HACCP Plan for Restaurant Template: How to Create One (Free Sample PDF)

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

In this article, we are covering all the aspects of the HACCP system there is to know. Feel free to navigate through the article by clicking on the topic you are most interested in.

WHAT WE'LL COVER:

Hazard Analysis Critical Control Point or HACCP is a systematic approach for food safety hazard identification, assessment of risk, control, and verification activities. It is an international regulatory standard for food businesses and manufacturing plants, serving the purpose of being compliant and offering safe food for the customers.

Any food operation that sells or serves food must provide control of food safety. It does not matter if it is a cafe, restaurant, hotel, shop, retail food establishment, or home kitchen making food to sell to customers. In other words, everyone in the food industry must have a HACCP plan so your customers can be sure that the food you're offering them, is always safe to eat.

It is not a plan that gets drawn up and forgotten. The real HACCP meaning gets revealed through practice. If the plan is easy to use, a HACCP plan becomes a tool that helps you evaluate your food safety hazards in detail to guarantee safe food products to all your customers.

In this article, we explain in detail the essential things that you need to learn about the HACCP plan. Alternatively, you can sign up right away to get a fully customizable HACCP plan in just an average of 1 hour. With our digital solution, food handlers can get a complete digital HACCP plan even without prior and extensive knowledge of food safety.

Creating HACCP Plan with FoodDocs

HACCP stands for Hazard Analysis Critical Control Point and it is defined as an active food safety program that uses a systematic approach to establish a control measure system and resolve the loss of control over food safety. HACCP is designed to be a food safety plan that aims to evaluate and monitor the whole food processing, conduct hazard identification, and address challenges with food safety.

The HACCP system is used to prevent unsafe food items from reaching consumers and control risks. The term HACCP represents the three main factors in this food safety management system.

The creation of HACCP goes way back to 1960 when the National Aeronautics Space Administration (NASA) was faced with the challenge of finding ways to come up with safe food products for space expeditions. Foodborne illness could mean life or death for an astronaut in space. There would be limited resources and equipment to aid if a food safety breach occurs.

Because of this concern, NASA used the concept of critical control points (CCP) from their engineering management into creating finished products for future space explorations. These points reveal areas that have unacceptable health risks and are considered hazards. After the success of NASA in implementing this concept, the food company Pilsbury adopted the CCP and used them to solve their food safety issues.

These successful applications of the CCP concept led the regulatory agency FDA to task Pilsburry to establish and manage effective training programs for other industries. Not long after, the birth of the Hazard Analysis Critical Control Point and its introduction to the food industry came.

Now, a HACCP plan is an international standard and is recognized by almost all food safety agencies. A HACCP plan describes your business' processes, associates dangers that you may experience, and helps to keep away from critical limits with the help of control measures. It also addresses the risks and dangers and provides appropriate actions to make your finished product safe.

HACCP is an acronym for three of the plan's essential components. HACCP stands for Hazard Analysis Critical Control Point. Below, we go through the meaning of the five-letter acronym in detail:

1. Hazard - Hazard identification is the first and main target of this food safety management system. Foodborne hazards are any contaminations that could be the result of inadequate processing, dirty raw materials or cooking utensil, or even cross-contamination in cooked materials. Potential hazards can be physical, biological, chemical, or allergenic in nature and can cause severe health effects.

They are called food safety hazards because of the potential risk they carry that could harm public health through unsafe food for consumption. The detection of contaminants at an early stage is key for safer food production in any manufacturing plant or food service in the food industry. Also, it's important to evaluate the degree of risk of each hazard and source of contamination to come up with appropriate direct control factors.

The analysis includes the assessment of the whole food operation from raw material production, food composition analysis, procurement, up to processing, conditions of storage, shelf life, and consumption. HACCP determines at which point could hazard contaminate the process and the product and can they be considered critical control points using science-based methods of analysis.

3. CCP - the last component of the acronym HACCP is the Critical Control Points. These points are the process steps within the whole food chain that needs accurate evaluation and require controls to remove potentially or inherently present food safety hazards or at least reduce them to a safe level. Critical control points require corrective action procedures and verification activities as control measures.

HACCP plan is commonly mistaken to be synonymous with a food safety plan and termed singularly as the HACCP system. Both plans are considered food safety management systems but have a few differences. Where a food safety plan is only concerned with establishing preventive measures, a HACCP plan also requires monitoring and verification reports. In addition, a HACCP plan is focused on monitoring critical control points, whereas a food safety plan is concerned with all other food service operations.

A HACCP plan is a written and legal document of the whole business process flow, hazard evaluation, control procedures, and continuous monitoring activities based on the principles of HACCP. Making a HACCP plan means having to spend a lot of time in the office, having meetings, inspecting the whole process layout, and often hiring a food safety consultant.

A food business HACCP plan consists of a detailed analysis of your operations, including any associated potential food safety hazards. It also includes appropriate preventive procedures to control the identified hazards and monitoring activities to ensure compliance with food safety standards.

This food safety plan is composed of several other minor plans, such as the following:

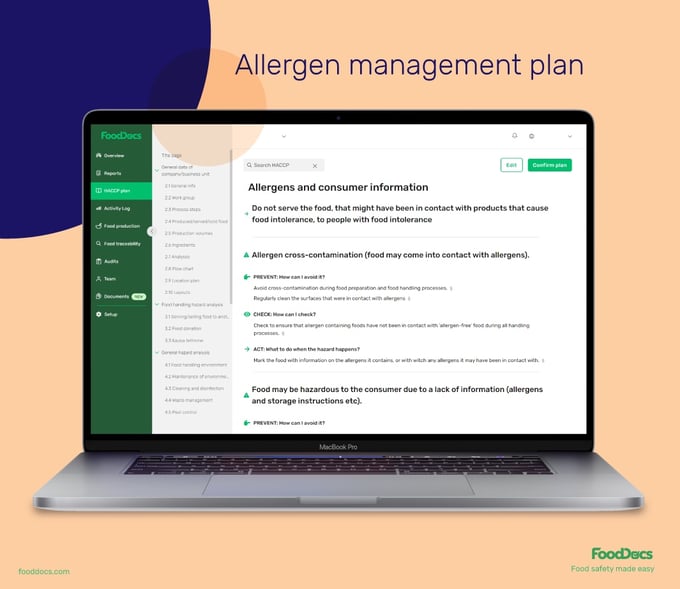

HACCP Allergen plan from FoodDocs

Your HACCP plan also describes in detail the nature of your business, the industries it works with, and the customers you consider as your market. One of the objectives of a HACCP plan is to lay out all of the businesses connected to your food establishment. Through this process, your team can clearly identify any points where hazards may be introduced.

Writing a HACCP plan is laborious and critical, but you do not have to worry. We at FoodDocs have devised a way to make the whole process easy, accurate, and less expensive. It may seem like a lot of effort, but your HACCP plan serves a very active, everyday purpose: to ensure food safety and have people return to your establishment or retail food store.

By following a HACCP plan or becoming HACCP certified, you build trust in your brand by protecting customers from any severe illness, making it more likely for you to have return visitors. You also need to have a HACCP plan before starting your food business or manufacturing plant and periodically review your HACCP plan if there are changes in the production processes.

You need a HACCP plan for two reasons.

First, having a HACCP plan, or at least a risk-based food safety management system, is legally required if you are in the US food industry. The existence of the HACCP plan and its compliance with the actual realities in your kitchen or food serving area is controlled by a government health inspector at least once a year.

Secondly, HACCP is designed to reduce the risk of safety hazards in your food and the chance of product contamination. The plan also helps you build a loyal customer base and lets you grow your business without any food safety issues.

What does HACCP help a business do? Here is a more detailed list of benefits you can get when establishing your HACCP plan.

1. It helps you serve safe products

Your HACCP plan has a summary of the business location and rooms where your food handling takes place. This will help ensure that your employees, food, and waste have a safety management system.

No one wants the multiplication of pathogens and other microbiological hazards to spread from raw food to other food and surfaces. Prerequisite programs and standards are established and monitored with your HACCP plan to help you deliver safe food products with excellent sanitary conditions.

2. It prepares you for any critical limit deviation

It gives you a full overview of all the steps related to food handling. These steps include the acquisition, food preservation methods, and the cooking process until your food product is delivered to the consumer.

The overview, with its description, is equally necessary for the person selling vegetables from their garden and with a big retail chain. Technological schemes and production process descriptions have the place that helps thoroughly analyze potential hazards and the actions required to address them.

For example, what precautions are taken to avoid company employees' hair and jewelry getting into food? What food preservation methods are used to prevent food from deteriorating due to the incorrect internal temperature or damaged packaging materials? What happens to the food when the refrigerators stop working or there is a power outage? What if the power outage only lasted 5 minutes? What if your food was left for too long at ambient temperature?

3. It helps everything run smoothly

All food handlers must regularly carry out pest control, laboratory analyses, HACCP training, renew their personnel's health certificates, and conduct a systematic HACCP audit. It is also a must to document critical factors such as the internal temperatures for every cooking step, the temperature of all the refrigerators, and the preparation times of products to prevent the multiplication of pathogens. All information must be compiled through monitoring records.

These are part of a food safety plan, making your HACCP plan a living, breathing assistant that supports you in every process step.

It is not a scary, bureaucratic document. HACCP is a constantly changing management tool that helps ensure consumer safety from products with safety issues. Equally importantly, your food safety plan helps cut costs by avoiding unsafe products and threats. Not something to forget about.

The requirement of whether a HACCP plan is mandatory or not in a food business is highly dependent on the type of industry and country your establishment is operating in.

Under their food safety regulation (EC) No 852/2004 of the United Kingdom, all food businesses must have a HACCP plan. Good hygiene practices and less strict risk-based plans would suffice for smaller establishments. The same criteria are also adopted globally.

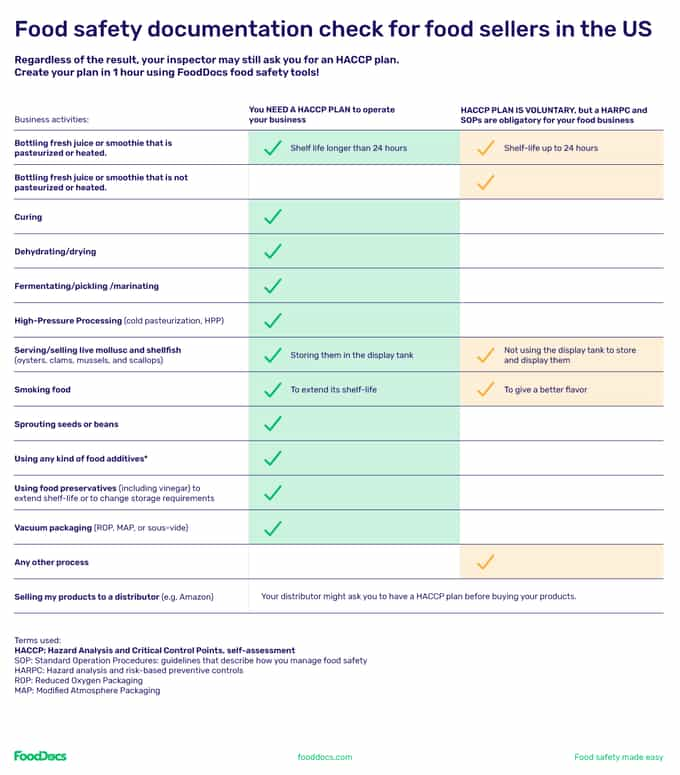

In the US, establishing a HACCP is voluntary for several food businesses. The applicable food safety requirement is based on particular operations considered by food safety agencies such as the Food and Drug Administration (FDA) and the USDA Food Safety and Inspection Service.

Particularly, juice beverage companies and businesses dealing with seafood products are governed by the FDA, and all food items under the USDA are mandated to implement a HACCP plan. For businesses under the FDA, finer screening and instructions are required.

Which food businesses require a HACCP plan in the US?

Here is a quick rundown of what awaits you when making a manual HACCP initial plan and lets you see the tasks behind it. The depth and complexity of a HACCP plan vary depending on its purpose. A HACCP generic plan can be used as a guideline for everyday activities such as preoperational activities and calibration. Although, some HACCP plans can be very specific and requires an in-depth analysis of the process. Below are the preliminary steps in creating a HACCP plan:

These preliminary steps, along with a plan summary table, all prepare your team to create your HACCP plan and proceed to fulfill the 7 principles of HACCP. Food handlers must precisely execute all preparatory steps as they are considered regulatory requirements to get accurate results from the HACCP plan. For a more detailed explanation of how to write a HACCP plan, click here.

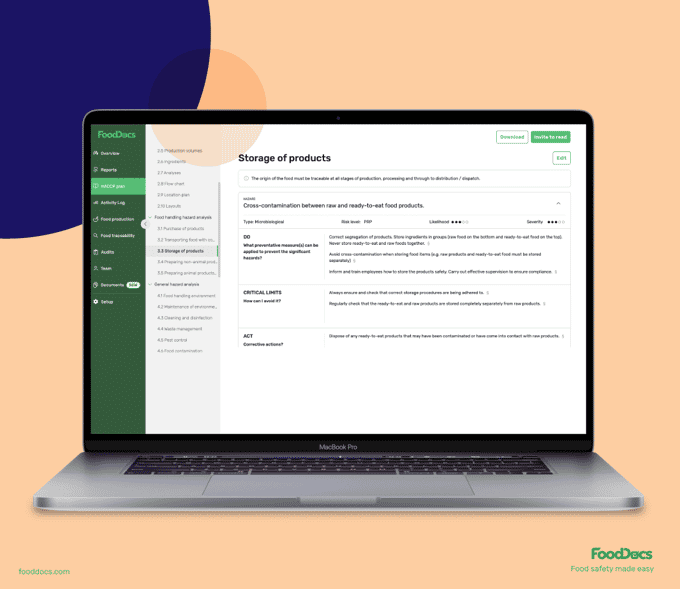

FoodDocs removes your worries about not knowing the ropes around building a HACCP plan. With FoodDocs, you do not need to worry about compiling tons of paperwork just to ensure your HACCP plan is working and complies with your local standards.

With our simplified process, all you need to do is answer a few basic questions regarding your food safety operations. After answering, our system will automatically generate a complete HACCP plan for you. It's time to leave the old way and save up on papers by going digital when it comes to your HACCP plan.

The seven HACCP principles ensure your food is kept safe throughout its life cycle, from raw material production to consumption. These principles are a step-by-step process of evaluating health hazards and establishing control measures for them.

The HACCP principles all aim to prevent food safety hazards from potentially causing a severe illness or even a foodborne illness outbreak. This objective is achieved by preventing and minimizing the risks before they even happen and preventing any severe health effects. The detection of contaminants and their assessment is part of this process.

The seven HACCP principles include the following:

All these steps, including an analysis summary table, require hours of meetings and collaborations with experts. Conceptualization and implementation can take up to 4 weeks to get the HACCP done while you don’t have much control over the process.

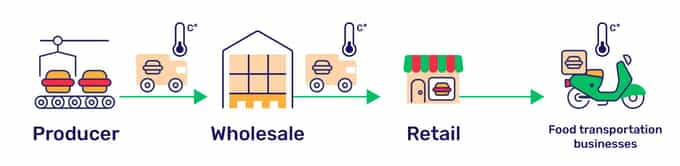

The aim of the HACCP plan is to prevent potential risks from causing food safety issues through hazard identification and control measures. The development of the process and application of a HACCP plan starts from the production of raw materials from the farm up to the consumers' tables, thus the farm-to-table concept. Every HACCP plan must include unique and specialized processes from food businesses to prevent loss of control.

The easiest way to understand the application of HACCP is by establishing monitoring systems with a comprehensive food safety management system. Your well-detailed monitoring system will be used to ensure that all food safety requirements, laws, and mandates are followed accordingly at all times.

Here are a few examples of how a HACCP system is used in the industry setup:

In the farm setting, HACCP is applied in the different stages of growing food materials. Some of the main concerns which can be addressed by a HACCP system include facility sanitation, proper application of fertilizers, analytical testing of procedures, pesticides, and other chemical agents, and chemical measurements for the presence of residual compounds in the produce. Additionally, procedures for monitoring and verifying postharvest conditions of harvested products are also under a HACCP system.

In food processing plants, HACCP is most useful in complying with the food safety parameters for product standards. The food safety plan is also helpful in testing every batch before processing and after. Adequate internal temperature and time of the thermal process are essential to keep a batch of food free from any microbial pathogen growth. Additionally, a raw material inspection of every batch before processing must always be documented.

Different adequate time-temperature combinations are required depending on the food packaging materials and the nature of the product to prevent the multiplication of pathogens. In addition to specific control point monitoring requirements for these parameters, microbial testing may be required by a HACCP system as part of a comprehensive verification.

During distribution and storage of products, like retail food establishments, or any kind of food service companies, like hotels, restaurants, schools, hospitals, safe food employee practices are very important. One of the most important critical control points includes keeping temperature.

Some products cannot stay at ambient temperature for too long after the cooking process or enteric pathogens and other microbiological hazards may start to proliferate. Such is the case for keeping the safety of raw meat and food quality control. When transporting products, food processing plants may have trouble with elevated temperatures in delivery trucks which contribute to the growth of spoilage microorganisms or other unwanted chemical reactions.

Proper CCP monitoring and monitoring records to control factors are essential in ensuring standard temperatures are being met. All monitoring procedures must be applied to every batch of food and throughout the whole supply chain, including the consumer's table.

At FoodDocs, we have created the best digital solution to get all of these monitoring requirements in the fastest way possible. With our built-in HACCP plan builder, you can get all of the most important HACCP plan components ready for implementation. Using our digital solution, you can save up to 120 hours from conceptualizing a comprehensive HACCP plan.

Our system is powered by artificial intelligence and a machine learning program. With these two powerhouse programs, our digital solution becomes more convenient and smarter as food businesses input more information. To date, at least 20,000 food businesses are enjoying food safety compliance thanks to our digital solution.

Large companies tend to compile a team of experts to create plans, while in small enterprises, it becomes a one-person job. When employees lack prior experience, assistance from external experts and food safety supervisors is often needed. Expert assistance may cost you thousands of dollars.

The practice has proved that the daily management of a HACCP plan, often over a hundred pages long, can be complicated and inconvenient for a company. It is difficult to know and remember everything, and not every business has the time or knowledge to go through the papers all the time.

This means that there is a constant threat and potential loss of control of food safety in the food chain. And the officials who come for their yearly check-ups are not allowed to approve a plan that has faulty or missing information.

The HACCP development of the process involves essential documents in addition to the seven major components. A HACCP plan example would normally include the following documents:

This is how usually one traditional HACCP plan looks like:

Requirements by regulatory authorities may sometimes be too complicated, long, and hard to find especially if you are new to the food industry. This reason is why food business owners often turn to HACCP consultants for help. Most often when hiring a consultant, unfortunately, people's approach to food safety changes. The responsibility to ensure food safety becomes delegated and actual food handlers become less involved which shouldn't be the case.

We believe that food safety compliance is something so important that everybody should understand and be involved. With or without a HACCP consultative process, food safety compliance is something that needs to be understandable and emphasized every day from the first minute you step into your food business.

That's why we have created FoodDocs and keep on improving it – to help people understand HACCP rules and how to follow them and produce wholesome food in the easiest possible way. We have compiled and digitized some of the most important food safety documents that you will need for your HACCP plan-making process.

Several HACCP plan templates are available if you want to build your plan manually. Alternatively, if you want to get the job done as fast as possible, without sacrificing the quality of your plan, use our built-in HACCP plan builder at FoodDocs.

Before being able to create an efficient HACCP food safety program and implement it, prerequisite programs must be implemented to prevent loss of control. Prerequisite programs are the foundation of food safety and the HACCP system and are composed of basic food safety principles including sanitary conditions.

They are concerned with the hygiene, environmental conditions, and sanitary condition of a business aimed at reducing the unacceptable health risk of potential hazards. Put simply, your company needs to implement programs such as Good Manufacturing Practices and Sanitation Standard Operating Procedures prior to making a HACCP plan.

Some prerequisite programs are used as guidelines in building a suitable processing facility design with basic conditions and proper verification reports if they comply with minimum criteria for food safety. Two of the most common prerequisite programs are the cGMP and SSOP.

This prerequisite program describes methods, equipment, facilities, and control of food safety and the minimum standards required to be met by manufacturers. The cGMP includes the following components:

The SSOP is a list of procedures for maintaining sanitary conditions in a manufacturing facility. It was designed to comply with the cGMP basic condition. SSOP checklist includes the following areas:

A HACCP plan is built around the principles of prerequisite programs for creating wholesome food. Other prerequisite programs may include allergen control programs and food hygiene regulations.

Where HACCP plans are not mandated by other companies, prerequisite programs such as the cGMP are required because they are minimum standards for safe working conditions. By complying with a strong set of prerequisite programs, your team becomes prepared for a HACCP food safety program.

Resellers and distributors, sometimes also regulatory authorities require a HACCP plan, sometimes even a HACCP certification. This means submitting to an accredited third-party certification body that will audit your manufacturing process and the successful implementation and application of requirements of your HACCP plan.

For example, Amazon requires it for the development of concrete products as well as with several retail stores. They require a HACCP certification to ensure the safety of the food in their business establishment or e-store.

Be sure that all your HACCP system documents are easily found, including the actual plan, monitoring sheets (including archived records), biological risk assessments, certificates, plans, schedules, and all other additional documents related to HACCP.

A HACCP certification process involves a series of inspections and frequent reviews, both on-site and documentation aspects. Certifications cost quite a lot and require an ample amount of your team's time, so you need to make sure that you are always prepared for it.

As you see, there is a lot of paperwork to be stored and found on time. The easiest way to store all this documentation is to have a digital HACCP program where everything is stored automatically on a continuous basis and easily found. Yes, exactly like it is in FoodDocs.

A HACCP plan is built and evaluated internally by the team you set up for establishing this plan. Local authorities and federal agencies usually evaluate your HACCP plan together with all other HACCP documentation. In some countries, audits are done before opening your food business, whereas, in other countries, audits and activity of verification reports come after opening.

Food safety agencies send qualified food safety inspectors and usually visit your business without informing you, at least once a year. Keep in mind that this inspection aims to ensure that the food you're selling to your intended consumers is safe and not to bully you. A food safety inspector acts as a guide and will help you when you're in trouble.

Everyone who creates a HACCP Plan also needs to update it in the future. When should a HACCP plan be checked? As said, the HACCP plan-making process is an ever-continuous task. This means that after establishing your HACCP plan, there may be some instances when you would need to improve on it or apply revisions.

For one, food safety inspections are most likely to bring about weak points in your plan that you would need to improve on.

Here are a few more particular scenarios that would call for an update on your HACCP plan:

Updating your HACCP plan can be a big task. In addition, it will take up a lot of your team's time especially if you are using the traditional, paper-based method. As such, a flexible, digital HACCP plan can be your best solution to constant improvements. For example in FoodDocs, you can change your HACCP Plan in a matter of minutes whenever you like.

FoodDocs also reminds you of the several obligations and deadlines that might otherwise be forgotten. For example, FoodDocs informs the kitchen teams when to monitor food internal temperature and the whole cooking process, take food analyses and do chemical measurements, order pest control, do the HACCP audit and redo hygiene training, and renew your personnel's health certificates, all in real-time. The platform works as a central knowledge base for your entire staff.

With FoodDocs, you can be sure that your HACCP food safety management system is compiled according to the law, that all necessary requirements are fulfilled, and all the required food safety documents are included.

Signing up with FoodDocs not only allows you to create your own, customizable HACCP plan in the fastest way possible, but it also gives you the following benefits:

FoodDocs creates your HACCP plan based on a bank of food safety knowledge on regulations and laws all over the world. This feature ensures that your HACCP plan will be accurate with what the authorities require. FoodDocs even supports you after all compliance documentation is completed.

The platform has a built-in solution for creating different plans - waste, premises, water, and sewerage plans. You can create them easily with our built-in tool, just by dragging all the needed points and arrows onto the plan. There is no need to use special designer tools or interior design programs.

It is a unique and amazing solution that makes FoodDocs 500 x faster than a traditional paper-based HACCP plan.

Complying with a HACCP plan means regularly conducting a HACCP audit and updating your documents on the basis of law and regulation updates for continual improvement. With all the focus you need to devote to your actual food service operations, daily management of paper HACCP plans is complicated and inconvenient.

Keeping up with all these changes and remembering everything from a very long HACCP plan is not an easy task.

FoodDocs allows you to keep all your information, procedures for monitoring, and schedules in the palm of your hands. You can keep all these things digitally and completely paperless.

Available data

All HACCP plans can extensively vary depending on your location, your nature of business, and other factors. At FoodDocs, all the necessary data are stored within its system. Food safety laws and regulations that are specific to your country will be applied to your HACCP plan.

More space for all your information

Food safety laws and regulations change every so often. This means more paperwork for your whole team. Going digital with your HACCP plan lets you save up on physical space and store all your information and HACCP records.

Safe and reliable

The complexity of monitoring can be a real challenge. As employees and the HACCP team varies, it's hard to continuously educate your employees about complete food safety. Using your conventional HACCP procedures for monitoring makes your business exposed to manipulation, misplacement, or intentionally damaging activities.

A digital HACCP system with FoodDocs ensures that all your data such as employee training records and continuous monitoring records are up to date and well protected. HACCP audit also turns into something easy, transparent, and easy to complete.

As a bonus, you will spend less time educating your staff because you can add all relevant instructions and videos to the task, making briefing new staff members quick and effortless. Most developed food businesses have chosen digital tools to follow their daily food safety tasks.

Your smart assistant in the kitchen

FoodDocs was created to give everyone a chance to eat safe food products and to help food business owners regain adequate time and improve the whole team's approach to food safety. Every establishment that serves or sells food can benefit from the features FoodDocs has to offer.

Quick and personal

As a digital food safety platform, FoodDocs allows you to compile a HACCP plan in an hour instead of undertaking a month-long paper management marathon through corrective action plans and landscapes for hazard analysis considerations.

The program creates a HACCP plan according to the business activities, your current requirements, and criteria for food safety based on straightforward questions such as:

What's more, is that your HACCP plan is very much customizable to your needs for any specialized processes. With just a few clicks, you can edit your HACCP food safety plan should there be any changes to your process.

HACCP plan from FoodDocs

FoodDocs ensures that you will never forget important dates such as your scheduled HACCP audit date. As a digital system, FoodDocs gives you the necessary flexibility to effectively monitor hygiene practices which helps to reduce the risk of food contamination.

With FoodDocs you can be sure all your food safety documents are compiled according to the law and that all the necessary applicable food safety requirements are always fulfilled. And the best thing? Getting your HACCP done in one hour means that your business will be ready to take off as soon as you are.

Let the expert AI system of FoodDocs do all the technical stuff for you and focus more on supervising your business. Sign-up with FoodDocs now and get a chance to try our 14-day free trial.

Need some quick answers to specific questions about the HACCP plan? Here are some of the most frequently asked questions about the topic:

HACCP is a systematic and scientific approach to food safety and the acronym stands for Hazard Analysis Critical Control Point.

The 7 principles of HACCP include the following

The whole HACCP plan-making can be divided into three different stages 1) preparatory stage, 2) hazard analysis, and 3) verification of the HACCP plan.

The most common food hazards are categorized into four types: biological, physical, chemical, and allergenic hazards.

Get the exact steps to easily write a restaurant HACCP plan or download our free HACCP plan for restaurants template PDF and get compliant even...

Get a clear and complete breakdown of the most common Critical Control Point examples in HACCP for biological, chemical, and physical hazards.

The HACCP allergen control program is one of the crucial prerequisite programs of an HACCP plan. These are the key components and goals of using one.