Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Discover the ins and outs of allergen management and how you can successfully implement and maintain a program.

Food allergies aren’t just a minor inconvenience. They can be life or death. Think about it: would you trust a meal if you weren’t sure whether it contained peanuts or not? For millions of people, even a trace of the wrong ingredient can trigger a severe reaction.

This is why allergen management is critical to food safety in any business, from a small bakery to a large food factory.

We’re going to walk through why allergen control matters, what regulations require, and how you can build an effective allergen management program step by step. (Spoiler: it’s not just about avoiding fines – it’s about protecting your customers and your reputation.)

Allergen management is critical to food safety because even trace amounts can cause life-threatening reactions in allergic individuals.

The U.S. requires labeling for 9 major allergens, while the U.K. mandates clear identification of 14 allergens on food labels.

An allergen management plan is a documented system every food business needs to prevent cross-contact and ensure accurate labeling.

Key components of a strong allergen control program include identification, segregation, cleaning, labeling, and staff training.

Labeling errors are the top cause of allergen-related recalls, making verification and change control essential parts of allergen safety.

Staff training is non-negotiable—everyone from warehouse workers to servers must understand how to manage allergen risks.

BRCGS Issue 9 treats allergen management as a fundamental requirement and expects cleaning validation and risk-based labeling.

Digital tools can automate recipe tracking, allergen labeling, cleaning verification, and traceability to reduce human error.

Precautionary labels like “may contain” should only be used after a documented risk assessment confirms unavoidable cross-contact.

FoodDocs' food safety management software simplifies allergen management through automated tracking, real-time allergen and recipe updates, and traceability tools.

Allergen management is important because it protects people’s lives. First and foremost, managing allergens is about human safety. Food allergies can cause anaphylaxis, a rapid and life-threatening reaction. The only way to prevent allergic reactions is strict avoidance of the allergen. A single mistake, such as a bit of egg white in a salad for an egg-allergic person, can send someone to the hospital or worse.

No one in the food business wants to be the cause of an allergic customer’s emergency. Remember, about 6% of adults and 8% of children in the U.S. have food allergies. That’s a lot of people relying on us to get it right.

Allergens are a major focus of food laws and inspections. In fact, undeclared allergens (allergens present in a food that aren’t listed on the label) are a leading cause of food recalls. Recent data showed that nearly half of food recalls (47% in 2022) were due to undeclared allergens and, in 2023, they jumped to 63%.

Regulators like the FDA classify undeclared allergens as a Class I hazard (meaning it can cause serious health harm). The fallout from a product recall is huge. One can result in lost sales, disposal of products, legal penalties, and damage to your brand. It’s estimated that a single recall can cost a company $10 million or more in direct costs, not counting the hit to consumer trust.

Simply put, allergen management isn’t optional if you want to stay in business; it’s a legal must and a smart insurance policy.

Beyond laws and numbers, think about your customers. Word spreads fast if a restaurant or product isn’t safe for people with allergies. On the flip side, food businesses that are allergy-aware gain loyal customers and a positive reputation. Parents of allergic kids, for example, will stick with a brand or café that “gets it” and makes them feel safe.

Trust is emotional and losing it can be devastating. A well-run allergen management program shows that you care about every customer’s well-being. It’s not just about avoiding disasters. It's about welcoming everyone to the table and giving them peace of mind.

Allergens vary by region, and so do food labeling laws. Let’s quickly review the big ones in the United States and the United Kingdom:

The FDA recognizes 9 major allergens that account for the vast majority of serious food allergies. These are:

Sesame is the newest addition (it became mandatory to label in 2021). Any ingredient containing protein from these must be declared clearly on U.S. labels.

For example, if a product contains casein (a milk protein) it must say “milk” in the ingredient list or in a "Contains" statement. These nine are responsible for most allergic reactions in the U.S., though people can be allergic to other foods too.

The U.K. follows EU rules which list 14 major allergens that must be declared. The list covers the common ones above and a few more:

Some of these might surprise folks in North America, e.g., mustard and celery are on the U.K. list, and sulphites (a preservative) if above a certain level, because they can cause allergic-type reactions or asthma issues.

In the U.K., if any of these 14 are ingredients, they must be highlighted on the label (often in bold text in the ingredients list). For instance, a label might list “flour (wheat)” or “spice mix (contains mustard)” so consumers can’t miss it.

It comes down to different regional diets and history of regulation. The U.S. started with 8 allergens in law (via the FALCPA 2004 law) and added sesame later. Europe took a broader approach with 14 from the beginning of their regulations.

If you operate internationally, you need to be aware of both lists. A granola bar with sesame and celery wouldn’t legally require a celery warning in the U.S., but in the U.K. it would – and failing to include it could get you in legal trouble there.

Remember: your allergen management plan should start with knowing which allergens you handle and which of those are regulated where you sell your product. Many companies choose to label for all 14 (plus others) across the board to be safe, but the allergen labeling rules differ and you must meet the specific laws in each market.

An allergen management plan (sometimes called an allergen control plan or policy) is a structured, documented approach that a food business uses to control allergen risks from farm to fork. It’s essentially a game plan for how you handle allergenic ingredients in your facility or kitchen so that you prevent cross-contact (unintended mixing of allergens into products) and provide accurate allergen information to consumers.

Think of it as a special extension of your food safety plan (HACCP). While your food safety plan covers all hazards (like bacteria, etc.), the allergen management part zooms in on those specific proteins that can hurt allergic individuals. Every food business, whether you manufacture cookies or serve meals in a cafe, absolutely needs an allergen management plan.

Here's why:

In the U.S., FDA’s Food Safety Modernization Act (FSMA) mandates control of allergens as a preventive control if you’re a manufacturer. In the U.K./EU, food businesses must ensure allergens are managed and declared properly (case in point: Natasha’s Law in the U.K. now requires detailed allergen labeling on prepacked foods made on premises, after a tragic death from an undeclared ingredient).

If you seek certification like BRCGS or SQF, those schemes have explicit allergen management requirements you must meet (we’ll discuss BRCGS Issue 9 soon).

A good plan lays out how to avoid cross-contamination. Making sure that the gluten-free soup doesn’t get stirred with a spoon that was in the clam chowder (shellfish alert!), for example.

It also ensures that what’s on the label or menu is truthful. It’s about consistency and checking every step: from supplier guarantees, to recipe control, to cleaning procedures. If everyone follows a clear allergen management policy, the chance of error goes way down.

An allergen management program usually defines who is responsible for what. For instance, purchasing staff know to verify ingredients and specs for allergens, warehouse staff know to store allergens separately, production folks know the cleaning protocols, and label designers know the exact phrasing needed.

It’s a team effort. Without a plan, you’re relying on assumptions and luck, which isn't good when the stakes are this high.

When allergen control is just as routine as handwashing or temperature checks, it becomes part of your company's food safety culture. Employees take allergies seriously, and customers notice that.

In a time when allergic consumers are hyper-aware, having a solid plan (and advertising that fact subtly through staff confidence and maybe info on your website) can set you apart. It shows professionalism and care.

In short, an allergen management plan is your blueprint to keep allergenic ingredients in their lane. It covers everything from receiving ingredients to delivering the final product to the consumer, making sure that peanuts stay in peanut cookies and out of everything else. Every food business needs one, no exceptions.

If you don’t have a written plan yet, now’s the time to create one. And if you do have one, it’s worth reviewing and updating regularly.

So, what does an effective allergen management program look like in practice? Let’s walk through a detailed, step-by-step guide. Every facility or kitchen is different, but these core steps will apply in most settings. The key is to be proactive and systematic. We’ll start from identifying risks and go all the way to ongoing training and verification.

“Know your enemies,” so to speak. Make a master list of all ingredients you use that contain any of the major allergens (U.S. big 9 / U.K. big 14, plus any others of concern). Don’t forget additives, premixes, and processing aids – anything that might have allergenic protein.

Get info from your suppliers about potential cross-contact. For example, does your spice supplier also handle mustard or sesame in the same plant? You might need to know that. This is essentially an allergen inventory and risk assessment.

Many companies create an allergen map of their process with a simple diagram showing where each allergen enters and flows through the facility. This visual can highlight points where cross-contact could happen.

It's also worth considering the menu or product line so you can determine which finished products contain which allergens. Make an allergen matrix. This info will drive all the next steps.

Once you know what you’re handling, do a risk assessment. Ask: How could this allergen get into something it doesn’t belong in? Common cross-contact routes include shared equipment, airborne dust (e.g. wheat flour), shared oil for frying, utensils, hands, and even spillage during storage.

For each allergen, figure out where contamination risks are and how severe they’d be. This risk assessment should be documented. Then, decide on control measures to eliminate or minimize each risk.

For example, if you only have one production line and you make both almond cookies and plain cookies on it, a control might be to schedule the plain (non-allergen) cookies first, then the almond ones, and do a full cleaning in between. We’ll get into specifics like cleaning and storage next.

The point here is to plan out how you will prevent cross-contact at every step, from receiving to processing to packaging.

Your allergen control is only as good as your ingredients. Work with suppliers to ensure they clearly declare allergens on their specs and labels. Require allergen information on every ingredient spec and have a procedure to review new ingredients before approving them. If a supplier makes a change (say they start adding soy to a flavoring), you need to know before that ingredient hits your line.

Some companies send allergen questionnaires to suppliers to understand not just the ingredient’s contents but the production environment (for example, does the sugar come from a facility that also packs milk powder, risking cross-contact?).

It also helps to have a policy for labeling and tagging allergens on receipt, e.g., when a pallet of almond flour arrives, tag it or color-code it so everyone knows it’s an allergen. This makes storage and use safer. Supplier control extends to requiring that they, too, have an allergen management program in place (it’s fair to ask for that in supplier approval).

In your storage areas (dry store, fridges, freezers), segregate allergenic ingredients. Don’t store a bag of milk powder right above a bin of sugar. If it leaks, you’ve just contaminated the sugar with milk.

Best practice is to designate specific areas or shelves for allergens. Keep them in sealed containers, clearly labeled. Many facilities use color coding – e.g. red stickers for allergenic ingredients – and separate those as much as possible. Also consider physical barriers: separate racks, rooms, or at least distance.

Allergens should be stored in a way that prevents any spillage or dust from reaching non-allergens. For example, you might store allergens on lower shelves so nothing drops down onto other items. During internal transport (like moving ingredients to the line), be mindful too. Use dedicated containers or make sure to clean shared tubs. Good warehouse practices nip a lot of problems in the bud.

The production phase is usually the highest risk, because this is where allergens can easily spread if not controlled. Ideally, use dedicated equipment or utensils for major allergens. For example, have separate scoops for gluten-free flour vs. wheat flour.

If you can’t dedicate whole equipment, then schedule production runs smartly to minimize risk. This usually means producing non-allergen or low-allergen products first, and the allergen-containing ones last in the day or before a major cleanup.

Some facilities even dedicate specific days to allergen runs. For example, a factory might produce only peanut-free products Monday through Thursday, then do peanut-containing products on Friday, followed by a deep clean. The goal is to avoid a scenario where an allergen is in the system and then a different product runs right after without proper cleaning.

Also consider implementing procedures like line purges (flushing a system, if liquid, for instance) when switching from an allergen to non-allergen product. And where possible, use physical barriers (e.g., enclosing allergen mixing areas, or at least doing allergenic tasks in a separate area of the room).

Many places also identify tools (like with colored handles or tags) that are only for use with allergenic foods, to avoid mix-ups. All these practices fall under what’s often termed allergen segregation or allergen control.

Even with good scheduling, you will need to clean equipment and areas to remove allergen residues. Allergen cleaning is not just a quick wipe; it often requires thorough disassembly and cleaning to reach all surfaces.

Develop sanitation standard operating procedures (SSOPs) for cleaning after processing an allergen. This may involve washing with detergent at the right temperature, rinsing, inspecting for no visible residue, and even swabbing for allergen residues (using test kits) as verification.

A crucial concept is cleaning validation, which means you should verify that your cleaning method actually removes the allergen to an acceptable level. This might mean doing an allergen protein swab or sending samples to a lab periodically to ensure, say, that after cleaning, there’s no peanut protein detectable on equipment.

If you can’t effectively clean something, you may decide it can only ever be used for that allergen (dedicated use).

You should also remember to prevent cross-contamination during cleaning. For example, don’t use the same cleaning brush on all equipment if it might carry allergens. Either have cleaning tools dedicated to allergenic areas or ensure they are cleaned thoroughly.

And to be thorough, go back to the sanitation standard operating procedures, write them down. For example, “After using the mixer for allergen X, take apart blades, soak in hot detergent water for Y minutes, scrub surfaces, etc., then swab test.”

Train staff on these methods (more on training soon). Good cleaning is one of the hardest parts of allergen control, so give it the attention it deserves.

Your product recipes or menu items should be centrally controlled so you know exactly which allergens are in each one. Any time you create a new product or change a formula, there must be a process to evaluate allergen impacts.

This is where having a clear allergen management policy for product development is helpful. For example, having formulating teams ask “do we really need to add a new allergen?” because adding one might complicate your whole facility’s risk profile. Once recipes are set, ensure that your labeling is correct for each product. This means your packaging or menu exactly matches the ingredients used. Have a verification step for label printing or menu updates.

Many allergen recalls happen because the wrong label was put on a product (e.g. a cookie with nuts got a nut-free cookie label by mistake). Implement checks at packaging: operators should confirm the label or packaging corresponds to the product running.

You should also manage label inventory and immediately dispose of old labels when formulas change to avoid mix-ups. It’s wise to have an SOP that if any ingredient changes or new allergen introduced, QA must review and approve new labels before release.

In food service, this might translate to updating recipe cards and allergen info charts that servers refer to. Never assume – always double-check the food allergen labeling against the actual contents.

All the fancy protocols mean nothing if your team doesn’t understand them. Allergen management training should be provided to every employee who handles food, from kitchen porters to chefs, from line workers to warehouse staff. Training isn’t a one-time thing either. Regular refreshers are important, especially if you change your plan or if regulations update.

Key topics include:

Make it relatable by asking things such as “How would you feel if someone had to use an EpiPen because of a mistake we made?” Empower staff to speak up if they see a risk. For example, if a worker notices someone used the wrong scoop, they should feel it’s their duty to stop the line and report it.

Also train your front-of-house or customer-facing staff: in a restaurant or cafe, staff must know how to check for allergen info and communicate clearly with customers. This includes knowing the procedure when a customer says “I have an allergy.” Typically to take it very seriously, check ingredient info or call a manager/chef, use separate utensils, etc.

Training can include some scary real-life stories (unfortunately, there are cases of fatalities from allergen slip-ups) to drive the point home. And don’t forget new hires – include allergen safety in onboarding.

The goal is to create “allergy-aware” champions in your workforce. When everyone from the line cook to the store manager understands allergen management, the risk of mistakes plummets.

Part of allergen management is making sure the end consumer gets the information they need. For manufacturers, this is primarily through accurate labels on packages (as we discussed). For food service or retail (deli, bakery, etc.), it means having a system to answer customers’ allergen queries.

This could be a well-maintained allergen matrix for each menu item that staff can consult. In many countries, it’s a legal requirement that you can tell a customer if a menu item contains any of the major allergens, even when it’s not prepackaged.

For example, in the U.K., even if you sell food without a label (like a cafe sandwich), you must be able to inform customers about allergenic ingredients when asked. Many businesses provide allergen menus or signage like “Please inform us of any allergies before ordering.” Make sure whatever info you provide is updated whenever recipes change.

Also, consider how you handle special requests. Some places have a policy to use a different colored plate or toothpick to mark an “allergy” order, and the chef personally verifies it. These extra steps can save lives and show customers you take them seriously.

As with any food safety program, if it’s not documented, it didn’t happen. Keep records of your allergen management activities: cleaning logs, training records, label check records, supplier allergen documentation, etc. This not only keeps you audit-ready and compliant, but helps in internal reviews.

Conduct internal audits focusing on allergen control – for instance, do a walkthrough and see if allergens are properly segregated, or swab some surfaces for allergen residue to verify cleaning effectiveness. Some companies do periodic “allergen drills” – pretending there’s been an allergen contamination and seeing if traceability and recall procedures work (this can be part of your crisis management program).

Verify that controls are working. For example, do random checks that the correct labels are on products, or send product samples to a lab to ensure no undeclared allergens are present.

Also, review the plan at least annually or whenever something big changes (new product, new allergen introduced, new equipment, etc). Allergen regulations and best practices evolve. Other known allergens like mustard might be added in the future.

Stay updated via FDA, FSA, or industry resources. Use any incidents (internally or from news) as learning opportunities to strengthen your system. Continuous improvement is key – the aim is zero allergen accidents, and if you ever slip, adjust the plan to prevent it from happening again.

That’s a lot to take in, but step by step, you can build a robust allergen management program. It might help to use a procedure template or checklist (see next section) to ensure you cover all bases. The main thing is to be thorough and never get complacent. Allergens don’t give second chances easily – one small oversight is all it takes. So we anticipate the risks and control them with a vengeance.

Every food business should have a written allergen management procedure (or set of procedures) that outlines exactly how allergens are handled. This document serves as a reference for training, a proof for auditors/regulators, and a playbook in day-to-day operations.

You can use this one as a template to build your own, tailoring it to your facility:

.png)

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Below is a sample of what a typical allergen management policy or procedure could look like with examples.

Describe why this procedure exists and to whom/what it applies.

For example: “To prevent allergen cross-contact and ensure accurate allergen labeling in all products made at XYZ Bakery. This procedure applies to all staff and all food products handled at our facility.”

Clarify key terms.

For example, define “allergen,” “cross-contact,” “major allergen” (possibly listing the allergens of concern), “precautionary labeling”, etc. Keeping everyone on the same page with terminology helps.

Who is responsible for what? For instance:

It’s good to list an Allergen Coordinator or point person for oversight.

List all allergenic foods or ingredients handled on-site.

For example, “Milk (in product X), Eggs (in product Y), Almond (in Z), Gluten (wheat flour in many products), Soy (lecithin in chocolate chips), etc.” This list should be updated whenever a new allergen comes into play. It helps as a reference.

Summarize the allergen risk assessment findings.

For example: “Wheat flour dust can contaminate other products – risk high; shared oven for products with and without nuts – risk medium, controlled by scheduling and cleaning,” etc. This just shows you’ve thought through where the risks are.

State that “All incoming ingredients are reviewed for allergen content. Suppliers must provide up-to-date allergen declarations. Upon receipt, allergenic ingredients are labeled with ‘ALLERGEN’ tags and stored as per Section 7.”

You might also note here: “No new ingredient is used in production until QA verifies its allergen information and confirms labels are updated.”

Detail how and where allergens are stored.

For example, “Allergen ingredients are kept on designated shelves in the dry storage, clearly marked. They are stored below non-allergenic items to prevent drips. Opened bags are kept in lidded containers. Separate scoops are used for allergen powders and are colored red.”

The more specific, the better – so staff know exactly what to do.

The production controls to help prevent cross-contact may contain sub-sections based on your food business's specific operations:

Describe cleaning procedures to remove allergens.

This could be detailed: “After processing products containing allergen X (list which allergens), equipment (list specific equipment) will be cleaned as follows: disassemble…, scrub with detergent..., rinse…, sanitize... Then QA will inspect for residues. Allergen test kits for X are used monthly to validate cleaning efficacy.”

If you have separate cleaning tools for allergens, mention that: “Brushes used for allergen cleaning are color-coded and not used for general cleaning.” Also mention cleaning of food contact surfaces in general areas, and how to handle utensils, aprons, etc., to prevent cross-contact.

Outline how you ensure correct labels.

For example, “For packaged products: Each product’s label is approved by QA with all allergens listed per regulatory requirements. A ‘Contains: ___’ declaration is printed for U.S. labels with the Big 9 allergens.

For UK labels, allergens are bolded in the ingredient list. An allergen chart is maintained for all recipes.” Also: “Packaging line checks: Operator verifies product name and allergen statement on label every run. QA performs label verification at start-up and every hour.”

If any precautionary allergen labeling (e.g. “May contain traces of X”) is used, state your policy that it must be based on risk assessment and not as a substitute for good practices.

For example: “‘May contain’ food allergy warnings are used only if after all controls, there remains a significant risk of cross-contact that cannot be eliminated. The decision to use such labeling is documented by the Allergen Coordinator.”

State that all relevant staff receive training on allergen awareness and these procedures.

For example, “All employees in production, warehouse, and quality departments are trained on allergen management at hire and annually. Training includes the contents of this procedure, importance of allergen control, and their specific duties. Records of training are kept.”

You might also mention that food service staff (if relevant) are trained how to communicate with customers about allergens.

If you serve or sell directly, include a section on how to handle questions.

For example, “Staff must refer to the allergen matrix and ingredient lists to answer customer questions accurately. If unsure, involve a manager. Never guess. We maintain an up-to-date allergen information sheet for all menu items.”

Also, “If a special allergen-free meal is requested, use the designated allergen kit (separate utensils, plate, etc.) and have a supervisor oversee its preparation.”

Describe how you verify that the plan works.

For example, “QA will perform monthly swab tests for allergens on equipment after cleaning to verify effectiveness. The Allergen Coordinator conducts a quarterly audit of ingredient storage and labeling practices. Any issues are recorded and corrective actions taken.”

Also, “We review all allergen-related customer complaints or incidents immediately and adjust procedures if needed.”

Note that this procedure is a living document.

For example, “This allergen management plan will be reviewed at least annually or whenever a new allergen or product is introduced, to ensure it remains effective and up-to-date with regulations.”

Include version number and date so everyone knows they have the current copy.

Remember: This is just a template; your actual allergen management procedure might be shorter or longer. The key is to cover how you identify, control, clean, train, and communicate about allergens. Having this written down is invaluable. It not only guides your team but also impresses auditors and inspectors because it shows you have a structured approach.

Feel free to use this outline as a starting point (an allergen management procedure template, if you will) and customize it to fit your operation.

Getting allergen labeling right is one of the most visible (and legally critical) parts of allergen management. If you’ve done everything to prevent cross-contact but then put the wrong info on the label, all that work was for nothing. Let’s look at how food allergen labeling requirements compare between the U.S. and U.K.:

U.S. packaged food labels must declare the presence of any of the “Big 9” major allergens (milk, eggs, fish, shellfish, tree nuts, peanuts, wheat, soy, sesame). The law gives two main ways to do this:

The FDA has strict rules – if an allergen is present, it must be on the label, no exceptions. If you fail to declare an allergen, it’s considered misbranding and a public health risk, hence the recalls.

Notably, the U.S. doesn’t mandate any particular format like bold text within the ingredients; the Contains statement is how it’s usually highlighted. There’s also no required list beyond the Big 9, but many companies voluntarily mention other allergens (like mustard or celery) if they know customers might care.

What about those “may contain” or “processed in a facility with…” statements (called precautionary allergen labeling)? In the U.S., these are voluntary. FDA does not have a specific regulation governing them – except to say they should be truthful and not misleading.

FDA guidance (and industry best practice) is that such statements should not be used as a crutch instead of good manufacturing practices. In other words, don’t just slap “may contain peanuts” on everything to cover yourself. You’re expected to do your best to avoid cross-contact first. Only use a “may contain” if, despite all reasonable measures, you determine there is still a real risk of trace cross-contact.

For example, if you produce chocolate bars with and without nuts on the same line and you can’t 100% guarantee no tiny bits might carry over, you might use “may contain tree nuts” as a last resort warning. The phrase “may contain” isn’t legally defined, but it’s commonly used, as is “manufactured on equipment that also processes X”.

The lack of clear rules in the U.S. has led to some confusion, but the bottom line is: always declare known ingredients, and use precautionary statements only when justified by risk assessment (never to excuse poor cleaning). Also note, if you do use precautionary labels, be specific (“may contain walnuts and almonds” is better than “may contain nuts” because consumers appreciate knowing which ones).

The U.K. (and EU) has a more prescriptive approach inside the ingredients list itself. All prepacked foods in the U.K. must have an ingredients list, and any of the 14 major allergens present must be emphasized every time they appear.

“Emphasized” usually means bold text, but could be ALL CAPS, underline or a highlight – as long as it stands out. For example, an ingredients list might read: “Ingredients: sugar, MILK, cocoa butter, ALMONDS (15%), emulsifier (SOY lecithin), natural flavor.” Often labels also have an allergen summary like “Allergy Advice: For allergens, see ingredients in bold.”

This is to make it absolutely clear to allergic consumers. If there’s no ingredient list (like wine or beer often don’t have one), then a “Contains: X” allergen statement is required on the label for any of the 14 (for example, wine would say “Contains: sulphites” if it has >10 ppm sulfites).

The U.K. also rolled out Natasha’s Law in 2021 for “PPDS” (Prepacked for Direct Sale) foods. This means if you pack food on site (like a sandwich in a cafe grab-and-go fridge), you must label it with the name and full ingredients with allergens in bold, same as any packaged food. This was a game-changer for many small businesses that used to just wing it with allergen signage.

As for “may contain” statements in the U.K./EU – they are allowed but regulated by guidance. The U.K. FSA suggests using phrases like “may contain X” or “not suitable for those with X allergy” only after a thorough risk assessment and only if the risk cannot be eliminated. This aligns with international best practice: precautionary labels should be a last resort.

There’s industry pressure to make these statements more standardized because overuse can erode their credibility. But legally, as long as you aren’t misleading and you’ve done your due diligence, you can use them.

Just remember that if you ever say “free-from [allergen]” on a product, that comes with an obligation: you must be really sure (via controls and testing) that the product is truly free of that allergen. For example, labeling something “gluten-free” in the U.K. means <20 ppm gluten by law, and you need to have ensured that through your processes.

In both the U.S. and U.K., failing to declare a mandatory allergen is a serious offense.

In the U.S., the product is considered adulterated/misbranded and will be recalled, and the company can face FDA warning letters or worse.

According to joint industry study by the Food Marketing Institute and the Grocery Manufacturers Association:

The costs for larger brands may be significantly higher based on the preliminary recall costs reported by firms of some recent recalls. And these are just the direct costs, which typically include notification (to regulatory bodies, supply chain, consumers), product retrieval (reverse logistics), storage, destruction, unsalable product, and of course, the additional labor costs associated with these activities as well as the investigation of the root cause. They do not include what could arguably be the more significant costs to the company from litigation costs, the costs from any agreed or mandated governmental oversight post incident, lost sales, and the impact to the company’s market value and brand reputation.

In the U.K., local authorities can take action, from forcing a product withdrawal to prosecution. There have been high-profile cases in the U.K. where businesses were fined or managers even jailed due to deaths from undeclared allergens (a notable case involved a restaurant whose staff assured a customer a dish was nut-free when it wasn’t). So these regulations have teeth.

U.S. uses the “Contains [allergen]” statements and covers 9 allergens; U.K./EU uses bold text in ingredients and covers 14 allergens. Both require clarity and have no tolerance for missing a major allergen.

As a best practice, many global companies design labels that meet both sets of rules. For example, an ingredient list with bold allergens and a contains statement – to simplify compliance across markets.

When creating your allergen management plan, ensure you include a section on label review so that every label or menu is checked against the recipe by a second set of eyes. It’s one of the cheapest safety nets you have.

The BRCGS food safety standard in particular has significant implications for allergen management. If your business is pursuing GFSI-recognized certifications like BRCGS (Brand Reputation Compliance Global Standards, formerly BRC), you’ll need to meet some specific allergen control requirements.

BRCGS Food Safety Issue 9 (the latest version of the standard, released in 2022) places strong emphasis on allergen management – so strong, in fact, that it’s considered a fundamental requirement. That means an auditor finding a major fault in your allergen controls could jeopardize your certification immediately.

The following sections are what the BRC Food Safety Issue 9 allergen management requires in plain terms:

BRCGS expects you to have a formal system in place to manage allergens and minimize cross-contact. This aligns with everything we’ve discussed so far. You should have a written plan/policy covering how you handle allergenic materials from raw material to finished product.

And critically, it must meet legal requirements for labeling in the country of sale. So if you’re BRCGS-certified and selling to multiple countries, your plan needs to ensure you comply with each country’s allergen labeling laws.

Clause 5.3.1 of BRC Issue 9 requires companies to assess all raw materials for allergens and potential cross-contact. This means you need to know for each ingredient whether it is an allergen or could carry traces of one from the supplier.

BRCGS suggests obtaining detailed info from suppliers, e.g. via questionnaires, to understand the “allergen profile” of each raw material and the facility it comes from. This is essentially what we covered in Steps 1–3 of our guide: allergen inventory and supplier info.

You are expected to identify and list all allergen-containing materials on site. A list posted on your wall or in your documentation of “these are the allergens we handle” suffices. It’s about awareness.

BRC also implies you should “map” where they are in your process (though it doesn’t use the word map explicitly in the requirement, it’s best practice to do so). The idea is you can’t control what you haven’t identified.

Although it’s not one bullet in the standard, it’s woven throughout that you must handle allergens in a way that minimizes cross-contact. This includes physical or time segregation, careful handling, etc. BRCGS will look for evidence like dedicated utensils, proper storage, and avoidance of airborne spread.

Clause 5.3.2 to 5.3.5 in earlier versions covered things like storage segregation and handling, which remain crucial.

Essentially, the auditor will want to see that in practice your factory keeps allergens under tight control (through all the means we discussed: segregated storage, clear labeling, equipment cleaning, etc.).

This is a significant area in Issue 9. There’s a specific clause (5.3.8) on cleaning, stating that equipment or areas must be cleaned to remove or reduce allergen cross-contact to acceptable levels.

Moreover, the cleaning methods have to be validated and verified regularly – meaning you can’t just assume cleaning works; you need proof, like allergen swab results or protein tests after cleaning.

They also say cleaning tools should be specific or effectively cleaned themselves to avoid spreading allergens. This aligns perfectly with what we outlined in our Step 6.

Under BRC, if you claim to clean between allergens, you better have a file of test results and procedures showing that it actually works.

BRCGS expects strict controls to ensure the right labels/packaging are used. Although that’s in the labeling section (5.2) of the standard, it ties directly to allergens. One mis-pack and you have undeclared allergens. So an auditor will check how you manage label changes, how you differentiate similar-looking packaging, etc.

For example, do you do manual label verification? Do you use barcode scanning on lines to ensure the correct label is applied? And how do you ensure old label stock with outdated allergen info is destroyed?.

In Issue 9, Clause 5.3.6 specifically addresses “alibi labelling” – which is BRC’s term for precautionary allergen labeling. It states that if your risk assessment shows you truly can’t prevent cross-contact, you should include a warning on the label, and that any such warning must follow applicable laws or codes of practice.

So, only use “may contain” if you need to, and do it in line with what regulators recommend. BRCGS wants this to be risk-based and not random, echoing what regulators say.

If you claim “free from” something, BRCGS Issue 9 has upped the game. Clause 5.3.7 requires that any allergen absence claim (like gluten-free, dairy-free, etc.) must be validated and verified with rigorous controls. That means if you say “peanut-free” on a cookie, you must have ensured through your processes (and likely testing) that it’s truly peanut-free.

You need to document how you validated that (maybe initial cleaning validations, or sourcing from guaranteed peanut-free facilities, etc.) and keep verifying (like periodic tests). They don’t want empty claims – you have to walk the talk for allergen claims.

Issue 9 oddly calls out pet food/allergen labeling (since some countries have laws for pet food allergen labeling, others don’t). For most readers here, that’s not relevant unless you make pet food.

But essentially, BRCGS says if you make pet food and the destination country has allergen label laws for it, you must follow them; if the country has none, then allergen sections might be “not applicable” except if you claim “grain-free dog food,” then you still must meet the requirements for a human food allergen claim.

BRCGS auditors will likely spend a good chunk of time reviewing your allergen procedures, observing practices, and even doing a traceback. They might, for example, pick a product that doesn’t contain, say, nuts, and ask you to show how you ensure it wasn’t contaminated by the nuts you use in another product. This could involve showing records of cleaning between products, or how you schedule those products, etc.

They might also inspect how you store allergens and check if your list of allergens matches what they see on site. Non-conformities in this section can range from minor (e.g. one container of allergen not labeled – fixable) to major/critical (e.g. systemic failure like no segregation leading to actual cross-contact risk – which could jeopardize certification).

In short, the BRCGS Issue 9 demands a comprehensive, risk-based allergen management system. It’s very much in line with everything we’ve discussed: identify all allergens, assess and minimize cross-contact risks, validate your cleaning, and label correctly including any “may contain” or “free-from” in a responsible way. If you adhere to best practices we outlined, you’ll likely meet the BRCGS allergen requirements.

It’s noteworthy that BRCGS (and other schemes like SQF, IFS, etc.) have pushed companies to formalize allergen control even before some regulations did. They treat it as a core component of food safety. If you’re not seeking certification, these standards are still great benchmarks of what you should be doing.

In fact, many customers (like big retailers) will expect you to meet BRCGS-level allergen control even if you’re not certified, because it’s considered the gold standard.

One takeaway: if you read BRCGS Issue 9 or its guidance, you’ll see allergens are no joke. The standard explicitly says the allergen management clause is fundamental. So, whether or not you go for that certificate, aiming to meet those requirements is a smart move for any food business that wants to operate at a high level of food safety.

You can have the best-written plan and the fanciest cleaning equipment, but without well-trained people, it all falls apart. Food allergen safety is ultimately in the hands of your staff on the floor and behind the counters.

This is why allergen management training is absolutely essential. It’s not just a tick-box for compliance – it’s about creating a mindset across your team that allergen control is serious and everyone’s responsibility.

Think about it: a single employee mistake – using the wrong ingredient, or grabbing the wrong ladle, or assuming a label was correct – can cause an allergic reaction in a customer. We’ve sadly seen incidents where a lack of training had tragic outcomes.

For example, a few years ago in the UK, a restaurant waiter didn’t understand that ghee (clarified butter) contained milk, assured a customer with a dairy allergy that a dish was safe, and the customer died from an allergic reaction. No one wants their business to be in that headline.

Training and awareness are how you prevent those human errors born of ignorance or complacency.

At a minimum, your food allergen management training should include:

Teach what food allergies are, how severe reactions can be (e.g. explain anaphylaxis briefly). When people realize “wow, even a tiny amount can send someone to the ER,” they understand why all these procedures matter. Sometimes showing a short video or testimonial from someone with allergies can make it hit home emotionally.

Make sure staff know which allergens your facility handles and in which products. Kitchen staff should know, for instance, “we use cashew paste in that sauce” or “this fryer is only for gluten-free items.”

In a bakery, every counter staff should know “which donuts have nuts, which are dairy-free”, etc. Essentially, they should memorize or have quick access to the allergen presence of each product you sell.

A handy allergen chart or cheat sheet is great, but training them on how to use it is key.

Walk through scenarios. For example, show how using the same knife on a peanut butter pie and then on a vanilla cake could transfer enough peanut to harm someone allergic. Show the proper way (clean or use separate knife).

Make it clear that things like wiping a surface with a dirty cloth can spread allergens. Emphasize habits like handwashing and changing gloves between tasks. If you have color-coded tools or dedicated equipment, show them what color corresponds to what allergen or product.

Role-play situations: “What do you do if you drop a scoop into the wrong bin?” Answer: Don’t just fish it out and continue – stop and get a clean scoop, segregate the affected material, etc. Giving practical “what-ifs” helps reinforce the correct actions.

For those who formulate or mix, stress the importance of not deviating from recipes. No adding an extra dash of walnut spice “for flavor” if it’s not in the recipe – because then the label will be wrong.

And conversely, if they ever need to substitute an ingredient, they must inform QA/management since it could introduce an allergen.

Basically, no unapproved changes. The same for labelers/packers: never swap a label roll without verifying it’s the right one for the product in front of you.

Especially in food service, train staff on how to communicate about allergens. This includes how to ask customers about allergies (“Do any guests in your party have food allergies or dietary needs?” is a good routine question), and how to respond when a customer declares an allergy.

Typically, the protocol is to take it very seriously: acknowledge it, notify the kitchen clearly, use whatever your system is to mark the order, and ensure it’s prepared separately.

Train them never to guess the answer to an allergy question. If they don’t know, they should say “I’m not sure, let me double-check with the chef or check our allergen guide.” It’s far better to spend an extra minute than to give wrong info.

Tone is important too; no eye-rolling or dismissing it as an inconvenience – the customer must feel confident that the staff cares. In training, instill a sense of empathy: “How would you cook for a friend who could die from peanuts? You’d be really careful, right? That’s how careful we need to be for our guests.”

Train what to do if something goes wrong.

If an employee realizes mid-process that, say, an allergen-free product might have been contaminated, they should know to stop the line or not serve the dish and immediately inform a supervisor. And if, worst case, an allergic reaction occurs on site, staff should know basic emergency steps (call 911, get the epinephrine auto-injector if available, etc.).

This might be beyond basic training, but even just knowing to call emergency services immediately can save a life.

Initial training is a start. But have refreshers at least yearly. Short toolbox talks or shift briefs can help. For example, doing a 5-minute reminder: “Hey team, remember to keep those allergen tags on ingredients and always double wash after handling raw eggs,” etc.

Use visual reminders in the workplace too: posters about allergen procedure, allergen charts on the wall, color coding legends, etc., to reinforce training. Sometimes, real-world news can be shared in training: “Last month, X company had to recall everything because of wrong labeling – we don’t want that. Let’s double-check our label procedures.”

When training is consistent, you’ll see a culture of food safety develop. Newer staff will be corrected by veteran staff if they slip up (“Hey, use the green cutting board for veggies, the red one is for cooked meat and allergens!”). That’s when you know the training has sunk in – when everyone holds each other accountable.

Positively encourage this because recognition for employees who excel in following allergen protocols can motivate others. Some companies incorporate allergen awareness into their reward systems or performance reviews, underscoring its importance.

Make sure management visibly supports allergen safety. If line workers are told to be careful, but a manager says “we’re busy, just get the food out, don’t worry about changing gloves this time,” that undermines everything. Training should include supervisors and managers so they lead by example, never cut corners, and back up their staff when someone says “I need to take 5 more minutes to clean this properly because of allergens.”

Training is where the allergen management program comes to life through people. It’s the glue that links your written policy to actual practice. Investing time in thorough training and fostering an environment where allergen safety is second nature will help significantly reduce the risk of allergen mishaps.

Plus, employees generally take pride in knowing they are protecting customers – it gives purpose to all those extra steps. Make allergen training a story, not just a lecture, and your team will remember it each time they pick up a tool or answer a customer’s question. After all, an ounce of prevention (or education) is worth a pound of cure, especially when a “cure” for an allergic reaction might be an epinephrine shot and a trip to the hospital.

It may seem like something from the old days, but all too often, allergen management is done with pen-and-paper checklists, memory, and manual tracking. While a committed team can manage this way, it’s getting harder to keep up, especially as regulations tighten and the complexity of supply chains grows.

This is why digital food safety tools are growing increasingly popular — and necessary. Embracing digital systems for allergen control and traceability can be a game-changer in how efficiently and reliably you manage allergens. This is why:

When there’s a concern that a product might have an undeclared allergen, time is of the essence. You need to quickly trace which batches, ingredients, and distribution channels are involved. Digital traceability systems let you pull this info with a few clicks.

For example, if you have software where all ingredients and their allergen info are logged, and all production lots are recorded, you can query, “Show me all products produced on Line 1 in the last week, and which of those should contain allergen X.” If something got mislabeled, you’ll pinpoint the affected lots fast.

Digital traceability is so important that regulators are pushing towards it – the FDA’s new traceability rule under FSMA, for instance, encourages electronic records for certain high-risk foods. While that rule isn’t specifically about allergens, the ability to rapidly trace is universally helpful.

Digital records mean no rifling through binders in an emergency; you have the data at your fingertips to do a recall or to answer an inspector’s questions on the spot.

Modern food safety software often includes features like a recipe management system or product specification module. In such a system, when you input a recipe, the software can automatically flag which major allergens are present (since it knows the ingredients’ allergens).

For instance, if you enter a new sauce recipe that uses Worcestershire (which contains fish in the form of anchovy), the software might alert you: “Contains Fish – don’t forget to label!” This reduces human error. Some tools provide an allergen matrix that updates in real time, which gives you a table of all your products vs. which allergens they contain.

If you reformulate a product, the digital allergen matrix updates immediately. This ensures everyone, from the QA person making labels to the chef updating a menu, is on the same page with current information. No outdated spreadsheets floating around.

Food businesses have gotten into recalls simply because they forgot to update one document when a recipe changed. Digital systems mitigate that risk by having one source of truth that’s always updated.

Let’s face it, documentation is one of the least glamorous parts of allergen control. But digital systems can make it much less painful. Instead of filling out paper cleaning logs that might get coffee spilled on them, staff can tick off cleaning tasks on a tablet or phone.

Instead of maintaining training logs in a file cabinet, you can have training modules online that log completion automatically. When an auditor comes, you can show them digital records for allergen checks, cleanings, supplier certs, etc., sorted and searchable.

Also, consider version control: your allergen management procedure (SOP) can be stored in a system where everyone always sees the latest version, and changes are tracked. No dog-eared old procedures from 3 years ago floating around in someone’s locker. This all leads to better compliance and less stress during inspections or audits.

Some advanced setups tie into production equipment or inventory management. Imagine a system linked with barcode scanners: when an operator scans a raw ingredient into a batch, if it’s the wrong one (with an allergen that shouldn’t be there), the system could alert or stop the process.

Or if someone tries to print a label that doesn’t match the product’s allergen profile, it could warn them. These kinds of checks are becoming more common. Even without that integration, simply having checklists in a digital app that require verification (like a photo of the correct label on product before starting a line) can enforce diligence.

Many tools can send reminders, too. For example, “Allergen swab test due today for Line 2”, which help ensure you don’t forget your verification activities in the busyness of the day.

Digital solutions can also host training resources or quick reference guides. For instance, an employee might have an app where they can quickly look up “What are the steps for allergen clean-up?” or view the allergen matrix for products if a customer asks.

Instead of hunting for the laminated chart, they could check their device. Some systems even include quizzes or periodic training refreshers that employees can do on their phone, turning training into a continuous process rather than a once-a-year meeting.

Beyond your facility, digital platforms can connect you with supplier data. Some cloud-based services allow suppliers to upload their product specs, allergen statements, and updates directly to a portal you can see. This means if a supplier changes an ingredient’s allergen info, you get notified through the system. It streamlines that communication.

You could also integrate with inventory systems so that if an ingredient with allergen X is used in a product without X, the system flags it as an error and potentially catches a cross-contact at the formulation stage.

In the unfortunate event you do have to recall a product for an allergen, digital tools help execute it swiftly. If you have a customer list or distributor list in the system, you can quickly send notifications. Also, having all your documentation in one place helps with the root cause analysis – figuring out how the mix-up happened, so you can fix it.

The bottom line: Digital tools reduce the chance of human error and make compliance easier. They serve as a safety net and a management aid. They also save time – what might take hours to compile manually (like preparing an allergen report for a new client, or double-checking all recipes for a certain allergen) can be done in minutes with a proper system.

Of course, technology is not a silver bullet. You have to set it up right and maintain the data. But the food industry is increasingly turning to software solutions for HACCP and food safety management, and allergen control is a prime beneficiary of this.

From digital checklists to allergen databases, these tools ensure nothing “falls through the cracks” because the consequences of an allergen slip are too dire.

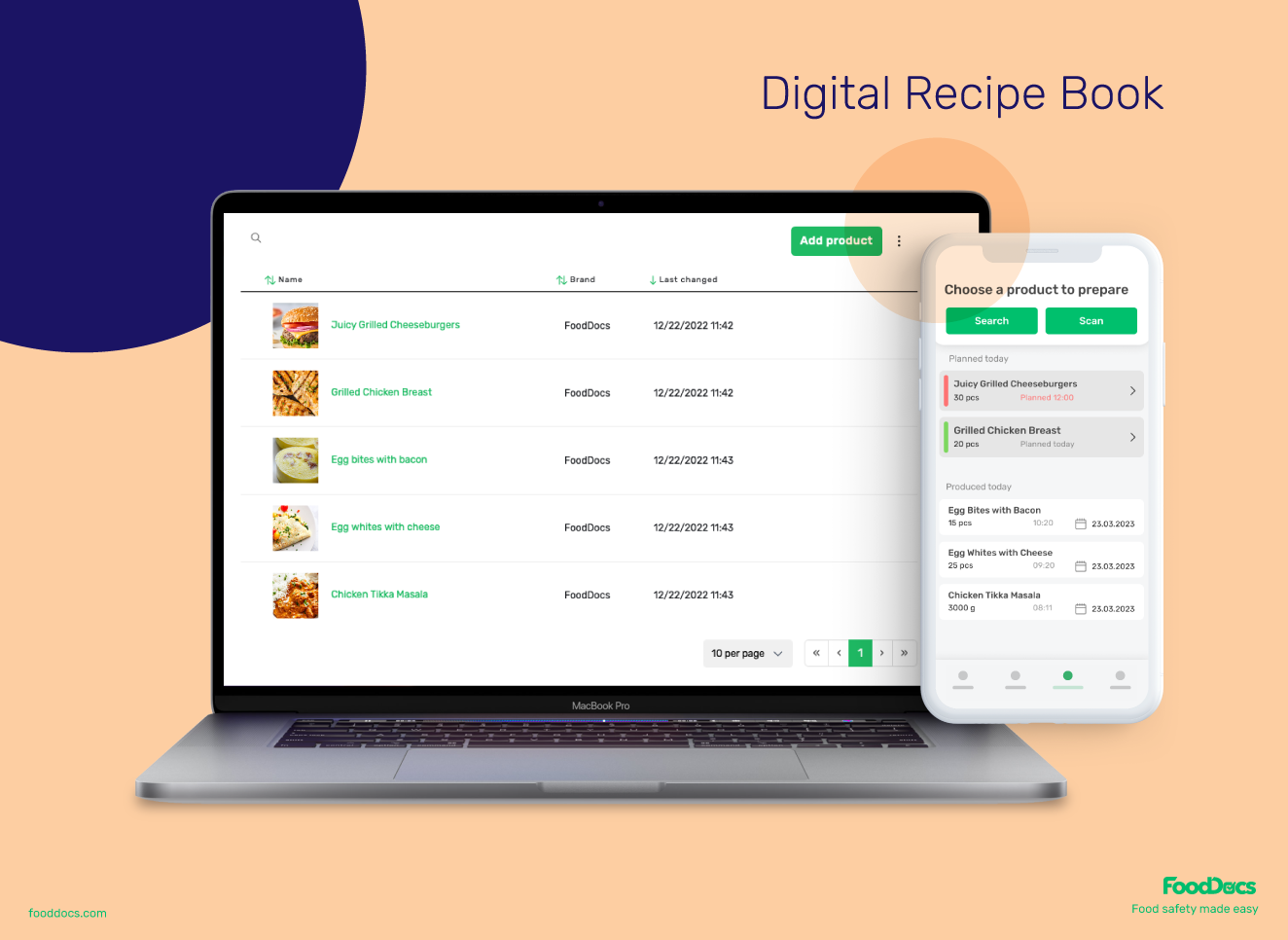

FoodDocs' food safety management software offers a monitoring and traceability solution that significantly simplifies allergen management. It provides features like:

Whether you need to maintain food handler certificates or training records, FoodDocs also stores your documents in the cloud, so your supplier specs and training records are accessible anytime. In case of a recall, having all this organized can help you respond in seconds.

Using a digital food safety tool will help ensure that staff aren’t relying purely on memory or manual logs. Instead, FoodDocs becomes a reliable assistant, making food safety monitoring, such as keeping track of allergen info and compliance tasks, day in and day out.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...