What is an Allergen Control SOP and Why Do You Need It?

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

What is an Allergen Control SOP and Why Do You Need It?

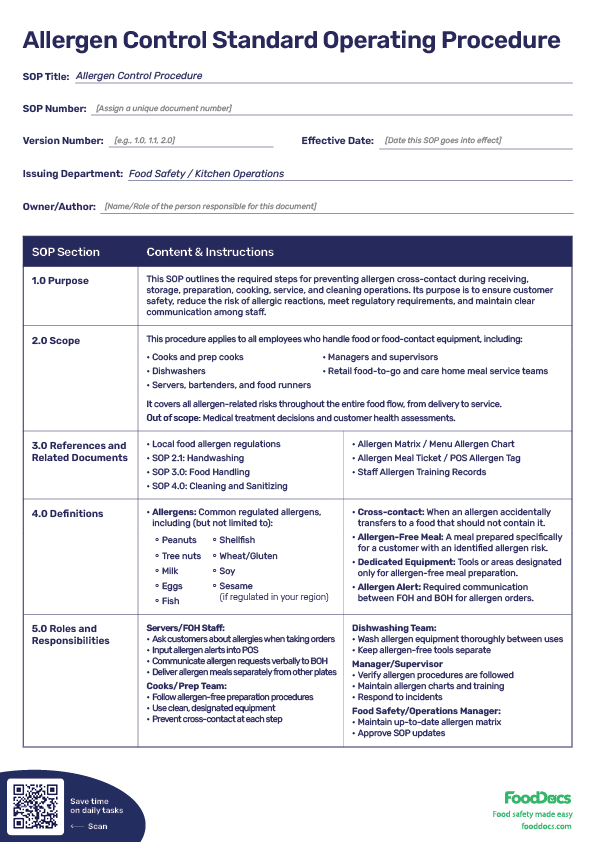

An allergen control SOP is a written plan for how your food business handles allergens every single day. These step-by-step instructions help Food Safety Leaders, Executive Chefs, Culinary Leaders, and the teams they lead identify ingredients that could cause allergic reactions, then control them at every step (from, e.g., receiving to prep to plating).

The ultimate goal is to keep customers who have allergies safe by stopping allergens from coming into contact with the wrong foods.

Researchers estimate that approximately 250 million people worldwide have one or more food allergies, with the United States accounting for around 33 million of that group. And even a tiny trace of the wrong ingredient can trigger life-threatening anaphylaxis.

In fact, undeclared allergens have become one of the top causes of food recalls globally. Nearly half of all U.S. food recalls in recent years happened because a major allergen wasn't properly disclosed on the label. Beyond the obvious risk to people's health, allergen mistakes can negatively impact your business if it’s hit with legal penalties, expensive recalls, and reputation damage.

A standard operating procedure for allergen control is part of both a food safety plan and a legal safeguard. It sits at the core of your food safety system alongside your HACCP prerequisites. When you follow it every day, people with allergies can safely eat your food and build trust with your brand.

Get our most popular allergen management resources

Key takeaways

-

The core purpose of an allergen control SOP is to prevent cross-contact and protect guests with food allergies.

-

Food businesses must keep a clear and updated list of which major allergens appear in every ingredient and recipe.

-

Safe allergen control depends on accurate supplier information and clear labels for all incoming products.

-

Cross-contact risk drops when kitchens use separate storage areas for allergen ingredients.

-

Effective allergen cleaning only works when staff follow a full wash, rinse, sanitize, and inspection cycle.

-

Guests can trust your answers when staff follow a single process for checking and confirming allergen questions.

-

A written SOP only works when every staff member is trained to follow it the same way.

-

Your team needs a simple plan that explains how to act during an allergen incident or guest reaction.

-

Daily proof of compliance comes from well-documented cleaning logs, label checks, training records, and up-to-date SOPs.

-

FoodDocs strengthens allergen control by giving teams digital step-by-step SOPs, guided visual tasks, and real-time compliance tracking.

Now let's break down which allergens you need to worry about and how to build a program that actually works.

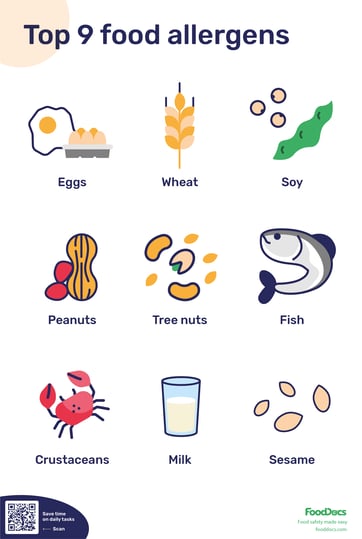

Which food allergens do you need to control?

The exact list depends on where you operate. Different countries track different allergens. In the United States, the FDA defines 9 major allergens (the "Big 9") that account for most reactions:

- Milk

- Eggs

- Peanuts

- Tree nuts (e.g., almonds, walnuts, pecans, cashews)

- Soybeans (e.g., soy)

- Wheat

- Fish (e.g., salmon, tuna)

- Crustacean shellfish (e.g., shrimp, crab, lobster)

- Sesame

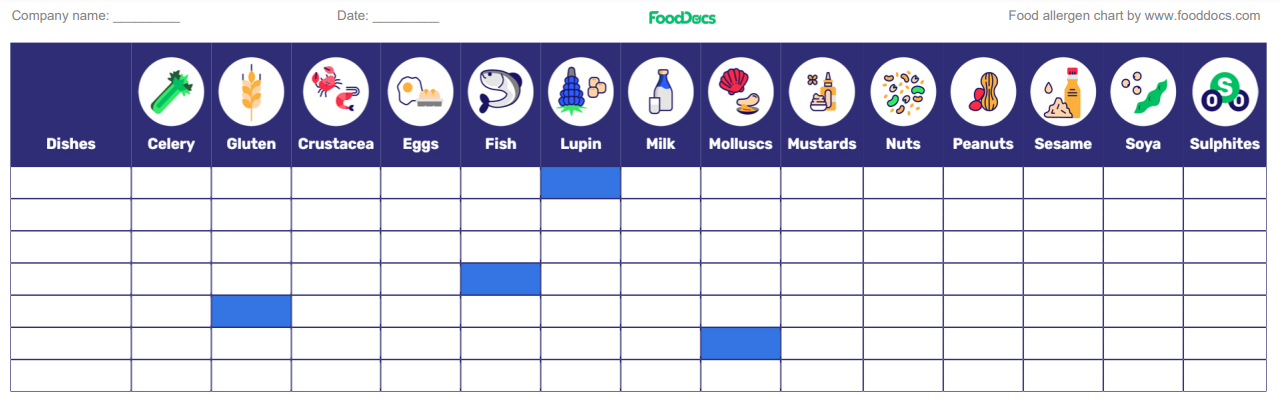

In the U.K. and European Union, they recognize 14 major allergens. Their list includes all the Big 9 plus a few extras like celery, mustard, lupin, mollusks (e.g., clams and mussels), and sulphites over a certain amount. Other countries have their own slight variations.

No matter where you are, you need to know which allergens are in your ingredients and recipes, and always be prepared to inform your customers about them. Start by going through every single ingredient you use and flagging anything that contains or comes from these major allergens. For example, worcestershire sauce contains fish (i.e., anchovies) and marzipan contains tree nuts (i.e., almonds).

Remember: you’ve got to perform this exercise every time you update your menu.

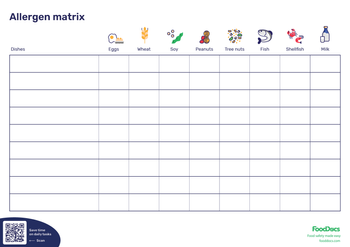

Download your Allergy Matrix template

It helps to keep a master allergen ingredient list. This becomes the foundation of your entire allergen control SOP, since it tells you exactly what needs special attention and what you need to tell customers.

Remember that allergen regulations require plain language labeling. Each major allergen must be clearly identified on product labels or menus by its common name (e.g., use "milk" instead of "casein"). Even if you run a kitchen without packaged retail labels, you still need to be ready to inform customers about allergens in each menu item.

Knowing the major allergens in your region and tracking any ingredient that contains them is step one to a solid HACCP allergen control program.

How do you create an allergen control SOP?

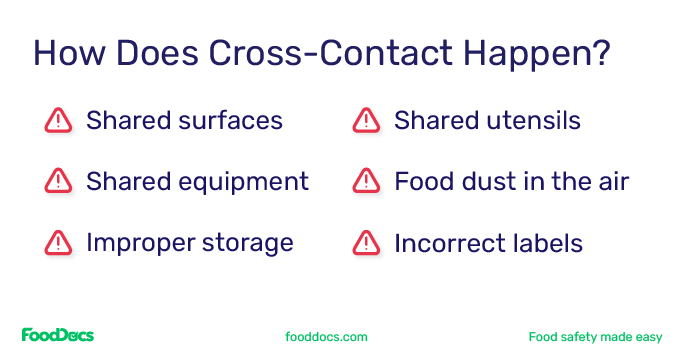

Building an allergen control SOP means looking at every stage of your operation to make sure allergens are handled safely. The main objectives are preventing cross-contact (i.e., the accidental mixing of allergens into other foods) and transparently informing customers about allergens.

Here are the key steps and what to include:

List all allergenic ingredients in your inventory

Begin by identifying every ingredient in your kitchen that contains one of the major allergens. From raw materials to sauces to additives, keep an updated allergen inventory list and refresh it whenever you add something new. This list is the backbone of your allergen SOP because it flags what needs special care.

Get allergen information from your approved suppliers list for each product. Ask for ingredient spec sheets or allergen statements. You need to know if, for example, a spice blend might be made in a factory that also handles peanuts. Documenting all this ensures you don't overlook hidden allergens that could bite you later.

Download your Basic Food Preparation Rules poster

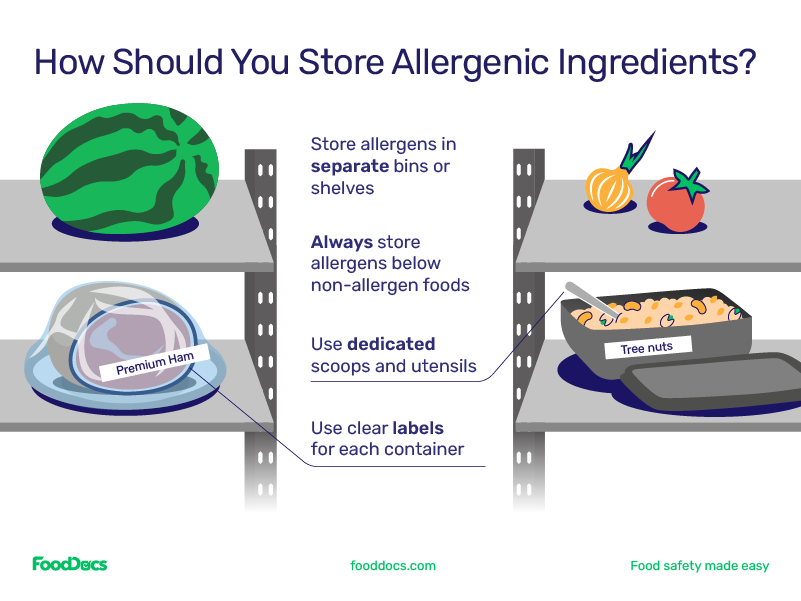

Separate and label allergenic foods in storage

Proper food storage prevents mix-ups. Store allergenic ingredients separately from non-allergenic ones to avoid accidental contact. For example, keep bags of almond flour or powdered milk on dedicated shelves, ideally below other items so nothing can spill onto non-allergen foods.

Use clear labels and even color coding. You might mark allergen containers with a bright sticker or put them in specific color bins (red for allergenic items works well).

Never store allergenic ingredients above foods that don't contain allergens. Ensuring the use of dedicated scoops and utensils for allergen-containing ingredients can stop cross-contact before it starts.

When you organize your pantry and walk-in this way, you greatly reduce the chance of a simple storage mistake turning into a serious incident. It's not necessarily complicated, but it must be consistent.

Download your Walk-in Cooler Food Storage Chart

Use smart scheduling and cleaning practices

In prep and production areas, if your kitchen layout allows, plan your workflow to minimize cross-contact. A common practice is scheduling recipes with allergens last in the day. If you bake both regular bread and gluten free bread, bake the gluten-free (no allergen) bread first, then the wheat bread (contains allergen) afterward so you're not contaminating the allergen-free batch.

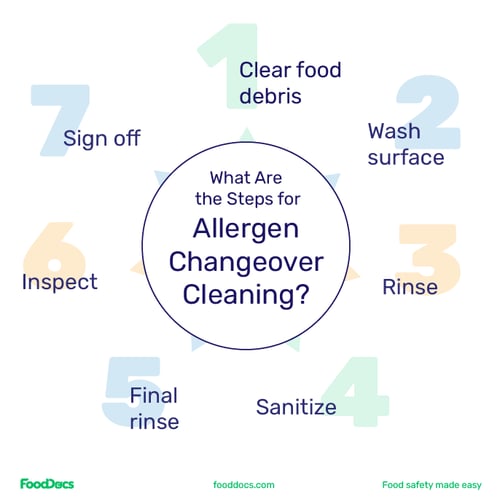

Whenever you switch from making a product with an allergen to one without, do a thorough allergen changeover cleaning. This means cleaning and sanitizing all equipment, utensils, and surfaces that touched the allergen. Allergenic proteins can hide in crevices of mixers, grills, slicers, and similar equipment.

So, your cleaning SOP should include detailed steps, including disassembling equipment if necessary, to physically remove all traces. Use appropriate cleaning agents and rinse well. Sanitizing chemicals alone won't remove allergens. You have to scrub them off.

Some businesses go the extra mile and use test kits (e.g., allergen swabs) to validate that cleaning worked and no residue remains. At the very least, verify that staff followed cleaning procedures every time through checklists or supervisor sign off. Smart scheduling combined with rigorous cleaning is one of your best defenses against cross contact.

Download your Sanitation Standard Operating Procedures

Prevent cross-contact during food prep

Beyond scheduling and cleaning, build everyday habits in your kitchen to keep allergens from spreading. This includes having dedicated utensils or tools for allergen containing foods, or thoroughly washing and drying them between uses. If you use a blender for peanut sauce, don't use the same blender for a peanut free sauce without cleaning it first. This is how you avoid cross-contamination.

Manage rework carefully. If you save trim or extra mixture from a batch that contains an allergen, label it clearly and only add it to future batches that will have that same allergen. Train employees on simple practices like washing hands and changing gloves when switching tasks or ingredients, and on cleaning shared surfaces like counters and cutting boards between uses.

Also consider physical separation where possible. If you have space, assign a specific prep table or fryer for allergen-free cooking, or use barriers to separate areas handling lots of allergens (e.g., a baking station with flour dust flying everywhere). Even things like airborne dust can carry allergens so use ventilation or distance to keep that contained.

These seemingly little details add a layer of protection to make sure allergens don't put your business’s reputation and clientele’s health at risk.

Download your Hand Washing Poster

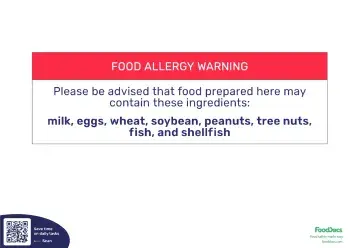

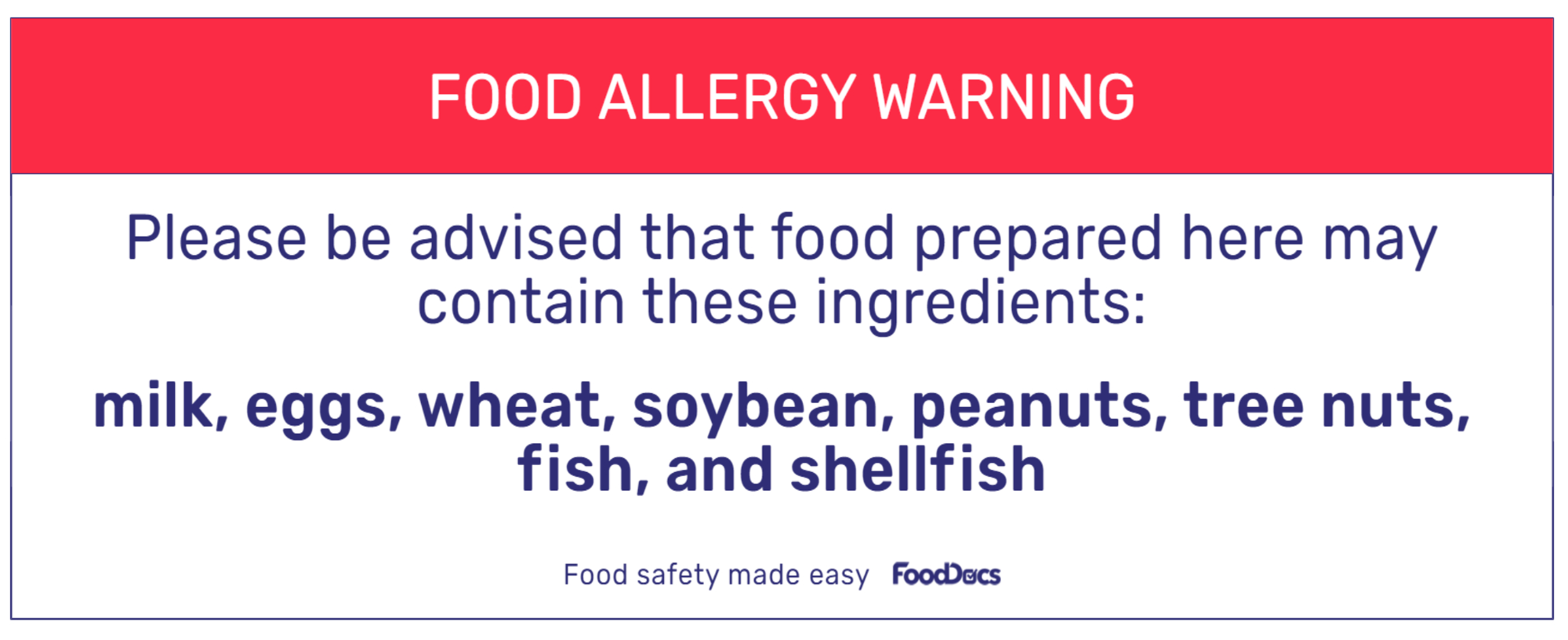

Ensure accurate allergen labeling and communication

Food labeling is an important part of your safety net. If a food does contain a major allergen because the recipe requires it, make sure the customer knows. For packaged foods, always include the allergen in the ingredient list or in a clear allergy warning statement on the label, as required by law. If you tweak a recipe or change an ingredient, update the label immediately if it affects allergens.

Mistakes happen when a product gets put in the wrong package or an old label isn't updated, so have a strict label control process. Double-check that the right label goes on the right product every time. It helps to keep only one type of label on the packaging line at once to avoid mix-ups.

In a restaurant or catering setting, this step is about your menu and staff communication. Menus should note dishes that contain common allergens, and staff should be trained to answer customers' questions accurately. Some companies also use precautionary labels like "May contain traces of X" or "Made in a facility that also processes Y" if there's a small risk of cross-contact that can't be totally avoided.

The bottom line is that your allergen SOP must ensure no product leaves your kitchen with undeclared allergens. Clear labeling and communication protect the consumer and protect you as a business.

Download your Food Allergy Warning

Train your team on allergen safety

Even the best written SOP won't work if your staff don't understand it. Employee training is a cornerstone of allergen control. Make sure every team member knows what the major allergens are and how serious reactions can be. Train them on their specific food safety duties. For example:

- Receiving staff should know to check ingredient labels for allergens

- Kitchen staff should know how to prevent cross-contact

- Servers should know how to communicate allergen info to guests

Emphasize simple but crucial practices like washing hands, changing gloves, and using clean tools between tasks. Initial training for new hires and regular refreshers (e.g., at least once a year or whenever procedures change) will keep knowledge fresh. A well-trained team is truly your first line of defense against allergen mistakes, so make allergen safety part of your kitchen food safety culture.

Put up reminder food safety posters, include allergen checks in daily routines, and encourage staff to speak up if they spot a risk. You can also use FoodDocs’ food safety management software to attach step-by-step photo or video instructions to every allergy-related task that staff might perform.

Document everything and review regularly

Keeping records is proof that you're following your allergen controls. Maintain logs for your:

- Cleaning schedules (e.g., allergen cleaning checklists signed off by a supervisor)

- Records of ingredient label checks

- Training attendance sheets

- Any allergen testing results (if applicable)

These records show consistency and can be crucial if you ever have an audit or a customer complaint. If you can store all these logs, checklists, and schedules digitally in a food safety management system, even better. Otherwise, doing this on paper can quickly get overwhelming, especially if your business has multiple locations.

Also, schedule a regular review of your allergen control program. Ideally annually and whenever you make a significant change. Update the plan if you introduce a new product with a new allergen, switch suppliers, change equipment, or if regulations change.

Great food safety leaders will involve their team in these reviews because often the people doing the daily work have insights into what could be improved or what risks they see.

By reviewing and revising the SOP periodically, you ensure it stays effective and no steps are overlooked as your business evolves and grows.

How do you verify your allergen control SOP is working?

Verification keeps your plan honest. It tells you if your written SOP is actually being followed day-to-day. Here are simple ways to verify your allergen controls:

- Spot check cleaning after allergen use: Managers should check key equipment after changeovers. If you use allergen swab tests, add them here.

- Review labels weekly: Look for outdated labels, missing allergen info, or packaging mix ups.

- Audit storage once a week: Check that allergenic ingredients are stored in the right area, with the right labels and tools.

- Watch a real prep session: Once a month, for example, observe a staff member switching from an allergen recipe to a non-allergen one. Note if they follow the steps correctly.

- Review supplier documents every quarter: Make sure suppliers have not updated formulas or allergen information without telling you.

Verification steps like these keep your SOP timely, accurate, and trustworthy.

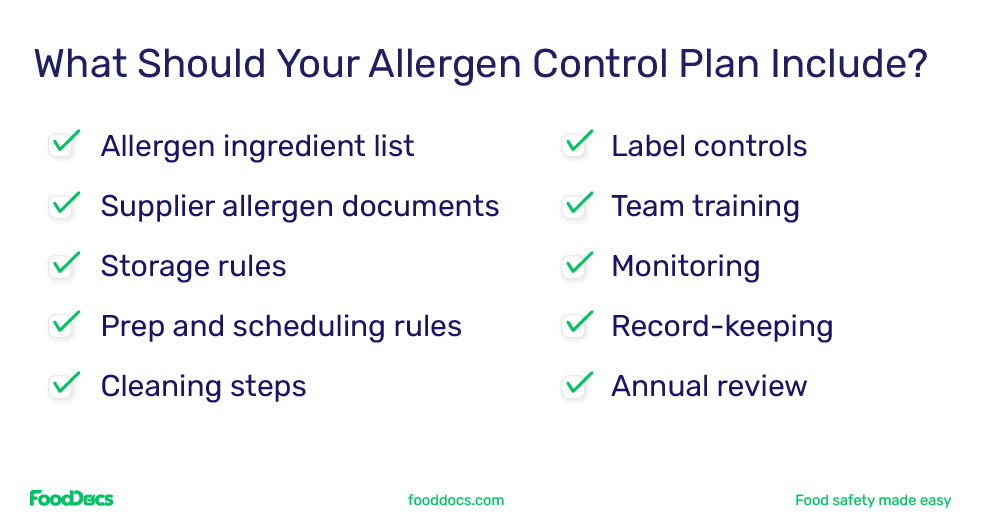

What should an allergen control plan checklist include?

When writing or auditing your allergen control SOP, it helps to break it into sections. Here's a checklist of key components that most effective allergen control programs will include. You can use this as a template or guide for your own plan:

Allergen ingredient list

A complete list of all ingredients and raw materials you use, noting which major allergens each one contains. Keep this list updated whenever you add or change ingredients. This serves as the foundation of your allergen control plan.

Supplier allergen info

Documentation from suppliers about the allergens in their products. Require allergen statements or spec sheets from each supplier, and prefer suppliers who have strong allergen controls themselves. Approve and re-evaluate suppliers based on how they manage allergen risks, and keep those documents on file for reference.

Storage and segregation procedures

Detailed procedures for how and where you store allergenic ingredients. This should describe segregated storage areas (e.g., a separate shelf or bin for allergens), container labeling, and methods to prevent mix-ups, such as using dedicated containers and utensils, and never storing allergens above non-allergens.

Production scheduling and equipment cleaning

Guidelines for scheduling production or prep to minimize allergen cross contact (e.g., running allergen-free products before allergen-containing ones). Include your sanitation SOPs for allergen cleaning, listing how to clean equipment after using an allergen (e.g., cleaning steps, cleaning agents, required disassembly) and how you verify the cleaning was effective (e.g., visual checks, swabs).

Cross-contact prevention practices

General practices to avoid cross-contact during operations. This can cover employee hygiene, rules about using or labeling rework that contains allergens, using dedicated or cleaned equipment, and any other handling protocols that keep allergens from spreading unintentionally.

Labeling and packaging controls

Steps to ensure every product is properly labeled with its allergen information. Describe your label verification process, for instance, checking labels against recipes whenever you pack a product, and controls to prevent the wrong labels or packages from being used. Include what to do if a labeling error is found (e.g., holding product, fixing labels). If you use precautionary "may contain" statements, note the policy on when those are used.

Employee training and awareness

Outline your training program for allergens. List what topics are covered (e.g., allergen awareness, cleaning procedures, emergency actions) and how often training happens. Include provisions for training new hires at orientation and doing annual refreshers for all staff. Note if certain roles get extra training (like those who handle labels or perform cleaning).

Allergen management team and responsibilities

If you have a designated allergen management team or coordinator, list their names and roles. For example, note who is responsible for maintaining the allergen list, who oversees cleaning and verification, who double checks labels, etc. Assigning clear responsibility ensures accountability for each part of the plan.

Monitoring and verification

Explain how you will monitor that each control is being carried out and how you will verify it's working. For example, you might state that a supervisor signs off on each allergen cleaning checklist and performs a swab test on equipment monthly, or that the storage area is audited weekly for proper segregation. This describes how you know the SOP is being followed daily.

Record-keeping

List the records you will keep related to allergen control and how long you'll keep them. This can include cleaning logs, training records, supplier allergen documents, label check logs, testing results, etc. Having good records proves your diligence and helps during inspections or if something ever goes wrong.

Plan review and updates

State your policy for reviewing the allergen control plan. For instance, "Management will review this plan annually and whenever there is a significant change in products, ingredients, or processes." You can also include a revision log (a table noting the date and details of each update to the plan). This shows that your program isn't static. You keep it up to date as things change.

Covering all these sections will enable your allergen control SOP to be thorough and robust. You can compare it against industry templates (e.g., some food industry associations and the FDA provide guidance documents) to ensure you didn't miss anything important. Some businesses even turn parts of this plan into daily or weekly checklists. For instance, a daily checklist for managers might include:

- Verify ingredient labels

- Check equipment cleaning before starting allergen-free product

- Ensure correct labels on products

Such checklists help make the allergen controls part of your routine operations.

Having a detailed written plan and routine checklists makes it much easier to follow and enforce allergen controls consistently. The written SOP sets the rules, and your daily practices make those rules a reality. With this in place, you are doing everything possible to let people enjoy your food without worry.

Always remember, the goal of all this is to let customers with allergies eat safely and confidently. An allergen control program that you implement every day is how you earn that trust.

How should staff respond to guest allergy requests?

Let’s look at what real pest control actions look like in practice from actual SOP templates.

Rodents (rats and mice)

Clear guest communication is one of the most important parts of allergen control. Even with strong kitchen procedures, the last step is your dining room. Guests rely on your team to give honest information at the moment. Here is what every restaurant should cover in its SOP.

Train staff to answer common allergen questions.

Servers should know which menu items contain the major allergens. They should also know which items can be made without them and which ones cannot be changed. Make sure they check with the kitchen when they're not sure.

Use one clear source of allergen truth.

Keep an updated allergen menu or chart that staff can use during service. This prevents wrong answers and keeps everyone aligned.

Teach servers to follow a simple flow:

- Listen to the guest

- Check the allergen chart

- Confirm with the kitchen

- Communicate the answer clearly

- Note the allergy on the ticket

Keep communication tight between front and back.

Every allergen ticket should be marked in a way that cooks cannot miss. Use a clear signal at the pass so the team slows down and pays attention.

What should you do if an allergen incident happens?

Even with good controls, mistakes can happen. Your SOP should guide your team through the exact steps to take if a guest has been served the wrong dish or is showing symptoms of an allergic reaction.

- Share ingredient details with the guest: Give them clear information about what the dish contained. Do not guess. Use your allergen chart to confirm.

- Stop service for that table right away: Remove the dish and prevent anyone from eating more of it.

- Alert a manager immediately: A supervisor should take charge. This keeps the response calm and consistent.

- Check the guest's condition: If there are signs of trouble like hives, trouble breathing, swelling, or dizziness, call emergency services right away.

- Hold and review any related food: Do not serve that batch again. Review labels, recipes, or steps that may have caused the mistake.

- Document the event: Record the date, dish, ingredients, and what happened. Note the team members working and any corrective steps taken after the incident.

This response plan protects the guest and helps you prevent the same error in the future.

How can FoodDocs help with allergen control?

Putting together and maintaining an allergen control SOP can be a big task, especially for busy restaurants or food producers. This is where digital food safety tools like FoodDocs can make your life much easier. FoodDocs is a smart food safety management software that can help you create, implement, and monitor your allergen controls (along with all your other food safety procedures) more efficiently.

Automated allergen SOP creation

FoodDocs’ food safety software can automatically generate the most common food safety SOPs your business needs, including an allergen management SOP, based on your specific operations.

When you set up your company profile in FoodDocs, it creates 15+ ready made SOP templates tailored to your type of business, and allergen control is one of them. You can customize these templates as needed to fit your kitchen. This means you get a head start with a professionally drafted allergen control plan without having to write it from scratch.

It covers all the key points (from storage and cleaning to labeling and training), and you can tweak the details to match what you do on site. This saves you hours of writing and ensures you don't overlook important elements.

Step by step instructions for your team

Beyond just creating the SOP document, FoodDocs helps you put the plan into action every day. The software lets you attach educational, step by step instructions (with text, photos, or even videos) to each monitoring task in your digital checklists.

For example, if you have a daily task for cleaning a mixer after using an allergen, that task in the FoodDocs app can include a checklist and photo or video guide of the exact cleaning steps to take.

This on the job guidance means even new or temp workers can follow your allergen procedures without constant supervision. The app essentially trains them as they work.

Real time monitoring and alerts

FoodDocs includes a mobile app and dashboard that track if tasks are being done on time. You can assign allergen control tasks to specific employees or roles, and the app will send them notifications to remind them. Managers get a real time overview of task completion, so you can see at a glance if today's allergen checks and cleanings have been done, even across multiple locations.

If something is missed or done late, you'll know right away. This helps ensure that critical steps like label checks or equipment cleaning never slip through the cracks. It's like having a digital assistant that keeps an eye on your allergen safety routines.

Frequently asked questions about allergen control SOPs

What is the difference between cross contact and cross contamination?

Cross contact means an allergen from one food moves into another food that should not contain that allergen. For example, a knife used to cut a peanut dessert is then used on a salad without cleaning. Cross contamination often refers to germs or foreign objects rather than allergens. For guests with food allergies, cross contact is the main risk, since even a small trace of the allergen can trigger a serious reaction. An allergen control SOP focuses on stopping cross contact at every step.

How often should a restaurant review its allergen control SOP?

Most restaurants review their allergen control SOP at least once each year. You should also review it any time you add a new menu item with a new allergen, change suppliers, move equipment, or see an incident or near miss. A short yearly review keeps the plan current and helps you catch gaps before they lead to problems.

Do small restaurants need a formal allergen control SOP?

Yes. Even a single site diner or cafe needs a written allergen control SOP. Food allergies don't only affect large chains, and a reaction in a small venue can be just as serious. A simple written plan helps you train new staff, keep menu notes correct, and show inspectors that you handle allergens with care. The document doesn't need to be long, but it should cover ingredients, storage, prep, cleaning, menu notes, and staff training.

What should staff do if a guest has an allergic reaction on site?

If a guest shows signs of an allergic reaction, staff should get help at once. Call emergency services, tell the guest you are calling for help, and ask if they carry an epinephrine auto injector. While medical help is on the way, keep any plates, tickets, and ingredient packs linked to the dish. After the event, record what happened in your incident log and review your allergen control SOP to find and fix the weak step that led to the reaction.

How can a restaurant prove it follows its allergen SOP?

To show that you follow your allergen control SOP, keep simple records. These can include cleaning logs for allergen changeovers, supplier allergen sheets, label and menu check records, staff training sign in sheets, and any allergen test results. During an inspection or after an incident, these records show that your controls are not just written, they are part of daily work. Digital tools such as FoodDocs can store these records and make them easy to find when you need them.