FREE CLEANING SCHEDULE TEMPLATE

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

What's the importance of cleaning schedule template?

Cleaning and sanitizing are two of the most important criteria for food safety practices. Every food establishment must implement these operations to ensure the safe production processes of a wholesome food supply.

These control measures embody the basic principle of how to keep food safety hazards, especially biological hazards such as harmful microorganisms, out of your kitchen and service area. Regardless of the type of food establishment that you have, you must always have a cleaning schedule.

It is an integral part of your food defense from food supply to your food transportation. To create an effective cleaning routine, use a HACCP cleaning schedule template.

Cleaning and sanitizing include several different factors to make these operations effective. These factors may be the type of solution you use, its concentration, the frequency of application, duration of cleaning, the areas that need to be cleaned, and more.

As part of every food business' approach to food safety and commitment to their consumers, you must have a complete and effective cleaning schedule in place. This objective ensures that your food establishment is only producing safe food products and is free from food safety risks.

Key points covered:

- A cleaning schedule template is vital for effectively organizing and documenting sanitation efforts in food establishments.

- The template helps ensure that food businesses meet food safety standards by keeping environments clean and minimizing biological hazards.

- It includes detailed parameters such as surfaces to be cleaned, products used, dosage, and frequency, ensuring thoroughness in cleaning protocols.

- Regular cleaning and sanitizing are essential to prevent the growth of pathogens and deter pests in food establishments.

- Cleaning schedule templates are customizable to fit the specific needs of different food operations, enhancing their utility and effectiveness.

- Proper use of cleaning products, as dictated by the schedule, helps avoid food contamination and ensures the effectiveness of sanitizing efforts.

- Cleaning schedules also serve as a training tool for staff on the proper cleaning methods and food safety protocols.

- Documentation of cleaning activities supports compliance with health regulations and can prove adherence in audits.

- FoodDocs provides a digital Food Safety Management System that includes tools for creating and managing effective cleaning schedules, ensuring tasks like cleaning and sanitizing are completed accurately and on time.

What is a cleaning schedule template?

A HACCP cleaning schedule template is a useful tool for creating a detailed plan on how to effectively reduce the risk of food safety hazards in your food establishment.

This document is an integral part of any food safety plan. Food safety consultants or an environmental health officer may request this document as an aspect of verification. It is used to create a schedule for the cleaning and sanitizing process of your food establishment.

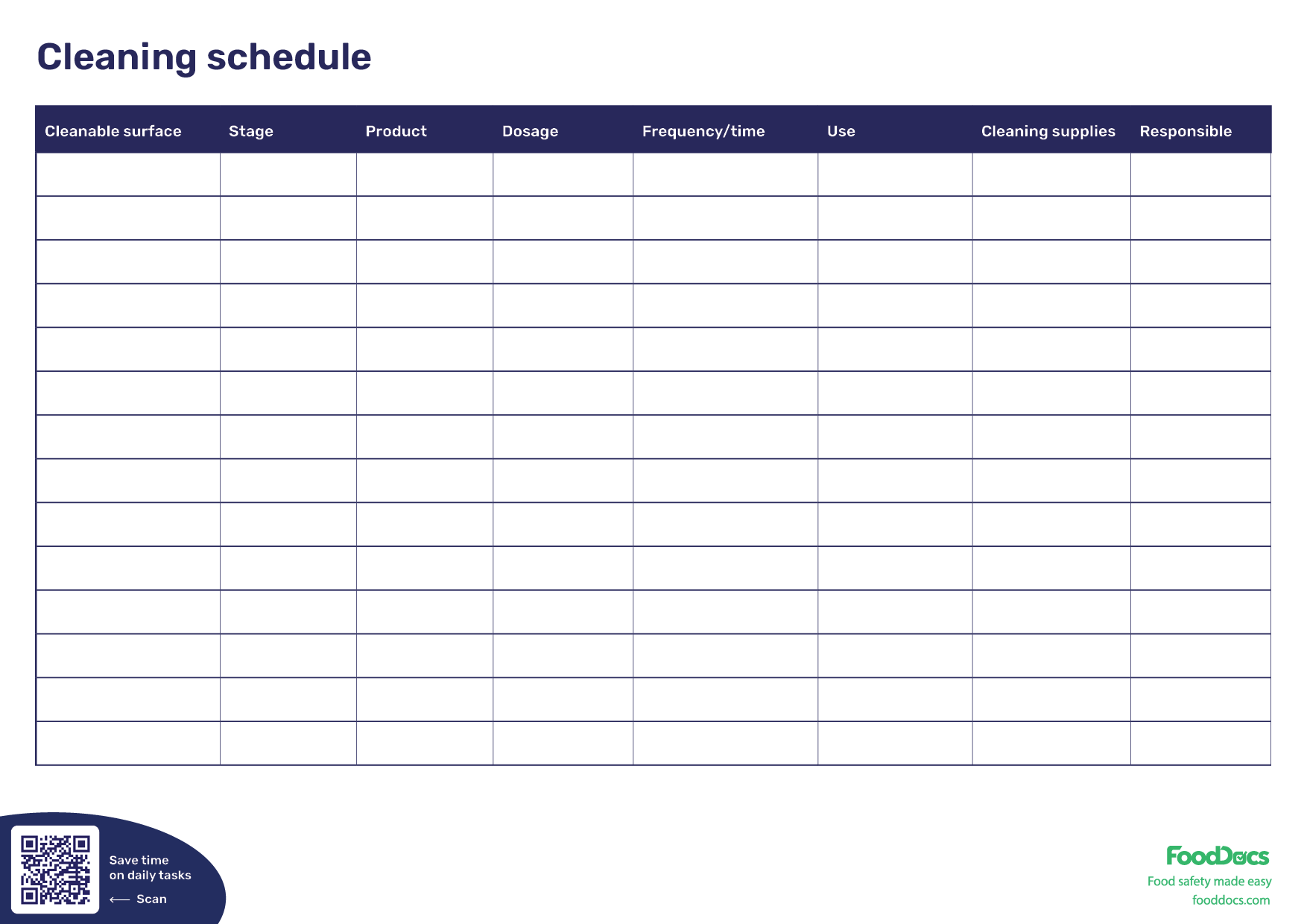

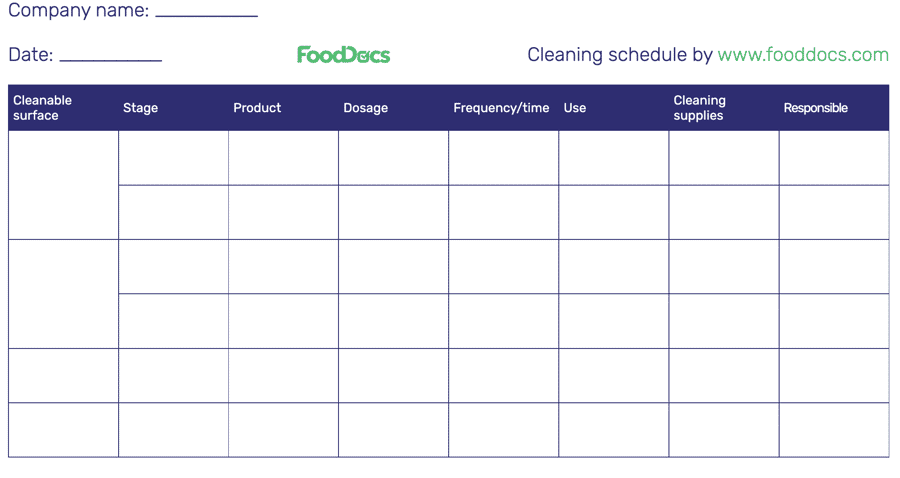

A cleaning schedule log is used to note when and how to perform the food operation. It includes the following components:

- Surfaces to be cleaned (Cleanable surface)

- Stage of operation (Cleaning or sanitation)

- Product to be used (e.g., liquid soap, hand soap, sanitizer, etc)

- Dosage

- Frequency of operation

- Other cleaning supplies needed

- Responsible employee

Other factors that significantly affect the effectiveness of the cleaning process may also be added such as contact time and temperature of the solution. Cleaning and sanitation need to be performed precisely as suggested by the manufacturer.

In the food industry, recommendations from health departments such as 50-100 ppm concentration of chlorine for at least 7 seconds or 200 ppm for quaternary ammonium salts for at least 30 seconds in ambient temperature are considered legal requirements for an acceptable limit.

These parameters ensure that the target outcome is achieved to make every food you produce safe. Any critical limit deviation related to these factors can affect the food operation's effectiveness.

Cleaning and sanitation of all surfaces where any raw material may come in contact are necessary operations for every food establishment. They must be regularly performed to ensure food safety.

Neglecting cleaning and sanitation can lead to the growth of many different pathogens and even attract pests such as flies and cockroaches.

Who needs a cleaning schedule template?

All food establishments in the food chain including a restaurant, food trucks, cafeterias, grocery stores preparing foods, and even a deli stand need a HACCP cleaning schedule template. Because every food establishment needs a cleaning plan, you'll surely need this document as part of your food hygiene plan. It would even be better if the template can be easily customized to fit your specific needs.

A cleaning schedule log can help food establishments organize cleaning-related activities and serve as a reminder for the whole team to keep your food facility always in top shape and reduce the risk of food poisoning.

How to create a HACCP cleaning schedule template?

To create an effective HACCP cleaning schedule template, your document must have the necessary parameters. These parameters are the information needed to ensure that the cleaning and sanitizing operations are effective to produce safe food products.

We know from our own experience that one of the biggest challenges of running a food business is keeping it clean. This can be a big challenge, as there are a lot of employees and they are constantly changing. To help you design an effective HACCP cleaning schedule template, here are some steps that you can follow:

7 Steps to a perfect cleaning schedule

STEP 1: Determine what needs to be cleaned.

The best way to do that is physically walk through all rooms and define all surfaces, items, spaces, and equipment that you need to clean regularly. It doesn't matter if you need to clean it daily, weekly, or monthly, just write it all down.

For example, sinks, floors, stainless surfaces, ventilation systems, hot marmite, fridges, doors, surfaces, toilets, mirror surfaces, trash bins, doorknobs, walls, closets, and artificial material surfaces.

STEP 2: Define whether the surface needs cleaning, disinfecting, or sanitizing.

What is the difference between cleaning, disinfecting, and sanitizing?

Determining whether the food contact surfaces that you listed need cleaning, sanitizing, disinfecting or a combination of two food handling practices require rationalization of their intended use. To understand which operation you need, learn to differentiate the three tasks.

- Cleaning refers to the physical removal of dust or any debris found on surfaces or any other source of contamination. It can be achieved through sweeping, wiping, washing, or manually picking up the dirt.

- Sanitizing effectively decreases the number of pathogens in food contact surfaces to an acceptable level. This operation does not guarantee the elimination of viruses on surfaces.

- Disinfection is the harshest operation of the three. It involves killing specified pathogens to kill them to nearly 100%. Disinfection products usually need a longer contact time with the source of contamination to allow the solution to work when compared with sanitizing.

STEP 3: Determine products, dosage, and proper use.

All chemicals used in food establishments for cleaning and disinfecting food contact surfaces and equipment must be approved as food safe. Otherwise, their use may lead to food poisoning as the solution gets into the food.

For every item, surface, or room, determine how the products are used including the correct concentration to be used. Follow the manufacturer's preparation and cleaning instructions to prevent overdosing and the use of the wrong cleaning products.

Detergents are mostly used when cleaning, and they clean the surface to remove grease, but they do not kill bacteria and viruses.

Sanitizers are used both as part of a two-stage cleaning procedure. First, use the sanitizer to remove dirt, food, and grease. Then, re-apply to the visibly clean surface and leave for the required time to sanitize the surface. Most sanitizers recommended for food contact surfaces include chlorine, quaternary ammonium salts (Quats), and iodine.

Disinfectants kill pathogens and viruses and are used on a visibly clean surface. Disinfection products do not work effectively if the surface is covered in visible dirt. Here, it's also important to leave the disinfectant product on the surface for the time specified in the product instructions to remove all bacteria.

*It's important also to note how to store the cleaning products – keep all chemicals and supplies separately in a special place, away from food areas.

STEP 4: Determine the frequency of operation.

Generally, the more people touch a surface or item, the higher is the risk of pathogen and the more often such a surface should be cleaned.

Some examples of often touched surfaces in or kitchen include preparation tables, utensils, counters, and your cooking equipment. These surfaces are commonly used the whole day for food preparation. They may be used for any raw food or sometimes ready-to-eat ones such as raw meat slicers, blenders, and other equipment for any cooking process.

Some examples of surfaces that need to be cleaned less often, but still tend to be forgotten are ventilation equipment, walls, lamps, and other complex equipment.

Set the cleaning schedule to clean frequently touched surfaces at least once a day. When space is a high traffic area, clean it even more frequently.

STEP 5: Choose the right cleaning supplies

If you want to keep your cleaning plan working and to ensure your kitchen is always tidy and free from contamination, you need to have a good selection of professional cleaning equipment on hand. Basic items include:

- Clean kitchen cloths

- Sponges and scourers

- Dusters

- Gloves

- Mops

- Brushes

- Drain cleaners

- Sanitizers and hand soaps

Make sure there are enough cleaning products to avoid cross-contamination. In addition, always check whether the cleaning equipment you have is in good condition. Any loose material such as brushes tends to leave bristles on contact surfaces and are then considered a potential physical hazard.

STEP 6: Set a team for your cleaning schedule activities

The next step in creating your cleaning plan is to define who will be responsible for these cleaning activities. This task encourages accountability from all of your employees. By involving your team in this work, they will also feel a greater sense of responsibility and perform their tasks better.

STEP 7. Documentation

An accurate record of the HACCP cleaning schedule template, when used correctly, is an important part of your food safety system. It can serve as proof that your food establishment upholds your commitment to serving safe food items. It also can become a support for your procedures for monitoring your cleaning operations.

Creating your own HACCP food safety cleaning schedule template can be tricky. You may need to customize it every now and then, especially during your pilot use. To help you get a flexible template, use our HACCP cleaning schedule template at FoodDocs.

This template considers the most important parameters when it comes to cleaning and sanitation. If you can't find the parameter that you need, then you can add it yourself. Our templates are completely customizable to help you build a better schedule for your team.

This template is part of our list of many other free, food safety documents such as any checklist template, posters, and consumer advisory.

Pair this free cleaning schedule log with a cleaning checklist template to optimize your cleaning operations and become part of your monitoring procedures and preventive measures. Check out our food safety template hub for more!

What are the benefits of a free cleaning schedule template?

When it comes to running a food business, cleanliness is a top priority. Whether you run a small restaurant, a hotel, or a retail store, all facilities must put food safety as a priority.

A kitchen must be clean not only because the law requires it but also because it keeps your staff and consumers safe from any potential hazard. Keeping a high level of sanitary conditions in your food establishment is an everyday task to ensure the safety of food products within the food chain.

Cleaning and sanitation are some of the most effective preventive measures against any potential health hazards that can lead to loss of control of food safety. To always maintain a clean condition in your food establishment, everyday hygiene procedures must be applied.

A proper cleaning plan helps to lower food waste, create a sanitary food production process, prevent foodborne illnesses from consuming unsafe food, produce wholesome food, and also keep the team on the same page about cleaning tasks.

A cleaning schedule log can help you with this:

- Guide. A cleaning schedule template such as what we have at FoodDocs already contains the most important parameters to create an effective cleaning schedule. This template can help your team save time and ensure that your schedule is complete and would serve its purpose.

- Reminder. Using a completed cleaning schedule template can help food handlers remember when, how, and which areas to clean. This schedule can help employees perform critical control procedures to reduce the occurrences of any potential food safety hazard. Some areas of a kitchen may need to be cleaned at least twice and sanitized once a day. This routine ensures that there will be no buildup of dirt or leftover debris anywhere in the kitchen for safer production processes.

- Accountability. A cleaning schedule template is also meant to encourage accountability. This schedule is used to take note of which food handler is responsible to perform a cleaning or sanitizing task. It can help in identifying whether the task was done or not or whether it was correctly done or lacking. This purpose can help food employees learn the value of food safety even when no one is looking. It can also serve as a note for the application of corrective action procedures in case a cleaning task was improperly done.

- Ensure food safety. Keeping your kitchen and service area always clean is an assurance of food safety. Cleaning any sanitizing ensure that the conditions for any of your food production process are at a safe level to prevent any unsafe food from reaching the consumers. Additionally, since cleaning solutions can also serve as chemical hazards, your food safety cleaning schedule can also act as a reference for the correct concentration of the solution and the recommended critical limits dilution for use.

- Employee training. More than just a schedule template, a cleaning schedule can also be part of a food employee's training. It contains the necessary factors to make cleaning and sanitizing effective which is an important part of any food safety management system. This schedule can be used to acquaint food employee's with the proper steps of cleaning for the control of food safety.

- Cost-saving. When your service and kitchen area are regularly kept clean and are free from any food hazard, your food business becomes farther from any food safety issues such as costly fines. A clean preparation area gives customers the confidence that the finished product that they are getting is clean and free from food safety risks. This schedule template can also become a cost-effective way to help your team reduce the amount of food waste as a result of spoilage from food contaminants.

How to ensure a clean food business with food safety management software

FoodDocs helps lift the responsibility of food safety off your shoulders. With our digital Food Safety Management System, you can rest easy that every cleaning, sanitizing, and food handling practices are subject to daily monitoring and are performed on time.

With a few clicks and simple answers to our system's basic questions, you can get a comprehensive digital food safety plan in just 15 minutes!

This digital FSMS was built with the knowledge of food safety consultants and experts together with the power of artificial intelligence. Our system automatically generates a complete digital FSMS based on the information you provide.

What do you get when you sign up with us? Here is a list:

- Save your employees' time from doing repetitive tasks using our digital monitoring forms. These forms can be used to make your everyday monitoring procedures faster and more efficient. With an auto-fill feature, our system automatically inserts information on your forms based on your previous data entries. All that is left to do is to verify the information.

- Never forget any food safety task such as cleaning and sanitizing with our smart notification system. With our mobile application, our system will send intuitive notifications to responsible food handlers and remind them of any food safety task that is due.

- Get a quick overview of your daily food operations using a real-time dashboard as part of our digital FSMS. With this feature, you can identify your strongest points and which areas need more attention. Save at least 20% of your time from micromanaging your everyday tasks.

- Store all of your digital food safety documents in one place with your dedicated cloud storage.

Never worry about how to navigate your way around our digital platform. The whole process would only be a question and answer exchange between you and our system. Need to change something to fit your daily operations? Our system can accommodate that! Every section of our digital FSMS caters to customizations to create a more fitting FSMS for your team.

In just an average of 15 minutes, you can get a comprehensive digital FSMS that can help you achieve a clean and sanitized food facility every day. Get any process step done and increase the efficiency of your team with our digital FSMS. Experience our services and try our digital FSMS using our free, 14-day free trial.