Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

A food establishment is always expected to work in a clean and conducive place.

The surrounding environment of a restaurant must be clean enough to prevent attracting any foodborne pathogens that may cause food poisoning to the customers.

When the foodservice and kitchen facilities remain unclean, they will surely attract biological hazards and will put the food companies in a bad situation. As a critical part of every food establishment's food safety management system (FSMS), every food safety team must have a food sanitation plan.

Included in the plan must be the design and sanitation principles of facilities, equipment, and the layout of the whole food establishment. Sanitation requires the efforts of all food safety workers for it to work as every step of the food chain must be kept clean and free from foodborne pathogens. Additionally, every food handler must be aware of proper food sanitation practices that must be monitored every day.

To help you prepare and ensure compliance with the most significant food sanitation laws, we've prepared this article for you. Learn about what is food sanitation and examples of this system.

Food sanitation refers to the creation and maintenance of sanitary conditions that reduce the risk of foodborne illnesses in food establishments. Businesses can maintain effective food sanitation and cleanliness by practicing good personal hygiene and safe food handling and preparation techniques.

Food sanitation consists of several different operations that help maintain the cleanliness of the entire facility, food contact surfaces, equipment, and other points of the food supply chain. Different states and countries may have their own sanitation standards that may impact factors such as approved cleaning agents, concentrations, and food sanitation practices.

Pathogens and other food safety hazards may linger on contact surfaces, equipment, and utensils. Without proper food sanitation, these pathogens can result in cross-contamination and potentially cause a foodborne disease outbreak.

Food safety refers to the set of practices performed to prevent the occurrence of foodborne illnesses, whereas food sanitation is the cleanliness and maintenance of the good and safe conditions of equipment and foodservice facilities. In principle, food sanitation is part of the bigger umbrella of food safety.

Food safety operations include cooking, chilling, storing, and avoiding cross-contamination. It involves operations that keep raw and ready-to-eat foods safe through thorough processing and safe storage. On the other hand, food sanitation in food processing involves operations that render the hands of food handlers, cooking equipment, storage containers, and preparation areas.

Both food safety and sanitation are significantly affected by the correctness and frequency of their execution as well as their constant monitoring. Food sanitation must be properly scheduled and regulated to achieve its objectives. In applying food sanitation, caution must also be applied. Excessive cleaning solutions can cause chemical contamination and will ultimately harm consumers.

In the food industry, sanitation is important because proper food sanitation practices can effectively reduce food safety risks, with the help of proper instructions and a regular schedule.

Specifically, food sanitation can help address the following four concerns:

Generally, good food sanitation practices can minimize the occurrences of issues such as cross-contamination. When equipment, contact surfaces, utensils, and other fixtures of the kitchen are always sanitized, there will be fewer pathogens to transmit. Food sanitation would also be able to address concerns with cross-contact among allergenic and non-allergenic foods. With proper food sanitation, food safety issues that go beyond foodborne illnesses can also be resolved. Food sanitation can also help spot physical problems with your facilities, physical contaminants, and other factors that may contribute to injuries.

Regular sanitation of foods also allows food handlers to determine whether equipment, utensils, and contact surfaces need maintenance or fixing. The maintenance of equipment ensures that it will be able to perform its intended use and prevent any substandard results. Additionally, food handlers can determine if there are any potentially hazardous conditions in the kitchen and food service operations area such as chipped walls and floors, bent contact surfaces, or even broken glass. These conditions may harbor pathogens or contaminate foods with physical hazards.

Additionally, when the equipment is up-to-date and the environment of the entire food chain is safe, clean, and conducive for work, accidents are significantly reduced. Food handlers are also less likely to get sick because of unhealthy working conditions. A part of cleaning and sanitation procedures in the food industry includes some hygiene practices such as regular hand washing. The cleanliness of a food worker's hand contributes to preventing foodborne illnesses.

Food sanitation does not only apply inside the kitchen. It must also be applied to the foodservice areas. Tables, chairs, counters, and other surfaces must always be cleaned to ensure that there are no pathogens or any food hazard entry points. When customers see such high standards for food sanitation, they gain confidence that your food business values their health and safety.

Food sanitation can only become effective when they are correctly performed and regularly monitored. Every team of a food business must include the monitoring of food sanitation in food safety management systems. Useful tools such as a cleaning checklist can be used to ensure that important areas are sanitized and maintained regularly.

Alternatively, your team can use our digital solution at FoodDocs. With our smart, digital FSMS, food workers can receive intuitive notifications that will remind them of any task that needs to be done on time - including cleaning and sanitation procedures in the food industry! Find out more about our digital food safety monitoring system.

Food sanitation encompasses many different fields. It does not only consider physical equipment or contact surfaces. Food sanitation is also concerned with food and personal hygiene.

Examples of food sanitation can range from proper handwashing to the correct application of sanitizing agents on food contact surfaces. Food sanitation procedures can also be for specifically controlling a particular food safety hazard. For example, sweeping and wiping counters can help minimize physical hazards, whereas food-safe sanitizers can reduce both biological and chemical hazards.

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

There are several food sanitation practices. Some are specific for a food business, whereas others can be general for all. Here are four basic sanitation practices that must be a part of every food sanitation plan for all food businesses across the food supply chain:

Although very simple, the proper way of handwashing minimizes the risk of causing cross-contamination, and therefore, foodborne illnesses. It is perhaps one of the most important food sanitation activities that a food handler can do to control any kind of food safety hazard. When we say proper handwashing, this includes the correct tools that you need such as antibacterial soap, a supply of water, a dedicated handwashing sink, and optionally a brush.

Handwashing must be done for at least 20 seconds as recommended by the Centers for Disease Control and Prevention. This duration would give enough time for any food handler to reach all areas of their hands when washing. Learn more about the principles, regulations, and proper ways of handwashing from this detailed article we wrote.

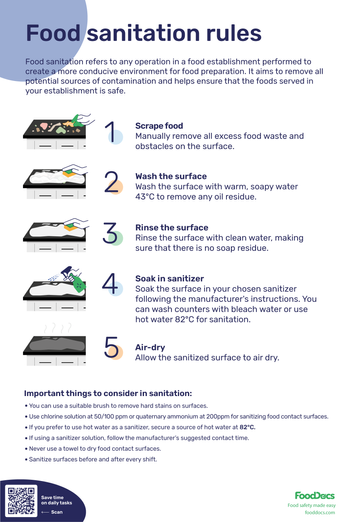

This food sanitation operation involves multiples steps for effectiveness. In order, the whole process must involve washing, rinsing, and sanitizing. The first step is cleaning and it involves manually removing debris, spills, and any visible dirt on contact surfaces. This operation can be done by using a clean cloth, water, and repetitive agitation of dirt. After cleaning, surfaces must be rinsed and then applied with sanitizing agents.

For sanitation of food contact surfaces, a few factors need to be considered:

All of these factors contribute to the effectiveness of sanitation. Depending on the type of sanitation method, whether heat or chemical treatment, all favorable factors must be followed. Additionally, cleaning must be done before sanitation. The effectiveness of sanitizing agents may be reduced if physical debris is present on food contact surfaces.

Food labeling is a very important part of food sanitation. It reduces the risk of mistakenly using harmful products such as allergenic foods for preparing allergen-free meals. In the case of food equipment, color-coded labels can be applied for proper identification and correct use.

Additionally, labeling cleaning and sanitizing agents can prevent their misuse. Smaller batches of cleaning solutions without proper labeling can be misplaced and significantly cause harm when mistaken for something else. Some cleaning or sanitizing solutions can be clear and look like regular water. Always make sure that all materials used for cleaning and sanitizing are all kept in one place that is far from the food preparation area.

When any food equipment is regularly cleaned and protected from food contaminations, its use can be extended for a very long time. Leftover food on a piece of equipment can cause rust especially in between the joints of the equipment. Foods that may be high in acid can increase the speed of metal deterioration and cause corrosion. Rust on metal equipment can get into the food being prepared and contribute to causing foodborne disease incidents.

A food sanitation plan can consist of a collection of operations that aim to create a clean working environment. For more effective food sanitation, all operations must be properly described. Directions on how to do them, when should they be done, on what surfaces should they be applied, and why they are important. All food handlers must be uniformly oriented with how a food safety plan should be carried out.

The last step in the cleaning and sanitizing routine is allowing the sanitizer to dry. Cleaning and sanitizing are two different operations that must be performed in combination to become effective in preventing foodborne illnesses. Their conduct must be properly done in sequence to become more effective. Food handlers must also take note of particular manufacturers' instructions for cleaning and sanitizing solutions. Instructions such as proper dilution and contact time significantly affect their effectiveness.

Particularly, cleaning and sanitizing must be done in 4 easy steps:

Each step is very important and is performed based on an established principle. For example, leaving pieces of food on the contact surfaces before applying a sanitizer would only spread the particles of the food on the surface. After sanitation, these pieces would attract contamination. Additionally, pouring hot water over pieces of food will sometimes be ineffective in removing the stains that have already dried out on the surface. Mechanical abrasion must be applied.

In terms of sanitizing, agents such as chlorine solution and quaternary ammonium salts at 50-100ppm and 200ppm respectively are advised for food facility use. At these given concentrations, pathogens can be effectively removed without implicating any harm to the food that will be prepared. Additionally, in some cases, commercial food surface sanitizers are rinsed with hot or distilled water before use.

Learn more about how to sanitize a meat slicer.

It is part of a food manager's responsibility to train their employees on food sanitation. This type of training can be under food safety orientation. A part of this food safety training with a focus on food sanitation aims to orient food workers regarding the consequences of poor food sanitation. Training food employees on food sanitation would allow them to understand the importance of each operation and promote commitment in them.

Specifically, food sanitation training must include the following topics:

Food managers must never assume that food sanitation and food safety knowledge is common for everyone. All food employees must always undergo proper and adequate hours of training to ensure that they are equipped with the necessary information.

Additionally, training must always be monitored to determine if employees do understand and know how to apply what they have learned. Incomplete applications of food sanitation operations can lead to problems such as chemical contamination of food or survival of pathogens on contact surfaces.

Food preparation equipment must be certified or classified for sanitation by regulatory agencies such as the FDA, CDC, and EPA. Other relevant organizations include the AOAC (Association of Official Agricultural Chemists) which establishes protocols and standards for sanitation and sterilization of equipment and the NSF (National Sanitation Foundation) International, which also creates national standards for foodservice equipment, ensuring that food equipment manufacturers comply with hygienic design and food safety regulations.

Cleaning, sanitizing, and storing food contact surfaces of equipment are all key steps to eliminating harmful microorganisms such as Salmonella and E. coli, and preventing foodborne illnesses.

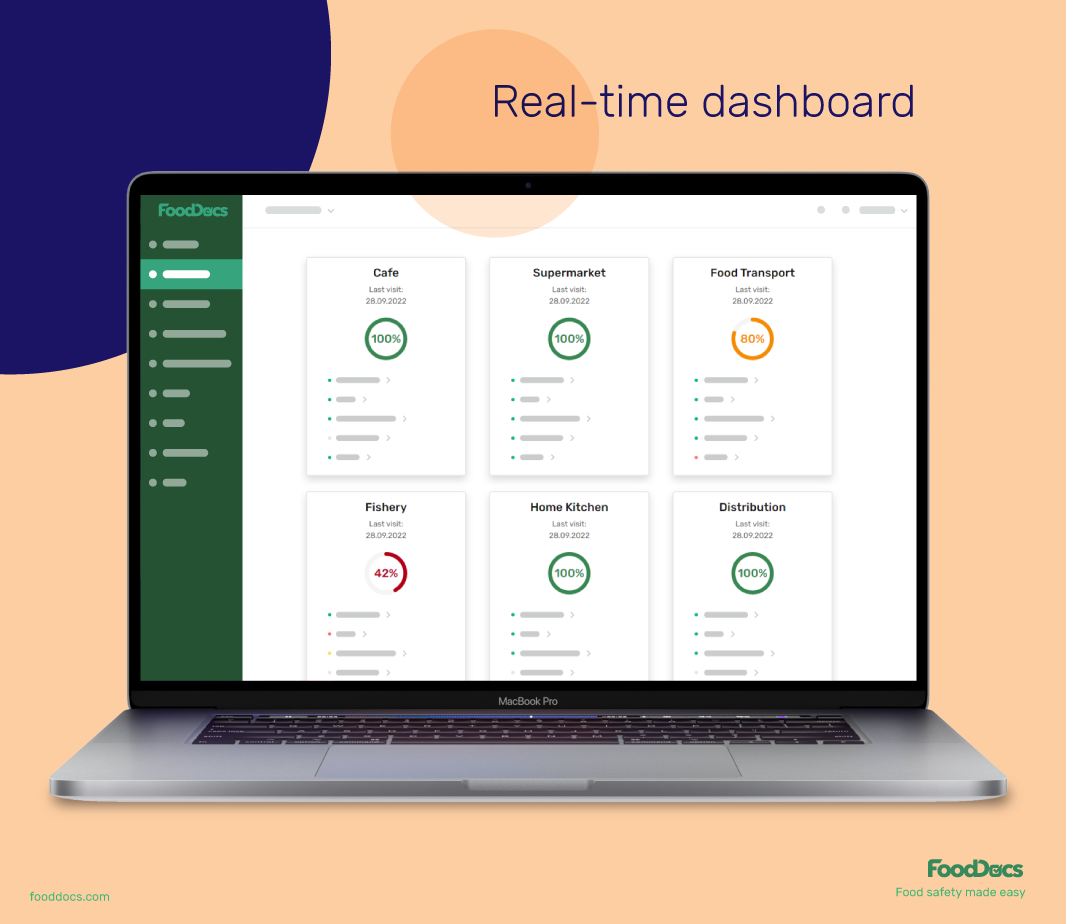

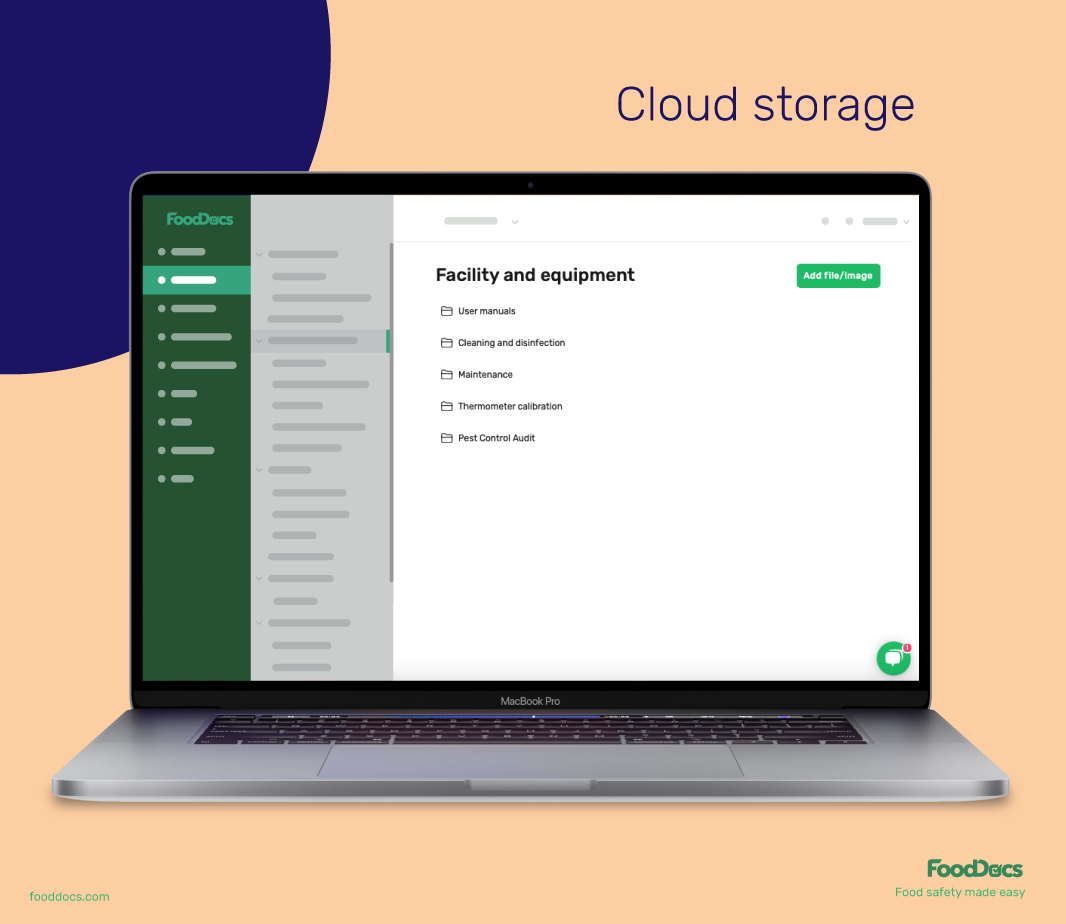

To help you with routine monitoring of cleaning and sanitizing operations, you need an effective food safety system in your food service establishment. At FoodDocs, our digital Food Safety Management System is the only solution you will ever need. Our system can automatically generate a comprehensively detailed FSMS in a matter of 15 minutes. The generated digital FSMS is built specifically based on your daily operations, including food sanitation!

With our system's digital monitoring forms and smart notifications, you can always stay on top of your daily food safety and sanitation tasks. We can help you achieve food safety standards compliance in the most efficient way possible.

Regular food sanitation procedures are essential in keeping food safety compliance in a food establishment. You can implement a cleaning and sanitation schedule or even use a cleaning checklist and food safety and sanitation poster to make your operations more efficient. A constant, organized, and accurate application process is key to food sanitation. When these operations are left out even for a day, the risk of causing foodborne diseases increases as well.

Even with a regular schedule, your food workers would have to manually check which high-traffic areas and contact surfaces would need to be sanitized. Any manual operation has a very high risk of being forgotten or done late. This is a big problem when it comes to sanitation. The accuracy and frequency of conducting sanitation procedures always play a big part in ensuring food safety.

Our team of food safety and technology experts has considered these woes and created the best solution for them. With the help of artificial intelligence, our team has come up with a digital Food Safety Management system that can help make food safety compliance easy and an enjoyable task for food businesses. Our system can automatically generate a comprehensive FSMS complete with the most important monitoring forms, checklists, and other documents needed to stay compliant.

One of the best parts of our system is that it does not require you to be tech-savvy to get a digital FSMS. Our system would only require you to answer a few basic questions about your everyday tasks and it will do the rest for you. In an average of 15 minutes, you can get a digital FSMS built specifically for your daily operations.

How can our system help you stay compliant? With our digital FSMS software, you can get the following:

Not only does our system promote efficiency and compliance, but sustainability as well. Using our digital FSMS, you would not have to bury yourself in a pile of monitoring forms and you can save space from all of the paper-based documents that you normally generate.

Our system was designed to base our automatically generated FSMS on your operations. Despite this, we understand how some businesses have their unique operations that may not be known to others. As such, our system allows customization to accommodate any revisions and improvements.

If you want to experience our digital FSMS product, we offer a free, 14-day trial. Using this trial, you can test whether our features would help you increase your team's efficiency. Join us and the more than 30,000 food business teams that are currently enjoying food safety compliance using our digital FSMS.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...