Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Discover the key to proper FIFO food safety and learn the 5-point checklist to do it right with ease and consistency.

Ever watched food spoil in the back of your fridge while the newer items get used first? That simple oversight is the same mistake costing restaurants and food businesses thousands of dollars and putting customers at risk. Yes, First In, First Out (FIFO) is an inventory method, but it's also the difference between safety and liability in food service.

One of the most well-known food storage systems is the First-In, First-Out food storage system or FIFO for food. This storage system was designed for food businesses only to serve customers the freshest and safest dishes. As part of every food handler's food safety training, they must know what FIFO means and how to implement it properly.

That's why proper food storage is an essential undertaking for every food business. A comprehensive food storage management system such as FIFO can lead your food business to more efficient food service and protect your consumers from foodborne illnesses.

The FIFO system optimizes food safety by using older inventory first to prevent spoilage and waste.

Implementing FIFO can enhance food safety and compliance, reducing the risk of foodborne illnesses.

FIFO stands for First-In, First-Out, a system that ensures foods are used in the order they are received.

Proper FIFO implementation can significantly reduce food costs and waste by utilizing ingredients before they expire.

Training and awareness are crucial for food handlers to effectively implement and maintain FIFO.

FIFO promotes efficient kitchen workflow and better inventory management, leading to smoother operations.

The system supports food safety laws compliance, helping businesses maintain proper storage and handling practices.

Challenges of FIFO include the potential for time-consuming processes and the risk of implementation errors.

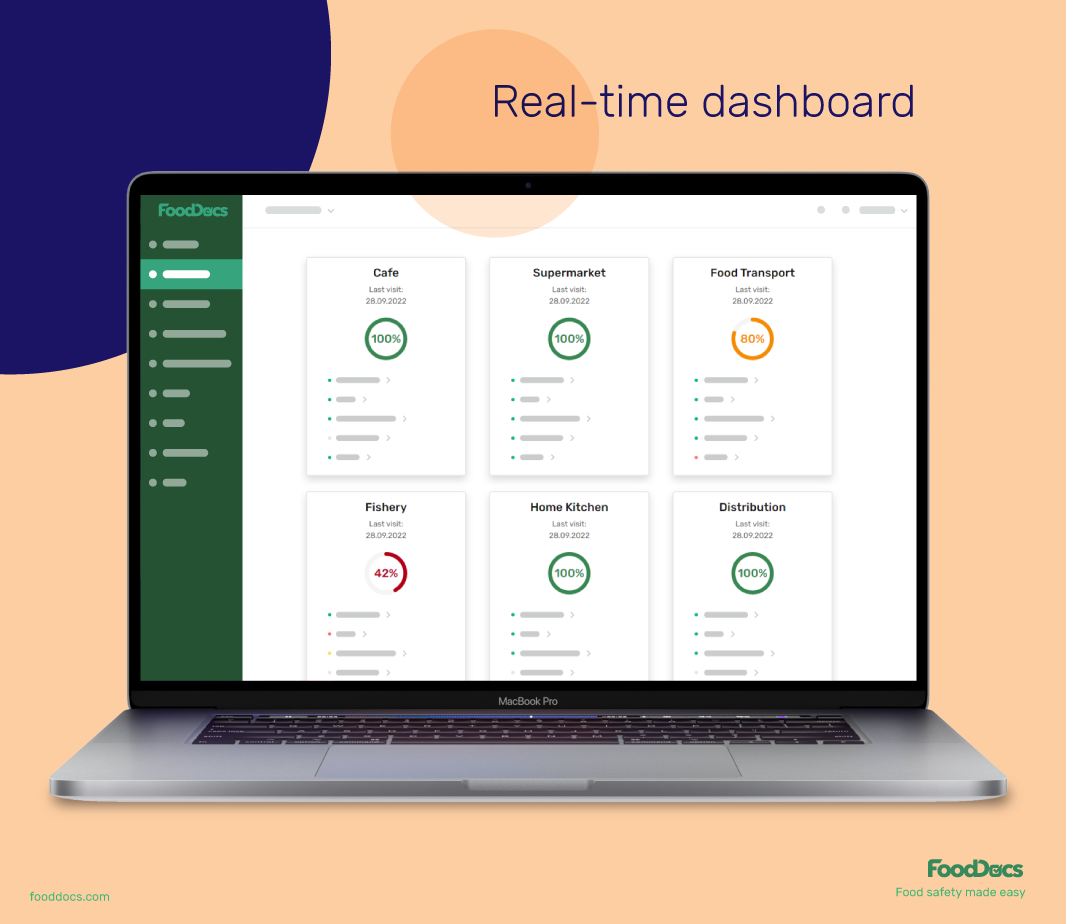

Food safety management software such as FoodDocs enhances FIFO by simplifying monitoring and ensuring compliance through smart notifications.

FIFO stands for First-In, First-Out, a food storage system designed to use foods that have been in your kitchen the longest. The FIFO method helps food service and production companies improve stock rotation to reduce the likelihood of serving or selling food that's beyond the best before or use-by dates, and prevent unnecessary food waste.

FIFO focuses more on foods' shelf life and ensures that all ingredients are optimized before they even go bad and become unusable. The process also promotes a faster system for locating which foods to use next and ensures that there will be no accidents in terms of using expired ingredients.

Food storage systems such as FIFO are most useful in businesses that deal with common food items and perishable food items such as time and temperature control for safety or TCS food. These kitchen inventory items require a stricter monitoring process to ensure food safety. A comprehensive food safety management system would combine the principles of FIFO and monitoring procedures to prolong the shelf life and maximize the potential use of food ingredients.

Proper food storage is part of the four major food safety practices always highlighted in the food industry. When food storage is implemented correctly, the product quality, nutrition, and safety of foods are preserved for superior food service. In terms of food safety, proper storage includes the proper arrangement of products such as in a fridge, containers used, the grouping of products, and keeping foods out of the temperature danger zone.

Problems such as cross-contamination can easily be prevented with proper food storage. Additionally, food storage systems such as FIFO help secure a healthy amount of stock in your inventory and improve the natural flow of food ingredients into the kitchen and service area. The FIFO system can also help your team integrate other food safety systems such as food inventory tracking, accounting, and other back-of-house systems.

Specifically, FIFO offers several advantages in food storage more than just organization. It is a multi-faceted system that can affect other food service areas and improve the overall efficiency of your food business. FIFO does improve not only food safety but also the quality and inventory accounting side of your food business.

Despite the many advantages of using FIFO, early implementation stages can be difficult for some. At this stage, food safety teams may find it hard to start in terms of monitoring, consistency, and expertise of the system. Specifically, the FIFO system can show disadvantages such as the following:

The FIFO system is an integral part of a food safety management system (FSMS). It can help reduce the burden of managing your inventory and complying with food safety regulations. Despite this, the transition that it takes for implementation can become a challenge. You can help your food employees understand the system more and use an intuitive monitoring system by using a digital Food Safety Management System solution.

To use the FIFO method to restock food, place newly received items behind those with earlier dates to ensure the oldest items are used first to minimize spoilage and waste.

Here are 5 simple steps food handlers can take to maintain FIFO compliance:

Making the FIFO system work requires food safety precautions. Remarks on the disposal and maintenance of expired foods must always be maintained for inspection purposes. This step also helps food handlers account for reasons why foods have gone past their use-by dates without being used and improve operations.

The FIFO procedure is a very useful system that can help food establishments optimize food ingredients and gain maximum benefits and increase restaurant profit margin. It uses a system that prioritizes using foods with the soonest expiration or use-by dates to reduce the likelihood of food waste and spoilage that can lead to foodborne illnesses.

This food storage system is concerned with both the accounting section and food safety section of your food business. Under the FIFO system, the following procedures are highlighted and implemented:

The mentioned three procedures make up the whole FIFO method. Although simple, food handlers must understand the importance of each procedure to accomplish FIFO implementation. The task of implementing the FIFO method does not stop on day 1. It must be consistently maintained to become effective and prevent any food safety and quality problems.

Although other systems such as the LIFO method (Last-in, First-Out), which is a reverse approach exist, the advantage of FIFO is still more appreciated in the food industry, especially in managing company stock.

A good FIFO method example can be found in a restaurant setup. In such a food establishment, it's very normal to stock items in bulk to reduce the average cost of deliveries, transportation, and even the cost per unit of the food ingredients.

As such, most food businesses build comprehensive inventory management systems to track the flow of food. These food ingredients may be of the same categories such as being very perishable, ready-to-eat, or raw ingredients. The process of procuring these products is a cycle and is done routinely.

Using the First-In, First-Out method, the items in inventory are regularly restocked even before they are completely consumed. Once new stocks arrive, the old batches may be forgotten.

While it is very tempting to use newer, higher-quality ingredient stocks to achieve superior quality, the older batches that are still wholesome must first be used. This is why outsourcing is done on time to ensure that the remaining stock is still safe to be used.

To prevent mistakenly using newer stocks first, the manufacturing information of the newer batches is recorded and used for organization. All new food ingredients are placed at the back of the storage area (e.g., walk-in cooler, freezer, or refrigerator), whereas the older ones are placed in front where food handlers can easily see and use them.

At this point, the organization of foods in a refrigerator must still follow minimum food safety standards to avoid cross-contamination. This is also the case for additional inventory purchases. When a restaurant business makes emergency purchases, older stocks are still placed in front.

With a food inventory management such as the FIFO system, you reduce food wastage by ensuring that the older stocks are used without the risk of food poisoning.

Let's use the following example of how a food worker should store food using FIFO and assume they're restocking cheese in the walk-in refrigerator:

Evaluating your storage needs is crucial for effective FIFO implementation. Start by reviewing your current stock. Take inventory of all food items and check their expiration dates. Ask yourself which items spoil fastest. Perishable goods like dairy products, fruits, and vegetables often need prompt attention.

Next, consider any limitations your storage space might have. Is there enough room for proper rotation? You'll want to redesign your storage layout to allow easy access to older stock. A well-planned warehouse layout is another foundational aspect. Place older stock in the front and new stock at the back. This layout will also make audits more efficient. Monitor how easy it is for staff to use the space effectively.

Once the storage assessment is complete, it's time to bring the FIFO plan to life. Start by organizing your inventory. Place older stock in a way that ensures staff use it first. A straightforward mapping system or clearly drawn layout helps illustrate this.

Following this, establish a tagging or labeling system. Use clear date labels to mark all incoming stock. An easy-to-read label on each item should display the receive date prominently. You might consider using color-coded tags to help staff see at a glance which items need priority. Jane Doe, a Food Safety Consultant, stresses the importance of clear labels. They allow quick identification of items needing use first.

Weekly checks are a must. Audits help ensure compliance. According to Dr. Michael Johnson, regular audits catch inconsistencies early. Monitoring and adjusting your system can prevent errors and correct inefficiencies quickly.

Training your team is pivotal in implementing FIFO. Kick things off with workshops to teach FIFO practices. Make these hands-on sessions. Let team members rotate stocks during the training to understand the system's nuances.

Real-world scenarios solidify understanding. Show examples of potential waste if FIFO isn’t followed. Stress how it impacts both the bottom line and food safety. This approach forms a base for ongoing adherence to FIFO rules.

Following the training, monitor staff practices. Note any deviations from FIFO protocols. Provide feedback regularly to help reinforce training concepts. Active engagement and feedback ensure improvements in adherence over time.

Training shouldn’t just be a one-time event. Follow up with feedback sessions. Make improvements based on staff input. Encourage them to share their perspectives and any challenges they encounter.

By focusing on storage needs, planning, and team training, you will set the foundation for a successful FIFO system. With these steps, you'll prepare for a safer, more efficient, and cost-effective food management process.

To help every food business reduce the burden of monitoring food safety operations and maintain food safety compliance, our team at FoodDocs has built a digital Food Safety Management System powered by artificial intelligence. With very simple steps such as answering a few basic questions, you can get a comprehensive digital FSMS in just an average of 15 minutes.

While there are several inventory stock management software programs available, our system can act as complementary software for monitoring food safety. With easy integration features, your food safety team will be able to easily monitor food storage conditions.

Specifically, our system can automatically generate a digital FSMS with the following features:

In addition to these features, our system can also accommodate improvements by making the major components of your digital FSMS customizable. The edit feature can also be used to create new monitoring forms that are unique to your food business.

While our product features a traceability system, our highlighted feature is in helping you create digital and automatic checklists and monitoring forms to control and ensure that FIFO is always followed. Our traceability system can be used to track and alert your employees on the maximum shelf-life of your products.

Food storage management is undeniably tied to the success of food safety compliance. Using our system, you can effortlessly create a digital FSMS that is built specifically on your food operations without spending too much time on conceptualization and revisions. You do not even have to be a food safety expert to use our digital solution.

Whether you are a newcomer to the food industry or a long-time player who is unsure in switching to a digital platform, our system can make your life easier. At FoodDocs, one of our main objectives is to make food safety compliance an easy job for everyone. We've taken out the tedious process of building every monitoring form from scratch and we've even improved it by making functions automated.

Start your food safety journey with us now and experience every feature that our system has to offer for free! Use our 14-day trial program and explore how our system can help you.

From the following four options, FIFO requires organizing stored food by use-by dates.

A. Throwing away leftover food

B. Using new food before old food

C. Organizing stored food by use-by date

D. Discarding refrigerated food after 3 days

You might see this question (and others) on a food handlers test.

FIFO and LIFO (Last In, First Out) may sound similar but differ significantly in function and outcome. While FIFO focuses on selling older stock first, LIFO involves selling the newest inventory first. LIFO is outdated, not only because it can cause product obsolescence but because it contradicts FIFO's freshness guidelines crucial for food safety.

The benefits of FIFO include a better control on perishable items, more predictable cash flow, and enhanced storage conditions. On the flip side, LIFO could result in outdated products still sitting unseen, creating inefficiencies. In tax contexts, LIFO can lower taxable income by matching rising costs to latest purchases. Yet, this is not common in sectors prioritizing food safety.

Strategically choosing between FIFO and LIFO affects operations and outcomes, both financially and in compliance. Food businesses must prioritize FIFO due to its role in minimizing spoilage, managing shelf life accurately, and aligning with global safety standards.

FIFO refers to the proper stock rotation system of products in a food business. It involves the process of date marking ready-to-eat and perishable foods to guide food handlers. By principle, the foods with the earliest date of expiration or use-by date must go in front or at the top of the storage system. This step allows easy access to the foods by the food handler.

FIFO also involves the process of grouping similar products together which makes it easier for food handlers to spot any irregular behavior of foods such as spoilage. The process promotes better organization of kitchen ingredients and raw materials which is most useful in controlling food safety and preventing issues such as cross-contamination that can induce foodborne illness.

FIFO a significant approach to food hygiene in terms of managing food stocks efficiently. For food workers, the FIFO system is the process of rotating food balances in inventory in favor of using earlier produced materials. It is a method that can help food handlers reduce the chances of food spoilage that can generate unnecessary waste.

In implementing FIFO, food handlers are responsible for recording important information for food storage and monitoring the actual flow of every food product or inventory tracing. They are also required to mark products with the date, when necessary, to ensure that the ingredients being used are still safe and wholesome.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...