Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

An OPRP is a control measure that is used to minimize the risk of food safety hazards.A part of being a food safety practitioner is understanding the many terms that can be confusing. Some of the most commonly confused terms are food safety operation terms. Food safety operations are often divided into different categories depending on their nature and level of urgency.

If you are currently in the process of building your systemic approach toward food safety or your Hazard Analysis Critical Control Point (HACCP) Plan, you may have come across the term operational prerequisite programs or OPRP. Most probably, you may have also seen the terms prerequisite programs (PRP) and critical control points (CCP) tied with OPRP.

All these food safety programs are essential, but do you know which one to use for a particular situation?

Key takeaways

The food chain industry has already established several ways to control food safety hazards. Despite the unavoidable presence of food safety hazards in a food business, foodborne illnesses are very preventable.

Achieving the objective of preventing foodborne illnesses helps reduce the estimated 3,000 deaths per year in the US and over 400,000 deaths worldwide. The key to preventing these deaths caused by foodborne illnesses and other customer requirements is the proper application of food safety operations.

OPRPs or operational prerequisite programs are control measures that are essential in controlling a specified food safety hazard to manage their introduction to the food processing system.

The term OPRP was first introduced by the International Organization of Standardization (ISO) in their food safety management system for food manufacturers' standards under the ISO 22000 food safety program. The operation was introduced to categorize food safety tasks that are essential for food safety control, yet are not critical. That is, their absence will not necessarily dictate that the produced products are unsafe food.

An OPRP's main objective is to minimize the likelihood of contaminating foods as well as the potential effect of food safety hazards on the finished product. Although essential in controlling food safety, they can be removed from the whole production process and the operation will still be safe. In the food industry, it is easy to confuse the term OPRP with CCP because most of their principles and basic conditions intersect.

Although an OPRP must be regularly monitored, it is usually immeasurable through specific parameters. OPRPs were conceptualized to help a CCP control food safety hazards and increase their effectiveness. The combination of control measures is expected to make a HACCP plan more effective. Additionally, an OPRP is established based on an accurately identified food hazard. They target these specific hazards rather than addressing the contamination source.

Even for some food safety professionals, the terms OPRP, CCP, and PRP can sometimes be confusing. All food safety operations are essential for food safety management but each task must be properly established to achieve its intended objectives. To do this, a food handler must be able to identify and contrast them apart.

We have prepared a table that summarizes the key areas that can help a food handler compare each category.

The combination of control measures may prove to be more effective in making food safer than just establishing critical control points. With the help of OPRP and PRP, hazards and the likelihood of hazard exposure are minimized, making CCP operations more effective. When properly executed and monitored, the need for corrective action or the potential of a recall action is less likely to be needed.

Below, we go more in detail regarding the differences between the three control measures.

Based on the initial definition, the terms OPRP and CCP are often confused to be the same. The reason behind this is that they have almost the same nature. Both operations refer to steps for the intended management of food safety hazards within the processing chain. Although true, OPRPs are not necessarily critical to the whole operation.

While a critical control point such as properly cooking foods to the correct internal temperature exists, this operation is not absolute. The whole HACCP plan is not necessarily a zero-risk program and cannot guarantee absolute control. As such, upstream operations such as an OPRP were established to help minimize any imminent food safety risk.

The key difference between the two operations is that a CCP is the last, critical step or key control operation to eliminate or minimize potential hazards to an acceptable limit, whereas an OPRP can be removed from the system and will not necessarily lead to producing unsafe foods. An OPRP is not considered an intrinsic step and therefore can be excluded from the system and will not increase the likelihood of food safety hazards occurring. Despite this fact, an OPRP is regarded as essential in controlling and ensuring food safety more effectively.

Additionally, a CCP is always established with non-acceptable and acceptable levels of critical limits. Although both CCP and OPRP are depended on an identified risk or food safety hazard, the monitoring results of an OPRP cannot be quantified and can only be evaluated through observable action criteria. A quick example of an OPRP would be the installation of surveillance cameras in a production setup. While this operation can increase accountability and prevent loss of control over food safety hazards such as intentional adulteration, removing it does not necessarily create a hazardous food manufacturing environment for producing foods.

In keeping a cooked product at a controlled temperature and out of the danger zone, food establishments can implement both a CCP and an OPRP. Cooked foods can be stored again in the refrigerator for later use. An appropriate CCP for this operation is to indicate the date and time of storage. Alternatively, food safety teams can opt to throw any leftover cooked food instead of refrigerating them for later use. The latter operation is considered an OPRP.

A prerequisite program or PRP includes basic controls concerned with making a conducive and hygienic environment to create safe food. Most operations involved in this category are general and are not established to control a particular hazard. Their main objective is to ensure the fundamental conditions relating to proper hygiene conditions, suitability of equipment, cleaning, sanitation, and the production environment to reduce the risk of food safety hazards.

The main difference between the two categories is that an OPRP is established to target a specific food safety hazard, whereas a PRP is a general operation. Examples of PRPs include sets of general food safety practices in the food industry such as Good Manufacturing Practices and the Sanitation Standard Operating Procedures. Prerequisite programs also include aspects such as the design and layout of the food establishment and employee facilities, food waste management, pest control, and food hygiene.

The given PRP examples are generally performed to reduce the risk of harboring food safety hazards. The operations can accommodate a wide range of food safety hazards such as the presence of a foreign body classified as a physical hazard and harmful bacterial strains which are biological hazards.

Similar to any other preventive controls, an OPRP keeps the production of foods safe. Every OPRP is designed specifically to maintain safety against a particular hazard. Although an OPRP can be removed from the food production system, its presence helps food businesses ensure that the CCPs are effective and that you are producing safe end products.

The inaccurate identification of an OPRP or a CCP and the wrong implementation of control measures may prove to be dangerous for a food establishment. OPRPs commonly do not have any critical limits when compared to CCPs. If a critical operation is identified as an OPRP instead of a CCP, problems such as constant breaches of standards may significantly increase the imminent food safety risk of foodborne illnesses.

Although critical limits for an OPRP are not common and often inapplicable, monitoring its effectiveness can help optimize food safety management through the assessment of control measures. The complete and accurate application of CCP, PRP, and OPRP make up a comprehensive and working HACCP food safety plan.

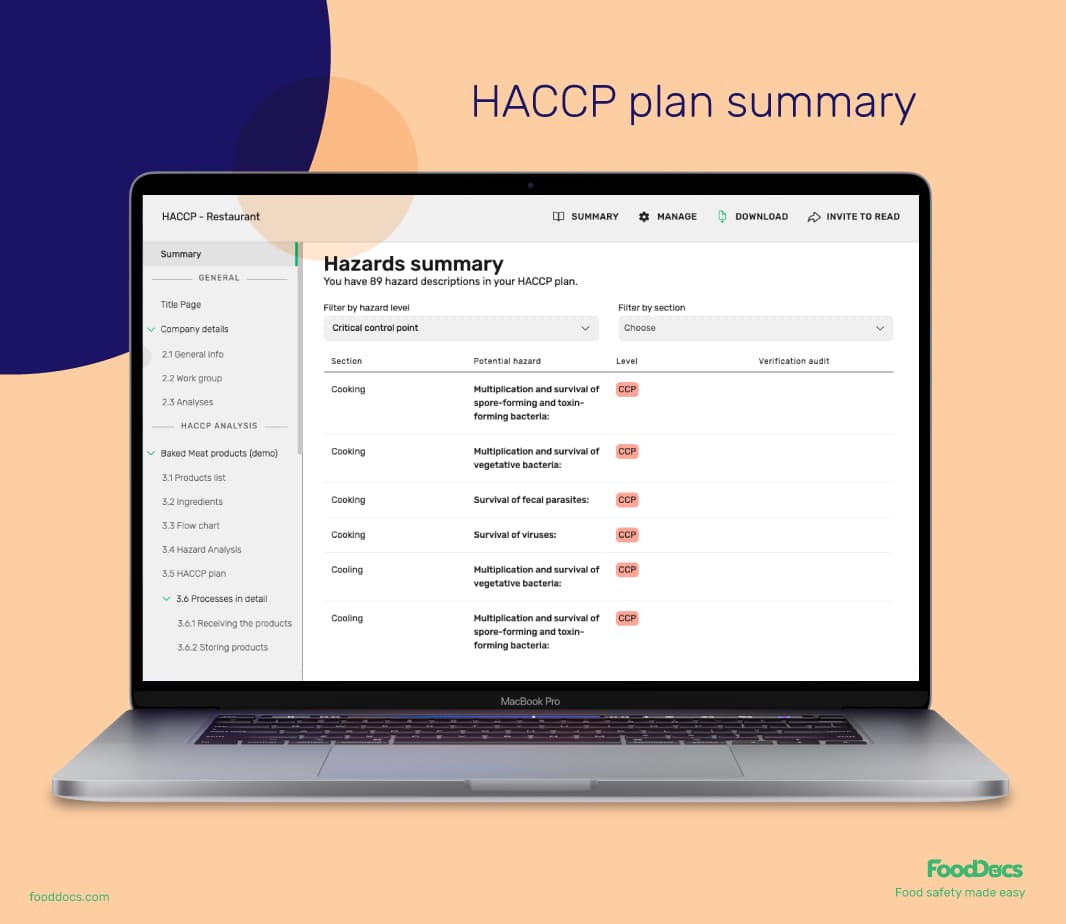

At FoodDocs, we have devised a free HACCP tool that lets you accurately identify the correct level of operation or define critical control points. Using our CCP identification tool, you can select a pre-listed food safety hazard from the dropdown menu, choose the likelihood of its occurrence, and then the potential effect it may have on your food business. This free tool is based on a risk assessment tool that helps you identify whether a hazard would require a PRP, OPRP, or a CCP for its control.

An operation can be regarded as an OPRP if it satisfies a few basic criteria. Some criteria may include the operation's ability to minimize a food safety hazard, a non-critical nature to the whole food production, and can be monitored through observations. As mentioned, although an OPRP is essential to minimizing the likelihood of causing foodborne illnesses, its exclusion from the operation will not immediately mean that the products are unsafe. As such, they can be seen as an additional control measure for food safety.

Some examples of OPRP include the following:

In recent times, the use of advanced technology has become an integral component of any intended control of food safety. Technology has offered stronger security and more accurate results when it comes to ensuring the safety of the foods being produced. Devices and software such as the following are currently being widely implemented across the food industry:

These technological additions to food processing can help increase efficiency in ensuring food safety. They intuitively help control any process step and spot potential food safety hazards.

For example, smart sensors installed in a kitchen appliance such as a refrigerator for cold storage help deliver information to a central server without the need for food employees to manually check the temperatures. These installments can be essential in keeping food safe as well as efficient. In their absence, food handlers can still check the temperatures manually.

Properly contrasting between the terms CCP, PRP, and OPRP can sometimes pose an indefinite pause in your HACCP plan-making process. Your team may need to spend a lot of time using a common decision tree that includes the distinction between OPRPs and CCPs before the implementation of any effective control process.

After which a subsequent step such as assessment of control measures multiple times and validating whether your decision is correct or not. The process of CCP and OPRP identification is one of the most time-consuming sections of making your HACCP plan.

Luckily, FoodDocs is here to help you. With our built-in HACCP plan builder software, you can get properly identified CCPs and all other important HACCP parts in just 1 hour. Powered by artificial intelligence, our system can automatically generate a HACCP plan that is specifically fit for your food business by using information from food safety regulations, established information, and our information bank.

Using our system, the process of identifying hazards, analyzing them, and assigning CCPs and critical limit designation can be done 500x faster than hiring a consultant to do the job, also much cheaper. Our built-in HACCP plan builder can automatically list all of the detailed CCPs related to your food business.

In addition, if your team is using different sensors from major brands for your monitoring procedures, you can easily integrate them into our system. You can then customize CCPs and designate them as an OPRP instead while identifying their function and the rationale behind this change.

With our software, you can achieve food safety compliance and satisfy customer requirements without worrying whether it would be able to accommodate your unique operations or not. Our system was built by food safety and technology experts while considering the most updated systems used in the food service industry.

Sign up now and enjoy our free, 14-day trial that you can use to build your HACCP plan in 1 hour. Purchase our plans and get full access to our system's features such as downloading your generated HACCP plan for your whole team.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...