Kitchen SOP Template: How to Create One and Why You Should

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

Kitchen SOP Template: How to Create One and Why You Should

Running a kitchen is a complex job with many moving parts. Kitchen SOPs (Standard Operating Procedures) are written guides that explain exactly how to perform a given task step by step so it’s done the same way every time, you keep customers safe, and you maintain high safety standards for your brand.

Think of it as a recipe for your staff to follow for operational tasks that ensure consistency across all shifts, from cleaning the fryer to chopping vegetables. Documenting the best way to do each routine task (like we outline in our “how to write SOPs template”) will help ensure everyone on the team is on the same page and they don’t overlook anything critical.

Get our most popular food business SOPs

Key takeaways

-

A kitchen SOP is a step-by-step written process that helps your team complete a kitchen task the same way every time.

-

Kitchen SOPs improve food safety and consistency by removing guesswork during busy shifts.

-

The most useful kitchen SOPs cover the work that happens daily, like opening, closing, cleaning, cooking, cooling, and storage.

-

Strong SOPs are written so a new hire can follow them, using short steps that start with clear action verbs.

-

The best kitchen SOPs include the basics like purpose, scope, roles, and a clear procedure, not just a list of steps.

-

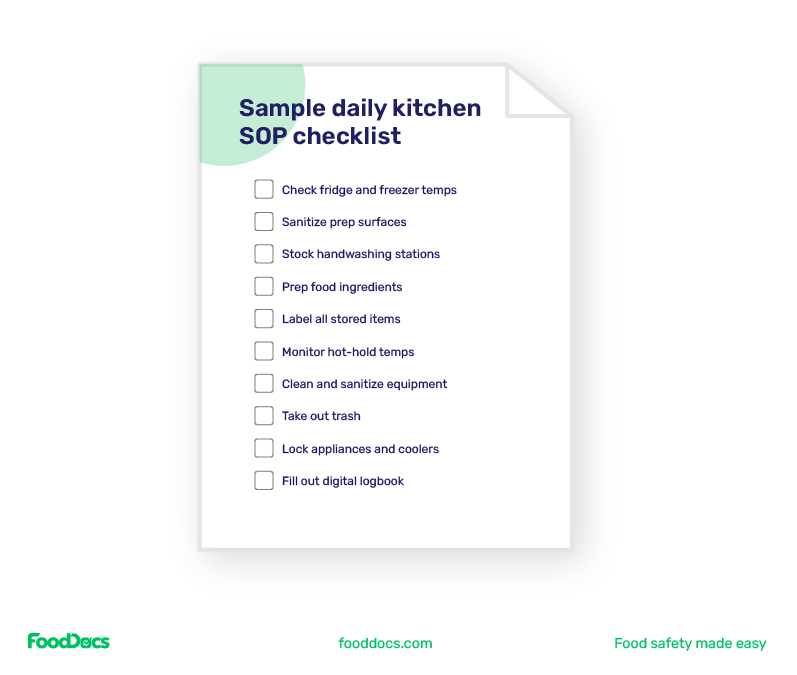

A kitchen SOP checklist helps with follow through by confirming the task was done, but the SOP explains how to do it.

-

Verification matters because it creates proof that standards were met through logs, sign offs, and corrective actions.

-

SOPs work best when they are easy to access in the moment, like posted at stations or stored digitally.

-

If your team resists SOPs, adoption improves when you start with one SOP that makes the shift feel easier.

-

Kitchen SOP software like FoodDocs can help by creating and managing SOPs with built-in instructions your staff can follow consistently.

Why do restaurant kitchens need SOPs?

Creating and using kitchen SOPs might sound like extra work, especially if you’re not using a time-saving damage-proof digital solution. But they are extremely important for a smooth, safe operation.

First and foremost, SOPs create consistency. Every cook and dishwasher will perform key tasks the same way, which means each dish is prepared with the same care and each cleaning task is done to the same standard. This consistency gives every customer the same quality experience, no matter who is working that day. It also reduces the chance of mistakes or oversights.

Instead of relying on memory or guesswork, staff can follow clear instructions. There’s much less risk of skipping a critical step or doing it improperly when an SOP is there to guide them.

Another big benefit is faster training and onboarding for new employees. Well-crafted SOPs act like built-in training manuals. If you’re using food safety management apps, a new kitchen hire can pull up the SOP with visual instructions and understand how to do the job step by step, helping them get up to speed quickly. This takes a lot of pressure off senior staff and managers, because the SOP is teaching the correct process in a consistent way each time.

Kitchen SOPs are also key for food safety and compliance. In the food industry, health inspectors and regulators want to see that you handle food and sanitation the right way. Having clear, written procedures for things like cooking temperatures, cleaning schedules, and equipment sanitizing shows that your team follows documented, safe practices.

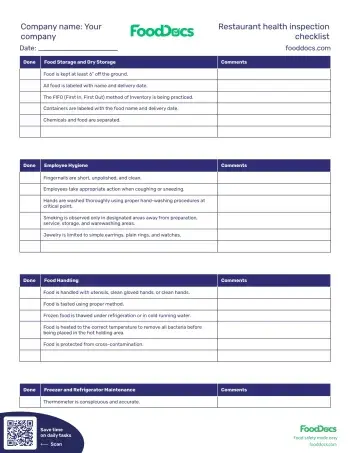

Download your Restaurant Health Inspection Checklist

If an inspector asks “How do you prevent cross-contamination in your kitchen?” you can show them an SOP that details exactly how your team does it. This not only helps you pass inspections and avoid violations, but it also makes it easier to trace and fix food safety incidents if something ever goes wrong.

When entire teams follow SOPs, the kitchen runs more efficiently and customers get a consistently good experience. Orders come out reliably, cleaning is done on schedule, and there are fewer surprises or emergencies. All of this leads to a smoother operation, higher food quality standards, and happier customers who notice the professionalism and keep coming back.

What kitchen SOPs does a food business need?

A typical kitchen will develop SOPs for all the key processes that happen regularly. The exact list can vary depending on your menu and operation, but here are some common areas where kitchen SOPs are essential:

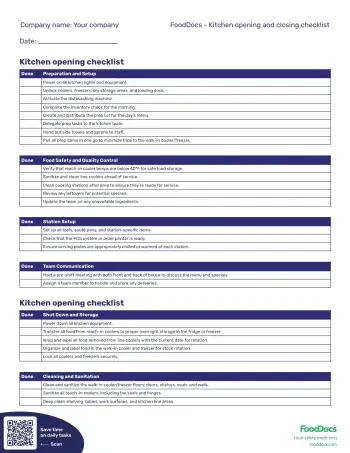

Opening and closing the kitchen

Step-by-step procedures for how to start up the kitchen at the beginning of the day (e.g., unlocking storage, turning on appliances, prepping stations) and how to shut down safely at night (e.g., cooling down equipment, covering and storing ingredients, cleaning work areas). This ensures nothing is missed at the start or end of a shift.

Download your Kitchen Opening and Closing Checklist

Food preparation and cooking

Instructions on how to prepare each dish or ingredient safely and consistently. This could include cooking foods to the correct internal temperatures, following recipes exactly, using the right utensils, and timing each step.

For example, an SOP might detail how to grill a steak to medium-rare or how to assemble a certain salad so it’s the same every time. Cooking SOPs help maintain quality and taste, and they reinforce food safety (like making sure chicken is always cooked to at least 165°F).

Cleaning and sanitation

There should be SOPs for cleaning and sanitizing kitchen equipment, utensils, and surfaces. These are sometimes called Sanitation SOPs or SSOPs. They outline how to properly wash, rinse, and sanitize items like knives, cutting boards, countertops, ovens, and so on.

For instance, you might have an SOP for how to clean the meat slicer at the end of the day, describing which cleaning solution to use and how to reassemble the machine after sanitizing. Cleaning SOPs also cover schedules (e.g. deep-clean the fryer every Friday) and ensure nothing hygienic is left to chance.

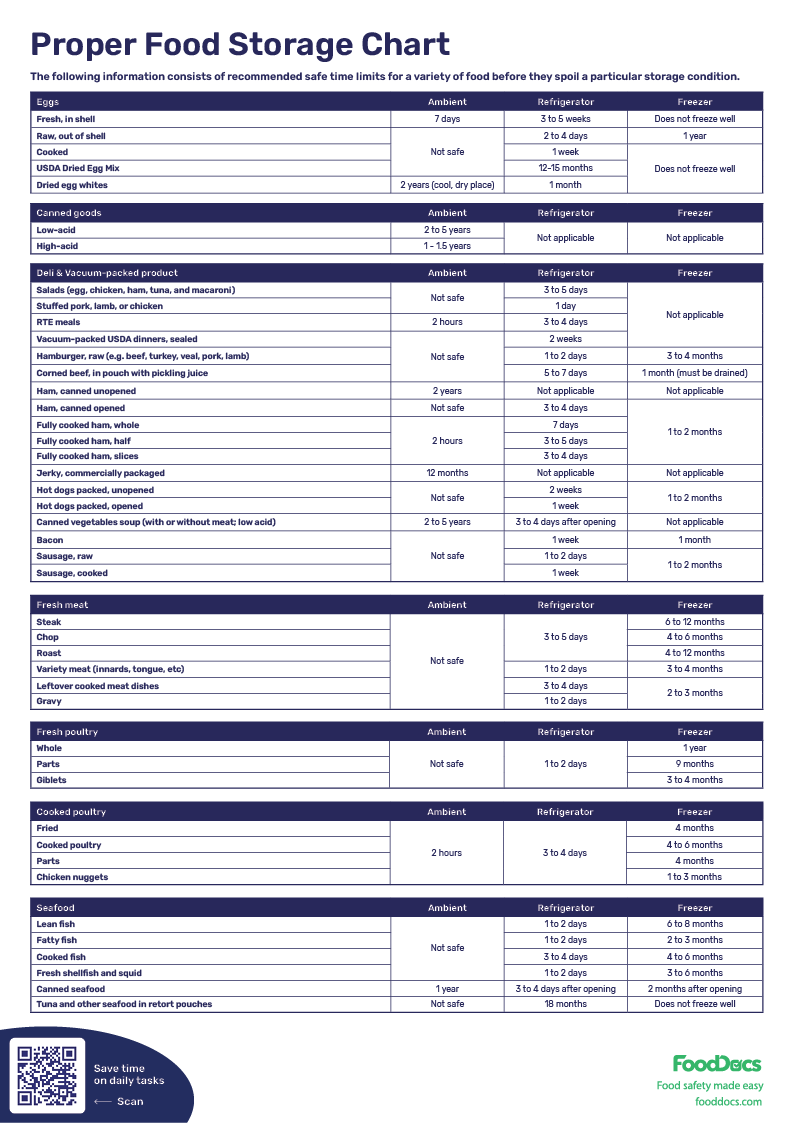

Food storage and handling

Procedures for receiving deliveries, storing ingredients, and handling food to prevent spoilage and contamination. This could include an SOP for how to label and rotate stock (FIFO, first in, first out), how to store raw meat on fridge shelves (always below ready-to-eat foods to avoid drips), and how to check and log refrigerator and freezer temperatures daily.

Download your Proper Food Storage Chart

Cross-contamination and allergen control

SOPs that focus on keeping allergens and contaminants separate. For example, using separate color-coded cutting boards and knives for raw poultry vs. vegetables, and cleaning surfaces between handling different foods.

If a kitchen deals with common allergens, you might have an SOP for allergen management (e.g., how to prevent cross-contact when preparing a gluten-free meal or how to clean a station after handling peanuts).

Download your Food Allergen Poster

Personal hygiene

Basic rules for the kitchen staff to keep food safe. SOPs in this category cover things like proper hand-washing technique (and how often to wash), rules about wearing gloves, hair restraints (hats or nets), and policies on not working when sick. While these might seem like common sense, writing them down in an SOP sets a clear standard everyone must follow.

Download your Hand Washing Poster

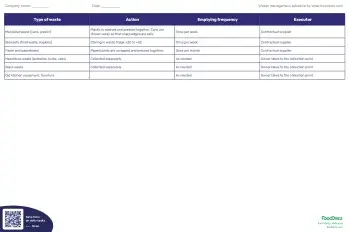

Waste management and pest control

Some kitchens have SOPs for how to dispose of food waste and garbage correctly (e.g. emptying trash, using the compost or recycling, cleaning garbage bins) to keep the kitchen clean and discourage pests. Relatedly, a Pest Control SOP can outline how to check for signs of pests and what to do if you find droppings or insects, to ensure a prompt and safe response.

And don’t forget front-of-house SOPs in a food business setting. While these are outside the kitchen, they are part of the overall operation. For instance, you might create SOPs for how hosts greet and seat customers, how servers take orders and handle complaints, or how bartenders close out the bar.

Download your Waste Management Schedule

How do you write a kitchen SOP?

Creating a kitchen SOP might feel intimidating at first, but you can approach it step by step. Here’s a straightforward process to write an effective SOP for your kitchen (or any part of your restaurant):

1. Pick a specific process and gather input from the experts

Start with one task that needs a standard procedure. It could be “How to clean the grill” or “How to calibrate a thermometer”. Involve the people who know the task best when drafting the SOP. Usually, this means the line cooks, chefs, or kitchen supervisors who do the job regularly.

Their hands-on experience is valuable because it helps them know the right way to do it and the common mistakes to avoid. If you’re writing an SOP for deep-cleaning the coffee machine, ask the person who always handles that job to walk you through it. In short, get the real-life know-how on paper.

2. Break the task down into clear, step-by-step instructions

Outline the process from start to finish as a series of simple steps, and list them in the exact order they should be done. Each step should be concise and action-oriented. It often helps to start each instruction with a verb.

For example: “Preheat the oven to 350°F,” “Wash all utensils in hot soapy water,” “Record the sauce temperature in the log.” Number the steps so they are easy to follow in sequence. If there are decision points or branches in the process (“If X happens, do Step 3a, otherwise do Step 4”), make sure to include guidance for those.

The goal is that anyone reading the SOP, even if they’re new, can carry out the task without needing to ask for extra help. If a step is unclear upon first reading, go back and rewrite it more simply.

Keep the language plain and direct. For example, writing “Clean the grill plates with a stiff brush to remove charred residue” is clear, whereas “It is imperative to clean the grill thoroughly” is vague and not actionable.

3. Include important details, measurements, and safety notes

As you document each step, add any crucial details that someone would need to do it correctly. These details can include exact amounts or times (e.g. “Add 5 mL of sanitizer per liter of water” or “Bake for 15 minutes”) and specific standards (“Heat oil to 350°F before frying”).

Also incorporate any safety precautions or critical checks at the appropriate points. For example, if a step involves slicing with a mandoline, you might note “Wear cut-resistant gloves while using the slicer.” Or if a step is to cool a soup, you might add “Make sure the soup cools from 140°F to 70°F within 2 hours (use an ice bath if needed). If it’s still above 70°F after 2 hours, inform the manager immediately.”

These kinds of details ensure the SOP isn’t just a generic outline, but a practical guide that covers all the little things that matter for doing the job right. Whenever possible, consider adding visual aids such as photo or video instructions, which is extremely helpful for staff understanding.

4. Test the SOP and refine it

Once you have a draft written, do a trial run to make sure the SOP actually works as written. A great way to test is to have someone who isn’t already an expert on the task follow the SOP exactly, while you observe quietly.

See if they can complete the task correctly using only the written steps. If they get confused, skip something, or have questions, that’s a clear sign the SOP needs adjustment. Maybe a step wasn’t detailed enough, or perhaps the order needs tweaking.

Use this feedback to improve the SOP before it becomes “official.” Your goal is to make the instructions clear as possible, so that even a brand new employee could successfully follow them.

5. Finalize, implement, and train your team

After refining the SOP, it’s time to put it into action. Introduce the new SOP to your kitchen staff and train them on it. Don’t just hand out the document and assume people will read it. Take some time in a staff meeting or training session to walk through the SOP together. Explain not just how to do the procedure, but why each step is important.

For example, you might say: “We sanitize the counters after washing them because the sanitizer kills germs left behind by soap and water”. When people understand the reason behind a step, they’re more likely to follow it correctly. Make sure everyone has a chance to ask questions.

This discussion ensures that the whole team is aligned and comfortable with the new procedure. After training, keep the SOP accessible (as we’ll discuss below) so staff can reference it at any time.

6. Monitor the SOP in use and update as needed

For most food business leaders, SOP monitoring is the most time-consuming part because you’ve got to check if staff are completing them on time, the right way, and across every station and location.

That gets harder as your team grows. It gets even harder once you add more sites. One missed cleaning task or one skipped temperature check can quickly turn into a recurring problem, especially when food safety leaders, Executive Chefs, and other staff are juggling multiple things during service.

In the early days of a new SOP, expect a few misses. People will fall back into old habits. They may skip steps during a rush, but what’s important is your ability to catch patterns early and reinforce the standard in a calm, consistent way.

This is also why many restaurants move SOP monitoring into digital tools such as FoodDocs. Instead of chasing paper checklists and hoping tasks were completed, you can see task status instantly and spot gaps before they become a bigger issue.

For example, FoodDocs includes a real-time overview where managers can check whether tasks are being completed across locations. Pair that with a digital log, and you get clear records of what was done, when it was done, who completed it, and in what department. That can save hours of supervision each week and make SOP follow-through and version update far easier to manage.

Creating SOPs is an ongoing process of improvement and training. Once you’ve got a strong set of foundational SOPs, you’ll wonder how you ever managed without them.

Download your Standard Operating Procedure Template

Can you use kitchen SOP templates or checklists?

Get our most popular food business SOPs

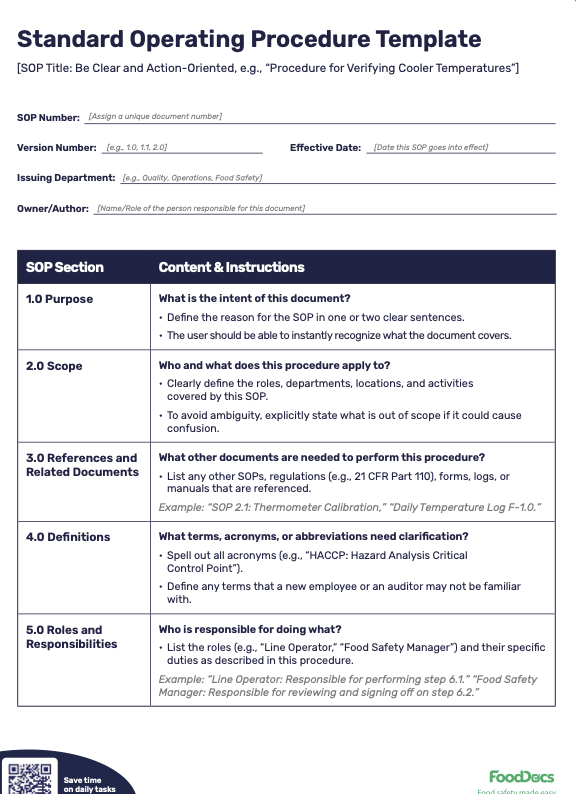

When writing a kitchen SOP, it’s important to cover all the bases so that the document is clear and complete. Most SOPs follow a similar basic structure. At minimum, a good SOP document will include:

- Title

- Purpose

- Scope

- Responsibilities

- Procedure steps

- Any references or records needed

Let’s break down the typical sections of a kitchen SOP template and what each one contains.

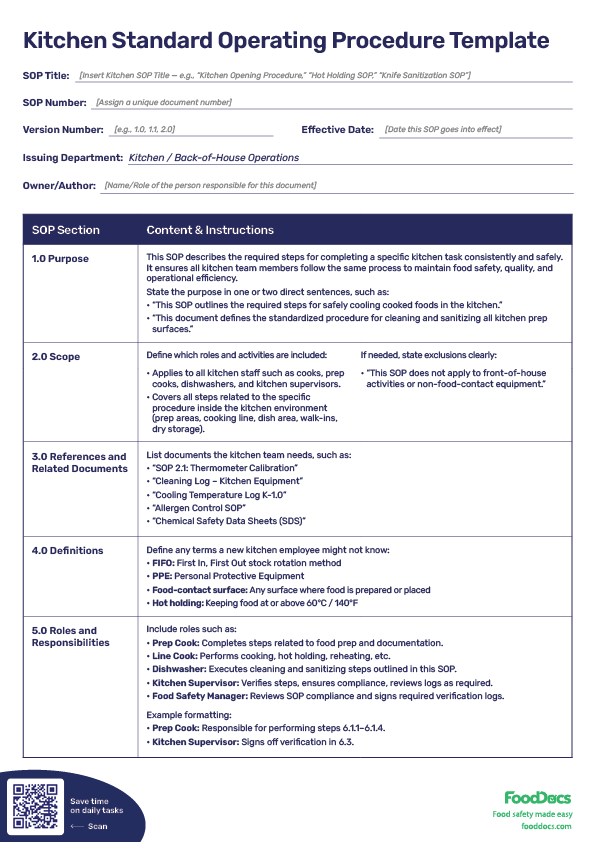

Title and document info

Every SOP should start with a header that identifies it. Include a descriptive title (for example, “Kitchen Opening Procedure” or “Knife Sanitization SOP”).

Also note any reference code or number for the SOP if your system uses them, the version number or date (to keep track of updates), the department (e.g. Kitchen/Back-of-House), and the author or owner (the person responsible for maintaining this SOP).

This basic info makes it easy to keep documents organized and know which is the latest version. For instance, the top of your SOP might look like:

- Kitchen Standard Operating Procedure – Hot Holding SOP

- SOP Number: K-1.2 (Version 2.0)

- Department: Back of House – Kitchen Operations

- Effective Date: Jan 15, 2026

- Owner: Executive Chef

Purpose

A brief statement explaining why this SOP exists (i.e., what is its intent or goal). The purpose focuses on the why behind the procedure. For example, the purpose might be, “To outline the required steps for safely cooling cooked foods, so that all team members follow the same process to maintain food safety and quality.”

In other words, what outcome does following this SOP ensure? A clear purpose sets the tone and importance of the procedure.

Scope

Details who and what the SOP applies to. This section defines the boundaries of the procedure. It should answer: which roles or job titles should use this SOP, and which activities or areas it covers. You might write, “This SOP applies to all kitchen staff (cooks, prep cooks, and dishwashers) and covers the steps for cleaning and sanitizing kitchen prep surfaces.”

If there are any exceptions or things not included, note them here too. For instance, “This SOP does not cover front-of-house cleaning procedures.”

The scope makes it clear where this SOP is meant to be used and by whom.

References and related documents

Many procedures rely on other documents or resources. This section lists any other SOPs, logs, forms, or manuals that someone might need to perform this task.

For example, a kitchen cleaning SOP might reference a Cleaning Checklist form that staff must fill out, or an Equipment User Manual for a dishwasher, or even another SOP (like “Refer to SOP 2.1: Thermometer Calibration” for checking thermometer accuracy). It could also include regulatory references, like a food code section, if relevant.

Listing these ensures that the person doing the task has everything they need at hand.

Definitions

If your SOP uses any technical terms, acronyms, or jargon, define them in a quick glossary here. The kitchen is full of shorthand and specific terminology that a new employee might not know.

For example

You might define terms like “FIFO” (First In, First Out stock rotation method), “PPE” (Personal Protective Equipment, such as gloves or goggles), “Food-contact surface” (any surface that touches food), or “Hot holding” (keeping cooked food warm at 140°F or above).

Spelling these out prevents confusion and ensures everyone interprets the SOP the same way.

Roles and responsibilities

This section spells out who is responsible for each part of the procedure or for ensuring it’s carried out correctly. In a kitchen SOP, you may list roles like Prep Cook, Line Cook, Dishwasher, Kitchen Supervisor, or Food Safety Manager, and describe each of their duties related to this SOP.

For example, “Prep Cook: Completes steps 6.1.1–6.1.4 of this procedure and fills out the cleaning log,” and “Kitchen Supervisor: Verifies that all steps were completed and signs off in the log (step 6.3.2).” This clarity helps everyone know their part. It also reinforces accountability because if something was missed, it’s easier to trace who was in charge of that step.

Not every SOP will need a lengthy roles and responsibilities section, especially if only one person ever performs the task, but it’s very useful for procedures that involve multiple people or oversight.

Procedure steps

This is the heart of the SOP: the detailed, step-by-step instructions on how to perform the task. It’s usually presented as a numbered list of steps, sometimes broken into sub-sections if the procedure has phases (e.g. Preparation, Execution, and Verification). Each step should be a command or action, written clearly and in order.

For example

A portion of a Kitchen Opening SOP procedure might look like:

6.1 Preparation:

- 6.1.1 Turn on the lights and hood ventilation system in the kitchen.

- 6.1.2 Wash hands thoroughly according to the Handwashing SOP before handling any food or equipment.

- 6.1.3 Put on a clean apron and ensure hair is fully restrained under a cap.

6.2 Cold Station Setup:

- 6.2.1 Verify all refrigerators are at or below 40°F; record temperatures in the daily log.

- 6.2.2 Bring out prepped ingredients from the walk-in cooler and stock the cold line (per the par levels in the Prep List).

6.3 Verification:

- 6.3.1 Chef inspects each station to ensure readiness.

- 6.3.2 Sign off the Opening Checklist to confirm the kitchen is set up properly.

The above is just an illustrative snippet, but it shows how you might structure the numbering (major steps and sub-steps). Writing the procedure section will likely be the most time-consuming part of creating the SOP, because you want to capture all the necessary actions in detail.

Be specific. If a step involves checking something, say what to check and what to do with the information (e.g. “If the fridge is warmer than 40°F, notify the supervisor immediately”). Use clear action verbs and keep sentences short. The procedure should read like a set of commands that anyone with basic training can follow.

Also, make sure to integrate any safety or critical control points into the steps at the right spots (e.g. “Wear gloves before touching ready-to-eat foods” or “Make sure the sanitizer sits for 2 minutes on the surface before wiping off”). This way, the procedure itself contains all the guidance needed to do the job correctly and safely.

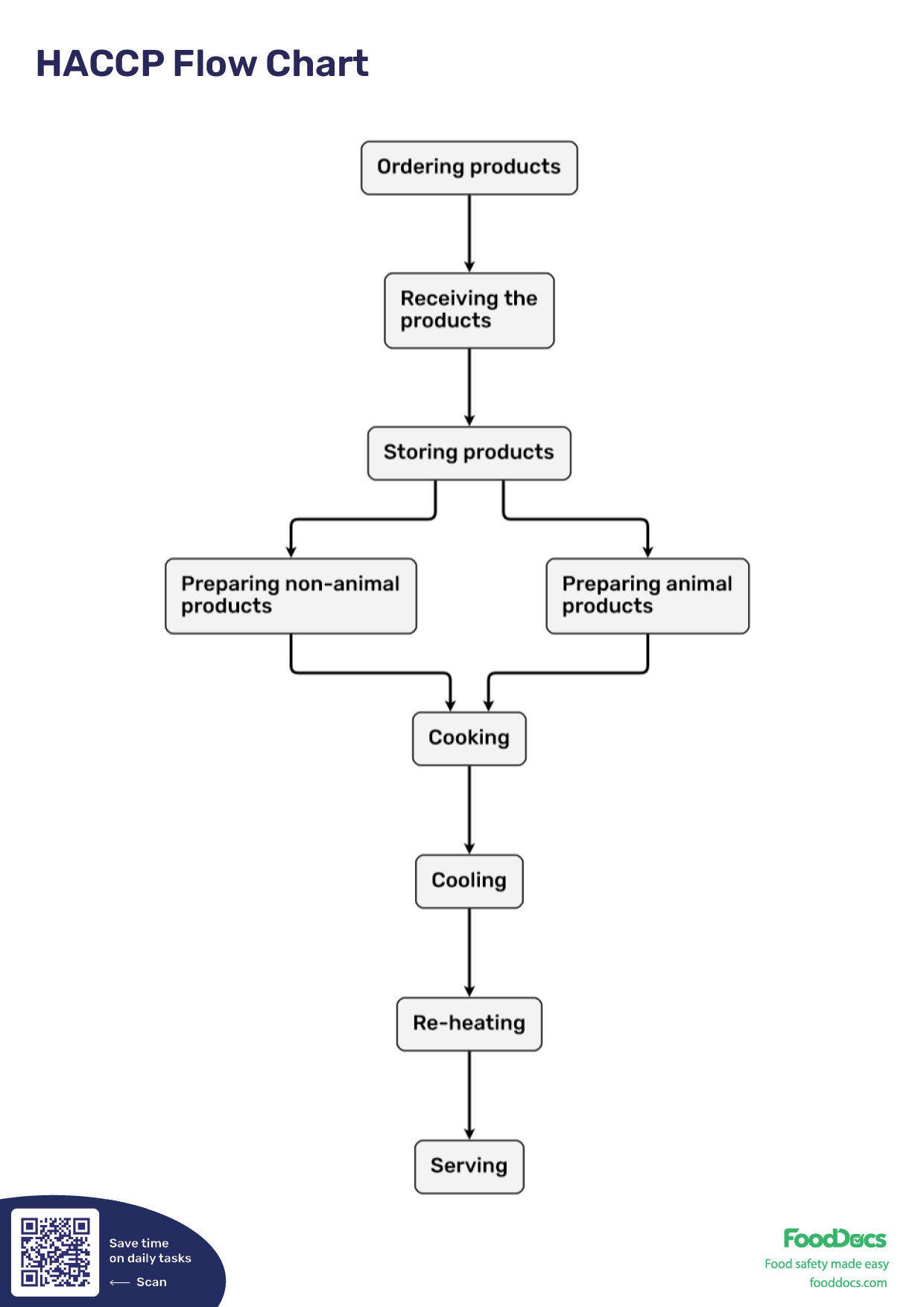

Appendices

If there are any additional materials that go along with the SOP, you can attach them or note them in an appendix. This might include blank forms (e.g., a cleaning log sheet employees need to fill out), checklists that accompany the SOP, diagrams or flow charts, or photographs illustrating a setup.

Download your Flow Chart Template

Revision history and approvals

Finally, a good SOP document will track its own history. At the bottom or end, include a section that records any revisions/updates (with dates and a brief description of changes made, plus a new version number if applicable).

There should also be a place for approvals (i.e., signatures or names of who prepared the SOP, who reviewed it, and who approved it. This creates accountability and ensures that at least two sets of eyes have vetted the procedure. It also helps if you ever need to show an inspector or auditor that your SOPs are up to date and officially adopted by management.

Not every SOP in every kitchen will have all these sections written out formally. But if you follow this template, you’ll end up with a thorough document. The key is that anyone reading the SOP should quickly grasp what it’s for, when to use it, who should use it, and exactly how to carry out the steps.

Including the sections above provides clarity. It’s better to err on the side of giving too much helpful information than too little. And if you use a standardized format for all your kitchen SOPs, it becomes easier for staff to navigate them because they’ll know where to look for each type of information.

What is an example of a Kitchen SOP?

Let’s bring it all together with a concrete example. Below is a snippet from a Kitchen Cleaning SOP — specifically, an SOP for cleaning and sanitizing equipment. This example will show how the sections and steps actually look in practice:

An example excerpt from a kitchen sanitation SOP, showing the policy, responsibilities, and step-by-step cleaning procedure for equipment.

In this example SOP, the Policy statement at the top might say something like: “Equipment must be washed, rinsed, and sanitized after each use to ensure the safety of food served to customers.” That sets the rule and the why.

Then the SOP lists Employee’s Responsibility (e.g. “After each use, the assigned staff member disassembles the equipment and cleans all removable parts”) and Manager’s Responsibility (e.g. “The kitchen supervisor checks that equipment is being cleaned properly and logs the completion”). By splitting responsibilities, it’s clear who does what. After that, the procedure steps are laid out in order.

For a cleaning SOP, the steps might include the following stages, each with details:

- Pre-cleaning: Remove large food debris from the equipment. Example step: “Scrape or rinse off any food particles from the mixer bowl and attachments before washing.” This ensures the washing step can be effective.

- Washing: Thoroughly wash all parts with hot soapy water (or an appropriate detergent) to remove grease and grime. Example: “Scrub all surfaces of the slicer with a nylon brush and approved detergent solution until visibly clean.” Only food-safe cleaning chemicals should be used, and the SOP would specify the exact product if needed.

- Rinsing: Rinse off the detergent with clean water to remove any soap residues. It’s important that no suds or cleaner is left, because leftover detergent can interfere with the sanitizer.

- Sanitizing: Apply an approved sanitizer solution to all equipment parts to kill any remaining germs. This could be done by immersing parts in a sanitizing bucket, or by wiping/spraying surfaces with sanitizer and letting it sit. The SOP should note the required contact time for the sanitizer – for example, “Immerse for at least 1 minute in sanitizer (200 ppm quaternary ammonium) at room temperature.” This ensures the chemical has time to do its job. If your sanitizer needs to be rinsed off afterward (some do, some don’t), the SOP will mention that too.

- Drying: After sanitizing, allow the equipment parts to air dry completely before reassembling or using them. “Do not towel-dry sanitized equipment; let it air dry on a clean rack.” This prevents re-contaminating the equipment with a possibly dirty towel and gives the sanitizer time to evaporate.

- Reassembling and/or storage: Once dry, put the equipment back together and store it properly until next use. “Reassemble the slicer and cover it with its dust cover to keep it clean.”

The SOP would also include any special notes or warnings, such as “Warning: If equipment cannot be fully cleaned and sanitized (e.g., due to a malfunction), it must not be used and the issue should be reported to a manager immediately.”

Remember: Any template or example SOP should be reviewed and customized for your specific kitchen. Every operation is a bit different. Use templates as a starting point, but adjust the steps, chemicals, times, and responsibilities to match how things are actually done in your restaurant. That way, the SOP isn’t just theoretically sound, but also practical for your team.

How do you implement and maintain SOPs in the kitchen?

Writing a set of excellent SOPs is a big accomplishment, but the job isn’t done when the documents are written. The real-world success of SOPs comes from how you implement them with your team and maintain them over time. Here are some tips to make sure your kitchen SOPs actually get used and stay effective:

Train your team on the SOPs

As mentioned earlier, don’t just distribute SOP documents and assume people will follow them. Take the time to train your staff on each important SOP, especially when it’s new. This could be part of your new employee orientation (e.g., teaching all new hires the “personal hygiene and handwashing SOP” on day one), and part of ongoing training when you roll out a new procedure.

During training, physically walk through the steps if possible. Show how to do it, then let them practice under supervision. Encourage questions. The more interactive the training, the more likely employees will remember the SOP and respect its importance. Also, explain the “why” behind steps during training (people tend to follow rules more diligently when they understand the reasoning).

For example, clarify that the reason for keeping a soup uncovered while it cools in an ice bath is to allow heat to escape faster and reach a safe temperature in time. These little insights stick with people.

Make SOPs easy to access

Don’t bury your SOPs in a binder that sits in the manager’s office. Employees should be able to quickly reference an SOP whenever they need to. A digital solution can be great (e.g., that stores all SOPs on a shared tablet in the kitchen, or on a company intranet or app that staff have access to). If you use food safety software, you might load them there.

Pro SOP tip

Most kitchens still rely on piles of paper sheets for checklists, temperature logs, cleaning schedules, and more. That puts the burden on food safety leaders to chase tasks and confirm people did them properly. Digital tools reduce that stress by prompting staff when an SOP task is due, guiding them through the steps (with visual aids), and saving a record when it’s completed. The right system makes compliance feel like part of the shift, not an extra job at the end of it.

It’s also helpful to post critical SOPs in the areas where they’re used. For example, you might laminate and pin the Sanitizer Preparation SOP right above the sink, or the Pizza Oven Cleaning SOP near the oven, so staff can glance at them as they work. The easier it is for your team to find and read the SOP in the moment, the more they will use it correctly.

On the other hand, if they have to dig through a filing cabinet for a procedure, they probably won’t bother. So, keep SOPs visible and handy.

Supervise and reinforce adherence

Especially when SOPs are newly introduced, managers and shift leaders should monitor how well they are being followed in day-to-day operations. This doesn’t mean breathing down everyone’s neck, but rather observing and gently correcting if someone deviates from the SOP.

It’s normal that at first, employees might forget a step or try to do it the “old way.” A friendly reminder like, “Hey, remember in the SOP we’re supposed to label that container with the date,” helps build the new habit. Incorporate SOP checks into your routine.

For instance, a food safety leader or Executive Chef doing a walk-through might have a mental (or written) checklist: “Are folks following the cleaning SOP at closing? Are they logging temperatures as per the SOP?” Some food businesses even include SOP compliance in performance reviews or weekly meetings (“We noticed we slipped a bit on following the cooling SOP on Friday, let’s tighten that up.”).

Positive reinforcement is crucial, too. For example, if you see that specific locations always complete SOPs correctly and on schedule, acknowledge the Head Chefs of those locations: “Great job maintaining our food compliance exactly like the SOP describes. That kind of consistency keeps our kitchen safe.”

Praising correct behavior goes a long way in creating a culture of doing things by the book.

Keep SOPs up-to-date

A kitchen is not a static environment. Menus change, new equipment comes in, cooking techniques evolve, and regulations can update. Your SOPs need to evolve as well to remain useful. Make it a habit to review your SOPs at least once a year. Some restaurants do this on a rotating quarterly schedule so it’s not overwhelming.

If something big changes (e.g., you introduce a new menu item that involves a different prep process, or a new law requires using different sanitizer), update the relevant SOP immediately. Don’t wait for an annual review in that case.

Also, if you ever have an incident (like a minor food safety issue or a near-miss), that’s a cue to revisit the SOP and see if it needs improvement to prevent a repeat. When updating an SOP, be sure to communicate the changes to your team clearly (don’t just silently swap the document).

Use version control: label the SOP with a new version number or date, and remove all the old copies so nobody accidentally follows an outdated procedure. Keeping SOPs current ensures they remain trusted and effective. An outdated SOP that mentions equipment you no longer have, or steps that no longer apply, will just confuse staff and erode confidence in your documentation. So, make SOP review and revision a regular part of your food safety management routine.

By focusing on training, accessibility, oversight, and updates, you’ll create an environment where SOPs are living documents that truly benefit your kitchen. The payoff is a more organized operation, easier training of new staff, and confidence that critical tasks are done right every time. Using digital food safety management tools can make maintaining and monitoring SOP compliance much easier (e.g., software that alerts you when a step is skipped, or that makes updating documents as simple as a few clicks).

How can FoodDocs help with kitchen SOPs?

If all this talk of writing, training, and updating SOPs feels daunting, the good news is there are modern solutions that can lighten the load. FoodDocs’s food safety management software makes creating and managing kitchen SOPs much easier.

- Start with ready made SOPs: FoodDocs can generate SOP templates based on how your operation runs, so you are not writing everything from scratch.

- Make SOPs easier for staff to follow: You can attach visual step-by-step instructions to daily tasks like temperature checks and cleaning, so staff have the on-demand guidance in their pockets during shifts.

- Get better oversight without chasing paperwork: FoodDocs keeps SOPs, logs, and records in one place, so you can quickly see what was done, what was missed, and what needs attention.

- Keep SOPs current: When a process changes, you can update SOPs centrally so everyone is working from the same version.

Automating parts of your food safety management, it frees up your time and gives you peace of mind that nothing is falling through the cracks. Many businesses find that such software not only boosts compliance and safety, but also cuts down on the hours managers spend on paperwork and supervision.

Compared to when food safety was still handled on paper, Ruth (a Food Safety Leader and Store Manager) spent a couple of hours per day getting the papers and going around checking or completing tasks.

Frequently asked questions about kitchen SOPs

What format makes kitchen SOPs easiest to follow?

Whenever possible, store and present your SOPs digitally. Use clear headings, numbered steps, and simple verbs at the start of each step. Include only the details someone needs in the moment (e.g., tool names, temperatures, times, and what to record). And as a default, always consider adding pictures or videos of the steps involved so it’s not just a wall of text.

What should you document for proof and audits?

Document what you check, who checked it, when it was checked, and what happened if something was off. Common records include temperature logs, cooling logs, sanitizer concentration checks, cleaning sign offs, and corrective action notes. Again, lean on digital food safety records as opposed to paper ones to eliminate the risk of damaged, improperly filled, or lost sheets.

How do SOPs connect to HACCP plans?

SOPs are the practical steps that support your food safety plan. A HACCP plan lays out hazards and critical control points. SOPs tell staff what to do day to day so controls are actually carried out, like checking cook temps, cooling safely, and preventing cross-contact.

Where should kitchen SOPs be stored for quick use?

Store SOPs where staff can reach them during a shift. That can be a wall binder, a shared tablet, a QR code posted at the station. Ideally, it can be a digital system staff can open on a phone. The best storage method is the one your team will actually use when they are busy.

What are the most common kitchen SOP mistakes?

The big ones are writing SOPs that do not match real workflow, using vague steps, skipping verification, and burying SOPs where nobody can find them. Another common issue is copying a template and never tailoring it to your equipment, menu, and staffing. A useful SOP is specific, simple, and tested in your kitchen.

How do you check if a kitchen SOP is working?

Watch the task being done and compare it to the SOP. If staff regularly skip a step, the SOP may be too long, unclear, or unrealistic. If the same mistakes repeat, add one clear check step, like a temp record or supervisor sign off, so problems show up early and fixes are simple.

Should kitchen SOPs be different across locations?

The structure should stay the same, so training is consistent across the company. The details should match each site, like equipment models, station layout, and local menu differences. A strong multi-location setup uses one “master SOP” with site specific notes where needed, so you do not end up with ten different versions drifting apart.