How to Master Standard Operating Procedures in the Food Industry

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

How to Master Standard Operating Procedures in the Food Industry

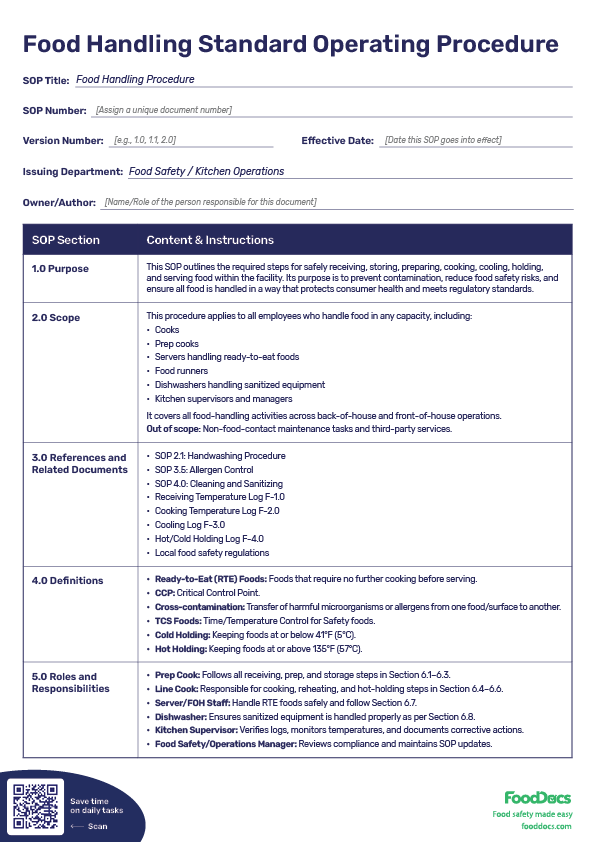

A standard operating procedure in the food industry is a written guide that tells everyone from Food Safety Leaders to Executive Chefs and front-of-house how to do something the same way every single time. These documents spell out the basics:

- What needs to be done

- Who's responsible

- What tools they need

- Where it happens

- When to do it

- How to get it done right

In practice, restaurant, retail, and healthcare groups will have detailed SOPs for everything including: checking food temps, calibrating thermometers, kitchen sanitation, equipment cleaning, and so on.

The size of your operation isn’t what matters here. What matters is that everyone needs to know the correct way to do each task and SOPs are what document the process so you can consistently achieve high safety standards that protect your brand and its patrons.

Get our most popular restaurant management resources

Key takeaways

-

Every restaurant needs SOPs to make sure food gets prepared safely and consistently, no matter who's working or which location you're at.

-

Good SOPs are clear about who does what, how they do it, and when it needs to happen so you’re always staying compliant.

-

Food handling, cleaning, storage, cooling, reheating, and personal hygiene all need written SOPs.

-

Personal hygiene SOPs should cover handwashing, sick policies, what people wear, and jewelry rules to cut down contamination risks and keep food, staff, and customers safe.

-

Front of house staff need SOPs too, e.g., to manage cleanliness, control allergens, and serve food safely.

-

When writing an SOP, start with the critical stuff that affects food safety or quality first, then break it into simple steps.

-

SOPs must be tested, taught, and monitored to ensure they’re realistic and staff are aligned and equipped to perform the steps.

-

Keep SOPs visible and accessible, whether that's on the wall or in an app so staff always feel confident and have a source of truth when they need to remember certain steps.

-

Health inspectors check SOPs during visits, especially for hygiene and temperature control and digital SOPs are the best proof that you have a safe and effective system.

-

Digital tools like FoodDocs can auto-generate SOPs, make it easy to train your team with visual step-by-step guides, track who's doing what in real time, and save up to 20% of food safety leaders’ time.

Why are SOPs important in food service?

SOPs keep food safe and quality consistent. When everyone follows the same procedures, you drastically cut down on contamination and foodborne illness risks, all while increasing operational efficiency.

Think about an SOP for cleaning and sanitizing kitchen surfaces that a large team and/or several locations will have to follow. If that's done right every time, you remove the ability for harmful bacteria to ruin the next meal, the likelihood of food waste, and the possibility of financial loss.

SOPs also help you meet health codes and pass inspections because they prove to inspectors that your restaurant has real methods in place, not just good intentions.

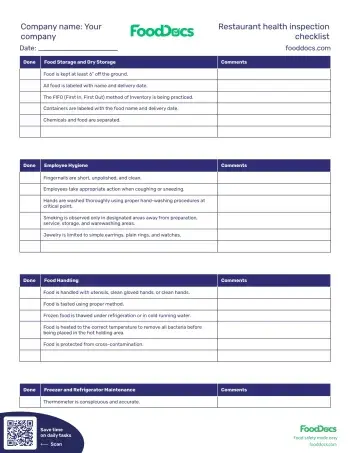

Download your Restaurant Health Inspection Checklist

SOPs enable customers to get the same experience regardless of when they visit because tasks like recipes or cleaning routines get done the exact same way by every employee. This builds trust and prevents mistakes before they even happen.

Clear SOPs, especially when delivered digitally with visual instructions, are a safety net that catch errors early by walking staff through the correct steps. This is especially helpful when training new staff. Instead of learning through trial and error, new hires can view an SOP and know exactly what to do. This speeds up training big time and makes people feel more confident faster.

For everyone on your team, clear procedures set clear expectations. And because people know what "right" looks like, there's accountability built in that results in serving safe, high quality food every single time.

What are examples of food handling and safety SOPs?

A restaurant typically needs SOPs for all the key aspects of its operations. This includes both back-of-house and front-of-house processes.

Food businesses need SOPs for tons of different tasks that touch food safety. Any routine process in your kitchen that could affect safety or quality should have a standard procedure documented and stored somewhere accessible.

Here are the common ones you'll see:

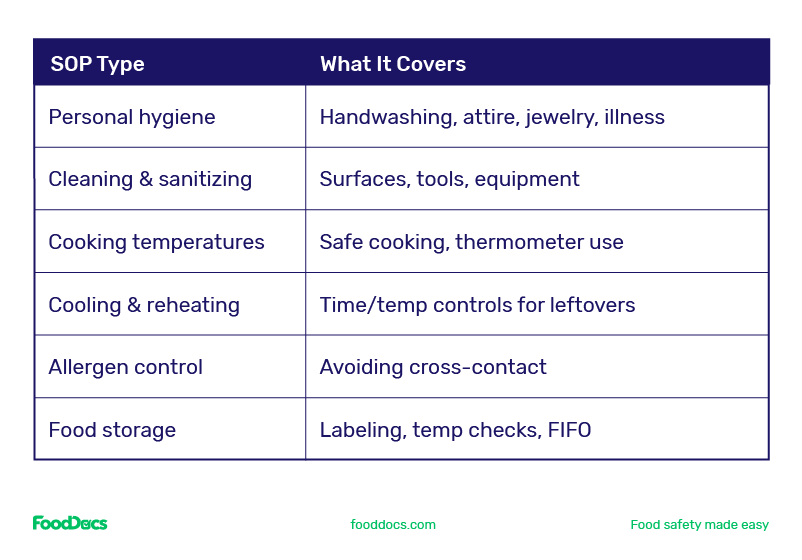

Personal hygiene SOP

This covers employee hygiene practices and includes rules about handwashing, wearing clean uniforms, limiting jewelry, and staying home when sick. All the things that prevent contamination from the people actually making the food.

Download your Hand Washing Poster

Cleaning and sanitation SOP

These include step by step instructions for cleaning and sanitizing things such as equipment, utensils, surfaces that touch food, specific rooms in your facility. It’ll answer questions like how do you clean cutting boards? How often do you run the dishwasher? What solution do you use on counters? This keeps the environment hygienic and safe.

Food storage and refrigeration SOP

This will teach staff how to safely store ingredients and leftovers and provide instructional answers to questions including where does raw meat go in the fridge? How do you label and date things? What temperature should the walk-in be? When do you check expiration dates? Storage mistakes cause a lot of problems, so businesses must offer clarity here.

Cooking and holding SOP

These SOPs include the standard steps for cooking food to safe temperatures and keeping it at safe temps until service. For example, chicken needs to hit a specific internal temp so how do you check that with a thermometer? How do you keep cooked food hot or cold while it's waiting to be served? This prevents undercooking and temperature abuse.

Cooling and reheating SOP

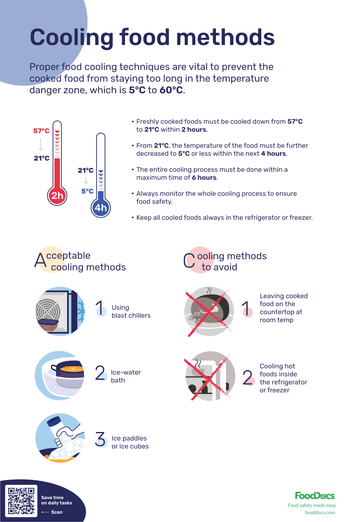

Staff will learn the directions for cooling foods quickly (e.g., the two-stage cooling method) and reheating them safely. You might use shallow containers, ice baths, or blast chillers for cooling. For reheating, there are specific temps and timeframes you need to hit. These prevent bacteria from multiplying during those vulnerable periods of time and temperature control.

Download your Cooling Food Poster

Allergen control SOP

Give staff clear and concise instructions on how to prevent cross-contact with food allergens. Things like using separate equipment for allergen free orders, labeling allergenic ingredients properly, and cleaning protocols that remove allergen residues. With food allergies on the rise, superior allergen management is becoming more critical every year.

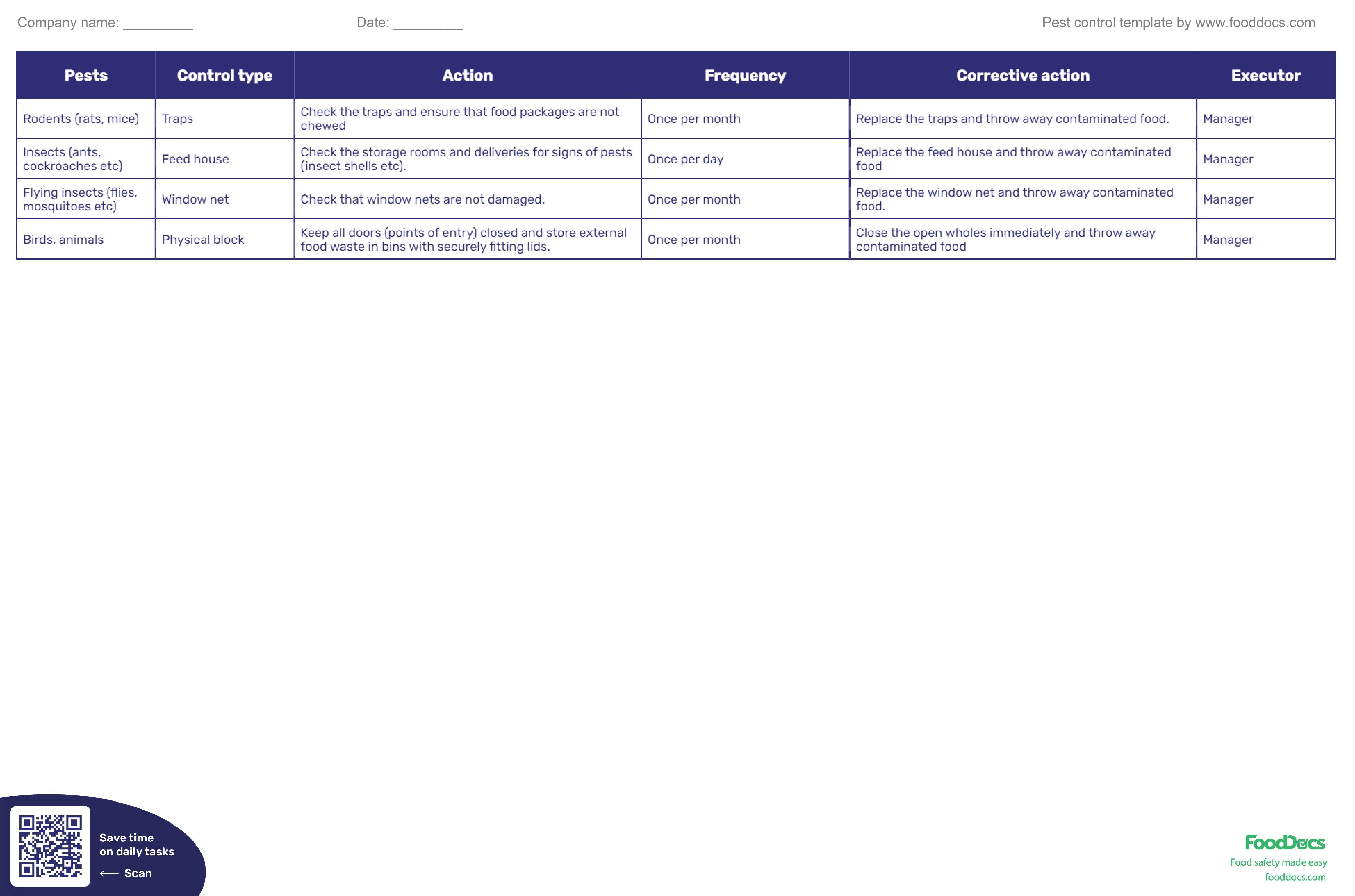

Pest control SOP

These steps for keeping rodents and insects out include detailed instructions on how to conduct regular inspections, keep doors closed, perform proper waste storage, and what to do if you spot signs of pests. Nobody looks forward to thinking about restaurant pest control, but strong awareness of pest management will keep you in control of potential problems.

Download your Pest Control Template

Waste management SOP

This will teach staff how to safely dispose of food waste and garbage including: handling grease, taking out trash regularly, cleaning trash bins so you don't attract pests or create odors, keeping a waste management schedule. Waste management isn’t glamorous work, but it's necessary to achieve and maintain high safety compliance standards.

Those are the most common examples. Food and beverage operations like restaurants, hotels, caterers, care homes, retail or food-to-go operations often have way more SOPs covering everything from kitchen work to customer service. Anything that impacts safety, cleanliness, or quality deserves a documented procedure.

The pattern here is simple: any repetitive task that matters should have an SOP so it gets done correctly and consistently.

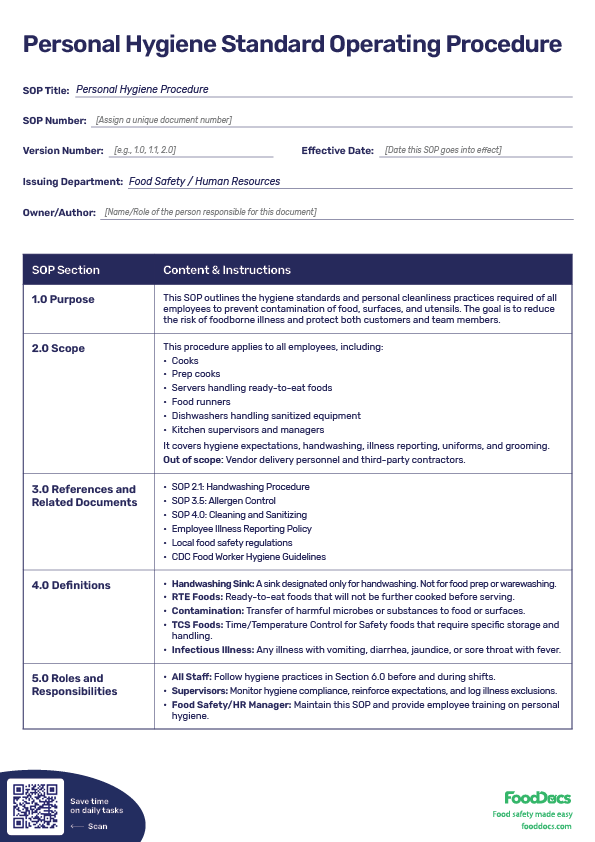

What should a personal hygiene SOP include?

Personal hygiene is one of the most important SOP categories because food handlers can easily introduce contamination if they don’t practice proper food safety. People naturally carry germs, so a personal hygiene SOP needs to clearly spell out how employees maintain cleanliness and health while working.

Download your Personal Hygiene SOP

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Here's what should be covered:

Health and wellness

Employees should show up to work healthy. If you're sick or experience symptoms such as vomiting or diarrhea, then stay home.

Employee health and illness SOP example

- Do not come to work if you have vomiting, diarrhea, fever, sore throat, or jaundice

- Report any illness symptoms to a manager immediately if they develop during a shift

- Sick employees must be excluded from food handling until cleared

- Managers must log all exclusions and return-to-work approvals

- Any open cuts or wounds must be covered with a bandage and a glove

Clean attire

People should wear clean uniforms or work clothes each day, and aprons should get changed whenever they're dirty. This prevents spreading germs from dirty clothes to food.

Uniforms and attire SOP example

- Wear clean clothing or uniforms at the start of each shift

- Change aprons when they become dirty

- Do not wear aprons to restrooms or outside food service areas

- Store personal belongings like phones, bags, and coats in non-food areas

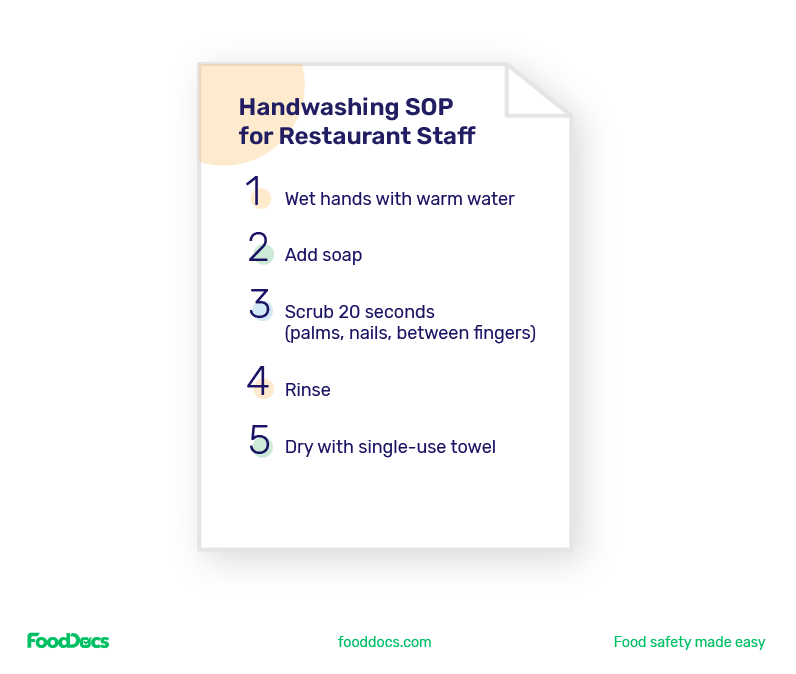

Proper handwashing

The SOP needs to spell out when and how to wash hands. “Properly” and “frequently” means after using the bathroom, eating, touching your face or hair, handling raw meat, and taking out trash.

Proper handwashing requires warm water and soap, scrubbing for at least 20 seconds, getting under nails and between fingers, rinsing, and drying with a single use towel.

Handwashing must also occur in designated sinks, not the dish sink or the prep sink to avoid cross-contamination altogether and keep everyone safe.

Handwashing SOP example

- Wash hands before shifts and after:

- Using the restroom

- Touching face, hair, body, phones, garbage

- Handling raw meat, cleaning chemicals, or money

- Eating, drinking, smoking, or taking breaks

- Use only designated handwashing sinks (never food prep or dish sinks)

- Handwashing steps:

- Wet hands with warm water

- Apply soap

- Scrub for 20 seconds (nails, fingers, palms)

- Rinse thoroughly

- Dry with single-use towel

- Use towel to turn off faucet

- Hand sanitizer may be used only after proper handwashing — never as a replacement

Download your Hand Washing Poster

Fingernails and jewelry

Employees need short, clean fingernails. Generally staff should avoid artificial nails or nail polish because they harbor bacteria and can chip into food. If your operation does allow polish, intact gloves are required.

Jewelry should be limited, too. Usually the only thing allowed in food prep is a plain wedding band. Rings, bracelets, dangling earrings, watches, they all trap dirt and bacteria. Plus they can fall into food, which is a food safety hazard.

Jewelry and accessories SOP example

- Only plain wedding bands may be worn

- No bracelets, watches, dangling earrings, or facial piercings allowed in food prep areas

Wounds and illness

Any cuts or sores on hands must get bandaged and covered with a glove on top. Staff with more serious wounds shouldn't handle food at all. Health departments are strict about this for good reason. The SOP should reinforce your employee illness policy so sick workers can focus on recovering more quickly and healthy staff and patrons can stay that way.

Hair restraints

Hair in food is one of the fastest ways to lose a customer's appetite and worse, trust. That’s why people should wear hairnets, caps, or tie their hair back to prevent hair from falling into food as part of foodservice employee dress codes. If someone has facial hair, beard nets might be required.

Hair and grooming SOP example

- Hair must be restrained with a hairnet, cap, or securely tied back

- Facial hair must be covered with a beard guard if required

- Fingernails must be short, clean, and unpolished

- No artificial nails unless gloves are worn at all times

No eating or drinking in prep area

The SOP usually reminds staff not to eat, drink, chew gum, or use tobacco in food prep areas. There should be a designated break area for that. If you need to taste food while cooking, use a clean spoon, step away from prep areas, then wash your hands.

Eating, drinking, and smoking SOP example

- No eating, gum chewing, or tobacco use in food prep, storage, or service areas

- Drinks must have lids and straws and be stored away from food and equipment

- Staff may eat or take breaks only in designated areas

When you cover all these points with the help of step-by-step instructions that include visual aids, your personal hygiene SOP makes sure each food handler maintains high standards. This protects food from being contaminated by human germs or foreign objects.

Executive Chefs, Food Safety Leaders, Operations Managers and other food industry leaders need to monitor and enforce these rules daily. Check that they’re done correctly and coach staff who slip up. When everyone actually follows a personal hygiene SOP, foodborne illness risk drops significantly.

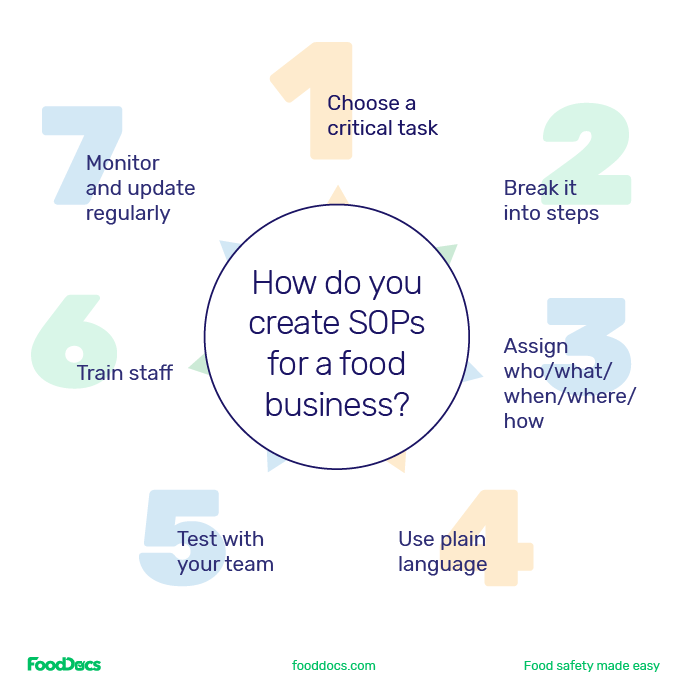

How do you create SOPs for a food business?

Creating an effective SOP doesn't have to be complicated. You're breaking down each important task into clear, doable steps. Here's a simple process that works:

1. Identify key tasks and risks

First, figure out which tasks actually need an SOP. Prioritize things that impact food safety or happen frequently. Think about areas that require a lot of explanation or where mistakes could cause real harm such as cooking, cooling, cleaning, and handwashing. These critical processes should get SOPs first.

Unless you’re using FoodDocs, for example, to auto-generate the most popular food industry Standard Operating Procedure documents, you can't do everything at once, so start with what matters most for your specific operations.

2. Record the steps (who, what, how, when, where)

For each task you've chosen, outline the steps with both text and photos or videos. Be specific about who's responsible, what materials or tools they need, when and how often it happens, where it takes place, and how to do it correctly. You're creating a set of written and visual instructions that anyone could follow, even someone brand new.

Include enough detail including visual aids so there's no guesswork, but keep the language simple. For example, an SOP for sanitizing a work table should list at minimum:

- Who does it (e.g., night shift cook)

- What to use (e.g., specific cleaning solution and cloth)

- When (e.g., after each service or every 4 hours)

- Where (e.g., all kitchen prep surfaces)

- How (e.g., exact steps to wash then sanitize the table)

- Why (e.g., to kill germs and prevent cross contamination)

The why gives people a reason to care about following the steps correctly.

3. Make it easy to follow

Good SOPs are short and straightforward so use plain language. Consider bullet points or numbered steps so it's scannable. If it helps, add visual aids like photos or diagrams. For example, show the proper way to store food or position a meat thermometer.

The easier an SOP is to read and understand, the more likely your team will actually use it. FoodDocs gives you the ability to add custom visuals to each task’s built-in instructions.

4. Involve your team

Get input from the employees who’ve performed the tasks that you’re drafting the SOPs for, whether at their current place or work or previous companies. There’s a good chance they know the ins and outs of certain SOP checklists and can tell you if something in your written procedure won't work in real life.

Once you have a draft, have a couple staff members test it by following the steps exactly. This shows you what's unclear or missing. Involving the team at this stage also gets their buy-in. People are way more likely to follow procedures they helped create or improve because it makes them feel invested.

5. Train everyone and implement

The next step is rolling it out the SOP. Hold a training session or show-and-tell for your staff about the new SOP. Explain the purpose and physically walk through the steps together. It's crucial that everyone understands the why behind it.

For example, "We cool chili this specific way to keep it out of the danger zone and prevent bacteria growth." When people understand why a step matters, they're less likely to skip it during a foodservice rush.

Provide access to the physical or digital SOP. In the FoodDocs mobile food safety app, for example, SOPs can be attached to every task as visual step-by-step instructions. Post it where it's handy if appropriate, like a handwashing SOP near the sinks. New employees should learn these SOPs during onboarding.

6. Monitor and enforce

After implementation, keep an eye on how things are going. Managers should monitor that employees are actually following the SOP in daily work. This could be as simple as observing shifts or doing occasional spot checks. Like checking if refrigerator logs are filled out properly.

Food safety monitoring software makes these insights possible because Food Safety Leaders and Executive Chefs can see exactly which tasks are being missed or incorrectly filled with the help of real-time activity logs across one or many locations.

If someone isn't following the SOP, find out why. Do they need a reminder? Is there an obstacle making it hard to follow? Consistent enforcement and positive reinforcement help turn SOP steps into routine habits that stick.

7. Review and update regularly

An SOP is not written in stone, it’s a living document. Schedule a regular review semi-annually or whenever you make a big change in your operation. Ask yourself if the SOP is still accurate and effective. If you get new equipment, new ingredients, or if regulations change, you might need to tweak your SOP. Digital checks that keep getting missed or filled incorrectly might also signal that the current SOP in circulation is unclear.

Also, collect feedback from your team over time. Maybe they found a better way to do a step that should be incorporated. Updating the SOP keeps it useful instead of letting it become an outdated pile of paper sitting in a binder collecting dust. Following these steps will help you build SOPs tailored to your food business that actually work in practice.

Remember, a food industry SOP is there to help your team and make operations smoother. Keep them user-friendly. Once they're in place, good SOPs save time, reduce mistakes, maintain compliance, and give you peace of mind that important tasks get done right even when you're not watching.

If writing from scratch feels overwhelming, try FoodDocs with a 14-day free trial or find templates and examples, and adapt them to your needs. The key is to just get started with one important process and keep improving from there.

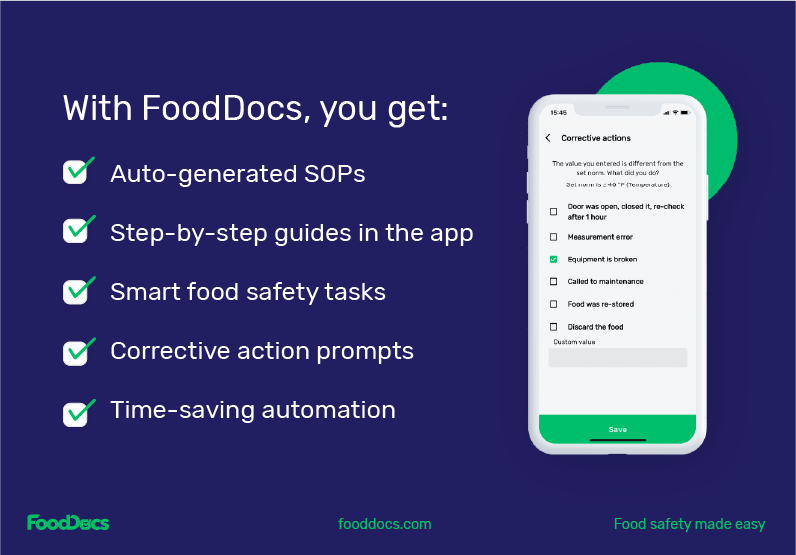

How can FoodDocs help you manage food safety SOPs?

Manually creating and tracking SOPs can be a lot of work, especially as your business grows. That's where solutions like FoodDocs' food safety management software comes in handy.

FoodDocs is designed to make managing food safety tasks, and the SOPs behind them, much easier. When you set up FoodDocs for your business, it will automatically generate many of the food safety documents you need, including standard operating procedures. You can customize them at any time.

Once your SOPs and monitoring tasks are in the system, FoodDocs shines in daily use. The mobile app makes filling daily tasks easy for your staff. It provides educational step-by-step instructions with the option for visual aids for each task right on their smartphone, which are essentially summarized SOPs at their fingertips.

Leadersrship gets a real-time dashboard to see what's been done and what's overdue, so nothing falls through the cracks and they can address food safety incidents immediately. This level of automation and oversight means you don't have to chase paper logs or wonder if a procedure got skipped.

Businesses using FoodDocs have reported saving significant time on routine food safety checks. Up to 2 hours every day saved on logging and monitoring tasks just by going digital. That's time you or your staff can spend cooking great food or serving customers instead of shuffling paperwork.

Frequently asked questions about food industry SOPs

What SOPs should front of house teams follow?

Front of house staff like servers, hosts, and runners might not handle food prep, but they still play a big role in food safety and guest experience. Their SOPs focus on hygiene, cleanliness, and proper service steps.

Some examples include:

- Hand hygiene before delivering food or beverages

- Proper handling of utensils, glasses, and napkins

- Cleaning and resetting tables between guests

- Reporting spills or broken items right away

- Knowing how to respond to allergen or food safety questions

These SOPs help keep the dining environment clean, reduce cross contamination risk, and support safe service. Like kitchen SOPs, they should be clearly written and part of regular staff training.

Where should SOPs be stored or displayed?

SOPs need to be easy to find and follow. Some belong in training manuals, others should be posted near the task location.

Here's a helpful rule of thumb:

- Mobile SOPs: use digital tools like FoodDocs to serve instructions in real time

- Training SOPs (like onboarding guides): keep in a shared digital folder or binder

- Daily use SOPs (like handwashing, fridge checks): post on the wall near the station

Wherever they live, SOPs should be kept clean, up to date, and easy to follow. Whether that's on paper or in an app.

How often should restaurant SOPs be reviewed?

You should review restaurant SOPs at least once a year or anytime there's a major change in your operations. This includes switching suppliers, updating equipment, or changing menu items.

You'll also want to review SOPs after a health inspection or if an issue occurs, like a food safety violation. Keeping SOPs up to date helps your staff follow the right steps and keeps your business compliant.

Do health inspectors check SOPs?

Yes. Many health inspectors ask to see written SOPs, especially for food handling, cleaning, cooling, and personal hygiene. SOPs show that your food business takes food safety seriously and has a consistent plan to follow regulations.

While not always legally required, having SOPs ready can speed up inspections and show that you're managing risks properly.

What's the difference between an SOP and a checklist?

An SOP explains how to do a task and a checklist is used to confirm that the task was done. For example, your SOP might explain how to sanitize food prep tables step by step. A checklist would be used to record that the sanitizing happened and was done correctly. They work together. The SOP guides the action, and the checklist tracks the completion.