Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

An individual working in a food business functioning directly with food is referred to as a food handler.

The food industry works because of food handlers. They perform the food preparation and safety principles that comprise the whole food industry. Put simply, any food business will not survive without food handlers.

Even with the help of automation, there would be no one to operate machines without food handlers. Food handlers are the backbone of any food establishment.

Training food workers on safe food handling is the responsibility of a reliable food business owner or food safety manager. Poor food handling is directly linked to the increase in foodborne illness cases. As such, it is a requirement for food handlers to receive appropriate training.

Keep scrolling to learn how you can make food handling training easier and help your employees comply with food safety standards efficiently.

WHAT WE'LL COVER:

A food handler is any individual working in a food business facility. They are involved in preparing and handling raw foods, operating food equipment, cleaning food contact surfaces, and any food operation with direct contact with food. Food handlers can be cooks, chefs, dishwashers, cleaning aide, and servers.

Food handlers are screened and employed by food business owners or managers to determine their competence in food service or manufacturing. Once hired, they are further trained to gain appreciation and knowledge of food safety and proper customer service.

Otherwise known as food workers, the hired food handlers are assigned specific tasks in a food business and are expected to maintain safety and quality through their work.

In general, food handlers are tasked to operate the different areas of a food business involving the following:

Depending on the dynamics of a food business, a food handler may be given more than one task. They are responsible for ensuring that food safety hazards are always controlled and foods are safe for consumption.

The responsibility of a food handler goes beyond just cooking food. Every food handler is tasked to protect consumers from potential foodborne illnesses. They are also responsible for protecting the company brand through proper food handling.

In particular, here are some of the principal responsibilities of a food handler:

More specific responsibilities in the different areas of a food facility are provided to food handlers. All working employees must be knowledgeable about the proper handling practices to protect public health from foodborne illnesses. Food employees must receive adequate and proper food safety training class to ensure their competency. Even though their job responsibilities are about handling food, they would also benefit from an online nutrition course, to build knowledge around food and nutrition.

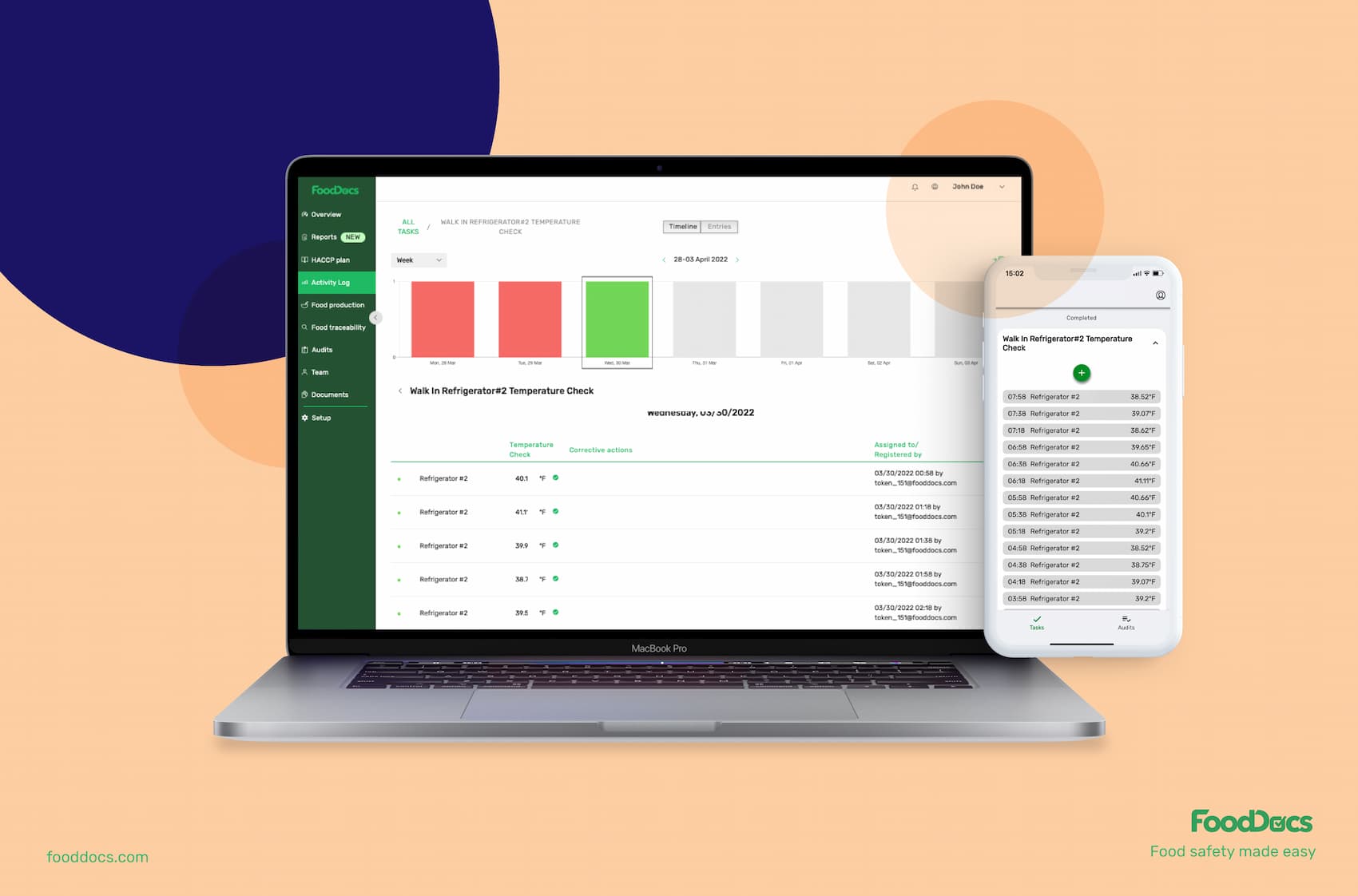

Use our digital Food Safety Management System to get a program that generates digital monitoring logs and promotes role-based tasks for your team. Ensure that every food handler is focused on their task by assigning particular logs to them. In addition, you can easily monitor and verify if every task is done on time and correctly in the palm of your hand.

Food handler training programs and understanding food safety regulations are important for all employees of a food business. Training programs commonly include basic information about food handling and the principles of food safety.

Securing food handling training can help reduce the risk and burden of food safety issues.

Different levels of food handler training programs are provided by federal agencies and private organizations.Depending on the position of a food worker, the level of training required may increase.

Some of the most important training that a food handler must have before working in a food business may include the following:

Food safety training programs are commonly divided into different levels. The degree of contact with food and responsibilities in the facility will determine the required level of training.

The mentioned food safety training topics are common for all levels of programs. These topics are fundamental for any food handler to ensure food safety in the workplace. More advanced training may involve a deeper understanding of biological processes, strategy making, and creating food safety plans.

Food safety training is often offered through different modes of teaching. The more popular option is online courses. These programs provide flexibility for the food handler. An individual can participate anytime they want and pause the module when needed. The advantage of on-site training from private organizations and government agencies is that they offer practical lessons for training food handlers.

At the end of every food handler training program and exam, participants are given a certificate as proof of successful completion. Food handlers can claim the certificate online. In some cases, the training program must be renewed to refresh and update the food safety knowledge of employees.

Some countries and states recommend the renewal of certificates every three years. On the other hand, food safety managers are required to renew training every 5 years.

In the U.S., all food handlers are required to undergo training before being allowed to work. As proof of proficiency, food handlers must secure a certificate, which is otherwise presented as a food handlers card in different states.

A food handlers card is a license presented to food safety inspectors. It is proof that a particular food handler knows the basics of food safety and is qualified to work in a food business.

The guidelines for securing a food handlers card and the frequency of renewal will depend on the food safety regulations of a state. In some cases, the qualifications vary from state to state as well. This fact makes a card inapplicable when you transfer states.

A majority of states in the U.S. provide in-state training programs that highlight the specific regulations of that state.

In the UK, food handlers are not required to secure a food safety certificate to work in a food business. The law only requires that food handlers must be able to show knowledge of food handling practices and receive adequate training.

Check out our list of answers for food handlers test to train employees and ensure their successful completion of an official exam.

After undergoing training, food safety managers can provide supplemental tools that will help food handlers.These tools can help improve the retention of information and the accuracy of the operations.

Most tools will highlight the essential information that you need to always observe in a food business. Some of the useful rules and tips that you need include:

Food handlers are required to know at least the fundamentals and principles of food safety procedures. An adequate appreciation of the operations can help food handlers improve their performance and secure food safety.

When a food handler knows the potential consequences of poor food safety practices, accountability can be improved.

At FoodDocs, we provide free food handlers solutions such as templates, checklists, and posters that you can use to guide food handlers. Access our HACCP plan and food safety template hub and check out our free resources.

Food handlers can significantly reduce the likelihood of bacteria in foods by practicing proper food hygiene. The presence of bacteria is a major type of biological contamination in the food industry. This food safety hazard is responsible for the majority of foodborne illness cases reported yearly.

Maintaining personal hygiene tasks can significantly reduce the risk of bacterial contamination to safe levels. In addition, other critical operations must also be observed. Operations, such as cooking, storage, and handling, all contribute to the safety of foods.

Read more about limiting the growth of bacteria.

Food handlers training is not only an essential job, but it is also a continuous one. This means that an employee will have to learn more tasks as they move along their careers. Managers need to pay attention to food safety training and provide the necessary knowledge to food handlers. While new food handlers are practicing a food safety procedure, managers must consistently take notes for future evaluation and feedback.

Food safety can only be achieved if the employees know how to control food hazards in the food business.

Nowadays, digital solutions, such as FoodDocs' digital Food Safety Management System, can help ensure that the knowledge and expertise from food handler training are consistently applied and maintained. With smart, digital solutions, food safety compliance can become more accessible.

When you use our digital Food Safety Management System, you can get the following features for all food employees:

-png.png?width=1417&height=924&name=Cooking_temperature%20(1)-png.png)

Cooking temperature log from FoodDocs

Employee hygiene checklist from FoodDocs

In addition to features that will ease up food safety training, our digital solution also provides features that can help boost management efficiency.

Real-time dashboard from FoodDocs

Food handler training module at FoodDocs

What's even more appealing about our digital solution is that you can get all of these features and more in just 15 minutes. Powered by artificial intelligence and a machine-learning program, our system can automatically generate all essential documents for your food business.

The whole process only requires you to fill up and answer a few basic questions about your operations and our system will do the rest.

In addition, you can further improve or tailor all food safety monitoring logs to your operations. All logs and checklists are easily customizable at any time.

Consistently train and monitor food handlers without putting in much effort using our digital food safety management system.

Use our free 14-day trial to experience how our system can help you maintain food safety compliance.

Are you still in the dark about the most important food handling techniques and training? Here are some frequently asked questions about food handlers.

Grocery store or retail workers with direct contact with food are also considered food handlers. Anyone working with foods, whether packing, preparing, cooking, or serving foods, is considered a food handler.

The most essential food safety rules include the following:

In order to prevent food contamination, a food handler must regularly practice proper handwashing. This simple food safety operation can significantly reduce the likelihood of causing foodborne illness to consumers.

A food service worker is otherwise known as a food handler. The term food service worker is often used for handlers working in the food service industry, such as in restaurants.

Yes. A food service worker is a more specific term for a food handler. They are food handlers working in restaurants, cafeterias, and grocery stores.

Before handling ready-to-eat foods, food handlers must wash their hands properly. Ready-to-eat foods are already about to be served to consumers. As such, food handlers must ensure that no contamination will occur between preparation and service.

The initial step for a food handler setting up a three-compartment sink for dishwashing is to thoroughly clean and sanitize the sink. This crucial action removes any dirt, debris, or residual food particles, preventing contamination of the dishes during washing.

A food handler must wear single-use gloves when touching ready-to-eat meals (especially if they consist of TCS food) that may come into touch with their palms. Gloves are also required for food handlers who have cuts, sores, or orthopedic devices on their hands.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...