Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Food safety staff need to be able to define TCS food or Time/Temperature Control for Safety food.

TCS stands for Time/Temperature Control for Safety. The term TCS is given to foods that generally spoil faster than others. These foods can either naturally have a high initial microorganism load or have optimal characteristics for the growth of pathogens.

From the TCS food meaning, one can understand that foods under this category are significantly affected by any time and temperature control. Understanding the behavior of TCS foods may significantly help food handlers how to formulate, prepare, and serve their food products to consumers. This task is an important responsibility of both food managers and food handlers to prevent foodborne illnesses and creating food waste.

TCS foods, also known as Potentially Hazardous Foods, are a group of products that require the factors of time and temperature to control the growth of microorganisms that are related to them. In this context, time and temperature are applied to cooking as well as the storage conditions of the foods before and after processing.

Foods under this category are naturally sensitive to contaminants around them. TCS foods are called such because time and temperature are the most influential factors that determine their long shelf-life.

As a wide range of food products are served in any food establishment, improper monitoring and storage may affect shelf-life and lead to food waste due to its composition.

Approximately 1.3 billion tons of food per year is wasted. This estimation accounts for at least one-third of the foods being produced and the majority is caused by spoilage.

There several factors to consider when keeping different types of food wholesome. As a food handler, you need to consider every factor to reduce the chances of food spoilage to safe levels. Keeping food spoilage under control helps food businesses such as restaurants reduce waste and contribute to food security.

WHAT WE'LL COVER:

The sensitivity of foods toward certain harmful bacteria depends on a few major factors including:

These factors depend on the food itself, otherwise known as intrinsic factors. They can be changed based on the formulation and preparation of the foods. Naturally, the level of the mentioned factors also affects the food's sensitivity. That is, when the acidity of foods is low and the moisture level is high, they are more sensitive to pathogenic bacteria.

On the other hand, when the acidity is high and the moisture level is lower, the food is more sensitive to molds and yeasts.

Such situations are where the effects of time and temperature can be manipulated to maintain a high level of food safety. Since acidity, extra moisture, and nutritional value cannot always be changed as they may affect quality – time and temperature controls may be applied.

Perhaps the most basic rule is for food handlers to avoid storing raw ingredients and cooked foods at the temperature danger zone for foods.

As food handlers, it is your job to know what food items need time and temperature control for safety. Having substantial knowledge about what are TCS foods ensures that your team will be able to keep your food products safe for a longer time. Additionally, it lowers the risk of causing foodborne illnesses to your consumers.

Processing and food handling practices help lower the risk of TCS food spoilage. The heat and shear force from cooking ensures that the harmful bacteria in food are reduced to acceptable levels. What about raw materials? For raw foods, proper storage would be the best solution to keep them safe.

How would you distinguish TCS food from non-TCS food? If you are the food handler tasked with preparing the food, you may have the most clues on which foods are TCS. If you are not sure, keep reading.

As mentioned above, factors such as acidity, moisture level, and nutritional composition affect the stability of foods. If any food has low acidity, high moisture, and abundant nutrients, then the food is most likely a TCS.

The most common items on TCS food list include:

The examples listed above have a few things in common: high moisture content, nutrients, and low acidity (except for fruits). These examples are known to be very sensitive to contamination and can spoil quickly when the conditions are not properly controlled. Using controlled temperature for a particular amount of time can keep TCS foods safe.

Here's a longer, more in-depth list of food items that need time and temperature control for safety.

These foods contain high levels of protein and water, creating a perfect environment for bacterial growth, especially Salmonella, E. coli, and Clostridium perfringens. When stored or cooked improperly, these bacteria can multiply rapidly, leading to foodborne illnesses. Handling meat safely is critical because cross-contamination with other foods can spread these pathogens.

Food safety expert tips:

Seafood is highly perishable due to its natural enzymes and high protein content, which can accelerate bacterial and toxin growth. Pathogens like Vibrio and Clostridium botulinum thrive if temperature controls are ignored. Additionally, toxins in fish like tuna can form even without spoilage if improperly handled.

Food safety expert tips:

Eggs are vulnerable to Salmonella contamination, especially in the yolks, as bacteria can penetrate even intact shells. Improper storage or handling, like using cracked eggs, can amplify the risk. Pooling eggs in large batches for storage provides an ideal breeding ground for bacteria.

Food safety expert tips:

The neutral pH and high nutrient content in milk and dairy support the rapid growth of harmful bacteria like Listeria and Salmonella. These items also spoil quickly if exposed to warm temperatures for extended periods. Pasteurization reduces the risk, but improper storage can still reintroduce contamination.

Food safety expert tips:

The high water activity and protein in tofu and soy create an environment where bacteria such as Bacillus cereus flourish. These products are particularly risky after opening, as exposure to air and utensils can introduce contamination. Fermented soy products have reduced risk due to acidic conditions, but fresh soy must be carefully handled.

Food safety expert tips:

Cut or damaged leaves provide exposed surfaces where bacteria such as E. coli can cling and multiply. Washing alone may not fully eliminate contaminants, especially if greens were grown or processed in unsanitary conditions. Refrigeration slows bacterial growth but does not prevent contamination entirely.

Food safety expert tips:

Once cut, the protective outer layer of tomatoes and melons is breached, allowing bacteria to access the nutrient-rich interior. Pathogens like Salmonella and Listeria thrive in the exposed juices, especially at room temperature. The low acidity of melons makes them particularly risky compared to whole produce.

Food safety expert tips:

These cooked foods are ideal for bacteria like Bacillus cereus due to their moisture and starch content. Improper cooling or reheating can allow spores to germinate and produce toxins. Leftovers that are held at unsafe temperatures for too long significantly increase the risk.

Food safety expert tips:

Sprouts grow in warm, moist environments, which are perfect for bacteria like E. coli and Salmonella to thrive. Contamination often occurs during seed sprouting and can persist even after washing. The small surface area and folds in sprouts make it difficult to remove bacteria effectively.

Food safety expert tips:

The absence of acid in untreated garlic and oil mixtures creates an anaerobic environment conducive to Clostridium botulinum. If staff improperly store this type of food at room temperature, spores can germinate and produce deadly toxins. Refrigeration or acidification is essential to inhibit bacterial growth.

Food safety expert tips:

Handling TCS food entails practices in controlling time and temperature. As a general rule, food handlers must always avoid keeping TCS food at 40°F to 140°F (5°C to 60°C) or the temperature danger zone. At this temperature range, your TCS foods are more sensitive and more likely to become spoiled by surrounding pathogens. The temperature danger zone serves as the optimum bacterial growth conditions.

Ideally, TCS foods must not be kept at the temperature danger zone range for more than 2 hours. Bacterial growth is optimal at this temperature range and can spoil foods faster. Practice hot holding and cold holding of finished products and storing raw material ingredients in a dry, cool place where contamination is kept at a minimum.

The TCS danger zone temperature range is 40°F to 140°F (5°C to 60°C), which is similar to the temperature danger zone for foods. Above and below this temperature range, foods are generally safer from spoilage and potential contamination. Use our Temperature Danger Zone Poster to help your team keep in ming the correct temperatures.

Generally, all TCS foods must be left out for a maximum time of 4 hours, ideally 2 hours only, within the TCS danger zone. When TCS foods are stored in the temperature range of 40°F to 140°F (5°C to 60°C) for more than 4 hours, the foods are advised to be discarded.

Sometimes, the maximum holding time at the TCS danger zone can be lower depending on the quality and safety of the preparation. It is always a good practice to check the temperature every two hours. This operation gives you the chance to apply any corrective action if needed.

In the case of TCS foods that are under cold holding processes with constant temperature monitoring, foods can be held up to a maximum of 6 hours. If within the time frame, the temperature increases to over the TCS danger zone, then foods must be discarded. Similar to hot holding, foods can also spoil faster even when held at a low temperature depending on the initial amounts of a pathogen.

Raw ingredients that are considered TCS food must be immediately cooked within the 4-hour window if they are not stored in a controlled temperature area. The same goes for cooked and ready-to-eat TCS food that requires reheating before serving and consuming.

Several simple steps can be taken to reduce the risk of spoilage of TCS food. In this section, we give you some very important tips, directions, and standards for keeping TCS food safe for a long time.

After properly cooking foods, they can still be contaminated and spoiled by pathogens. The rate at which cooked foods spoil depends on their surrounding factors, such as their containing temperature. For foods that have been cooled and stored in the refrigerator, they must first be reheated to at least 165°F (74°C). This step ensures that any contamination that may have occurred during cooling and storage is eliminated.

Remember that reheating is different from hot holding. Never attempt to use equipment used for hot holding temperatures to reheat foods. Additionally, the heat during this step must be equally distributed within the product and must be done most efficiently. Some operations that you can do to reheat foods include using a microwave or a stovetop while occasionally stirring the dish.

Cooling TCS food, unlike warming, must be done within a prescribed time. As per the recommendation of the FDA, TCS food must be cooled from 135°F (57°C) to 70°F (21°C) in the first two hours after cooking. Afterwhich, the internal food temperature must reach 40°F (4°C) from 70°F (21°C) in the next four hours. This process is called the two-stage cooling process. The total cooling time must not exceed a total of 6 hours.

Foods under refrigeration temperatures can be stored for longer times as bacterial processes are slowed down or stopped. To maximize protection against contamination, foods must be properly stored based on their categories. This means grouping foods based on their required degree of processing. Use a fridge layout poster to identify how to properly group foods together in a refrigerator.

Cooling in the fastest way possible is important and needs to be done properly. One way that you can apply is to divide the TCS food into several smaller or wider containers. The point of this method is to increase the surface area of the food so heat can travel faster into the environment. Remember to make sure that the containers are all clean and will not cause any cross-contamination.

Another way to cool foods fast is to place the container on top of an ice bath. Continuously stirring the TCS food will redistribute the heat and allow the food to cool faster.

Thawing refers to the process of melting frozen, cold foods. During the thawing of frozen food, pathogens that may have survived processing or are naturally present in ingredients may be reactivated and continue their biological processes. That means they can make the food unsafe and increase the risk of causing foodborne illnesses.

To ensure that these pathogens in food will not be able to cause any harm, thawing must be done as fast as possible.

If you're wondering how to thaw TCS food, some of the safest ways include:

The principle behind these suggested operations is to prevent the potentially existing pathogens from gaining time to recover and cause changes to the food. Thawing foods at room temperature on a kitchen counter will not only attract pathogens but also allow the preexisting ones to spoil your food even before cooking.

Date marking is a process of assigning a date and/or time to food that is made in your food establishment and is expected to be held longer than 24 hours. TCS foods are only advised to be stored at 41°F (5°C) or lower.

This food safety regulation was specifically established by the Food and Drug Administration to prevent the pathogenic microorganism growth of cold-tolerant bacteria Listeria monocytogenes.

The potency of cold and hot holding cooked TCS food only depends on the thoroughness of processing. If the processed TCS food does not properly reach its target internal temperatures, it is still considered a highly hazardous food. The proper cooking process with the correct time-temperature combinations is also key to reaching the maximum time for keeping foods safe.

Different TCS foods have different proper temperatures and target pathogens. Use a properly calibrated food thermometer and a cooking temperature chart to ensure that you would reach the target temperature.

Fluctuations in storage temperature can significantly affect the safety of TCS food. The recommended minimum temperature must be constantly maintained if you want to maximize TCS food wholesomeness to the suggested maximum holding time.

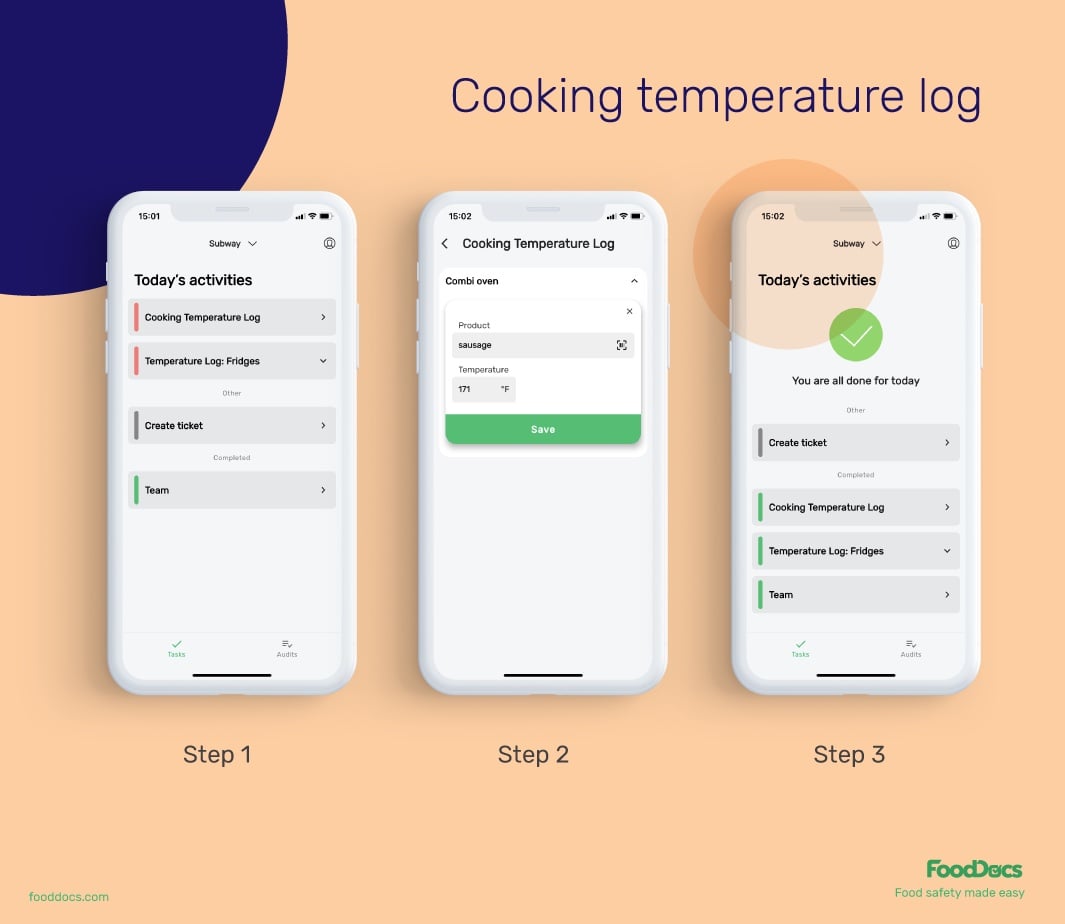

To do this, sign up for our digital food safety or always have a temperature log sheet prepared to record accurate temperature readings. This operation is part of your food safety management system and must be properly maintained throughout holding your TCS food.

Any TCS food can remain safe for consumption provided that it is maintained properly at the correct temperature within the prescribed time. Failure to protect TCS food from spoilage increases the risk of food wastage as well as causing foodborne illnesses to dangerous levels.

To help you manage TCS foods, ensure that your food safety management system is comprehensive enough for the job.

As we've explored in this article, understanding TCS food meaning is the first part of building a good food safety strategy against food spoilage and foodborne illnesses.

The spoilage of TCS food does not only pose a threat to public health but to the standing of your food business. Failure to maintain the safety and quality TCS food may significantly reduce your productivity.

Specifically, knowledge of TCS food definition and any proper time-temperature control for better food handling can help your team address the following concerns:

TCS foods are potentially hazardous. They encourage pathogen growth regardless of proper food handling. As such, their surrounding ideal conditions must be properly maintained to ensure their safety. Once spoiled and consumed, contaminated TCS food can cause foodborne illnesses or potentially an outbreak.

Spoilage of TCS food may not be very obvious sometimes. Bacteria and other harmful microorganisms that produce toxins will not often immediately produce any changes in the characteristics of the food. This type of spoilage may be very dangerous as toxins are very tolerant to processing such as cooking.

When the internal composition of the food cannot be altered to make it safe, the next best way to keep it safe is to control TCS food temperature and its time of storage.

Obviously, when foods get spoiled, they are automatically considered food waste. Spoiled foods often produce changes in their characteristics such as:

Once any or a combination of these changes occurs, TCS foods are considered spoiled. The mentioned changes are the result of nutrient breakdown caused by the existing pathogen. In conditions favorable to pathogens, spoilage can become faster.

The sooner your team figures out how to set up proper time-temperature controls for your foods and ingredients, the more foods you can save from becoming wasted. Reduced waste means your ingredients are optimized and converted to profits properly.

The growing concern regarding the sustainability of food supply is also significantly affected by the spoilage of foods. As such, TCS foods are the target of many studies that are related to keeping them safe for a long time.

Keeping raw ingredients and cooked foods wholesome ensures that communities are fed and that supply is constant. The uninterrupted supply of food in an economy ensures the productivity of the workforce.

But how do you approach TCS foods in a way that sets your business up for successful compliance?

Time and temperature are two of the most significant factors for food safety. Whether the operation is cooking, storage, delivery, or receiving process, the time and temperature of both foods and the surrounding environment will affect their safety.

The problem that all food businesses face — especially as they scale — is that if every operation in your food establishment requires maintenance of any time-temperature condition, you quickly begin to drown in monitoring forms, data, and temperature readings.

A traditional food safety management system would compel you to use paper-based monitoring procedures that are not sustainable in the long run and increase risks of damaged or lost food safety records.

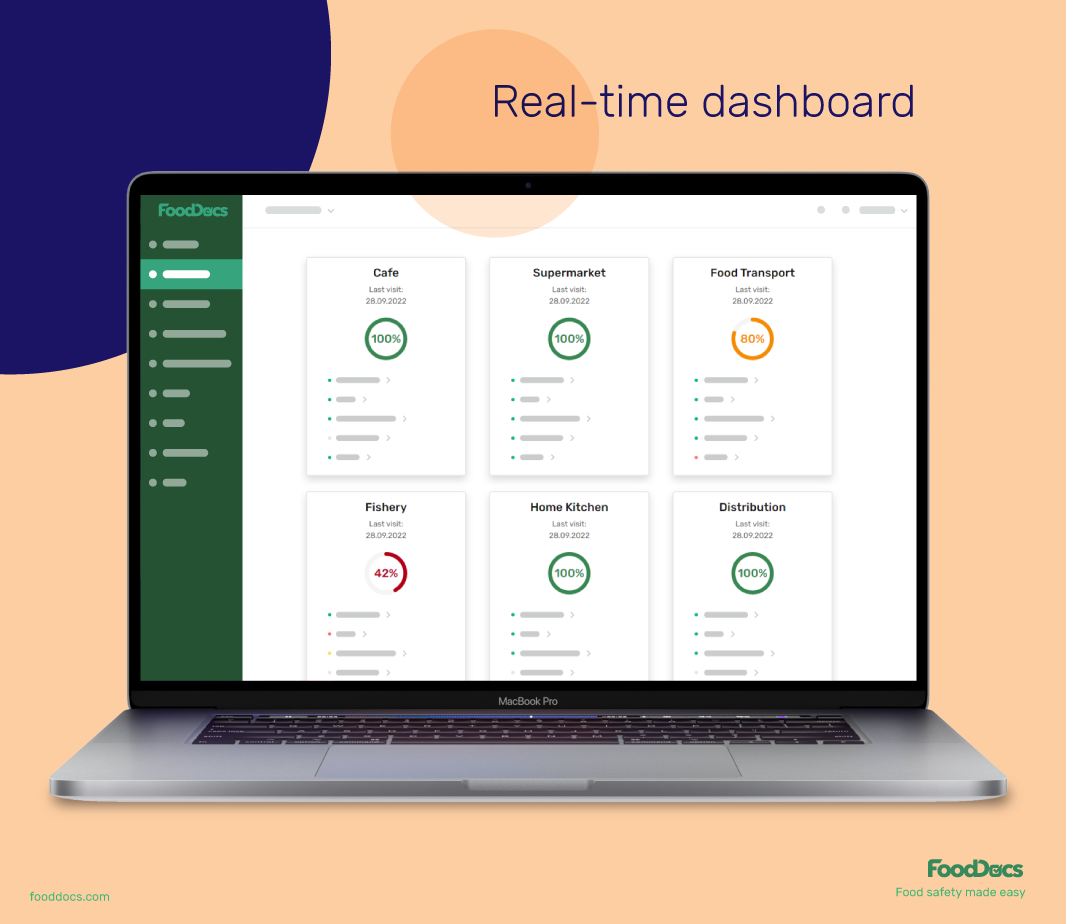

What FoodDocs' digital Food Safety Management System does is quickly transform traditional paper-based systems into digital solutions, making it easier for teams to stay compliant with food safety standards, from monitoring to traceability.

Here are just some of the features you'll get with our food safety software:

Want to experience these benefits first-hand? Start your 14-day free trial today and get your food safety system set up in 15 minutes!

TCS stands for Time/Temperature Control for Safety. These foods require controlled time and temperature settings to prevent the growth of harmful microorganisms that could lead to foodborne illnesses.

Generally, bread is not considered a TCS food because it has low moisture content, which does not support rapid bacterial growth. However, bread with perishable fillings or toppings may require temperature control.

Bread is not a TCS food. This type of food, although low in acidity, has very low moisture content. As such, bread is very stable even in ambient temperatures. Also, foods such as powdered milk, dried beans, and uncooked rice are not considered TCS foods.

Foods that do not need temperature control typically have low moisture, high acidity, or low nutrient content, such as whole fruits and vegetables, dried grains, and certain canned or shelf-stable items.

The most common way to protect TCS foods is by maintaining them outside the temperature danger zone (40°F to 140°F) and using proper refrigeration, cooking, and holding temperatures to limit bacterial growth.

To reduce pathogens to a safe level, TCS foods should be cooked to their appropriate internal temperatures and held at these temperatures for a specific time as recommended by food safety guidelines.

After heating to 165°F in a microwave, TCS food should be allowed to stand for at least 2 minutes. This standing time helps distribute the heat evenly to ensure all parts of the food reach the necessary temperature.

Cooked TCS food must be cooled from 135°F to 70°F within two hours, and then from 70°F to 41°F or lower within an additional four hours, totaling six hours for the complete cooling process.

Hot TCS food must be held at a temperature of 135°F or above to prevent bacterial growth.

The maximum receiving temperature for most TCS foods is 41°F. However, live shellfish, milk, or shell eggs can be received at a maximum of 45°F under the condition that they are cooled to 41°F or lower within four hours.

Typically, non-TCS foods are those that don't require refrigeration to prevent bacteria growth, such as bread, whole fresh produce, and items with high acidity or low moisture. You would need to specify the list for a specific answer on which item is not a TCS food.

Leftover TCS food should be consumed or discarded within seven days of preparation if held at 41°F or lower. It's important to label and date the leftovers to ensure they are used within this safe timeframe.

Ready-to-eat TCS food stored at a temperature of 41°F or lower must be sold, consumed, or discarded within seven days. The date marked should be the date by which the food must be used or discarded, not necessarily sold.

The FDA’s recommended safe refrigeration temperature for TCS foods is 41°F or below. However, 40°F is often used as a guideline to provide an additional safety margin.

Milk should be stored at or below 41°F (5°C) to slow bacterial growth and maintain freshness.

Milk can typically last 7–10 days in the fridge after opening if stored at or below 41°F, although this can vary based on factors like pasteurization and handling.

Shellfish tags are documentation required by food safety authorities that trace the origin and harvest location of shellfish. These tags must be kept on file for 90 days after the shellfish are used, aiding in traceability and safety.

Shell eggs are whole eggs in their shells, commonly used in cooking. They are considered TCS foods and require proper storage and handling to reduce the risk of Salmonella contamination.

Pooled eggs refer to eggs that have been cracked open and combined in a container. This practice requires extra care, as pooling increases the risk of bacterial contamination if not properly managed and immediately refrigerated.

Yes, tofu can go bad, especially if stored improperly. Fresh tofu should be refrigerated and used within 3–5 days of opening, as it is a high-moisture, protein-rich food that supports bacterial growth.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...