Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Foodborne illness and their adverse reactions are often caused by cross-contact or cross-contamination. How do they differ?

In any business in the food service industry, one thing that you want to avoid is causing food poisoning or any food-related incidents. Being involved in such an issue may cost you a significant deal in terms of your reputation and revenues. There are two common reasons behind foodborne illness cases, and they are attributed to either cross-contact or cross-contamination. Although closely related, the two terms involve entirely different aspects. In this blog post, we dive more into cross-contact vs cross-contamination.

WHAT WE'LL COVER:

Every year, approximately 48 million consumers are affected by foodborne illnesses, whereas at least 200,000 consumers seek medical care due to allergic reactions to food. This set of statistics shows how important it is for food business owners to focus on preventing scenarios that can lead to cross-contact or contamination.

Learn how does cross-contact differ from cross-contamination and how you can manage allergens and other food safety hazards using FoodDocs' digital Food Safety Management System from this article.

The term cross-contact refers to the accidental transfer of an allergen from one food to another, making food unsafe for consumption. The event only requires for a product with a known allergen to come in contact with a common surface or another product.

Cross-contact examples include when a food handler prepares a salad with peanuts and then proceeds to handle a piece of bread without the allergen. The food handler may accidentally transfer small pieces or particles of peanut protein into the bread, which is enough to trigger an adverse reaction in consumers.

Another example is when a food handler reuses a jar used to contain flour without sanitizing it. The allergen-free product that will be placed inside the jar is then affected by allergenic contact. Cross-contact exposure can result in life-threatening cases.

On the other hand, cross-contamination of food refers to the transfer of any of the three types of food safety hazardsfrom one point to another. The food hazard may come directly from another food, the food handler, or a contaminated food contact surface.

The hazards involved in cross-contamination may be a result of any of the following:

For example, a food handler prepares a potentially contaminated raw chicken on a cutting board, and they do not wash the knife that they use in between preparation. Despite changing the chopping board, the unsanitized knife can transfer the contamination to the next food to be prepared.

In summary, the difference between cross-contact and cross-contamination includes the following points:

Both types of food contamination cause food poisoning, but the effects can vary depending on the ingredient or factor that caused the event.

In this section, we discuss the following:

Food allergens present a great risk for any food business. Consumers who accidentally eat a food allergen may suffer from mild to severe reactions, which can be life-threatening. Exposure to food allergens, even in small amounts, can become a significant problem for any food business.

Food handlers must understand how cross-contact can occur in food manufacturing facilities. This step will help them avoid any activity that can lead to the spread of food allergens in your business.

Cross-contact can occur in two different ways.

Direct cross-contact occurs when a food item with an allergenic ingredient comes into contact with allergen-free foods during preparation.

In a kitchen setup, direct cross-contact can occur when allergen-free and allergenic foods are stored in the same area. For example, if your team stores naturally gluten-free grains, such as rice, together with bread made from wheat flour, food proteins from the bread, and even from crumbs of gluten, it may transfer to the rice.

Even though only a portion of the food came in contact with allergen-free food, people with food allergies and immunocompromised health may still be significantly affected by exposure to food proteins.

Direct cross-contact may occur as a result of poor food preparation and cooking practices.

Indirect cross-contact refers to the transfer of an allergenic food particle through a third medium. This medium may be a food handler, food contact surface, or a utensil used to prepare an allergenic food ingredient.

For example, your employees are preparing a pie for a meal, and they use a knife to cut the product before serving it to the customer. The same employee then only wiped the knife, used it to cut vegetables, and forgot to wash their hands with soap and clean water. In this case, particles of the gluten-containing food may still be on the knife. For some customers, contact with gluten and other potential allergens can cause significant negative effects.

It does not take a large piece of an allergen from the offending food to trigger a food allergy reaction. Even a small drop of peanut butter can trigger a peanut allergy. That is why food manufacturers are encouraged to mention if a food product is produced in a location where allergens are handled.

Despite the significant effects of cross-contact, preventing it from happening is quite an easy task. The key is to implement strict food safety management. Operating with both allergenic and allergen-free foods is not impossible with a trained business team.

Food business managers can implement the following practices to prevent cross-contact:

Make your operations more efficient and cross-contact-free by using our smart solutions. With our digital Food Safety Management System, you can ensure that food handlers will never forget hygiene tasks and monitoring operations that will control allergens in your business.

Get automatically generated monitoring logs and checklists from our artificial intelligence-powered system.

In this section, we discuss the three main types of cross-contamination:

Similar to cross-contact, cross-contamination can also come from different points of your kitchen. Food safety hazards are all over your food establishment, and it only takes one misstep to spread them throughout your operations.

Food handlers must remember how contaminants spread and understand how cross-contamination occurs.

Below are the three main routes of cross-contamination in a food business:

Foods naturally carry foodborne microorganisms. In some cases, mishandling raw foods can spread these microorganisms and cause foodborne illnesses.

During storage, foods stored close together or in the improper arrangement may contaminate neighboring foods. Products such as raw meat may drip blood on ready-to-eat foods, which contaminated the product.

Another example is when food handlers mix a new batch of food with a previously hot-held product. The displayed food, while still safe, is already exposed to environmental contaminants. Mixing in a new batch may cause cross-contamination in a self-service area.

Food handlers are the fastest spreaders of foodborne pathogens, such as harmful bacteria and other hazards in a food business. Humans naturally carry pathogenic microorganisms on their skin, and the lack of personal hygiene may cause bacterial contamination of the food being prepared.

In addition, food handlers can carry pathogens by handling raw foods and then not washing their hands before handling ready-to-eat foods. Food handlers can also cause third-degree spread by contaminating utensils, which can also contaminate food.

As mentioned, food safety hazards can be transferred from any food contact surface into the food being prepared.

The best example of this scenario is when food handlers use the same cutting board to prepare raw foods and ready-to-eat products. Unlike raw foods, ready-to-eat foods will be directly served to customers after preparation. There is no more extra step to reduce the level of contamination to acceptable levels.

Food contact surfaces and pieces of equipment can collect food residue, which can then become contaminated. Once the fresh food being prepared comes into contact with a contaminated kitchen appliance, it can then get contaminated and cause foodborne illness.

Awareness of the main sources of cross-contamination is the first step to preventing it from occurring. Food handlers must be trained to be aware of which practices could lead to cross-contamination.

Basic food handling practices are the most effective ways to prevent cross-contamination. Simple steps such as handwashing can make a significant amount of difference. Food handlers must also learn how to identify food contamination.

In addressing cross-contamination, prevention is key and more efficient than addressing it as it happens. The risk of causing foodborne illness is higher when cross-contamination is present, even with a succeeding step to reduce its level.

To help your team avoid cross-contamination, follow these guidelines:

The best way for you to ensure that these operations are observed is to implement a comprehensive food safety management system. At FoodDocs, we elevate the common functions of a food safety system by incorporating the efficiencies of artificial intelligence.

Use our digital solution to ensure that your food business stays compliant with food safety regulations. Keep cross-contamination controlled and your customers safe from foodborne illnesses.

Constant monitoring and a comprehensive food safety system can guarantee that cross-contact or cross-contamination will occur in your operations.

Both contamination events can be prevented with proper food handling. Ensure that your team is properly guided and follows the highest standards for food safety by implementing our digital Food Safety Management System.

When you use our system, you can get the following benefits:

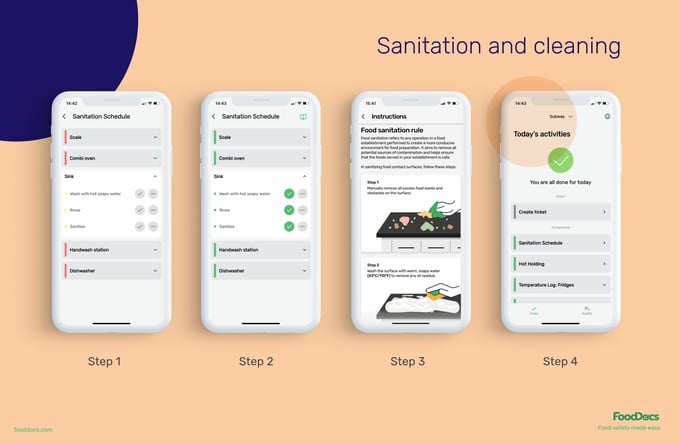

Sanitation and cleaning checklist from FoodDocs

Cooking temperature log from FoodDocs

Each monitoring log comes with detailed instructions to help your employees perform the tasks properly.

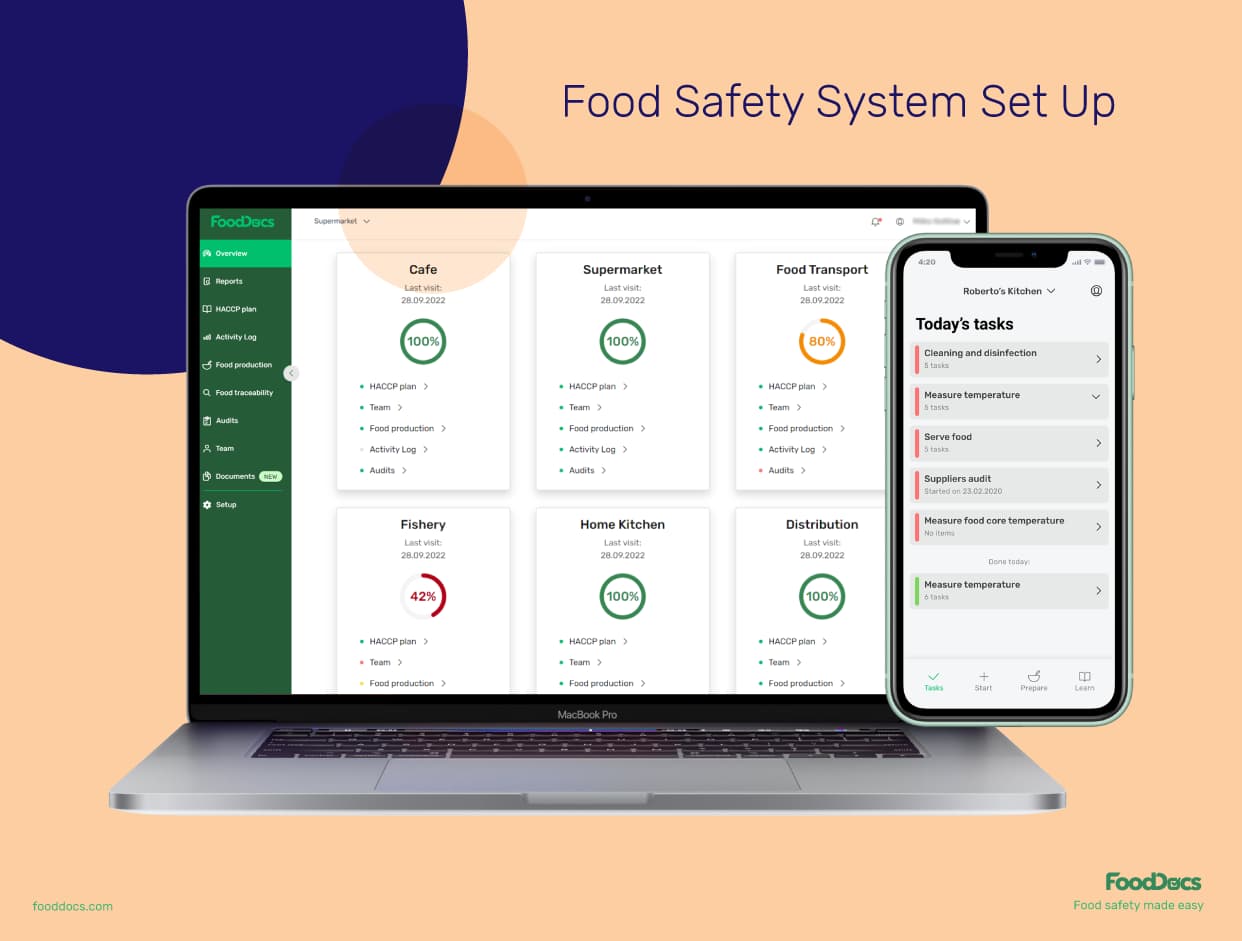

FoodDocs Food Safety System Set Up

In addition to features that focus on ensuring employee compliance with food safety procedures, our system also offers smart solutions for managers:

Powered by artificial intelligence and a machine-learning program, you can get a comprehensive digital Food Safety Management System in just 15 minutes.

The process of setting up your system only requires you to answer a few basic questions about your business.

Improve the generated logs and checklists by further customizing them to your operations.

Maintain compliance and protect your consumers from the effects of cross-contamination and cross-contact now. Use our free 14-day trial to experience the efficiency of digital solutions.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...