COOLING FOOD POSTER

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

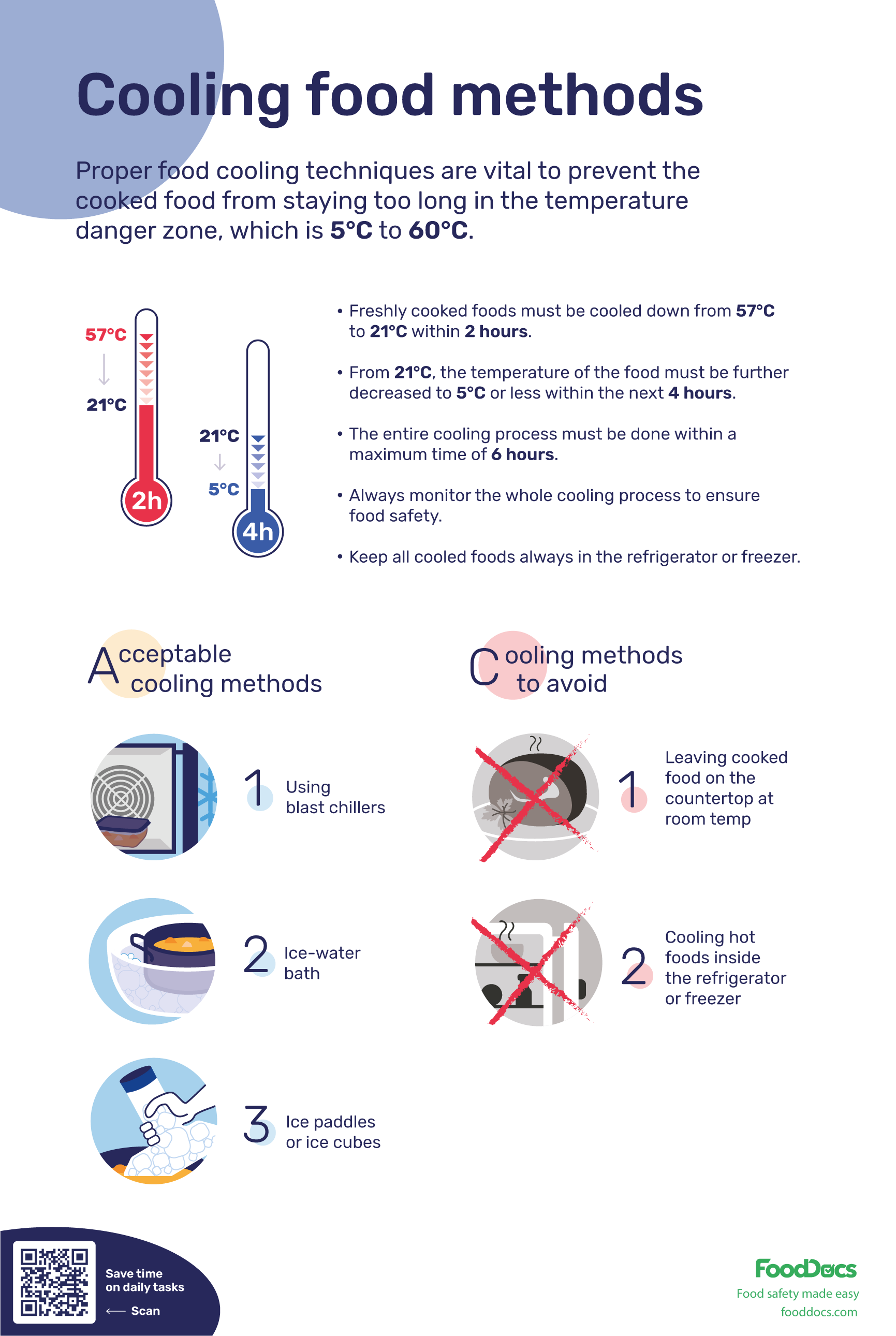

How to use the FoodDocs cooling food poster?

Cooling is a simple yet essential operation in any food business. It must be done properly to extend the shelf life of freshly cooked foods. Follow these steps to get your copy for free:

- Familiarize yourself with the Cooling food poster.

- Enter a valid email address under the poster.

- Click "Download." Your downloaded poster will automatically be saved into your downloads folder.

To effectively use this poster, orient your employees about the significance of cooling foods properly and introduce the poster to them. Make the poster accessible to everyone by pinning it in a visible area where cooling is mostly done, such as on the refrigerator door.

Key points covered:

- Cooked foods must be properly cooled to maintain food safety before low-temperature storage.

- Foods must be cooled from 135°F to 70°F (57°C to 21°C) in the first two hours and must reach 41°F (4°C) or less in the next 4 hours.

- The entire cooling process must be completed within the first 6 hours. Going beyond this time frame increases the risk of contamination.

- The three approved methods for quickly cooling foods include a blast freezer, ice paddles with water and ice cubes, and an ice-water bath.

- The cooling process is affected by the amount of food, the cooling method used, the external effort applied, and the proficiency of the food handler.

- Freshly cooked foods must never be left on a kitchen countertop at room temperature to cool as they are exposed to the risk of food contamination.

- Never put freshly cooked food inside any unit for refrigeration, as this will bring the internal temperature of the cooling unit down and endanger the safety of other foods in the unit.

- The cooling process must be constantly monitored to ensure food safety.

- Monitoring cooling food methods has become easier with digital solutions like FoodDocs digital Food Safety Management System.

Keeping foods fresh with expert-approved rapid cooling methods

Cooling food is a critical phase in maintaining the safety of food products between cooking and refrigeration.

Properly cooling food is a key operation in maintaining food safety in any food business. When done correctly, the expected shelf life of the food product can be achieved and potentially optimized.

According to a Centers for Disease Control and Prevention study that summarized 10 years' worth of information, at least 504 foodborne illness outbreaks originated from restaurant food businesses due to improperly cooled foods. This ten years' worth of data shows how important it is for a food safety team to learn how to cool foods properly for cold storage.

WHAT WE'LL COVER:

- What are the temperatures for safely cooling foods?

- Acceptable methods for cooling food

- Which method for cooling foods should not be used?

- Proper cold-holding temperature for TCS foods

- Steps for cooling food

- Factors affecting the safety of cooling

- Monitor temperatures for cooling food

- Tips for cooling food

- Intuitive solution to monitor cooling food methods

- Frequently Asked Questions

What are the temperatures for safely cooling foods?

To remain safe after cooking, the food must reach the cooling safe temperature of 70°F (21°C) within the first 2 hours and continue cooling until it reaches 41°F (4°C) within 4 hours.

Food handlers must familiarize themselves with these two points to maintain food safety. The food supply chain often identifies this process as the two-stage cooling method.

The main objective of cooling foods to a particular temperature range within a given time frame is to prevent the food from staying too long in the bacteria temperature danger zone, which is 40°F to 140°F (5°C to 60°C). Within this temperature range, foods are more likely to spoil faster as the growth of harmful bacteria and other microorganisms is favored.

Using rapid cooling methods, the potentially contaminating microorganisms will not have enough time to reproduce to exceedingly dangerous levels. Rapid microorganism growth is slowed at lower temperatures, restricting their ability to digest the food and creating unwanted and unsafe changes.

Cooling food after processing requires close monitoring to become successful.

If unregulated, the cooling process can become an introduction point for the contamination of food and spoilage. This potential hazard makes cooling foods a critical control operation for food handlers.

The best way to monitor the entire cooling process is to use FoodDocs' smart Food Safety Management System. Using our smart software, you can get an automatically generated food cooling log with fields for the essential process information. Record the temperatures at each step and ensure that the process is done accurately with the help of our smart solutions.

What are the 3 safe methods for cooling food?

The methods used for cooling food must be able to do the job as fast as possible or within the prescribed time without sacrificing the food's quality.

In addition, the preferred method must not become the source of contamination during cooling.

- Using blast chillers. Commercial blast chillers or tumbler chillers are exclusively used to reduce the temperature of foods quickly.

- Ice-water bath. This alternative method is efficient for solid dishes or foods with pieces of solid ingredients that cannot be watered down.

The food being cooled is either placed in a ziplock bag or deep bowl and is placed over an ice-water mixture to help the temperatures equilibrate. The ice and cold water mixture will help cool the food through conduction.

- Ice paddles or ice cubes. These methods use ice that will come in contact with the food. Ice paddles, or ice wands, are commercial kitchen utensils filled with ice cubes and water and stirred around the food to distribute the cold temperature.

On the other hand, loose foods, such as soups and gravies, can be filled with ice cubes directly as the added water will evaporate after reheating.

Food safety and health departments, such as the U.S. Food and Drug Administration, approve these three methods above. They are considered safe, provided that food handlers and managers in restaurants follow proper food safety measures and temperature regulations. Such measures include isolating the food from other potentially contaminating objects and using only purified and clean water for cooling.

When cooling food what is the maximum time?

The entire food cooling process must be done within a maximum time of 6 hours. After this allotted time, the cooled food must be kept inside the refrigerator or freezer unit types with consistent monitoring.

Compared to the proper cooling of food, which methods of cooling foods should not be used?

When it comes to cooling foods, specific methods should be avoided to ensure food safety and prevent the risk of accelerated bacteria growth.

Below are two methods that should be avoided when cooling foods.

- Leaving food on your countertop

- Placing hot foods inside the refrigerator

Leaving food on your countertop

At some point, you may have thought of leaving your food on the countertop for cooling and returning to it afterward. Room-temperature cooling is very prone to food contamination and spoilage. This method exposes the high-risk food longer to the temperature danger zone.

When perishable foods are left to cool at ambient temperature, whether protected from external contamination or not, they are still exposed to the temp danger zone. Any leftover harmful microorganisms may have the opportunity to recover and multiply as the food cools down at ambient temperature.

As a rule, do not leave freshly cooked foods on a countertop to cool to prevent overhead contamination.

Placing hot foods inside the refrigerator

Another method for cooling foods that should not be a common practice in your food business is cooling hot foods inside the refrigerator or freezer. Not only is this method dangerous for the food being cooled but for the other foods inside the refrigerator as well.

When hot foods are placed inside the refrigerator or coolers, cooling may be faster than leaving it at ambient temperature or other refrigeration steps. Despite this, the unit temperature inside the refrigerator will decrease from the heat from cooked foods.

Foodborne pathogens can contaminate and spoil the food as the refrigerator temperature differs from its preset specifications. Other cold food products, especially high-risk hazardous food, can also get spoiled during this time. Frozen foods can also thaw and be prone to contamination.

What is the proper cold-holding temperature for TCS foods?

The cold holding temperature for TCS foods must be 41°F (5°C) or below. TCS foods or time/temperature control for safety foods are perishable products or hazardous foods requiring critical food safety control. To maintain safety, they must be cooled and held at a particular temperature.

The proper cold-holding temperature for TCS foods refers to the temperature at which these foods should be stored to prevent bacterial growth. At 41°F (5°C), the growth of harmful pathogens is significantly slowed, keeping TCS foods safe for a more extended period.

Within how many hours must cooked TCS food be cooled from 135 to 70?

Cooked TCS foods must be cooled from 135°F (57°C) to 70°F (21°C) within 2 hours after cooking. This is the first step of the 2-stage cooling method.

Within the first two hours, cooked TCS foods must be rapidly cooled to reduce any risk of contamination from their environment. This rapid cooling can be facilitated using equipment such as a blast chiller.

The concept is to ensure that the cooked TCS food does not remain within this temperature range for an extended duration.

What are the steps for cooling food?

Cooling different types of food consists of simple steps that must be precisely done to avoid food contamination. Each step must be followed correctly to ensure that the resulting cooled food will not encounter any food safety issues once it is refrigerated.

- Prepare the freshly cooked food for cooling. Start by portioning batches of food into smaller amounts and placing them in shallow containers of food. Do not close the container, as this will trap the moisture in and prevent the excess heat from escaping.

- Start the initial 2-hour cooling process. Place the hot food in a well-ventilated area away from direct sunlight, dust, or other sources of contamination. Unventilated food areas can make the cooling process harder.

- Monitor the temperature of the food. Regularly measure the internal temperature of the food being cooled using a calibrated probe thermometer. The goal of the initial cooling step is to reach 70°F (21°C) within two hours.

- Transfer the food to the refrigerator. Once the food reaches the target temperature, transfer it into the refrigerator at the temperature of 40°F (4°C) or below. Properly cover the food with plastic wrap or sanitized lid to prevent cross-contamination. Leave enough space in between the foods for air circulation.

- Monitor the shelf-life of the cooled food. As foods have a limited shelf-life, the newly cooled product must be entered into the traceability system for further monitoring by food workers. Remember to label the product to guide your team on the estimated shelf-life of the product.

Download our free Proper Food Storage Chart as a guide to the estimated shelf-life of different products used in a food business.

If initial cooling fails, take immediate action to prevent the growth of pathogens. Additional cooling steps, such as further dividing the food into smaller portions or increasing the airflow, can be done.

What is the maximum amount of time that the entire cooling process may take?

The entire cooling process must be completed within 6 hours. This duration is divided into two stages.

The first stage is to cool down the food from 135°F (57°C) to 70°F (21°C) within the first two hours, then from 70°F (21°C) to 41°F (5°C) or below in the next four hours.

It's crucial to monitor the temperatures during both stages using food thermometers to ensure that the food is cooling at the proper rate. If the cooling process takes longer than the recommended timeframes, there's an increased risk of bacterial growth and potential foodborne illness.

What affects the safety of the food cooling process?

Although the food cooling process is performed for food safety, the process is not immune to contamination. If done incorrectly, food spoilage can still occur.

Below are factors that every food handler must consider to ensure that the cooling process is correct and will achieve its objective:

1. Time of cooling. As previously mentioned, the entire cooling process must be completed within a maximum time of 6 hours. Beyond this time frame, the risk of food poisoning increases. Some cooling methods are more appropriate for certain food types.

- For example, if you are cooling a big batch of thick soup with cooked meat and vegetables, using the blast chiller may take longer than ice paddles or ice cubes. As such, food handlers must assess which method would be most efficient for cooling.

2. Temperature. This factor is what needs to be closely monitored during cooling. The proper temperature of the food will dictate whether it is ready for cold food storage or is still within the critical time.

Inaccurate temperature readings may lead the food handler to believe that the food can already be refrigerated when the core is still hot, and it can still significantly affect the cooling unit's temperature.

3. Thickness or density of the food. The efficiency and safety of refrigeration cooling methods for food are significantly affected by the thickness, arrangement, density, and other properties of food.

- Thick cuts or a large mass of oily food would generally take a longer time to cool down. While the core of the food is still hot, the exterior portion may already be exposed to the temperature danger zone. The thicker or denser the food, the slower the core heat will displace. As such, a mass of food must be divided into smaller portions to speed up the process.

4. Food container. Different packaging materials for food containers conduct heat differently. For food mixtures being cooled using the ice bath method, a stainless steel bowl will cool the mixture faster than a thick plastic container. Stainless steel transfers heat more efficiently than other containers.

5. Applied external force. This factor applies to common cooling methods that use stirring, such as in ice-wand cooling. Cooked foods naturally have different temperatures throughout their composition. Heat can sometimes be trapped in the middle point of the food, especially for thick products.

- To avoid this, external force through stirring or mixing is applied to redistribute the heat throughout the liquid food and facilitate the proper cooling process.

6. Food safety training. This factor is a significant point that must be highlighted during food handler training. The proficiency of food handlers in preparing the cooked food, cooling, sanitation, and monitoring can determine the success of the entire process. Food handlers with insufficient training and knowledge of temperature requirements can increase the likelihood of contamination.

Other factors, such as the cleanliness of the tools and the plain water you are using, will also affect the safety of the process.

Food handlers must consistently practice food hygiene to avoid the likelihood of contamination. They must also always be alert and on time to monitor the safe temperature of foods to ensure the process is still on track.

Improper cooling practices can result in bigger problems and can put the lives of customers at risk.

Why should you monitor temperatures when cooling food?

Monitoring the cooling process ensures that the operation is free of contamination and will not be subjected to unfavorable conditions until it is completed. Monitoring includes temperature reading and recording the measurements.

Due to the strong influence of temperature and process efficiency on both the completion and safety of the cooling method, the process faces a significant risk due to inaccurate monitoring.

Achieving the target temperatures within the prescribed time will determine whether the food was exposed to the temperature danger zone.

Consistent monitoring will significantly reduce the opportunity for pathogens to reproduce. It is also an essential task to allow food handlers to address any concerns immediately. For example, if the internal temperature of the common food item is still higher than 70°F (21°C), the food handler can exert extra effort to speed up the process and achieve the final target temperature earlier.

Use a temperature log and a properly calibrated accurate food thermometer to monitor the cooling process and food temperature.

Tips for cooling food

On top of the three approved cooling methods for cooked foods, food handlers must also be aware of other factors to ensure food safety. The success of the cooling method also relies on how safe the food safety operation will be.

To help your team successfully cool foods without the threat of contamination, follow these food safety guidelines:

- Ensure that all utensils used to cool foods are clean and sanitized properly.

- Only use clean and purified water for making an ice-water bath.

- Divide the food into smaller portions or lay them flat to facilitate the cooling process. Do not try to chill large quantities of food at once.

- Use a properly calibrated food thermometer to monitor the temperature of your foods.

- Never place hot foods inside the refrigerator. This will change the overall temperature inside the refrigerator.

- Use shallow containers for faster cooling.

- Label cooled foods before refrigerating.

- Follow proper organization of foods inside the refrigerator to avoid contamination after cooling.

- When using the ice-water bath method, stir the food with a sanitized ladle to redistribute heat.

What is an intuitive solution to monitor cooling food methods?

Throughout the cooling process, monitoring and recording the temperature of your foods will be done multiple times. If you have large batches of prepared foods, you will need to perform food processing tasks more.

FoodDocs' intuitive food safety software makes this easy.

Cooling log to help monitor the process intuitively

Monitor your cooling operations using an automatically generated and customizable Cooling log. Use this log equipped with intuitive solutions to record temperature readings during the entire cooling process.

- Product being cooled (Barcode compatible)

- Starting time

- Starting temperature

- Temperature after two hours

- Final temperature

With the help of this feature, you can ensure that all freshly cooked foods are cooled properly and safe from contamination. You can keep records of the most critical information about the process and have extensive documentation of cooling foods stored in one place.

Educative instructions to guide food handlers

All food safety operations rely on the accuracy of execution to become effective and efficient. As such, we developed a smart solution to help food handlers perform food safety practices accurately.

All automatically generated monitoring logs come with step-by-step instructions on how to perform and monitor a particular task. For our Cooling Log, a pre-uploaded instruction on performing the two-stage cooling process is available.

Restaurant managers can use this to train food handlers during onboarding and as a reference for daily operations. You can also upload your versions of the instructions as images or video clips.

Smart notifications to help keep track of tasks

To help food handlers simultaneously keep track of all food safety tasks, you can use our smart notification system. This smart solution was developed to help remind food handlers of important tasks.

Using our smart notification system, food handlers will receive intuitive alerts whenever a task is due. Use this feature to remind food handlers about the two main stages of the cooling method.

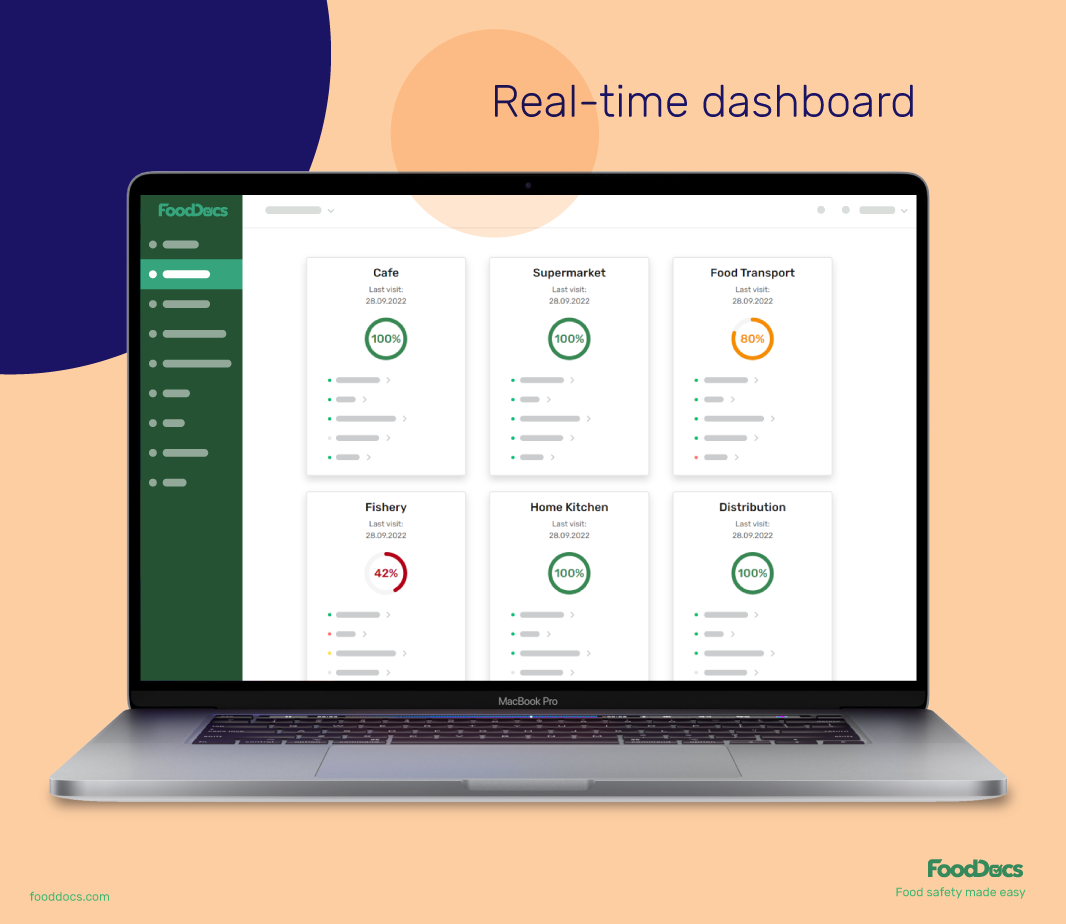

Real-time dashboard to give you an overview of operations

Monitor your food safety operations remotely with the help of our real-time dashboard.

Using our real-time dashboard, save at least 20% of your time from supervising your team.

This feature shows an overview of your daily operations where you can immediately identify areas that need to be addressed.

Know when food service operators successfully cool freshly cooked batches of your products. The dashboard will also show you instances when problems are encountered during cooling. Through this, you can easily address incidents right away.

Allow our digital Food Safety Monitoring System to take care of the repetitive, everyday tasks so you can focus on the other aspects of your food business. Using artificial intelligence and a machine-learning program, you will get a monitoring system tailored to the nature of your operations.

You can further improve the monitoring system according to your needs, as it can be customized. Maintain compliance with food safety regulations most efficiently by using our digital solutions for food businesses.

Start your food safety compliance journey by booking a free demo call.

Frequently Asked Questions

What is the first step in the cooling process?

The first step in the cooling process is to cool the freshly cooked food from 135°F (57°C) to 70°F (21°C). This step ensures the food product will not be exposed to the temperature danger zone for a critical time.

To help perform this step easily, the cooked food must be prepared by dividing it into smaller portions before cooling.

The freshly cooked food will take longer to cool if it is left in bulk. To aid the cooling process, it must be portioned into shallow containers, increasing the surface area of the food from which heat will escape.

By prioritizing rapid initial cooling, you establish a strong foundation for subsequent stages and minimize the risk of foodborne illnesses caused by inadequate cooling.

Why should you cool hot food quickly?

During the cooling of hot foods, there is a window period for opportunistic pathogens to contaminate and spoil the food. This is especially true once the hot food reaches the temperature danger zone of 40°F and 140°F (5°C and 60°C, respectively).

Cooling food from 135°F to 70°F (57°C to 21°C) in the first two hours and down to 41°F (4°C) or less in the next 4 hours ensures that the food stays safe.

Which of these methods is not safe for cooling food?

- Leaving the food on the countertop at room temperature.

- Cooling the hot food inside the refrigerator or freezer.

What are the risks when cooling food?

- Temperature danger zone

- Inaccurate temperature measurement

- Inefficient cooling

- Cross-contamination

What is the maximum amount of time that the entire cooling process may take?

The entire cooling process must be completed within 6 hours.