Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

All food must be stored 6 inches (15 cm) off the floor to prevent the contamination.

The importance of proper storage practices cannot be underestimated in the food industry. This aspect of food safety can help protect customers from foodborne illnesses caused by contamination.

An essential practice under food storage is maintaining an appropriate distance between the stored food and the floor. Many local health codes adopt this 6-inch rule. Some allow exceptions for certain packaged goods (e.g., milk crates or canned drinks) if the floor is clean and the containers are waterproof, but the safest approach is to always keep food on approved racks or pallets above the ground.

Read more about these key ideas and learn about the importance of storing foods above the floor. We also discuss the significance of consistent monitoring in maintaining proper storage using intelligent solutions from our software.

Food products and raw items must be stored at least 6 inches (15 centimetres) off the floor. At this distance, the food will be kept safe and far from any potential contaminants and food allergens.

Placing food above the floor also reduces the risk of pests, such as insects or rats, damaging the food. While this general food safety practice is not a strict rule, it can help you comply with the established law of preventing contamination in a food establishment.

The US FDA's Food Code, which provides model food safety regulations for states to adopt, recommends that food be stored in a clean, dry location and protected from contamination, including contact with the floor. It does not specify a minimum distance from the floor.

As previously mentioned, there is no specific guideline about this food safety practice in the US and UK; storing foods at least 6 inches from the floor is the most common recommendation.

The distance between the floor and the food being stored acts as a buffer zone that will help prevent cross-contamination in a food business. In addition, the zone allows your food handlers to easily clean and sanitize the floor without affecting the food.

While the recommended distance between the floor and the food is 6 inches, you also have to consider other factors. Some countries have specific industry requirements, such as using crates or shelving to hold cooked and ready-to-eat foods. For example, in Canada, it is a common industry requirement for establishments to have shelvings for storing food in Canada.

For some food businesses, the space provided for storing foods may be very limited. This situation can be a challenge, but any clean, sturdy solution that keeps food off the ground can work. For example, food-grade pallets, dollies, or risers are acceptable in place of permanent shelves as long as you keep them sanitary.

Suppose this is the case in your food business; here are some effective alternative methods:

When using different ways to elevate food off the ground, always ensure that you are using approved and sanitized equipment. In the US, although there are no regulations prohibiting the use of wooden pallets, you are required to ensure that the pallets you use are properly treated, pest-free, and will not cause any type of contamination, whether physical or biological contamination.

Remember, whichever method you choose, it must be easy to clean and pest-free. Avoid makeshift platforms that can’t be properly sanitized. Never leave food in unprotected cardboard on the floor, even temporarily, as it can absorb moisture and attract pests.

In addition to elevating foods off of the ground, make sure to organize and group foods according to their proper category to avoid cross-contamination. For refrigerated storage, use our Free Fridge Organization Chart.

Public health agencies stress this rule for good reason: Storing food at a distance from the floor is a practical way to prevent food from becoming contaminated. The practice is essential for any food business to maintain proper food hygiene and prevent the risk of contamination.

Here are the key food storage points for placing foods 6 inches (15 centimeters) above the ground:

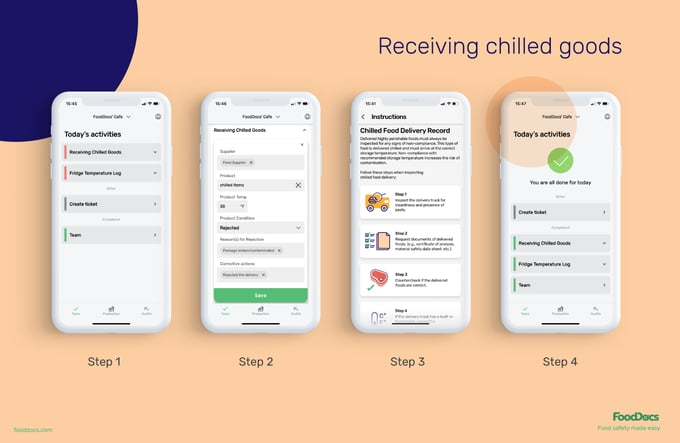

To ensure food safety compliance when it comes to food storage, constant monitoring must always be practiced. Use FoodDocs' intuitive Food Safety Management System to monitor all food safety tasks in your food business.

Use the customizable and smart monitoring checks and logs generated by our software to monitor raw ingredients during delivery up until their storage. Remind your team of proper food storage guidelines using smart notifications and alerts.

Cross-contamination between food is most likely to occur if ingredients and products are not properly stored. Improper storage practices can allow harmful bacterial growth to spread from one food item to another, leading to potential foodborne illnesses. The rules of proper storage must never be an afterthought in food service establishments, food retail, or manufacturing.

It is part of your responsibility as a food business to ensure that foods are stored properly. To help you avoid bad storage practices, we listed 10 bad food storage practices that you need to avoid:

Incorporate these key areas for observation into the customizable monitoring logs and checklists that you get from our smart software. Ensure that all food safety guidelines for storing foods are always properly monitored and complied with digital monitoring logs and checklists.

Proper storage of dry goods is part of an effective pest management plan. By using proper storage techniques, you can ensure that your dry goods are kept safe, and their quality is preserved from the effects of pest infestation.

There are more ways to prevent pests from damaging your ingredients than just keeping foods off of the ground. Here are some effective ways and essential tops that you can follow:

By following these guidelines, you can effectively store dry goods and minimize the risk of pest infestation, helping to maintain their quality and freshness for a longer period.

Dry goods should always be stored away from moist food products and raw foods. When packaging and storing dried foods, always use tightly sealed containers to prevent moisture reabsorption and pest infestation.

Proper dry food storage practices:

To ensure your efforts to properly store dry goods are working, regularly inspect dry goods for any signs of pests or spoilage. If you find droppings, webbing, or an off odor, remove the affected product immediately and clean the area.

All foods must be properly stored at least 6 inches (15 centimeters) above the concrete floor and no less than 18 inches (46 centimeters) away from the wall and ceiling.

This gap is important because it allows inspectors to walk around and check for pest activity, and makes it easier for your team to clean along the walls. It also promotes airflow to prevent condensation on walls that could affect food.

Choosing the correct flooring material for a food establishment is a critical decision to make. According to food hygiene regulations, floors in food storage areas must be smooth, non-absorbent, washable, and made of non-toxic materials.

The flooring material you use in your establishment may affect cleaning efficiency and the presence of contaminants in your facility. For example, restaurant and manufacturing businesses often choose resin-based floors over concrete material for ease of cleaning and durability.

Consider the following factors when choosing the flooring material for your business:

One of the most important factors to consider is that the flooring material should be easy to clean and sanitize. This factor also includes that the floor must not collect dirt. Designs with gaps tend to collect food particles or dust, which can cause contamination.

Additionally, special structures such as floor coving must be considered. Floor coving is used to have a seamless connection between the wall and the floor, preventing dust from collecting in corners. Use smooth and cleanable materials, such as epoxy coating, stainless steel, or ceramic tiles.

The same goes for the floor-wall junctions. You must seal the edges because curved coving where the floor meets the wall (instead of a 90° corner) helps to eliminate cracks where dirt or pests could collect, making the floor much easier to keep clean.

The kitchen and storage area have very high humidity. Choose non-absorbent materials for floors and walls. In practice, suitable options include sealed concrete, epoxy resin, and quarry or ceramic tiles. Porous materials like unsealed wood or carpet are not acceptable because they can harbor moisture and bacteria.

When floors and walls absorb moisture, mold, mildew, and bacteria can grow on them and contaminate the entire food preparation and storage area. Choose any impervious material that does not absorb water.

The material used for the flooring must be able to withstand heavy foot traffic, equipment movement, and impact from external forces without breaking. Choose materials that require a lower level of maintenance. Chipped flooring material may lead to contamination of food by foreign material.

In addition to food safety, the flooring material must also be safe for employees. The food storage area is very prone to food spills, which can lead to slips and falls. Use smooth materials with anti-slip coatings to reduce the likelihood of accidents.

Flooring materials will be regularly treated with chemical and bactericidal solutions. As such, they must not negatively react and be able to withstand sanitizers without being damaged.

Unlike broken tiles or worn wood, certain flooring materials, such as vinyl or epoxy, can be tightly sealed and installed with coved bases, preventing vermin infestation. This helps maintain a hygienic environment and reduces the risk of food contamination.

When choosing the proper list of materials for your food business floor, you must always consult with local health and safety departments. Health agencies set up regulations on proper facility layout and materials to use to avoid workplace accidents and meet minimum food safety standards.

Every food business must ensure proper food storage for both raw and ready-to-eat items. This aspect of food safety is essential for preventing the spread of foodborne illnesses and causing food spoilage. It helps in both protecting public health and optimizing the shelf life of raw food ingredients.

Ensuring that food products are stored at least 6 inches above the floor is just one of the many rules of sanitation and proper storage that is important to be monitored. Proper handling and storage start from receiving the products during delivery. At this point, your employees must ensure that the process is being monitored internally also so that outside inspectors can witness your high standards for food safety.

Use our smart Food Safety Management System and its intuitive solutions for monitoring. Our innovative software is powered by artificial intelligence, which can help you establish your monitoring system in just 15 minutes.

You can use the following features and benefits that will help you monitor food storage rules, such as keeping foods off of the floor:

Our system can help you ensure that your employees understand the importance of keeping food off of the ground and storing them properly. All monitoring checklists and logs come with detailed instructions on how to perform and monitor food safety tasks.

You can also add your own version of the instructions as images or videos. In addition, you can fully customize all generated templates or create your own versions from scratch.

With the help of our smart software and its digital solutions, you can ensure food safety compliance and optimization of your food ingredients and products. You will always be sure that all products and ingredients are stored in the correct conditions and regularly monitored for compliance.

You can experience the benefits of our intuitive software for free today when you sign up for our free 14-day trial.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...