | Cook allergen special orders separately; Use separate utensils for allergen special orders; Wash hands, change apron, change gloves before cooking allergen-special orders; Avoid cross-contact with allergen; Allergens SOP; Identify allergen special orders by using a clear markers (different shape and/or color of plate, colored flags); Wash, rinse, and sanitize utensils and equipment that will be used to cook allergen special orders |

|

| Is CCP? | Yes | |

| Process Step | Cooking | |

| Potential hazards (P) Physical (C) Chemical (B) Biological |

(B) Multiplication and survival of spore-forming and toxin-forming bacteria: Staphylococcus aureus Clostridium perfringens Clostridium botulinum Bacillus cereus | |

| RLTO (Reasonably Likely to Occur) | Yes / No | |

| Justification of Decision | USDA FSIS Unreported Allergens; Food Code 2017 Recommendations of the United States Public Health Service Food and Drug Administration |

|

| Preventative Measures | Handwashing SOP; Pasteurization of dairy products; Heat treatment at 176˚F for 10 minutes; Proper refrigeration |

|

| Is CCP? | Yes |

HACCP Hazard Analysis Template

The first step to the seven principles of a Hazard Analysis Critical Control Point (HACCP) system is a hazard analysis. The hazard analysis template above will help you take that first step. Like any other systematic approach, identifying potential problems and conducting a thorough analysis are key steps to creating a robust preventive program.

A successful and complete hazard analysis can help HACCP teams create accurate and effective measures to control food safety hazards. Through this step, the HACCP team can focus on which parameters must be studied and monitored to create a complete HACCP plan.

How to use this hazard analysis template

This template includes several columns that guide your team through identifying hazards. Here’s how to use each one:

- Processing step: The specific task or step in food handling (e.g. receiving, cooking, cooling).

- Hazard: Describe the potential hazard and categorize it as biological (B), chemical (C), or physical (P).

- RLTO (reasonably likely to occur): Decide if the hazard is likely to occur in your setting. Mark “Yes” if the hazard could realistically happen unless a control is in place.

- Justification: Explain why the hazard is or is not likely. Use facts, past incidents, or supplier data.

- Preventive measure: List the action that controls the hazard (e.g., cooking to a safe temperature, supplier checks).

- Is this a CCP?: Mark “Yes” if this step is a critical control point that must be monitored for safety.

This step-by-step approach helps food handlers clearly understand which hazards need attention and which ones are controlled by existing procedures.

Key takeaways

- Hazard analysis is essential for implementing a HACCP food safety system by identifying potential hazards in a food business.

- Performing hazard analysis helps in the careful assessment of all operations from receiving raw materials to distributing finished products.

- The analysis includes identifying hazards, assessing their severity, likelihood of occurrence, and classifying them to establish critical control points.

- Hazard analysis is crucial for food manufacturers to maintain safety compliance and produce safe food products.

- Proper hazard analysis reduces the risk of foodborne illnesses, injuries, or financial losses by allowing the creation of effective preventive programs.

- A systematic approach to hazard analysis includes listing manufacturing steps, identifying hazards, and evaluating their potential impacts.

- Traditional methods of hazard analysis can be time-consuming and prone to errors, often requiring manual listing and tabulation.

- The digital solution from FoodDocs significantly speeds up the HACCP plan creation process, making it faster and cheaper than traditional methods.

WHAT WE'LL COVER:

The presence of food safety hazards in a food business is inevitable. The chances of these potential hazards causing problems can be minimized depending on your team's approach to food safety. To help you understand hazard analysis and guide you on how to perform it, you can read through this article and find out more efficient solutions on how to compose it, like the hazard analysis free tool above.

What is hazard analysis?

Hazard analysis is the first step in implementing a HACCP food safety system and is performed through the collection of information on the potential hazards in a food business and studying them. This process aims to carefully assess all of the operations in your food business and identify the potentially present hazards. It includes operations from receiving raw materials up to the distribution of finished products.

After identification, every health hazard will then be subjected to further analysis, such as determining its level of potential severity, the likelihood of occurrence, and its classification as a hazard. These parameters will serve as the basis for the next HACCP principles, such as establishing critical control points.

Who needs to complete a preliminary hazard analysis?

Hazard analysis is a critical step for a HACCP food safety program as well as other food safety management for food manufacturers. It is essential to be performed to maintain food safety compliance and for the production of safe food products. As such, hazard analysis must be initiated by any business serving or selling food to customers.

Regardless of whether the food business is required to implement a HACCP plan or not, hazard identification procedures are essential tasks for the production of safe foods. Food processing plants and food service businesses would significantly benefit from identifying every potential hazard in their business.

Using a hazard analysis template helps organize each step in your process, making it easier to spot food safety risks. With a consistent format, your team can review which steps are most likely to cause harm and what actions are needed to control them. It is especially useful for restaurants, where many different ingredients and cooking processes are used every day.

Your hazard analysis template should help you answer:

- What are the food safety hazards in each process step?

- Are these hazards likely to occur?

- What controls or actions should be in place to prevent them?

Why is a process hazard analysis important?

Through hazard analysis process, food business teams can properly prepare and create preventive programs to protect consumers from potential hazards and unsafe conditions. When the hazard analysis step is carried out correctly, the probability of causing foodborne illness, injury, or loss of profit, as a result, is significantly reduced.

Hazard analysis is an essential step for a risk-based program, such as HACCP, to work. Through the activities involved in this process, your involved workers can properly plan and prevent the contamination of your wholesome food products and occurrences of outbreaks and food recall.

If your HACCP team fails to identify and analyze a particular hazard, appropriate safety control measures may not be set for the undetected hazard and can harm your entire processing. Regulatory hazard assessment is the process of finding the root causative agents of potential food safety issues in your operation.

During safety inspections, undetected hazards may prove to be significant problems and will merit the attention of a food safety inspector.

What are the most common hazards in restaurant kitchens?

Use the table below to help your team spot frequent hazards found in restaurants:

| Hazard type | Example | Preventive measure |

|---|---|---|

| Biological | Salmonella in raw chicken | Cook to 165°F, keep refrigerated |

| Chemical | Cleaning residue on prep table | Rinse and dry surfaces before use |

| Physical | Glass from broken container | Store glass items carefully, inspect equipment |

| Allergen | Nuts in dessert | Use labels, separate prep area and utensils |

| Biological | Bacillus cereus in rice | Cool quickly, store below 40°F |

| Physical | Metal shards from broken blade | Regular equipment maintenance, visual checks |

What's an example of a hazard analysis in a restaurant setting?

Here’s how a restaurant might fill out the hazard analysis template for grilled chicken:

- Step: Receiving raw chicken

- Hazard: Salmonella (B)

- RLTO: Yes

- Justification: Raw poultry often contains Salmonella

- Preventive measure: Use approved supplier, store at ≤ 40°F

- Is this a CCP?: No

- Step: Cooking

- Hazard: Undercooked chicken (B)

- RLTO: Yes

- Justification: Cooking is needed to kill pathogens

- Preventive measure: Cook to 165°F, check temperature

- Is this a CCP?: Yes

- Step: Plating

- Hazard: Allergen cross-contact (C)

- RLTO: Yes

- Justification: Shared utensils may cause allergen transfer

- Preventive measure: Use color-coded tools, staff training

- Is this a CCP?: No

6 Steps to conduct a hazard analysis

Follow these steps to perform a basic hazard analysis:

- List all the steps in your process, from receiving ingredients to serving food.

- Identify potential hazards for each step. Categorize them as biological, chemical, or physical.

- Assess how severe the harm would be if the hazard happened.

- Assess how likely the hazard is to occur without controls.

- Decide what actions or controls can prevent or reduce the hazard.

- Mark whether each step is a critical control point that needs close monitoring.

This process should be done with your HACCP team and reviewed regularly.

How to complete a hazard analysis with a template

Hazard analysis is a systematic process. Its effective execution lies in the correctness of each step taken to finish the process. Hazard analysis starts right after your HACCP team has verified that your flow chart diagram is accurate.

To ensure that all potential hazards are identified and analyzed, follow this sequence of steps for a hazard assessment form:

1. List all the manufacturing process steps in your food operation from the flow chart diagram (e.g., delivery of products, cooking process/thermal process)

2. Under each process step, identify every possible food safety hazard and label each hazard according to the types of key hazards i.e., (P) physical hazard, (C) chemical hazard, and (B) biological hazard.

e.g., (P) presence of foreign material residues from food packaging, (M) survival of pathogenic microorganisms after cooking

3. Describe the potential severity of the hazard in question if left uncontrolled and the likelihood of this hazard from occurring. Use the common scale provided in a risk assessment matrix.

4. Clearly identify how the hazard can become a significant problem in the food processor.

5. For processes that are considered to have significant potential to harm consumers, assign appropriate preventive measures.

6. In preparation for the next principle of HACCP, identify whether the process step is critical in controlling the particular hazard with a (YES) or (NO).

Proper hazard analysis evaluates all food safety hazards but only considers assigning preventive measures to hazards that have a reasonable probability of occurring.

What is the easiest way to analyze hazards?

The traditional way of regular hazard assessments is through manually listing everything and creating tables either on paper or creating a spreadsheet. This process takes so much time and is very prone to human errors. An extensive range of hazard identification and analysis can last up to weeks.

You can use our Free Hazard Analysis Template, which has a built-in gauge for the severity and likelihood of a hazard from occurring and columns where you can clearly assess every hazard. This free basic hazard identification template was made to help HACCP teams accurately analyze and compile hazard evaluations.

You can also use our free flow chart template tool to construct a detailed flow diagram of your operations that you will need for hazard analysis as a step guide.

Despite the convenience that our free hazard analysis template provides, you would still need to spend more time listing every hazard, analyzing them, and providing justifications and preventive measures for each. But there's a better, more cost-effective solution.

Get your hazard analysis and entire HACCP Plan done in 1 hour

Hazard analysis is just the first step in the long process of building a HACCP food safety plan. This step already consists of several processes, which will only be followed by additional steps from the 6 remaining principles of the HACCP system.

Getting your HACCP plan done as fast as you can means being able to operate safely as well. This means that having a HACCP plan is a top priority. Building this plan is not an easy task and takes several days or weeks, even with the help of a food safety consultant.

Luckily, our food safety experts at FoodDocs have come up with a digital solution that produces a done-for-you HACCP plan in just 1 hour! Using our built-in, customizable HACCP plan template builder, you can get a comprehensive HACCP plan template by just answering a few basic questions about your food business.

Once you are done, our system can automatically generate the HACCP plan template through the help of artificial intelligence and further improve it with our help. Sign up for a 14-day free trial today!

You can get all the following components when you use our digital solution:

- Prerequisite programs

- Basic food flow chart of your operations

- Complete hazard identification and analysis

- Established critical control points with critical limits

- CCP monitoring procedures

- Established verification procedures

- Record-keeping and documentation procedures

What is even greater with our system is that you can further customize every component to add, change, or improve the important information and fit your operations even better.

Save a significant amount of time from building your HACCP plan by using our digital solution. Comparatively, our solution is 500x faster and 15x cheaper than hiring a consultant to do the job for you.

Frequently asked questions

To help you understand this topic on hazard analysis more, here are some of the most commonly asked questions.

What is an activity hazard analysis used for?

Hazard analysis is a procedure used by the food industry to identify and evaluate potential food safety hazards and use the information as a basis for establishing preventive and corrective measures.

How do you perform a hazard analysis?

Hazard analysis is performed by listing all potential food hazards in your operations and describing every hazard based on their severity, likelihood, and general category of hazard. After these basic steps, a clear justification of how these hazards can harm public health and appropriate types of controls must be provided.

What is a hazard analysis in the food safety industry?

A hazard analysis is the process of identifying potential food safety hazards that can happen at every step of food preparation. It is the first principle of the HACCP system and helps food businesses find risks before they become problems. These hazards can be biological (like bacteria), chemical (like cleaning agents or allergens), or physical (like broken glass or metal fragments).

This step helps food handlers determine where food safety issues might happen so they can plan how to prevent them.

What does RLTO mean?

It stands for “reasonably likely to occur.” It means the hazard could happen if there’s no control in place.

What are critical control points (CCPs)?

These are steps where you can apply a control to prevent, eliminate, or reduce a hazard. For example, cooking to a safe temperature is often a CCP.

Who should complete a hazard analysis?

Your HACCP team or a trained food safety manager should lead the hazard analysis. It helps to involve kitchen staff who know the daily process well.

How often should we review our hazard analysis?

Review your hazard analysis at least once a year or any time you change a menu item, process, or supplier.