PRODUCT SPEC SHEET TEMPLATE FOR FREE

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

How to use a product spec sheet template for food safety

Feel free to use our free product specification sheet template to satisfy customers' product requirements and boost sales with an established food product.

Follow these steps to use our product spec sheet template:

- Complete the template. Enter the product information, edit all applicable fields, and add more when needed.

- Attach the product's image. All important information is preset in the template.

- Enter a valid email address

- Click "Download."

The generated product spec sheet should then be in the downloads folder. It's free.

For a more complete and intuitive solution, learn about our smart Food Safety Management System at the end of this article.

How to create product specification sheets that ensure food safety and quality

Food business managers are responsible for product specification sheets for employees, potential customers, and food authorities. It is one of the important documents on what food manufacturing businesses need to cover in their HACCP plan. A product specification sheet is an ideal tool that gives everyone an idea of what to expect from products.

Key points covered in this article:

- Product specification refers to the quality and safety characteristics of a particular product.

- A product specification template is a document that contains important information and exact requirements about a product, the process involved in making it, and safety standards and details.

- Customers and legal authorities require product specification sheets as proof that a product follows food safety regulations and is of good quality.

- An accurate product specification sheet can help businesses maintain consistent quality, safety, supplier relations, and cost control.

- A food product specification sheet should be communicated to the team through proper documentation, training, internal communication, and visual aids.

- FoodDocs' smart Food Safety Management System can create templates for product specification documents that contain all the necessary information needed for a complete document.

WHAT WE'LL COVER:

- What is product specification?

- What is a product specification form?

- What is the importance of an accurate product spec sheet?

- What should be on a product specification sheet?

- How to enhance food safety using product specification sheets?

- When to use a food specification manual?

- How to effectively communicate product specifications to employees, customers, and authorities

- Digitizing product specification sheets for food safety monitoring

What is product specification?

- Physical characteristics. Include acceptable quality parameters based on dimensions, weight, color, and materials used.

- Product performance criteria. Include the specifications on the product's durability, shelf-life, and other measurable factors.

- Safety and quality standards. Add any relevant industry or regulatory standards that the product must adhere to, ensuring its safety, reliability, and compliance with applicable guidelines.

- Packaging requirements. Mention specifications regarding the material, dimension, labeling, and shipping instructions of the packaging material.

- Product tests and analysis. Attach guidelines for product testing, quality control, and certification processes to ensure that the product meets the specified standards and requirements.

Product specifications provide a common understanding of the product's characteristics which are communicated throughout a food business.

What is a product specification form?

A product specification form, otherwise known as a product data-sheet or sometimes a product information sheet, is a concrete document that contains the summarized key specifications of a product. It serves as a reference guide for customers, distributors, retailers, and other stakeholders who need quick and essential information about the product.

This crucial document is usually built into the development process and contains answers to the following questions:

- What must be built? (Nature of the product)

- What should this product be used for?

- How is success measured? (Quality parameters)

- Who is this product for? (Target market)

- What value will it bring the business?

A well-rounded product specification sheet must be clear, concise, and accurate when providing a detailed product description. This document control is sometimes called a food product spec sheet, finished product specification, or quality specification.

A product specification sheet can be applied not only to finished products but to raw materials as well. It must contain the standards and the actual values obtained from specified quality tests and the product's design, features, materials, dimensions, performance characteristics, and any specific requirements or standards that need to be met.

The purpose of a product specification form is to ensure clear communication and understanding between different stakeholders involved in the production and distribution of a product.

When to use a food specification manual?

A food specification manual is a compilation of product specification sheets. In a way, this manual is a food company's recipe management tool that contains all of its key ingredients, processes, and safety protocols for particular foods. A comprehensive food specification manual can be used for the following operations:

- Product development. A food specification manual serves as a comprehensive guide for formulating new food products. It outlines the desired ingredients, their specifications, and the required processing methods. It can be used as the basis for previous trials that have already been done before.

- Supplier selection. With the manual's clear definition of the desired quality and safety requirements, it would be easier to identify suppliers that meet the specified standards. It acts as a reference for comparing supplier capabilities and assessing their compliance with regulatory and industry-specific requirements.

- Safety and quality control. The specification manual is an integral tool for managing food safety. It contains food safety guidelines, hazard analysis, and sanitation procedures related to a product. The manual can help maintain consistency concerning the safety of a product.

- Stakeholder communication. The manual serves as a means of effective communication between suppliers and customers. It establishes clear expectations for ingredient quality, specifications, and safety protocols.

- Audits and inspections. Food specification manuals promote continuous improvement within the organization. They can be used as the basis for inspections whose results can then be used for further improvement.

All food businesses would benefit from having a comprehensive food specification manual. This document can help improve communication among all participants in the food supply chain and have an equal understanding of a product's accurate specifications.

What is a product spec sheet in manufacturing?

In a food manufacturing setup, a product specification sheet can be used by production process personnel and quality assurance specialists as the basis for the minimum quality parameters of a product.

It serves as a guide for the manufacturing product team to ensure consistent and accurate production and quality control.

A product spec sheet in manufacturing usually contains the following information:

- Bill of materials or the list of ingredients, materials, and equipment to be used

- Manufacturing processes or workflow description

- Quality standards and parameters

- Testing procedures

- Packaging and labeling specifications

- Production timeline and projection

A product spec sheet in manufacturing helps streamline operations, minimize errors, and facilitate effective communication between different departments involved in manufacturing, such as engineering, production, quality assurance, and logistics.

One business can have tons of product specification sheets, and the best way to manage them is to use FoodDocs' Food Safety Management System. Using our smart solutions, businesses can get a digital database where they can upload and manage all food product spec sheets digitally. In addition, our software features other AI-powered solutions that you can use to improve your food safety system.

What is the importance of an accurate product spec sheet?

An accurate spec sheet facilitates consistent and high-quality production. Food businesses use this document to have a uniform understanding of how a product should look or perform.

A complete product spec sheet can help businesses evaluate different product options, conduct testing and certification, and address any concerns during manufacturing.

Specifically, here are key operations and business functions that a product spec sheet can help you manage better:

- Product development process. In the early development stages of a product, a product specification sheet is important to remind the product development team and to effectively communicate technical details, such as what the product is, who it is for, and what should be the product's value.

- Food quality. The team can always use the technical document for verification procedures for any important detail about the product. Specifications may be about color, consistency, or any potential defects of the product to monitor. Quality specifications mostly inform the customer about the ingredients of each product and its condition of production.

- Food safety compliance. An accurate product spec sheet helps ensure compliance with food safety requirements. It allows manufacturers to demonstrate that the product meets safety standards, environmental regulations, and other industry-specific guidelines during the manufacturing process.

Incorrect information can sometimes cause serious public health safety issues, especially regarding food allergies.Foodborne illnesses or even death in the case of serious food allergies can arise because of misinformation.

Suppose a product has special instructions, such as the requirement to be stored in refrigerated conditions, and this information was not indicated in the product specification sheet. In that case, customers may place them at room temperature, which will cause the food to spoil.

The more accurate the information provided, especially for complex products, the higher the level of food safety for everyone. - Food manufacturing. Accurate product specifications help manufacturing teams produce products more efficiently.

Accurate specifications enable manufacturers to optimize their processes, ensure consistency, and meet production targets effectively. - Cost control. Product spec sheets help control costs by ensuring that the right materials, components, and processes are used during manufacturing. Accurate specifications prevent unnecessary expenses caused by using incorrect or incompatible materials or inefficient manufacturing methods.

In addition to food safety issues, mislabeling products in product specification sheets can also lead to problems related to food laws from groups of the community. A good example would be the declaration of the Halal status of a product. This matter is very crucial for Muslim consumers and other groups that require a specific compatible product to their beliefs. - Supplier verification. A food product specification template helps to ensure that food suppliers understand the exact specifications of the products being supplied. Also, what quality attributes need to be met, and what food safety controls need to be performed? It means that they can use this document as a quality standard required at the delivery on the suppliers' side.

It can be used to address issues as a product spec sheet example normally contains corrective actions in case of non-compliance.

An accurate product specification sheet is critical for maintaining quality, meeting customer expectations, complying with regulations, minimizing unnecessary costs, and optimizing manufacturing processes. It helps enhance understanding of a product, which could lead to reduced errors.

How to enhance food safety using product specification sheets?

Product specification sheets play a vital role in ensuring food safety for any food business. They provide detailed information and guidelines that will help clarify key areas in the production. Here are the critical contributions of product specification sheets in different areas of food safety:

- Traceability. By documenting information such as supplier details, lot numbers, and production dates, product specification sheets enable quick identification of the source of any quality or safety issues. The documents can be used to determine areas that may have been the source of the issue.

- Food storage and shelf life. Accurate and specific information on product specification sheets regarding storage conditions and shelf life helps maintain the quality and safety of food products. Proper storage instructions, including temperature ranges, moisture levels, and packaging requirements, ensure that products are stored under appropriate conditions to prevent spoilage.

- Food allergen management. Product specification sheets should clearly indicate the presence of common allergens, potential cross-contamination risks, and proper handling instructions. This information enables effective communication across the supply chain and ensures appropriate labeling and segregation practices.

- Food recall. In the unfortunate event of a product recall, having detailed product specification sheets is invaluable. These sheets serve as a reference for identifying affected products by matching batch numbers, production dates, or other relevant identifiers. This facilitates efficient and targeted removal of affected products from the market, protecting consumer safety.

- Food sanitation. Product specification sheets can outline sanitation requirements, including cleaning procedures, sanitizing agents, and frequency of cleaning. Clear instructions in the product specification sheet contribute to consistent sanitation practices and help meet regulatory requirements.

Well-written product specification sheets are essential documents needed for comprehensive food safety plans, such as a HACCP plan. They are clear instructions and complete guidance documents for particular food products in the business.

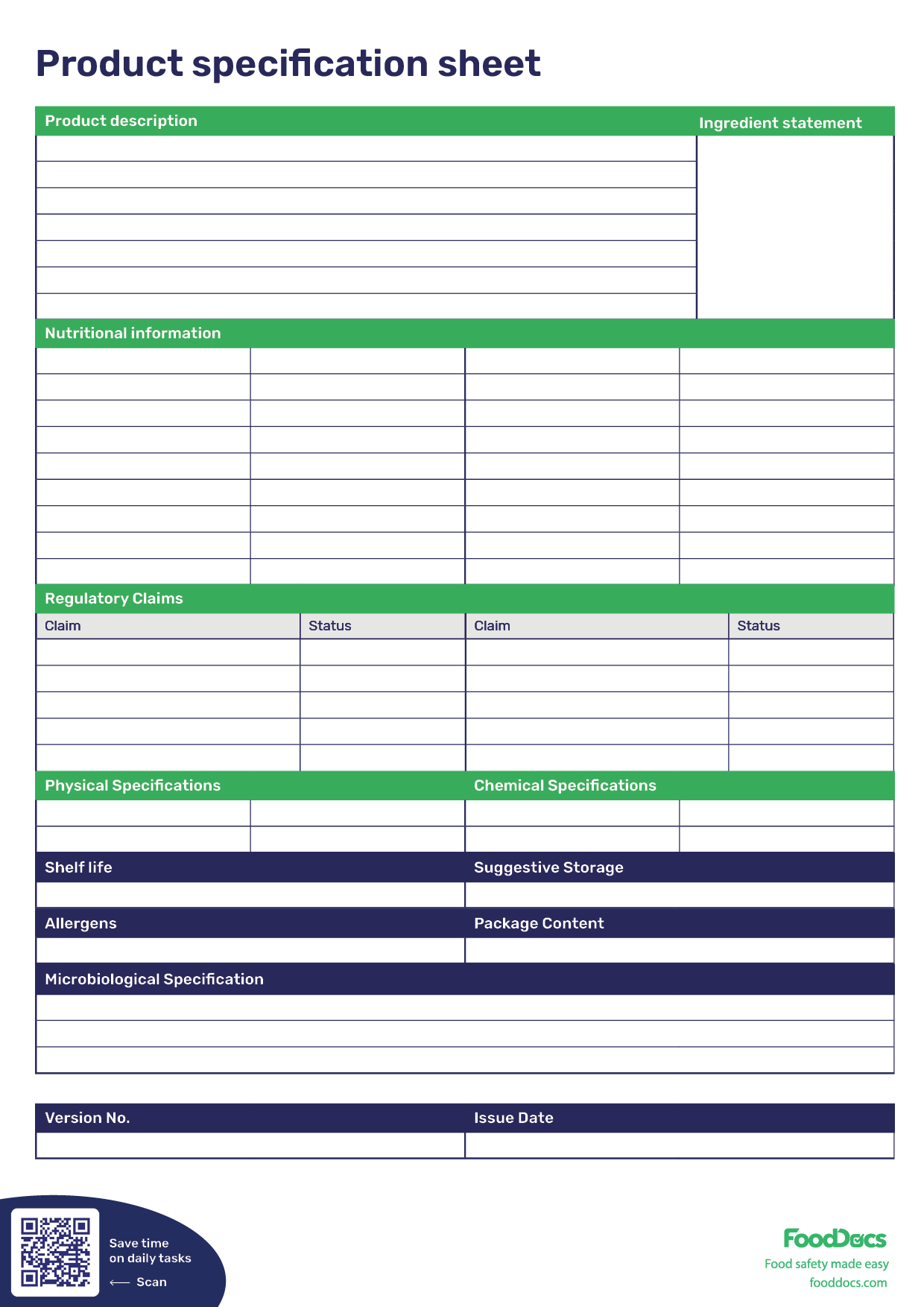

What should be on a product specification sheet?

Product specification sheets need to cover all important details, such as product color, flavor, texture, and tolerances for specific defects. A product spec sheet also must contain specific notifications such as the presence of allergens, potentially toxic compounds, or ingredients that might require regulations for immunocompromised individuals.

The document must indicate any fortification, preservative, or sometimes even special production process used to make the product.

We have listed some of the most commonly indicated information in a food product specification sheet for most types of food businesses.

1. General information about the product

-

- Product name and technical description

- Reference photos of the product

- Target consumer

- Brand or manufacturer details

- Country of origin, country of sale

- Product code

2. Quality-related information

-

- Sensory characteristics of the product (e.g., color specifications, consistency, odor, flavor, and texture)

- Processing methods

- Size or weight of units

3. Ingredients

-

- List of all main ingredients, including additives and preservatives

- Allergen information

- Nutritional content

4. Packaging specifications

-

- Intended storage parameters

- Unit price

- Design details

- Packaging materials used

- Packaging dimensions

- Shelf-life

- Proper storage requirements

-

- Indication of dietary appropriateness for vegetarian, vegan, coeliac, lactose intolerant, nuts, and peanut allergy sufferers, halal, and kosher.

-

- Physical, chemical, and biological tests done

- Compliance with food safety regulations and certifications (e.g., FDA, HACCP).

- Organic, Non-GMO, or other specific certifications, if applicable.

Remember that these are the most common ones. We always suggest consulting with local authorities to find out local food safety requirements that apply to the food business. Other product specs may also contain material handling procedures, HACCP specifications, and other related documents.

How to write a product spec sheet example?

Product specs are usually made even before actually making a product and are improved and updated through a series of meetings and trials.

However, some businesses may have only recently started creating their product specification sheets. This is often due to regulatory and legal requirements in their respective locations.

Here are 10 easy steps to making a product spec sheet for food products:

Step 1. Create a document outline

List the structure of the product spec sheet. This type of document can be tailored according to the necessary information needed for production. Additionally, consulting with the local health department is a great idea if they require a standard outline.

This step requires collaboration from other departments of a business. Gather which information is important for the safety and quality of the product and add them to the outline.

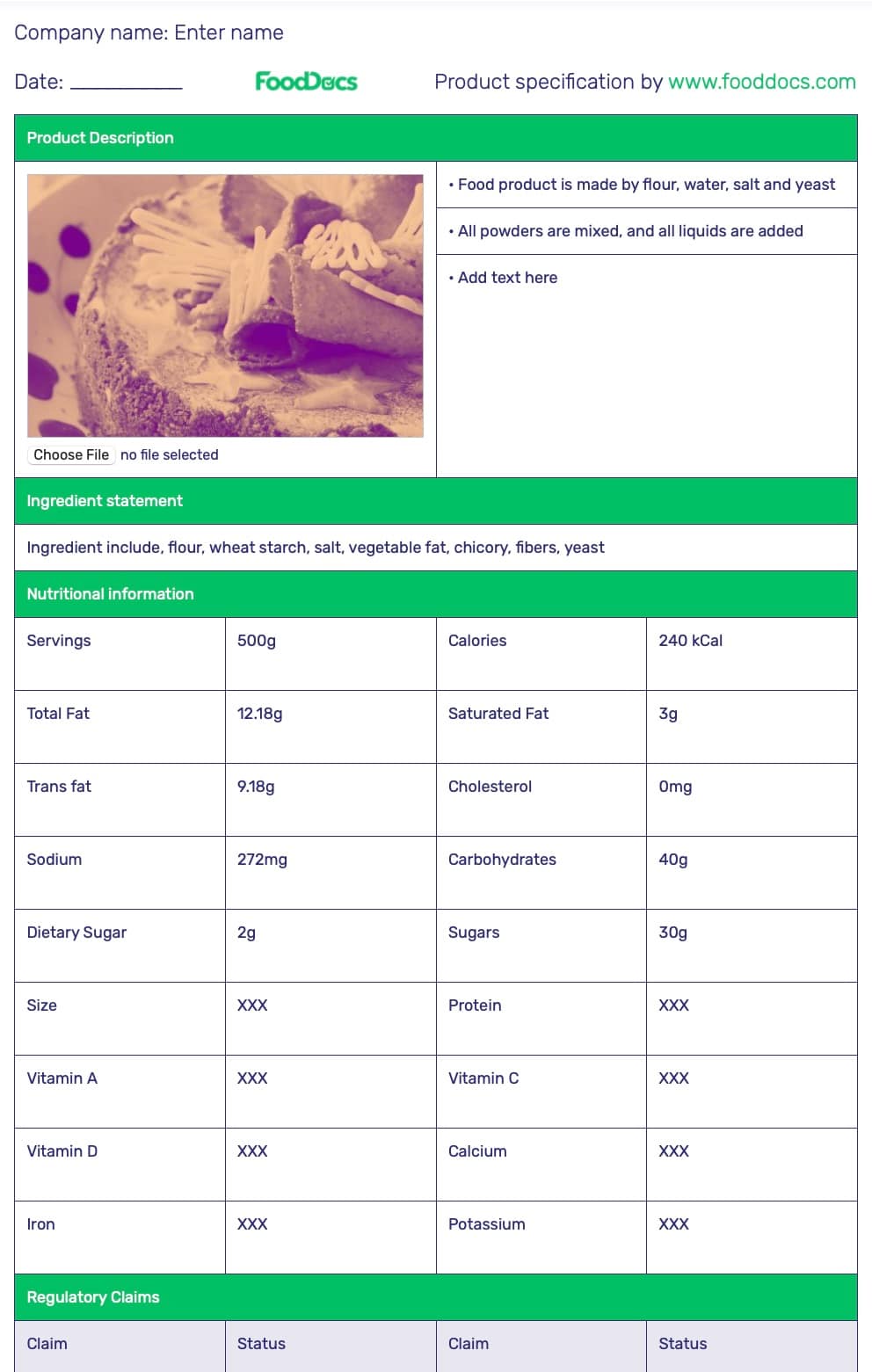

Step 2. Write the product information

Start by listing the product's name and a brief description of its purpose. Include in this step the brand name and other essential information about the manufacturer.

Step 3. Describe the product's physical specifications

Under this step, describe how the product is supposed to look like. For physical product features, make sure to include concrete, definitive words that the team can understand.

This section can be more understood when images of the product are attached.

Step 4. List the product's ingredients

List all of the necessary ingredients used to make the product. This section may also contain alternative ingredients in case one is not available.

Step 5. Write the process of making the product

In this section, write a step-by-step or general description of how the product is made. A concrete product specification sheet may also include precautionary measures, corrective actions, and other supporting processes.

Step 6. Write the product's nutritional information

Provide a detailed nutritional content per serving or specified quantity. Include information about calories, macronutrients (protein, fat, carbohydrates), vitamins, minerals, and any other relevant nutritional components.

Step 7. Highlight the product's allergen and dietary information

Always list any allergenic ingredient that may be inside the product. This is a critical food safety element. Consult local health regulations regarding which food ingredients are considered major allergens for the business location.

In addition to allergen information, indicate if the product is suitable for specific dietary preferences or restrictions, such as vegetarian, vegan, gluten-free, etc. This information will help the team manage production isolation.

Step 8. Specify the product's packaging information

Describe the packaging materials used for the product, whether plastic, glass, or something particularly made for the product. Provide the dimensions and total weight of the packaging material.

Include the shelf-life or expiration date and the storage requirements of the product.

Step 9. List the product's certifications and compliance documents

Outline any certifications or compliance requirements specific to the food product, such as FDA regulations, organic certifications, Non-GMO labels, or any other relevant industry standards.

Step 10. Review and edit the document

Review the entire product specification sheet for accuracy and completeness. For this step, seek the help of other departments to determine if all information is actually correct.

Product specification sheet example using a free template from FoodDocs

How to effectively communicate product specifications to employees, customers, and authorities?

The key to effectively using product specification documents is to communicate the information thoroughly to team members, suppliers, and authorities. This main objective can be achieved through the following methods:- Clear documentation. Develop a clear and concise manual of product specifications. Make sure that the used language and terminologies are understandable throughout the company to avoid miscommunication.

- Employee training. Incorporate the introduction of product specifications and their significance during employee training. Provide comprehensive training sessions that cover all aspects of the product specifications.

- Standard Operating Procedures (SOP). Use established product specifications in developing SOPs for food operations. Include clear instructions, checkpoints, and quality control measures within the SOPs to maintain compliance and meet the desired product standards.

- Internal communications. Encourage open communication and provide a platform for employees to ask questions or seek clarification regarding the specifications. This can also help the team improve product specifications.

- Visual resources. Use charts, posters, infographics, and diagrams to enhance the retention of product specifications. Use our wide range of free tools and visual aids from our Template Hub to help the team understand food safety even better.

By using these strategies, employees, suppliers, and authorities will have an equal understanding of the product's specifications in the context of their food safety management system. This can also help ensure consistent compliance with food safety regulations.

Digitizing product specification sheets for food safety monitoring

As mentioned, product specification sheets are important documents for any food business. Whether in manufacturing, food service, or retail, product specifications help standardize operations and safety practices.

In a food business, there can be hundreds of product specs to organize. This is where the efficiency of a digital Food Safety Management System software comes into play.

Use the following features to help manage and digitize product specification sheets for food safety monitoring:

- Digital product specification sheets

- Detailed instructions and smart notifications on food safety practices

- Traceability

- Real-time overview

Digital product specification sheets

Using our software, food businesses can manage all product specification sheets and communicate them seamlessly with all concerned employees. This feature can give you an overview of product ingredients while highlighting the significant allergens in every product.

Easily upload all of the existing recipes and product specifications into our system. Review processing operations, ingredient suppliers, product specifications, and active recipes for multiple products in one place. Food business owners can seamlessly digitize all specification sheets using our smart software and manage them more efficiently.

Detailed instructions and smart notifications on food safety practices

Product specification sheets are critical documents that must be clearly introduced to the entire team for uniform and better understanding. All team members must become familiar with properly handling key products that may contain allergenic ingredients.

To help food safety teams with this task, our smart software features step-by-step instructions on each monitoring log and checklist to help you train and orient food handlers on essential food safety tasks. Use these instructions for a more efficient onboarding process and introduction of your product specification sheets.

In addition, our smart solutions include a notification system that aims to help food handlers to remember the essential tasks that need to be done. Smart alerts are sent to assigned employees, reminding them of which tasks are next.

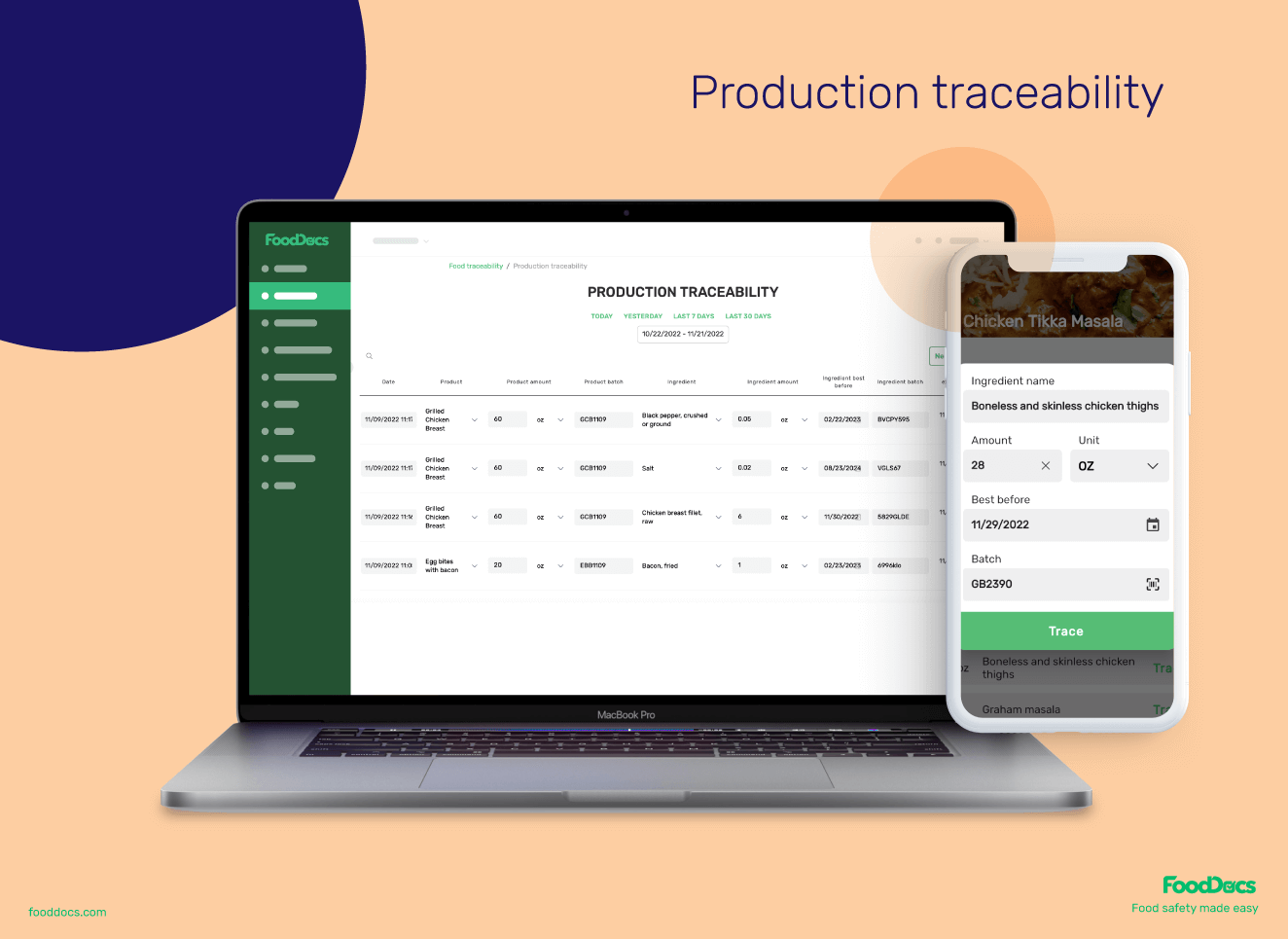

Traceability system

In addition, using our Traceability System can help quickly identify ingredients and product batches that may have food safety issues. After identifying all of the necessary ingredients from the product specification sheet, use our Traceability System to determine which batches of ingredients were used to produce a non-compliant product.

Our Traceability System automatically logs the estimated shelf-life of ingredient batches logged into the system through the product specification information. Through this feature, our system can automatically alert food handlers if a batch of ingredients is almost at its expiration date. Food safety teams can ensure that all ingredients are optimized without generating food waste.

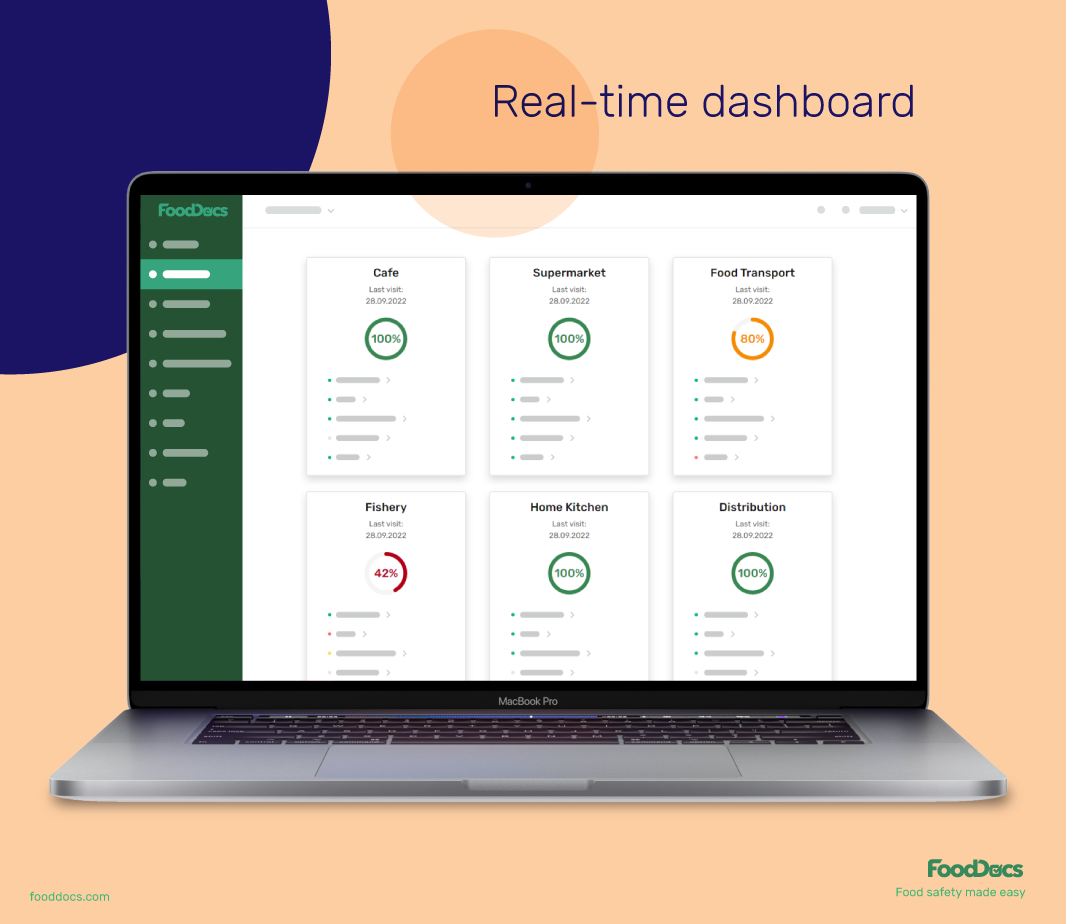

Real-time overview

Optimize the use of your product specification sheets to the fullest by using our real-time overview! Using this feature, you can easily identify key areas that are non-compliant with your product specifications.

The overview system shows which tasks are correctly done and which ones need more attention, saving you time from manually verifying tasks one by one.

This powerful feature lets food safety managers get an overview of multiple locations in one view.