Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Food traceability has been in the limelight lately and the truth is, it should always be.

The FSMA 204(d) Final Rule in particular has the clock ticking for any business that works with items on the Food Traceability List. As a result, many food companies are searching for food traceability systems that will help make food safer while supporting their business goals.

But we understand that the food industry is diverse and finding the best food traceability software can be overwhelming. So we've curated a list to help focus your efforts as you try to improve your food traceability process.

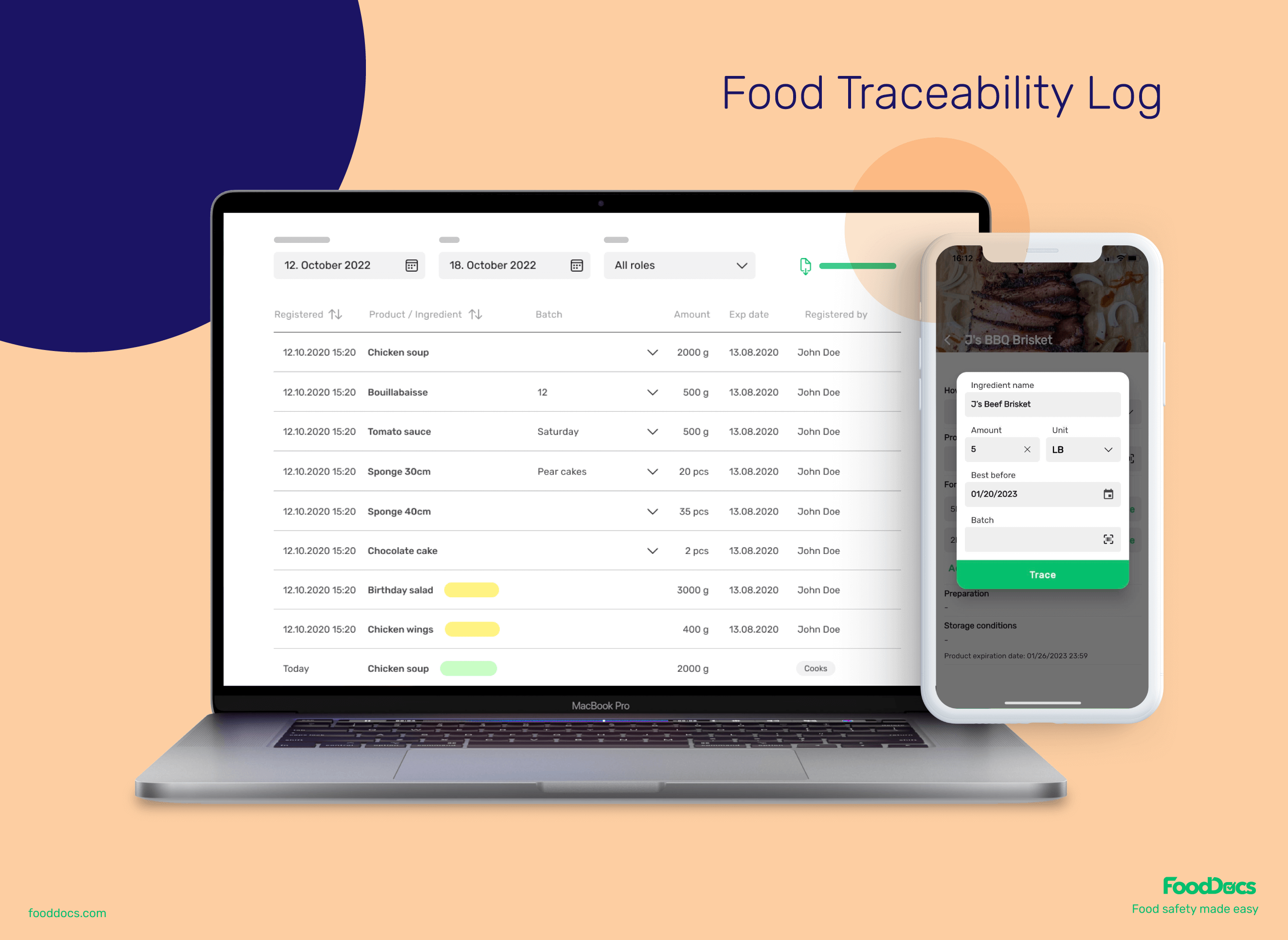

FoodDocs provides an all-in-one food traceability software tailored for food producers, processors, and distributors. The food traceability system has core features that are especially beneficial for central kitchens, ready-to-eat food production, beverage production, bakeries, butcheries, and more. It simplifies compliance with food safety regulations and ensures efficient recall management.

Free trial: 14 days

Pricing: Starting at $2999/year

Available on: Web, iOS, Android

3iVerify specializes in digital food safety compliance and traceability, particularly beneficial for small to medium-sized food manufacturers, importers, and processors. It integrates traceability into an overall food safety and quality management system, providing a seamless approach to managing food safety risks.

Free trial: Not available

Pricing: $250/month/user (according to Capterra)

Available on: Web

Kelsius provides automated food safety and compliance monitoring through its FoodCheck 2.0 system, designed for large enterprises and multi-site operations in the food service and healthcare industries.

Free trial: No

Pricing: Not available on website

Available on: Web, iOS, Android

FoodReady provides a comprehensive food traceability software solution designed for small to medium-sized food producers, processors, and manufacturers. It helps businesses manage their entire traceability process efficiently, ensuring compliance with FSMA and other regulatory requirements.

Free trial: 14 days

Pricing: Not available on website

Available on: Web, iOS and Android (depending on plan)

Check out the in-depth comparison of FoodReady vs FoodDocs.

Safefood360 offers a comprehensive traceability module designed for medium to large food producers and processors. It integrates seamlessly with other food safety management systems, making it ideal for enterprises that need to ensure compliance with stringent food safety standards.

Free trial: Not available

Pricing: Not available on website

Available on: Web, iOS, Android

FoodLogiQ is designed to enhance traceability and compliance for food producers, processors, and distributors of all sizes. It helps businesses align with FSMA 204 requirements and improve food supply chain transparency.

Free Trial: Not available

Pricing: Starting at $32,000/year (according to Capterra)

Available on: Web

Navitas Safety provides a comprehensive allergen management solution suitable for small to medium-sized food businesses, including catering, retail, and manufacturing. The solution helps manage allergens and ensure compliance with food safety standards.

Free trial: Not available

Pricing: £90/month/user (according to Capterra)

Available on: Web, iOS, Android

Check out the in-depth comparison of FoodDocs vs Navitas Safety.

JustFood ERP provides integrated traceability and ERP solutions tailored for food manufacturers of all sizes, particularly beneficial for mid-sized to large enterprises. It helps companies streamline their operations and ensure compliance with food safety standards.

Free Trial: Information not available

Pricing: $120,000/month (according to Capterra)

Available on: Web

While a single business likely won't have visibility into the entire supply chain, everyone using one of the best food traceability software solutions will help government organizations and other health authorities find recalled products in question, and even prevent future recall events.

Food traceability software enables companies to track and document the production, processing, and distribution of food products. This technology in food traceability provides a digital trail that helps producers quickly respond to safety issues, optimize supply chain operations, and ensure compliance with food safety standards.

In light of the United States' Food Safety Modernization Act (FSMA) regulations, for example, businesses need to be able to know and record where food items came from and where they went. And soon.

On this topic, Sara Bratager, a Food Traceability and Food Safety Scientist at the Global Food Traceability Center at the Institute of Food Technologists, said:

Policy plays a major role in the advancement of traceability. Effective traceability systems have proven beneficial in a myriad of ways, but those benefits are not sufficient incentives for most industry actors to take on the burden of end-to-end traceability implementation. Regulatory requirements are needed to motivate widespread adoption.

Food traceability software should be able, at the very least, to help you with:

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

The 5 benefits of using food traceability software are:

Food traceability software allows companies to quickly identify and isolate contaminated products, reducing the risk of foodborne illnesses. This proactive approach ensures that any potential issues are addressed before they reach the consumer, maintaining high safety and quality standards.

Staying compliant with food safety regulations such as FSMA, HACCP, and ISO standards can be complex. Traceability software helps maintain accurate inventory control and generates necessary documentation automatically, simplifying compliance processes and reducing the risk of non-compliance penalties.

Good food traceability software allows companies to monitor every stage, from raw materials to finished products by providing end-to-end visibility into the supply chain. This transparency helps in identifying bottlenecks, optimizing processes, and ensuring that all components meet safety and quality requirements.

In the event of a product recall, food traceability software enables companies to quickly trace and withdraw affected products from the market. This efficient recall management minimizes the impact on the business and consumers, protecting the company’s reputation and reducing potential liabilities.

Streamlining production processes through food traceability software reduces waste and enhances overall operational efficiency. By automating data collection and analysis, companies can make more informed decisions, improve resource allocation, and boost productivity.

The ability to monitor and record data in real time provides immediate insights into the production process. This capability ensures that any issues are detected and addressed promptly, maintaining continuous control over product quality and safety.

Automated alerts notify staff of potential issues or deviations from set standards as soon as they occur. This feature helps in quickly addressing problems, reducing downtime, and ensuring consistent adherence to safety protocols.

Generating detailed reports for audits, compliance, and performance analysis is crucial for maintaining high standards. Comprehensive reporting tools help companies track their progress, identify areas for improvement, and provide evidence of compliance during inspections.

From meat producers to beverage companies and near everything in between, seamless food safety integrations will allow for the efficient flow or data and movement of food products. and cohesive management of business operations. This integration ensures that traceability data complements other critical business processes, enhancing overall efficiency.

An intuitive user interface ensures that all team members, from production staff to quality managers, can easily navigate and use the food traceability software. This accessibility improves user adoption, reduces training time, and ensures that the software’s full capabilities are leveraged.

We hope the details above make your search for the best food traceability software for your business easier and more efficient.

In terms of the next steps, give food traceability tools a try if there's a free trial or book a quick demo to see how it works. This will enrich your search for the best food traceability software and allow you to make the right decision.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...