Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Proper food hygiene is a minimum requirement for every food business serving customers.

Every consumer has the right to safe and good quality food. However, now and then, people worldwide get sick from consuming unsafe food. Such events prove shortcomings in a food business's commitment to food hygiene and safety. Food hygiene is a crucial aspect of ensuring food safety and preventing foodborne illnesses.

Whether producing food at a factory, working in a catering service, or a restaurant, maintaining food hygiene is critical in keeping harmful contamination in control, thus protecting your consumers and your reputation.

This article is a comprehensive review of food hygiene– the fundamental principles, food hygiene facts, how to pick a proper food hygiene course online, and what to understand from a food hygiene rating scheme.

The definition of food hygiene refers to the practices that a business applies to protect consumers from any risks of foodborne illnesses that bacterial contamination or spoilage can cause, such as: food handling, preparation, and storage. Particularly, food hygiene deals with the biological aspect of keeping food safe.

Food hygiene is a collection of practices and guidelines to keep your operations clean and under healthy conditions.

This term is concerned with food handling, transport, proper storage of food, and the actual processing of your materials. Specifically, the objectives of food hygiene include the following:

Achieving and maintaining food hygiene is an essential task for every food business, wherever the business is in the world. Combine the power of technology with food hygiene practices by using the FoodDocs Food Safety Management System. Our smart software covers monitoring tasks for maintaining strict food hygiene standards. Use our software tools, such as a smart notification system to remind food handlers of important, everyday hygiene tasks.

Technically, they are not the same. Although, in some cases, food manufacturers use these terms interchangeably, they have different meanings and have different principles.

Food safety includes a wide range of areas to ensure that food is safe and fit for human consumption. This term is used to describe a wide management system that is applied by a food business to ensure that hazards are controlled to acceptable levels.

Food safety is concerned with all types of hazards and includes the system of corrective actions, monitoring, and how to achieve safe operations. In short, food safety is the bigger umbrella, and food hygiene is under it. Food hygiene is the practice of doing the directives from food safety as cleanly and safely as possible.

Food safety refers to a holistic approach to controlling and managing food safety hazards. It spans from sourcing raw materials, processing, food packaging, transporting, and finally, until the products are ready for sale. During processing, food is vulnerable to biological, physical, chemical, and allergy contamination.

Food hygiene standards mainly cover conditions, rules, and procedures to prevent biological food contamination, leading to foodborne illnesses. The measures range from proper food handling, thorough cleaning process, preventing cross-contamination, etc. In comparison, traceability and correct food labelling are part of food safety management but not necessarily in food hygiene standards.

While food safety encompasses a broader perspective, including hazards beyond hygiene, food hygiene specifically emphasises the cleanliness and sanitation practices necessary to maintain safe and hygienic food handling.

In conclusion, it could be said that food hygiene is a part of food safety as it goes deeper into sanitation practices, which are fundamental to food safety. It is important to remember that both concepts are essential to ensure the safety and quality of food.

There are numerous benefits a business will enjoy from maintaining good hygiene practices. Below are some key signs of why it is important to apply food hygiene to your operations.

Food and hygiene should always go hand in hand. A food business is obliged by food hygiene legislation to provide wholesome and hygienic food. Implementing food hygiene standards is a crucial step to achieving the ultimate goal.

Through practising good food hygiene, your company will be able to continuously serve safe food and gain a good reputation from consumers. Failure to observe hygienic practices can lead to complaints and issues with public health safety.

Improper food handling will lead to unnecessary waste. For example, if cross-contamination occurs during packaging, depending on the degree of food contamination, a batch can be forwarded to disposal.

If in case the products get distributed before detection of contamination, your business will be forced to recall and either reprocess or dispose of your contaminated products.

Proper food hygiene practices ensure that little to no waste is produced and that they are well managed.

When a business constantly delivers high-quality, safe products as consumers expect, it's good for its reputation and business sustainability.

Reports of food recalls or public health issues linked to your business can harm your brand's name. In addition, most consumers return to the brands they are most familiar with and have had satisfactory experiences.

Practising food hygiene in the operation facilities does not only improve your business. It also teaches your restaurant employees and everyone involved in the production to apply hygienic processes in their everyday lives and therefore improve their way of living.

In addition, for food hygiene training to be effective, it must be applied and practised every day and become a part of your restaurant staff's routines.

Reduced food waste, streamlined workflow, and improved productivity are a direct result of good form of hygiene measures. Without much food waste and continuous and efficient workflow, your company saves on cost and can positively affect profit.

The fastest way for your team to achieve all of these benefits is for you to employ a comprehensive Food Safety Management System (FSMS). To speed things up, get your own smart Food Safety Management System in just an average of 15 minutes using our software.

With our digital solution, you can get all of the essential food safety monitoring forms related to your food operations and start your digital food safety compliance journey right away.

Food hygiene can be applied in almost all areas of a food manufacturing business. From the actual food production process of your raw materials to the delivery of your products, food hygiene is very much applicable.

Consumers should also be aware of what food hygiene is. It is a role that everyone plays.

Effective cleaning is vital to ensure that all equipment and surfaces are free from food contamination. This principle applies to kitchen utensils, working areas, and even your raw materials. Cleaning also pertains to the sanitation process of food contact materials before working. Some of the essential activities include:

To make cleaning procedures clearer, make your monitoring forms that include areas to be cleaned and disinfected, who are tasked to do the cleaning, and how often it should be done.

Use our Free Restaurant Cleaning Checklist to ensure that your team is always prepared for cleaning tasks.

In addition, cleaning instruction materials, such as how to dispose of trash bags properly, how to use cleaning materials properly, and how to store cleaning materials, and a checklist of what to do in a day can also be helpful in reminding your employees how to conduct the cleaning procedures.

Use our free monitoring form template for your cleaning schedules. This template could be perfect for you as it can be tailored to your food business operations. We offer you a wide range of templates you can use to complete your food safety management system.

Thorough cooking is necessary to kill harmful bacteria that potentially cause food poisoning. Each food item requires a different amount of cooking time and a safe and proper temperature up to the centre of your product.

A food hygiene poster displaying the correct cooking temperatures for each type of food is essential to ensure no single item is undercooked. Food safety standards for the correct temperature must always be present and accessible for relevant food business operators as a reference to prevent the growth of bacteria and other harmful pathogens.

To maintain food safety, it's important to reheat your food if it has been left at room temperature for an extended period, as this helps prevent any potential contamination.

Download and use our Free Cooking Temperature Charts to ensure proper cooking and production of safer foods.

Proper chilling is crucial to stop bacterial growth and keep food safe, particularly for perishable food such as ready-to-eat salad, cooked meat, etc. The most recommended method for cooling foods after cooking is the two-stage cooling method.

Storing your food products before or after use prevents the multiplication of harmful microorganisms. Chilling means storing your food in conditions with adequate temperatures around or equal to at least 35°F to 40°F (2°C to 4°C).

The main objective of this food hygiene practice is to keep foods away from the temperature danger zone.

Download our Free Cooling Food Poster and use it in your kitchens as a guide for the approved methods and guidelines for cooling foods.

One of the biggest concerns in food hygiene is the problem of cross-contamination. This problem occurs due to improper segregation of materials, using similar utensils for raw and cooked food, improper wiping of the working area and others. For example, bacteria can spread from raw foods to the finished product when equipment and utensils are not segregated appropriately.

Proper segregation is one of the best ways to avoid cross-contamination. Raw ingredients must always be separated from cooked ones to avoid the risk of contamination of already processed food.

Because there is no other processing after the food is cooked, the contamination cannot be controlled. Proper segregation also includes setting a space for dried and wet products.

Cross-contamination can also be prevented by implementing a good workflow. An effective workflow that can apply food hygiene & safety does not have any "backflow" where a processed product returns to previous sections of the working area. In this way, contaminations can be controlled more efficiently.

Another widely known method for preventing cross-contamination is the use of colour-coded chopping boards. A colour is assigned to a chopping board, indicating the only type of food for which it can be used on.

Improper handling during transport from your premises to stores may lead to contamination and food spoilage. Therefore, it is vital to ensure that the containers provide adequate protection from potential contamination, keep the appropriate temperatures for chilled or frozen products (refrigerated vans, cool bags) and separate raw products from ready-to-eat ones.

Included in this principle is to clean the vehicle regularly as well. One common rule during transport is that any food product, whether raw or cooked, must be 6 inches above the floor of your vehicle. That is, pallets, crates, or trays must be used to hold your products. In addition, a vehicle used for raw materials must not be used for delivering finished goods at the same time and without proper transition cleaning.

Every personnel working in food handling areas is responsible for maintaining personal hygiene habits.

Safe food and hygiene are two items that work together. Personal hygiene practices refer to your and your employee's practices and routines in caring for your body and keeping it clean. Some of the essential practices include:

A food business is always expected to generate waste. These wastes can be, but are not limited to, fruit peels, raw material packaging, bones, seeds, and even spoiled foods. The mentioned list of wastes includes both biodegradable and non-biodegradable materials.

These food wastes must be kept far from the working area to prevent possible contamination. In addition, biodegradable wastes attract all types of pests. Their clearance must be more frequent than other waste materials to prevent any pest from residing around your production area.

A single location, far from where foods are stored, must be dedicated to waste management.

Safe drinking water is one of the most widely used ingredients in all businesses. It is not only used for formulation and food preparation, such as in juices or in cooking for a restaurant.

Water is also used for cleaning raw materials and utensils alike. As such, water quality in all areas of your food business must have a clean and potable source.

Before operations, your working area must be cleaned and sanitised properly to ensure that no contaminants are present. During off-working hours, dust may build up on the countertops as a result of a lack of proper air ventilation.

As such, it must be included in a monitoring form always to check if preoperational sanitation is done. Preoperational checking also allows your production team to verify if any maintenance needs to be done regarding your operations. Similarly, it is equally important to sanitise your working area after work.

This assures you that no waste or leftover food is left anywhere around your working area. Pre- and post-operation checklists must be provided to the sanitation crew.

Use our free Opening and Closing Checklist to ensure that all pre- and post-operational activities are done for a safer working environment.

A part of keeping food and hygiene together harmoniously is proper orientation and continuous development of your staff's understanding of food hygiene. New employees must be oriented with how your business implements food hygiene practices and emphasise the importance of these steps.

Food businesses are required by law to provide adequate food hygiene training for food handlers and staff. It is crucial that every person has comprehensive knowledge and knows their roles in maintaining food hygiene & safety.

Along with a series of basic food safety training, refresher courses must also be conducted. This activity helps the management to remind all employees of the importance of food hygiene and include any incidence of non-compliance to food hygiene for reference.

Part of a working food hygiene system is properly monitoring and documenting these activities as proof of compliance. Make your work easier by using our free templates for all your monitoring form needs. You can easily document different activities, such as cleaning schedules, pest control and waste control, that will be on the food hygiene inspections list. That way, you'll always be ready for your next food safety inspection.

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Below, we share useful facts about the importance of food hygiene and tips on how you can maintain a strict level of cleanliness in your food business kitchen.

Below, we list essential food hygiene facts and tips for a hygienic kitchen, handling food safely, and protecting customers from potential health risks.

Food hygiene is a valuable aspect of every food business. Every year, customers are affected due to the lack of proper food hygiene controls in some businesses, which significantly affects their way of living and the economy.

Keeping food safe is everyone's business. Every member of the food supply chain has a fair share of responsibility, hence the farm-to-fork approach. It is also consumers' responsibility to ensure that food stays fit for consumption.

Here are some basic food hygiene rules and tips every food producer should follow:

Having a sound understanding of food safety is a prerequisite for anyone working in food-related enterprises. Therefore, food hygiene and safety training are legal requirements in many countries, such as the UK, Canada, and Australia.

It is not only compulsory for food processors but also for catering, restaurants, cafés, retailers, and various premises involved in the food chain, such as wholesalers, school canteens, or food banks.

Orientation, training, and refresher courses aim to emphasise the importance of food hygiene and update existing knowledge about food hygiene. Training in food hygiene must be facilitated by an expert in the field or accredited regulatory agencies and must cover the following topics:

To gain sufficient knowledge, staff can learn from various sources, such as:

Well-informed personnel are key elements to achieving a strong food hygiene system and implementing your food safety plan.

Using our smart Food Safety Management System, you can get monitoring logs and checks with detailed instructions on performing and monitoring food safety tasks. Our customisable features also let you upload your own versions of instructions. This feature also makes the onboarding and training process easier for your team.

The extent of food hygiene knowledge is based on the roles and job descriptions of your business. For example, a food quality manager should know how to implement a food safety management system, such as HACCP or ISO 22000, whereas a food handler who has direct contact with food on a daily basis must know the foundation of food hygiene rules and how to implement them.

These principles include prerequisite programs such as sanitation standard operating procedures and good manufacturing practices.

Food hygiene and safety training are generally divided into three levels, with an occasionally offered 4th level by a competent authority.

Level 1 food hygiene covers "food safety awareness" and is a basic level course. This level is intended for personnel who don't have direct contact with food but work in food preparation and handling areas or where the food is handled elsewhere.

The main objective is to raise awareness in the workplace in relation to food service. Training courses include basic food and hygiene practices, keeping the working area clean, minimising contamination in served food, and acquaintance with key food safety issues.

This food hygiene course is suitable for bar workers, warehouse staff, waiters, kitchen porters, food delivery riders, etc.

This level covers "food hygiene and safety" and is designed for food business operators who have direct contact with food, whether in preparing, handling, or packaging the food. These employees are normally responsible for the implementation of critical control points approved in the HACCP food safety plan of your business.

A trainee will learn the food handling practices and food hygiene, such as food allergen awareness and allergen control, as well as relevant legislation items. It also emphasizes the importance of each practice and clarifies a deeper understanding of why and how to control food hazards.

This course is perfect for production staff, cooks, baristas, and kitchen assistants. It applies to businesses, including hotels and restaurants, food manufacturers, hospitals and cafeterias. This level of training is the minimum standard for most businesses to operate. Generally, this level requires a 70-75% pass mark as proof of proficiency.

The content covers "food safety supervision" and is similar to the Level 2 food hygiene course, with some additional materials on implementing the food safety management system, auditing, and training staff for the production of safer foods. This course is designed for supervisory and managerial roles for retail, manufacturers, and catering service.

Employees with control over handling a group of people are encouraged to take such a course; for example, quality supervisors, restaurant managers, and supermarket managers.

Under this level, managerial employees are also taught strategies on how to spread their food hygiene knowledge to their subordinates in the most efficient way possible and find ways how to apply food hygiene practices throughout the operations.

Although uncommonly introduced to most businesses because of the level of technicality, the level 4 training course covers "advanced food safety management" and applies to managers as well in the food manufacturing industries. A minimum of level 3 training is required before access to level 4 is granted, and this course needs physical appearance to participate.

This level deals with more technical aspects of food safety and contamination, microbiology and foodborne illnesses, hazards and their control (HACCP), advanced sanitation strategies, and the roles of managers in food safety.

After completing a course, a trainee will receive a food hygiene certificate. This document is valid proof that a trainee has completed a food hygiene course and has relevant competency as mentioned in the course content.

A food hygiene certificate in the UK doesn't expire. However, food industry experts suggest re-taking the course at least every three years to keep up with legislation updates and other developments and refresh previous information.

If you are promoted to a higher position, you must take a more advanced course to upgrade your knowledge. For example, as production staff, you have a Level 2 Food Hygiene Certificate. Upon getting a promotion to supervisor, you will need to get a Level 3 Food Hygiene Certificate.

Certifications in food hygiene and safety are an important part of food safety management. They also contribute to the overall rating of a food business during an inspection.

The Food Hygiene Rating Scheme (FHRS) is a set of health standards that businesses put into practice to help consumers determine where to buy their food products. To inform consumers about the level of competency of a business in terms of food hygiene and food safety, food hygiene ratings are given to food businesses depending on their level of maintaining food hygiene.

The responsibility of conducting food hygiene inspections in England, Wales, and Northern Ireland falls upon the Food Standards Agency (FSA) in the UK. The agency oversees the assessment of food hygiene standards in these regions to ensure compliance and safety.

Meanwhile, Scotland has a similar scheme called Food Hygienic Information System, which Food Standards Scotland runs.

The rating of food hygiene aims to provide information for consumers regarding food hygiene and safety, but not on the quality (taste, services or culinary skills).

Food businesses, such as manufacturers who do not provide direct food services to consumers, are not included in this rating scheme. Similarly, the rating usually takes time because of comprehensive reviewing, so relatively new businesses may not have a rating.

You can expect to find food hygiene ratings in various types of business premises, such as:

The rating is displayed in a spot that customers can easily see, such as the front door, entrance, or windows. You can also search for it online on FSA's website.

A high rating also acts as a marketing tool to improve customers' trust in a food business, leading to higher sales. The food rating is mandatory to be posted in Northern Ireland and Wales and is only encouraged in England.

Read more about the Food Hygiene Rating Scheme from our detailed article here.

In short, the FSA considers three areas when assigning businesses their food hygiene ratings: 1) how hygienically the food is handled, 2) the condition of the structure of the premises, and 3) the sufficiency of its Food Safety Management System.

Keep reading for a more detailed breakdown.

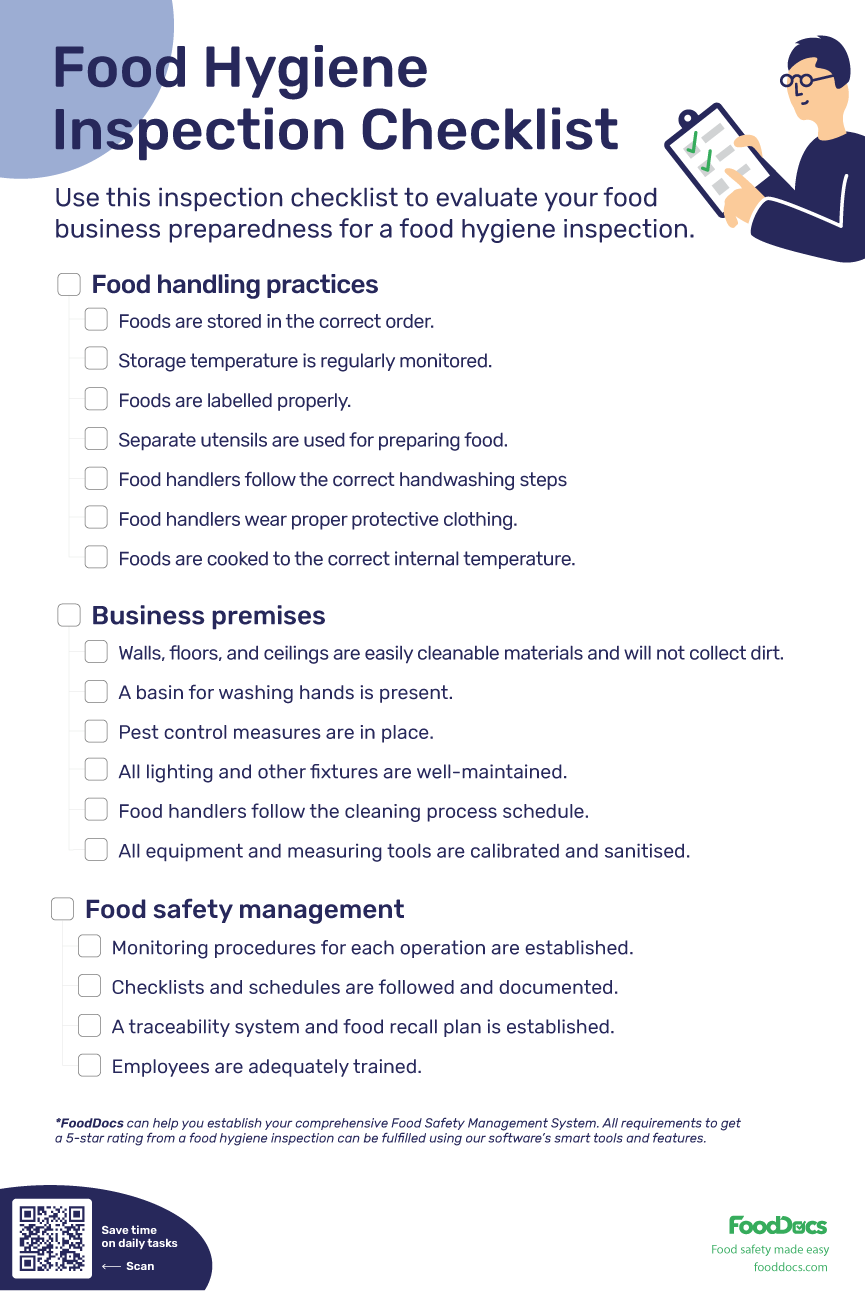

Assessment of food hygiene rating includes three primary aspects, which are based on the compliance of a business to legal regulations on food safety and hygiene. They are broken down into a food hygiene inspection checklist that will be evaluated on the inspection day.

The food hygiene rating is on a scale of 0 to 5, with 0 being the lowest (need urgent improvement) and 5 being the highest (very good).

Inspection frequency depends on the potential risk to health. The lower the risk, the longer the interval for the next inspection. Generally, it's anywhere between 6 months to 2 years. Environmental Health Officers carry out inspections.

Businesses with low ratings must make significant improvements immediately within a scheduled timeframe. If the food safety officer concludes that the food might be unsafe and the company poses a serious risk to human health, this can result in partial or complete closing down of the business.

Results of the assessment usually are released 14 days after the date of inspection, and stickers of their scores are given. Results are also posted on the Food Standards Agency website.

Keeping up with all the tasks and food hygiene laws needed to ensure food safety can be a bit overwhelming to everyone on your team. Not to mention that all of these tasks must be done every day, before and after working operations.

As such, the best way not to miss any task on your food hygiene practices is to make a checklist of the most important daily tasks that need to be done every day.

A helpful and efficient checklist would comprise the following points:

All of these and more points are needed to be regularly checked and must have their monitoring forms. Luckily, our team at FoodDocs has made quick and easy-to-use food hygiene and safety checklist templates needed for keeping food hygiene in your business effective and efficient.

Our templates contain the basic and most important information you need to guide you on how to start making your forms. If our forms seem not to fit your operations, you can easily customise them to fit your business operations.

Poor hygiene poses risks to public health, damages reputation, and can lead to legal issues. Non-compliance with hygiene standards can result in fines, penalties, and even closure of the business, causing financial losses and potential unemployment for those involved. Food handlers must practice strict hygiene when working in a food business.

If the court finds a business guilty of breaching food hygiene legislation, the owner or proprietor is the one who will be prosecuted.

In the UK, if a food business breaches food hygiene legislation, the court can fine the owner or proprietor up to £20,000 for each offence. According to Stephensons, that's the maximum for a single charge, so it's possible that the total fine can end up being much more than £20,000. In addition to fines, the court can hand out a prison sentence of up to two years.

Keeping personal hygiene is an easy task and should not be overcomplicated. There are many simple ways to maintain good hygiene in a food establishment setting.

The most important aspect of personal hygiene for food handlers is proper hand hygiene.

Hand hygiene is a critical approach to hygiene practice and in preventing the risk of contamination of food with harmful bacteria, viruses, or other pathogens

Ensure that all basic hygiene precautions are executed correctly and timely by implementing our smart Food Safety Management System.

Food hygiene is an integral part of the food safety management system. It needs to be consistently maintained for a food business to continue operating. Emphasis on this importance is stressed in every food safety law adopted by any country.

To maintain high standards for food hygiene and safety, food premises must use a comprehensive and inclusive food safety management system. This solution is what we specialise in at FoodDocs. Our team of food safety experts came up with the most efficient and effective digital solution to comply with food hygiene rules in your food company.

Using FoodDocs, you can get up-to-date and essential customisable food safety monitoring forms that are automatically generated by our AI system. It is also beneficial that you can tailor all forms according to your business operations.

For example, you can use our employee hygiene checklist that will help your team remember the essential hygiene tasks that need to be done every day. Add more hygiene tasks according to your business needs.

You can also use our Cleaning checklist, which contains essential tasks for maintaining compliance with food hygiene regulations. Incorporate your business operations and upload your personal tutorial instructions to help your team perform every task correctly.

Cleaning checklist from FoodDocs software

Ensure that all food hygiene tasks are done on time and never forgotten by activating our smart notification feature. Our system will automatically send alerts to assigned food handlers, reminding them of tasks that need to be done.

What is unique with our system is that it only requires you to answer a few basic questions about your operations, and our AI system will take care of the rest. In about 15 minutes, you will get an automatically generated digital FSMS built particularly based on your needs.

Improve your food hygiene rating by using smart digital solutions that will help you boost efficiency in your operations. With these smart solutions, you can ensure that all food hygiene tasks are done.

Make food hygiene and safety your priority, and implement your smart Food Safety Management System today.

Start managing your operations through a more sustainable and efficient paperless solution from FoodDocs. You don't need extremely technical knowledge to maintain a high level of food safety standards with our digital solution.

Do you want to experience these benefits first-hand? Use our free 14-day trial and experience how our solution can help you become more efficient.

Using effective food hygiene practices, a good way of deterring pests is to keep outdoor areas clean and weeds-free, ensure any bins have easy-to-clean close-fitting lids, and regularly disinfect them. This is because weeds and garbage often attract and provide pests with both food and shelter.

Some indicative signs of a rodent infestation in the food industry include droppings, gnaw marks, tracks, grease marks, strange sounds, and nests.

When it comes to dress codes for food service employees, food service employees must wear clean uniforms, including shirts, pants, hair nets, appropriate shoes, and aprons, to minimize the risk of cross-contamination from dirty clothes. Uniforms should be free of holes, rips, loose buttons, and visible dirt. Food handlers must wear effective hair restraints like chef hats and are restricted from wearing accessories except for plain wedding bands.

A documented dress code policy must be part of company guidelines and communicated clearly to employees during food hygiene training. While dress codes may vary with the business theme, the primary rule is that uniforms must not contribute to food contamination.

In the UK, the scheme that the Food Standards Agency (FSA) uses to evaluate a business's food hygiene standards and helps consumers choose where to buy food is the Food Hygiene Rating Scheme (FHRS).

In the UK, the temperature danger zone for food is between 8°C and 63°C. This temperature is the range in which bacteria can grow and cause foodborne illness.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...