Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Every food business in the food industry has its unique operations and food safety hazard based on the products and services that they use. As such, all food businesses are expected to have food safety management systems that are well-structured based on these operations.

These systems would include building a Hazard Analysis Critical Control Point (HACCP) plan where any food safety risks and any potential hazards related to your processing facility and operations are listed, analyzed, and addressed by the food safety team.

And that involves knowing what critical control points do not include and what they do.

Key takeaways

Critical control points are essential in preventing or eliminating food safety risks to acceptable levels within a food business.

Every food business should have a structured food safety management system, tailored to their specific operations and hazards.

Building a Hazard Analysis Critical Control Point (HACCP) plan is crucial, involving identification, analysis, and management of food safety risks.

Operations related to the quality of food, such as garnishing, do not constitute critical control points in a HACCP plan.

Critical control points focus on food safety rather than quality, affecting operations like cooking or cooling which directly impact product safety.

Prerequisite programs, while important for maintaining food safety, do not control specific hazards like CCPs do but support overall food safety management.

Identifying critical control points requires careful consideration and a systematic approach to ensure correct implementation.

Quality control measures, although crucial for product standards, are managed separately from critical control points.

FoodDocs' food safety management software AI system allows food businesses to establish and monitor critical control points efficiently, ensuring compliance and safety.

One of the trickiest parts of making this plan is identifying which operations are considered critical control points. This process takes several steps and careful considerations to fulfill and ensure that they are correct. In this process, you also have to consider what critical control points do not include.

In the food industry, there are general operations that are considered as CCPs regardless of their point of application in all product distribution systems from initial acceptance of raw materials to end-product testing. These operations undergo several screening questions to analyze if more attention needs to be focused on them or if you need to set critical limits for them.

Critical control points are more concerned with creating a safe product than one with the best quality. As such, operations concerning the visual presentation of the products are often left out from HACCP food safety programs.

Here is a list of the critical control point examples and operations not considered as CCPs that will be discussed in this article.

Critical control points are any process within a food business where parameters can be implemented to prevent or eliminate any potential hazard or food safety risks to acceptable levels. CCPs are considered important control measures in keeping food safe and making wholesome food. Also, they are part of most food safety programs.

Any food processing facility such as a food plant, restaurant, or retail establishment must identify these operations. Standards are set to determine if they are still within the limit. Crossing these critical limits significantly increases the chances of causing foodborne illnesses or any related injuries.

As we have mentioned, CCPs are more concerned with food safety than the quality of the product being produced. Although not critical, other operations also need occasional monitoring and contribute to the totality of the product, therefore are still part of the food safety management. Learn more about critical control points in-depth here.

Operations in the food production journey such as prerequisite programs are not necessarily considered CCPs. Although significant in keeping food safe, some of these practices are preventive measures more than control measures.

Critical control points are more concerned with operations that are considered as a last resort to controlling or eliminating a potential hazard. This means that there is no longer any subsequent or alternative process step that will eliminate the identified potential hazard.

Below are a few more operations that critical control points do not include.

The quality of a finished product refers to the total attributes of a product that are considered acceptable to consumers. These characteristics include the shape, size, color, texture, mouthfeel, flavor, aroma, and nutritional content of the food product. Although food quality is one of the main driving factors that customers consider when buying and significantly affects food sales, it does not contribute to the safety of the product.

Process testing related to quality is more of a concern for the quality department rather than food safety. Finished product quality can sometimes be used as an indicator for safety issues such as when discoloration occurs or off-odors as a result of microbiological contamination are observed. These observations are then used for critical control point determination.

The quality of equipment used in food production significantly affects the outcome of the products. Despite this, they are not part of the CCP group. Problems and maintenance regarding the quality of equipment, even if they come in direct contact with food, are more part of prerequisite and preoperational programs than CCPs.

Quality of equipment includes proper maintenance and calibration of process monitoring instruments to ensure that uniform quality and consistent results are produced.

Garnish or visual presentation is a food preparation step that is purely concentrated on the quality of presented products. It is how products are decorated on a plate for serving in restaurants or what the product packaging looks like. Unless the food packaging materials contribute to the keeping quality of the product such as smart and active packaging, their visual presentation does not affect food safety.

This food operation refers to the quality of serving the customers. It is how food handlers present themselves, communicate with the customers, and how they address any reasonable possibility of issues that may or may not be concerned with food safety.

Customer service is the attention that employees in a food business provide customers with so they would feel heard. It may also sometimes include the sanitary conditions of a processing facility. Although important in the food business and increasing annual sales as a whole, the breach of customer service will not affect food safety nor can food handlers put critical limits to measure it.

Now, this is a tricky point. Prerequisite programs (PRP) and critical control points both contribute to maintaining food safety. Despite these, PRPs such as Sanitation Standard Operating Procedure and Good Manufacturing Practices are general food safety practices and standard operating procedures that are not meant to control any specific food safety hazard in your operations. They are mostly activities that help control hazards such as cross-contamination within the whole process operation.

This program includes adequate training, proper employee hygiene, control of employee health conditions, maintenance of clean outer garments, sanitation controls, proper food processing facility layout, clean processing plant environment, and ensuring the sanitation and cleanliness of food contact surfaces. Additionally, specific control points such as prewashing agricultural products such as fresh fruits are considered PRPs.

Prerequisite programs are part of the basic food safety practices and are the solid foundation used for the determination of compliance with HACCP food safety programs.

Although these operations are not considered as CCPs, they also significantly affect how customers perceive your food business. These operations would also need appropriate monitoring procedures. On the other hand, quality control aspects generally contribute to food safety but are still part of the management of a food business. These operations are commonly also audited by any regulatory agency as part of the food safety manual.

Critical control points are an integral part of a HACCP plan in the food chain. These operations are identified as the last food production process step available to control or eliminate a food safety hazard. They are based on the type of potential hazard present in food processing which can be a chemical hazard, physical hazard, or biological hazard.

Their identification may sometimes need the help of a critical control point decision tree or a hazard matrix. Critical control points are commonly accompanied by a set critical limit or physical parameter which determines the minimum and maximum actual values that are still acceptable and will not cause any foodborne illnesses. They are established to prevent the loss of control of food safety.

Examples of CCPs may include:

The food preparation involving the application of heat on raw materials reduces the amount of any remaining biological contaminants such as a microbiological pathogen and makes any type of product for distribution shelf-stable. Heat inactivates microorganisms and makes safe food products. Cooking or the application of thermal process becomes a critical control point for products that will not undergo further food production process while still having desirable characteristics for a pathogen.

As an example, grilling beef patties, a product that is intended to be eaten right away, at a particular internal food temperature ensures that the patty is safe to eat as the pathogens have been inactivated. In this case, heating is crucial to make the patties safe for eating, making it a potential critical control point. This is also the case for the processing of juice products where pasteurization is used to keep the products safe.

On the other hand, operations such as baking where heat is only applied to make a dough, a raw product, into an edible one by reducing water activity with no relation to associated food hazards cannot be considered as CCP. Although this extends the product's shelf life and improves eating qualities, it does not affect the safety of the product. Different types of food require different internal temperatures. Find out which actual times suit your products.

This food operation pertains to the rapid decrease of temperature of the product after it is processed. If the cooked foods are displayed at room temperature to cook and allow them to cool down by natural means, the risk of contaminating the product significantly increases.

Cooling is suggested to be completed within the first 2 to 4 hours to prevent contamination of food and extend their shelf life. A very long cooling process encourages microbial growth or contaminates the food at room temperatures.

Some foods such as soups, cafeteria food, and other foods meant to be displayed are required to be held at 140°F (60°C). This is not done to just keep the foods warm and presentable to consumers, the main principle of hot-holding is to prevent any pathogen from growing on the food by maintaining a relatively high temperature.

If foods such as those served in cafeterias are held at around the temperature danger zone which is around 40°F to 140°F (5°C to 60°C), chances are, microbiological contamination will occur even before distribution to consumers. Hot-holding is considered as a CCP since it is the last step for some food products before consumers eat them.

Ready-to-eat foods such as sandwiches, smoked fish, and cooked meats can sometimes be refrigerated to be sold for later. Before consumption, these foods may need to be reheated to eliminate biological hazards. During this food process, enteric pathogens such as bacteria can recover since the food only came from refrigeration and not freezing. These pathogens can get the chance to multiply faster and even create spores and natural toxins that cannot be killed by regular processing and therefore create hazardous foods.

When reheating food items, make sure to reach the internal temperature of 165°F (74°C). This includes reheating casseroles and leftover food.

These mentioned operations are examples that are used for a generic type of HACCP plan. Critical control points in the food industry are always accompanied by an accurate record of monitoring procedures, corrective action procedures, and accurate documentation processes as mandatory requirements for record retention of HACCP food safety programs.

Other critical control points can include product formulation control and control of chemical contamination such as color additive control or adulteration with lubricants. In addition, verification activities such as microbiological testing and other additional testing are important to ensure that the CCPs remain controlled. Every food processing plant and food establishment is required to have a plan that consists of these processing procedures for purposes of product safety.

The process of determining which operations in a food business can be considered as a critical control point can be very hard. Aside from being very confusing, there are a lot of considerations needed to be evaluated before declaring an operation as a CCP in the food industry.

You can use tools such as a CCP decision tree, hazard matrix, or external links from regulatory agency guidance to help you identify CCPs in combination with your process flow chart. Although, remember that critical control point determination is just one part of making a HACCP food safety manual and your systematic approach to food safety.

HACCP plan-making takes 7 primary steps and a few other preparatory operations for successful implementation within the food chain. You would need to build a food safety team composed of food safety experts and representatives from other departments of your food business to ensure that all areas of your operations are covered. As a food safety supervisor, what if there is a way to simplify all of these operations and finish your HACCP plan in just 1 hour?

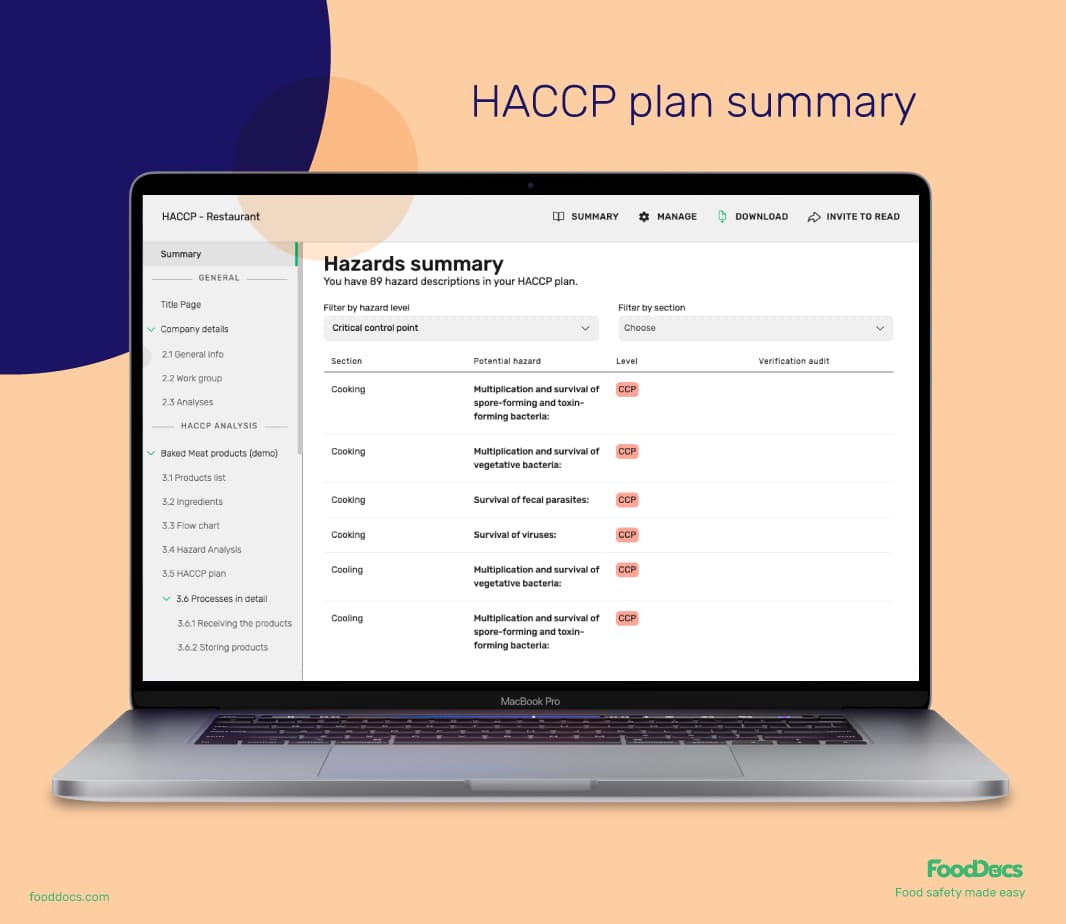

This is exactly our approach to food safety at FoodDocs. Using machine-learning programs, our built-in HACCP plan builder can automatically generate a HACCP food safety plan that is specific for your current process and help you get compliant in just 1 hour. Our process starts by asking you a few basic questions about your operations and the nature of your food business. These questions include:

By answering these questions, our built-in software automatically creates a comprehensive HACCP plan with all the necessary documents for HACCP compliance. Our expert AI system developed by food safety experts from FoodDocs generates the following electronic records and documents:

Our system guarantees a 120x faster process than seeking expert advice from a food safety consultant to help you make your HACCP plan for compliance. You can skip using a very complex decision tree as we identify all hazards for you. We understand how some food companies have specific operations that are unique from other business entities.

To allow you to improve your digital HACCP plan prior to implementation, you can customize and edit any section for any applicable provisions or necessary improvements. Address any competitive hardship in terms of food safety and create a significant advantage by allowing us to help you get HACCP compliant.

Achieve assurance of compliance in no time with our built-in HACCP plan builder and cut all the meetings and revisions you are bound to go through if you choose to use the traditional method. Spend more time with the effective implementation of your HACCP plan and managing your food business with all the time you can save when you join us at FoodDocs.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...