Sanitation Standard Operating Procedures SSOP Template (Free Download)

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

CLEANING AND SANITIZING

Standard Operation Procedure (SSOP)

Sanitation Standard Operating Procedures (SSOP)

Operating a food business means you also have to be well-versed when it comes to knowing the correct sanitation procedures and employee hygiene practices. Cleanliness of your facilities is a prerequisite to keeping a food business running and preventing any foodborne illness from occurring as a result of consuming your products.

Every food handler must be properly guided and trained on how to conduct effective cleaning and sanitizing procedures. Written procedures guided by food safety regulations in cleaning such as the Sanitation Standard Operating Procedures or SSOP are a vital tool for this task.

Building a food establishment must always be guided by established principles of sanitation as well as food safety regulations. These principles include the proper design of facilities, and the flow of traffic, including the materials used for making food contact surfaces.

Key takeaways

-

Sanitation Standard Operating Procedures (SSOP) are critical for maintaining cleanliness in food handling environments.

-

SSOPs are mandatory for all food establishments to ensure operations are conducted under sanitary conditions.

-

The SSOP framework helps prevent foodborne illnesses by outlining specific cleaning and sanitizing procedures.

-

FoodDocs offers a free, editable template to help businesses easily create and implement their SSOPs.

-

SSOPs must clearly define the responsibilities of employees and managers to ensure the effective execution of sanitation practices.

-

Regular and thorough cleaning schedules are essential, as stipulated in the SSOP, to minimize the risk of contamination.

-

Proper training and accountability mechanisms are integral to successfully applying SSOPs in food businesses.

- Ultimately, SSOPs support the overarching goal of food safety management systems: to produce safe and wholesome food.

-

FoodDocs' food safety management software can simplify the creation and management of SSOPs and other food safety documents.

SSOP meaning: What is SSOP in the food industry?

SSOP or Sanitation Standard Operating Procedures are written documents regarding the correct steps, areas, and monitoring procedures related to keeping a clean environment to prevent product contamination. The documents included in this program are standardized detailed procedures for cleaning and sanitizing a food facility. The SSOP contains the basic sanitary principles for a food working environment.

Similar to other SOPs, an SSOP is a set of imperative rules that are vital to keeping a food business free from food safety hazards. They include operations that must be done before, during, and after food preparation to maintain a clean condition for processing. These operations are specific with what, how, and when to do them. An SSOP must also clearly state the responsible food handlers for conducting an operation as well as corresponding corrective actions in case of a standard breach.

In the words of the USDA:

The establishment must maintain daily records sufficient to document the implementation and monitoring of the Sanitation SOPs and any corrective action taken. When the establishment or FSIS determines that the Sanitation SOPs may have failed to prevent direct contamination or adulteration of product, the establishment must implement corrective actions that include the appropriate disposition of product, restore sanitary conditions, and develop measures to prevent recurrence.

All operations under an SSOP must be properly monitored to ensure that they are properly conducted. Misapplication of sanitation controls may encourage food safety hazards such as cross-contamination or even cross-contact. An SSOP may include operations that involve the following:

- Cleaning equipment

- Daily monitoring and sanitation inspection

- Pre-operational cleaning

- Midshift cleaning procedures

- Post-operational processing shift cleaning

- Operating CIP cleaning

- Control of employee health conditions

Who needs an SSOP checklist?

Regardless of whether a food establishment is required to make a HACCP plan or not, an SSOP is a vital prerequisite program. Since every food establishment must operate under sanitary conditions, having an SSOP is mandatory. Whether your food business is a restaurant, food truck, cafeteria, cafe, or food processing plant, you will have to establish SSOP. Most food safety inspections conducted by a local health department would inquire about this document together with proof that it is being followed.

What are the benefits of the SSOP?

The main objective of an SSOP document is to prepare your food facility for every processing day operations and to maintain a high level of sanitary conditions throughout. It helps create a system in your team in preparation for stricter food safety programs such as a HACCP plan. Specifically, an SSOP can offer a lot of different benefits such as the following:

- Reminder: The instructions in an SSOP must be very detailed. This factor is to help food employees remember all of the many different steps in performing the correct cleaning process for particular equipment, food contact surface, or even the entire facility. An SSOP can be used as a guide for food employees to ensure that the sanitation operation is correctly performed and prevent employee accidents.

- Organized operation: Some food sanitation operations must be done in a certain manner. An example would be when an employee is washing a piece of equipment. Most equipment such as a meat slicer, after use, may still have debris from the processed raw product. These food particles will render an operational sanitation procedure ineffective and can lead to the contamination of meat products. As such, the equipment may need to be carefully dismantled, washed down with hot water for cleaning, and then sanitized. Doing this whole operation in the wrong sequence may only worsen the food safety hazard and risk contaminating foods. An SSOP can become an accurate guide for food handlers to become more organized.

- Encourage accountability: An SSOP must always be accompanied by appropriate monitoring forms such as a cleaning checklist. These forms will serve as proof that the established SSOP is being applied. They can also be used as a reference whenever standards are breached. Every monitoring form tied with an SSOP will require the assigned employees to sign their names to ensure that someone did the task. By doing this, you can easily identify who to ask regarding a sanitation operation for verification purposes.

- Food safety assurance: When the working environment is consistently maintained, customers can rest easy that the foods they get are safe and wholesome. An SSOP can help reduce the risk of cross-contamination in cooked products which can spread foodborne pathogens and can result in a foodborne illness outbreak. When food handlers abide by your established SSOP, you can be sure that all of your operations will have lesser risk from food safety hazards. File your SSOP together with other monitoring records to ensure that all the important operations are duly performed.

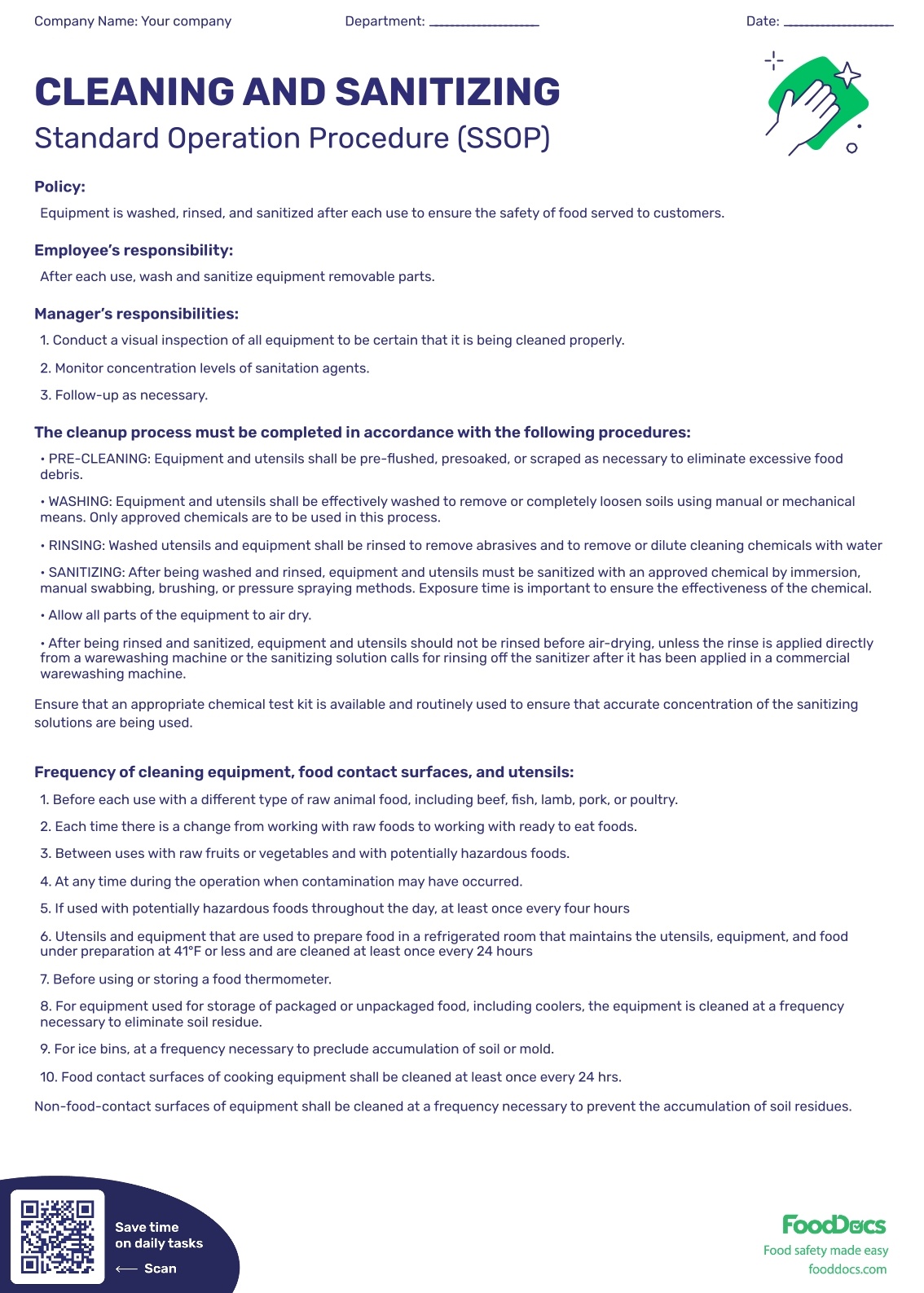

Sanitation Standard Operating Procedures example

-1.jpg?quality=low&width=643&height=900&name=FoodDocs%20-%20Sanitation%20Standard%20Operating%20Procedures%20(SSOP)-1.jpg)

Sanitation Standard Operating Procedures (SSOP)

Operating a food business means you also have to be well-versed when it comes to knowing the correct sanitation procedures and employee hygiene practices. Cleanliness of your facilities is a prerequisite to keeping a food business running and preventing any foodborne illness from occurring as a result of consuming your products.

Every food handler must be properly guided and trained on how to conduct effective cleaning and sanitizing procedures. Written procedures guided by food safety regulations in cleaning such as the Sanitation Standard Operating Procedures or SSOP are a vital tool for this task.

Building a food establishment must always be guided by established principles of sanitation as well as food safety regulations. These principles include the proper design of facilities, and the flow of traffic, including the materials used for making food contact surfaces.

Key takeaways

-

Sanitation Standard Operating Procedures (SSOP) are critical for maintaining cleanliness in food handling environments.

-

SSOPs are mandatory for all food establishments to ensure operations are conducted under sanitary conditions.

-

The SSOP framework helps prevent foodborne illnesses by outlining specific cleaning and sanitizing procedures.

-

FoodDocs offers a free, editable template to help businesses easily create and implement their SSOPs.

-

SSOPs must clearly define the responsibilities of employees and managers to ensure the effective execution of sanitation practices.

-

Regular and thorough cleaning schedules are essential, as stipulated in the SSOP, to minimize the risk of contamination.

-

Proper training and accountability mechanisms are integral to successfully applying SSOPs in food businesses.

- Ultimately, SSOPs support the overarching goal of food safety management systems: to produce safe and wholesome food.

-

FoodDocs' food safety management software can simplify the creation and management of SSOPs and other food safety documents.

SSOP meaning: What is SSOP in the food industry?

SSOP or Sanitation Standard Operating Procedures are written documents regarding the correct steps, areas, and monitoring procedures related to keeping a clean environment to prevent product contamination. The documents included in this program are detailed procedures for cleaning and sanitizing a food facility. The SSOP contains the basic sanitary principles for a food working environment.

Similar to other SOPs, an SSOP is a set of imperative rules that are vital to keeping a food business free from food safety hazards. They include operations that must be done before, during, and after food preparation to maintain a clean condition for processing. These operations are specific with what, how, and when to do them. An SSOP must also clearly state the responsible food handlers for conducting an operation as well as corresponding corrective actions in case of a standard breach.

In the words of the USDA:

The establishment must maintain daily records sufficient to document the implementation and monitoring of the Sanitation SOPs and any corrective action taken. When the establishment or FSIS determines that the Sanitation SOPs may have failed to prevent direct contamination or adulteration of product, the establishment must implement corrective actions that include the appropriate disposition of product, restore sanitary conditions, and develop measures to prevent recurrence.

All operations under an SSOP must be properly monitored to ensure that they are properly conducted. Misapplication of sanitation controls may encourage food safety hazards such as cross-contamination or even cross-contact. An SSOP may include operations that involve the following:

- Cleaning equipment

- Daily monitoring and sanitation inspection

- Pre-operational cleaning

- Midshift cleaning procedures

- Post-operational processing shift cleaning

- Operating CIP cleaning

- Control of employee health conditions

Who needs an SSOP checklist?

Regardless of whether a food establishment is required to make a HACCP plan or not, an SSOP is a vital prerequisite program. Since every food establishment must operate under sanitary conditions, having an SSOP is mandatory. Whether your food business is a restaurant, food truck, cafeteria, cafe, or food processing plant, you will have to establish SSOP. Most food safety inspections conducted by a local health department would inquire about this document together with proof that it is being followed.

It's important to note, as Michael Cramer, PCQI and former Denior Director of Food Safety and Quality Assurance for Ajinomoto Foods North America, reminds us:

The more detail that is included in an SSOP, the more elements USDA will be able to assess for compliance. Unnecessary details provided in the SSOP that may not be specifically or consistently met (i.e., water temperatures, chemical strengths, tools used) can result in noncompliance reports.

What is the easiest way to create SSOPs?

Making an SSOP for all applicable areas in your food establishment can take so much of your time. As such, you may need a versatile SOP template that can accommodate changes and is flexible enough for all of your cleaning operations. Use our free SSOP template at FoodDocs. You can customize it according to your desired SSOP content and design and then download it for filing and distribution among your team members.

Additionally, you can get all other important documents related to the SSOP such as our restaurant cleaning checklist and more. Head over to our HACCP plan template hub for more checklists, templates, posters, and examples of monitoring records for cleaning and other food safety operations. If what you need is a complete HACCP plan, FoodDocs is the solution for you.

Read more about our built-in HACCP plan builder in the next section.

Get your SSOPs and HACCP done in 1 hour

A clean and sanitized working environment and proper employee hygiene practices are prerequisites to producing safe and wholesome food. Establishing an SSOP is a vital step before the HACCP plan-making procedure. This prerequisite program sets out the correct cleaning process of a food establishment to ensure that the occurrence of food safety hazards is minimized. Establishing an SSOP can be very time-consuming. It must be meticulously prepared to ensure that your detailed HACCP plan is efficient and working.

Your work does not even stop even after establishing an SSOP. After this process, you would still need to spend several hours with your team to create a HACCP plan. Luckily, at FoodDocs, our services go beyond just providing you with an SSOP template.

With our built-in HACCP plan builder software, you can cut several months of preparation time for your HACCP plan. In just 1 hour, our system can help you create all the most important documents for your HACCP plan.

We have reduced the process of making a comprehensive HACCP plan to just requiring you to answer a few basic questions regarding your operations. Using artificial intelligence, our system will automatically generate the HACCP plan tailored specifically to your operations.

What will you get with our built-in HACCP plan builder?

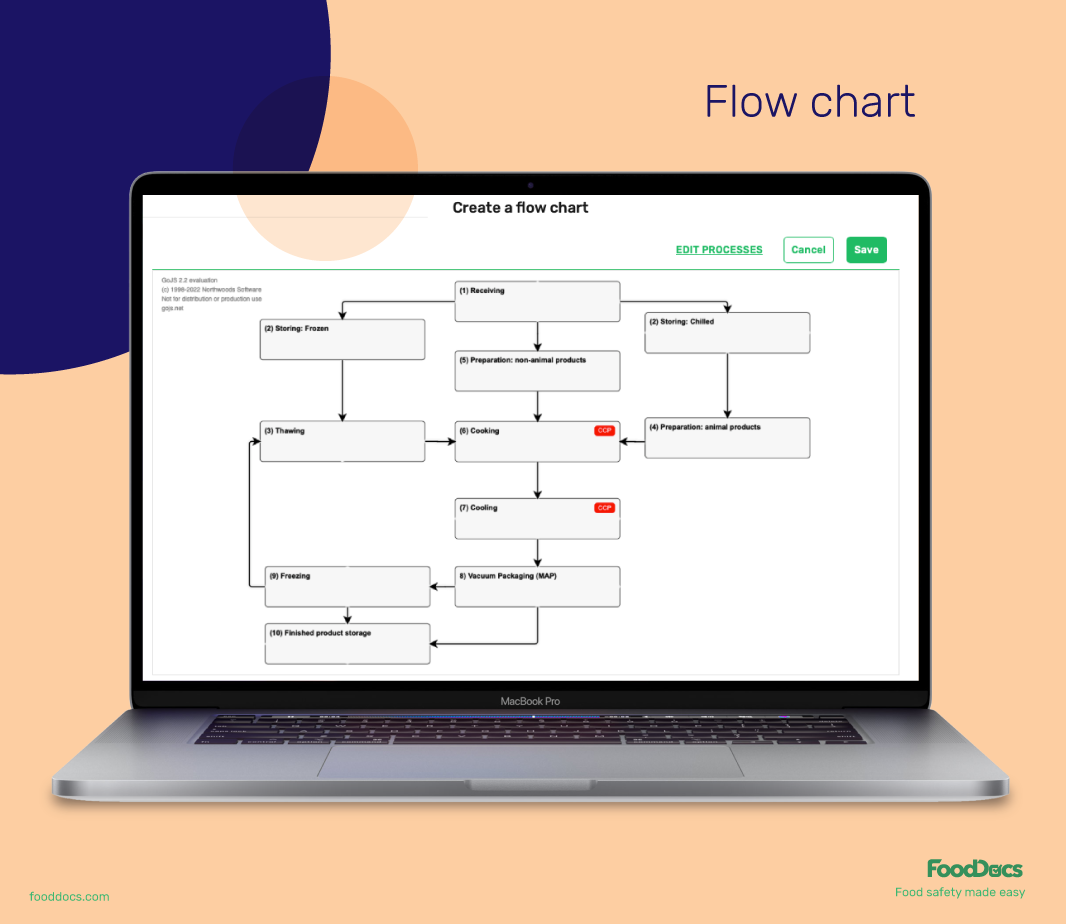

- Basic flow diagram of your operations.

- Properly identified and analyzed food safety hazards.

- Established critical control points and appropriate monitoring procedures.

- Accurate critical limits.

- Corrective actions for all CCPs.

- Established verification procedure.

- Record-keeping procedures for all documents.

Our product offers a much cheaper solution when compared to hiring a food safety consultant without compromising on quality. Our system creates a very detailed and thorough plan for you! When you use our built-in HACCP plan builder, you get to save 15x the amount of what you pay for a consultant and you can get your plan 500x faster.

Additionally, our system accommodates any changes by allowing you to customize particular areas of your HACC plan.

Use our free, 14-day trial to generate your plan. Sign up and purchase our plans to download and share your HACCP plan with your team and food safety inspector.