Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Controlling FATTOM factors is one of the main principles of the food safety approach in any food business.

Foodborne illnesses are caused by pathogenic microorganisms that enter the food system.

This situation is an ongoing problem for food businesses. One of the main approaches used by the food industry to ensure that harmful microorganisms are controlled is understanding the factors that affect their growth.

FATTOM stands for Food, Acidity, Temperature, Time, Oxygen, and Moisture, which are essential factors influencing microbial growth in food.

Controlling these factors is crucial because foodborne illnesses are primarily caused by pathogenic microorganisms that thrive under certain environmental conditions.

Temperature control is pivotal, as pathogenic bacteria rapidly multiply between 40°F to 140°F, known as the temperature danger zone.

Acidity levels significantly affect microbial growth; lower pH levels can inhibit the growth of harmful bacteria.

Moisture content is critical since higher water activity supports faster microbial growth, making dry foods generally safer.

Time management ensures that foods are not exposed to risk-enhancing conditions like the temperature danger zone for prolonged periods.

Limiting oxygen exposure can suppress the growth of aerobic microorganisms, using methods like vacuum sealing or modified atmosphere packaging.

Understanding and manipulating FATTOM factors help food businesses develop effective strategies to prevent foodborne illnesses.

Regular monitoring and adjusting of FATTOM factors are implemented through critical control points in food handling and processing.

FoodDocs offers digital solutions for real-time monitoring of FATTOM factors, enhancing compliance and operational efficiency in food safety management.

A suitable mnemonic device to remember all the essential factors that need to be controlled to minimize microbial growth is FATTOM: Food, Acidity, Temperature, Time, Oxygen, and Moisture.

Controlling FATTOM factors is one of the main principles of the food safety approach in any food business. Most food handling procedures and critical control steps are based on controlling FATTOM and adjusting them to become favorable to food safety.

Understanding FATTOM is an essential prerequisite to controlling food safety and preventing the 6 most common foodborne illnesses from harming your customers.

The FATTOM acronym stands for:

The FATTOM acronym refers to a collective set of factors that affect the safety of foods from potential contamination and microbial spoilage. These factors all contribute to the presence and growth rate of foodborne pathogens.

Food ingredients and the common food business setting are perfect conditions for the growth of harmful bacteria and other foodborne pathogens. As such, the factors under FATTOM in food safety were identified and used as the basis for food handling operations.

Manipulating and monitoring these factors in a food business setting are key operations in maintaining food safety. Most, if not all, critical control points and monitoring operations are based on controlling these factors during food production.

The FATTOM meaning refers to the critical factors that affect the growth of foodborne pathogens in food. These factors are essentially considered in any food business for controlling food safety.

Below, we discuss each factor in detail and how they affect the growth of bacteria and other pathogens.

In FATTOM, the "F" stands for "Food."

Like humans, microorganisms use food content as a source of nutrients. Different food products are rich in nutrients that can sustain the growth of microorganisms. In general, more nutritious foods, those rich in proteins and carbohydrates, are more likely to be contaminated by bacteria and cause food spoilage or foodborne illnesses.

Some examples of high-risk foods that are rich in nutrients include meat, chicken, seafood, cooked rice, eggs, and leafy greens. These types of foods are at a higher risk of becoming contaminated in a food kitchen. They are otherwise known as TCS foods or time/temperature control for safety food groups.

Microorganisms are naturally present in foods. Preparation, pretreatment, and cooking minimize any potentially harmful bacteria in foods and makes them safe for consumption. A critical step in ensuring efficient processing is to ensure high-quality materials that are free of any contamination.

To control and prevent microbial contamination, food ingredients must always be secured through thorough proper handling, cooking, and storage.

Learn more about tips on handling TCS foods from our detailed article.

In FATTOM, the "A" stands for "Acidity."

Acidity refers to the pH of the food or the presence of hydrogen ions in its system. The pH of a system is a spectrum of different levels represented by a range of numbers from 1 to 14. To more acidic the food is, which is characterized by sourness, the closer its pH is to 1.

The acidity of food and its surrounding can determine which type of foodborne pathogen is most likely to contaminate your food. Microorganisms have different pH requirements for optimal growth.

In low pH or acidic conditions (pH 1-4, high; 5-6, slightly acidic), common bacteria are less likely to contaminate foods. This is true for acidic foods like citrus, tomatoes, and fermented products. In such cases, foods are more likely to be contaminated by molds or acid-loving bacteria.

This factor is used in the food service industry to control the growth of food poisoning bacteria while changing the quality of foods. Acidity regulation is one of the main principles of fermentation as a food preservation technique.

The first "T" in FATTOM stands for "Temperature."

This factor refers to the temperature at which foods are exposed to. It can either refer to the food storage temperature or proper food temperatures for cooking.

Temperature is a critical factor for the growth of microorganisms in food. Pathogenic microorganisms optimally grow at room temperature or within the temperature danger zone, which is between 40°F to 140°F (5°C to 60°C). In this favorable condition for pathogens, the number of microorganisms can double very fast and cause food spoilage.

In general, most microorganisms cannot survive very high or very low temperatures. This is the rationale behind cooking and storage. Foods are cooked to high temperatures, which are known to kill potential bacteria. On the other hand, foods are stored at low temperatures to slow down or stop the growth of any existing microorganism.

High-risk perishable foods must not be exposed to the temperature danger zone for more than 2 hours, or else the food must be disposed of.

In monitoring the correct temperature, a properly calibrated thermometer and temperature logs are essential.

Use our free calibration log template, cooking temperature log, and cooking temperature chart to guide food handlers on how to monitor and control the temperature for food safety properly.

The second "T" in FATTOM stands for "Time."

The factor Time refers to the food's duration of exposure to unfavorable conditions. At most, high-risk foods are only safe to consume when they stay less than 4 hours within the temperature danger zone. The longer any food stays within this temperature range, the more likely dangerous bacteria to affect the product.

In a food business setting, food ingredients and finished products must always be kept in conditions that are unfavorable for microorganisms. Foods and their storage conditions must be consistently monitored to ensure their safety and quality.

Even foods stored in hot or cold holding areas have a maximum time limit for display. As foods are generally perishable, food handlers must always be conscious of every product and ingredient's maximum shelf-life. Foods must always be stored properly.

Use our product shelf life chart to guide food handlers.

In FATTOM, the "O" stands for "Oxygen."

Microorganisms can be either aerobic or anaerobic. Aerobic microorganisms are those that require oxygen to survive, whereas anaerobic microorganisms cannot survive in their presence.

It is important for food handlers to determine the pathogen of concern to understand if the presence of oxygen will support bacterial growth in a food or kill it. The best example of controlling oxygen in a food production or food service setting is vacuum-sealing foods. When foods are vacuum-sealed, the oxygen is removed from the packaging, and the products are expected to last longer.

Another example of limiting oxygen access to foods is storing them in airtight containers. When stored in a refrigerator, sealed foods are less likely to be contaminated.

In FATTOM, the "M" stands for "Moisture."

Moisture, in the acronym FATTOM, refers to the presence of water surrounding the food and the available water within the food's system. In general, foods with very high moisture are more likely to be contaminated and spoil faster than foods on the drier side.

Microorganisms require water to grow, and its abundance helps them spread and multiply even faster. There are many ways of controlling moisture in food.

One preventive control that involves moisture is reducing the moisture content of foods through drying. This food preservation method uses heat to remove moisture, making the food more stable and protected from microbial growth.

In some cases, dry foods can reabsorb moisture from the air, which will make them prone to contamination again. This is especially true for high-moisture conditions. To prevent this, food service businesses maintain a very low humidity in storage areas by using dehumidifiers.

Understanding these factors can help food handlers create efficient controls and monitoring checks. Food businesses can better protect their foods and customers from food contamination and optimize their resources without generating too much food waste.

Use our list of other free posters on food safety topics to guide food handlers on how to manage FATTOM factors.

The considerations involved in controlling FATTOM significantly apply to all high-risk foods. All known monitoring controls and correct food preservation methods are based on these factors and are very common in any food business.

Below, we look more into how FATTOM affects food safety in food businesses and list some operations used to control them:

As mentioned, microorganisms use the same nutrients as humans to survive. The more nutritious a food is, the more likely it is to get contaminated and cause food poisoning.

The most applicable example of this is the category of high-risk foods. The foods that are under this group include may include the following:

All of these foods have a lot in common in terms of nutritional value. They are all either high in protein, carbohydrates, vitamins, and minerals. The nature of foods and their nutritional content makes them the primary target of microorganisms as a food source.

All food products are categorized as either low-acid, high-acid, or neutral, depending on their pH level. Examples of low-acid foods include meat, vegetables, milk, and soy. In general, these foods are less stable than their counterparts.

Low-acid foods require more attention during preparation to ensure that they are shelf-stable. A good example of this condition is low-acid canned foods. These food products require higher or longer heating treatment to ensure that bacteria and other pathogens will not spoil them. In some cases, these foods are added with organic acids, such as citric acid, acetic acid, or lactic acid, to increase their acidity.

In addition, high-acid foods, such as fresh fruits or preserves and fermented products, require fewer preservatives to become more stable. Although higher acidity makes foods more stable, adding organic acids is not always applicable. Remember that acids make the food become sour. To compensate for the effect of low acidity, low-acid foods use other factors for stability.

Temperature is one of the most widely used factors in ensuring food safety for any food business. It applies to storage and cooking conditions. Inactivating microorganisms using heat or slowing down their growth in low temperatures are some of the basic operations in food service, retail, and production.

Some operations that help control microorganisms through proper temperature control include the following:

These operations are all critical for maintaining food safety. Their main may either be one of the two:

Temperature-related operations can only be effective if they are well-maintained and monitored. Microorganisms can survive or build resistance if they are given enough time or leverage to recover. In cooking, foods must be heated to the correct internal temperature range. A few degrees of the recommended temperature may allow some cells of pathogens to survive and cause food poisoning after a while.

The time factor is commonly associated with the food's exposure to unfavorable conditions. Operations in food businesses, such as cold and hot holding, are used to prevent foods from staying too long in the temperature danger zone during display.

Foods are only allowed to stay within the temperature danger zone for a maximum time of four (4) hours. Beyond this period, foods are no longer safe for consumption and must be properly disposed of.

In food businesses, oxygen is excluded through operations such as vacuum-sealing foods and canning. These operations remove oxygen so that common microorganisms will not grow on the foods and spoil them.

In contrast to microorganisms that require oxygen to survive, canned foods and vacuum-sealed products have different concerns. Microorganisms, such as Clostridium botulinum, a known pathogenic bacteria, can only survive in vacuum conditions. This pathogen can cause a significant amount of damage when consumed.

To control such situations, vacuum-sealed foods are often treated with other factors to prevent anaerobic microorganisms from contaminating them.

Other operations that help exclude oxygen in foods include oxygen scavengers, which absorb oxygen in sealed containers.

Food manufacturers often indicate on labels the guideline, "store in a cool, dry place." This instruction intends to prevent foods from absorbing moisture from the environment, which can make them more prone to contamination.

Most pathogens grow well in very moist environments. This is the rationale behind drying foods. In general, foods with very low moisture content are more shelf-stable and less likely to be spoiled by microorganisms.

Food businesses can control moisture in the air, or humidity, by controlling the air circulation in storage areas. Foods can also be protected from further moisture reabsorption by sealing them in airtight containers before refrigerating them.

All operations involving the FATTOM factors are sensitive and require extensive monitoring. Microorganisms can find opportunities to grow when food handlers do not know how to control these factors.

To help food businesses stay on top of the FATTOM factors, use a digital Food Safety Management System. FoodDocs' software is compatible with IoT sensors, and temperature readings from storage areas can be automatically logged into our system. Using this integration with our software, you can monitor the sensitive factors in real time, wherever you are.

The factors under FATTOM are critical in maintaining food safety for any food-handling business. Understanding these factors can help create strategies for preventing foodborne illnesses from the growth of harmful microorganisms.

When food handlers understand how the FATTOM factors affect the safety of food, they gain an appreciation of the food handling procedures assigned to control spoilage and contamination. In addition, understanding FATTOM prepares food handlers on how to combine strategies that will create long-lasting and shelf-stable products.

It allows food safety managers to create monitoring controls that will help maintain compliance with food safety regulations. Food businesses that can effectively control FATTOM can also optimize their resources by preventing the spoilage of foods.

Ensure the safety of your food products and consumer by keeping the FATTOM factors in control with FoodDocs' digital Food Safety Management System.

Using food safety management system software, food handlers will be able to access monitoring logs for each operation. Food handlers will also receive intuitive notifications alerting them of tasks that need to be done. Stay on top of monitoring every FATTOM factor with our smart digital solution.

All food handlers in food service, production, and retail must be aware of FATTOM for food safety. These factors are critical for preventing the contamination of foods and causing foodborne illness outbreaks.

Understanding the principles of FATTOM is an essential part of food safety training programs for food handlers.

In addition, food safety professionals, including food inspections, auditors, and consultants, are expected to understand FATTOM for proper assessment of food handling operations in businesses.

There are many known strategies for controlling FATTOM factors for food safety in any food business. These strategies are usually identified in food safety plans as control points.

Here are some practical tips for controlling each FATTOM factor for food businesses:

Food

Remember that you can only prolong and optimize the shelf-life of foods if they are not previously contaminated. Impose strict monitoring procedures when receiving food supplies from your supplier.

Acidity

Increase the acidity of low-acid foods for canning.

Use organic acids that match the profile of your food product, and consult food safety regulations regarding the allowable limits of acids. Not all food products are compatible with the addition of acids.

Temperature

Use a calibrated thermometer to ensure that foods are cooked to the recommended internal temperature.

Avoid storing high-risk foods in the temperature danger zone.

Consistently maintain storage temperature for high-risk foods.

Monitor temperature controls at regular intervals, especially for food storage. Ensure that monitoring logs are well-documented and accessible for traceability in case of food safety issues. Temperature monitoring for cooking is a critical food safety regulation.

Time

The longer foods are exposed to unfavorable conditions, the more likely is contamination to occur. Consistently monitor the shelf-life of products to ensure that your team is only using fresh and safe ingredients.

Oxygen

Before implementing controls related to oxygen, make sure that your team has conducted a thorough hazard analysis. This step will determine if your products are safer in the absence or controlled presence of oxygen. If foods are susceptible to anaerobic pathogens, you may need to adjust other factors.

Moisture

The moisture in the environment is as important as the moisture of foods. Moist environments tend to invite more bacteria and other pathogenic microorganisms. This condition increases the likelihood of contaminating moist foods even higher.

The key to optimizing these factors and controlling food safety is consistent monitoring. Food businesses would benefit most from a comprehensive food safety management system that will capture critical information about the FATTOM factors in a timely manner.

Food business teams can immediately apply corrective actions in case of non-compliance when they have a comprehensive overview of each factor's status.

Consistent monitoring of the FATTOM factors is one of the core operations in any food business. Operations related to controlling FATTOM are essential for maintaining food safety, and their importance cannot be stressed enough.

Food businesses can have multiple, or even all, operations needed to control FATTOM, and doing all of them at once is a big task. With the help of FoodDocs' digital Food Safety Management System, every food safety team can efficiently and intuitively monitor FATTOM-related operations and maintain food safety compliance.

Powered by artificial intelligence and a machine-learning program, our smart software can provide the following benefits for food businesses:

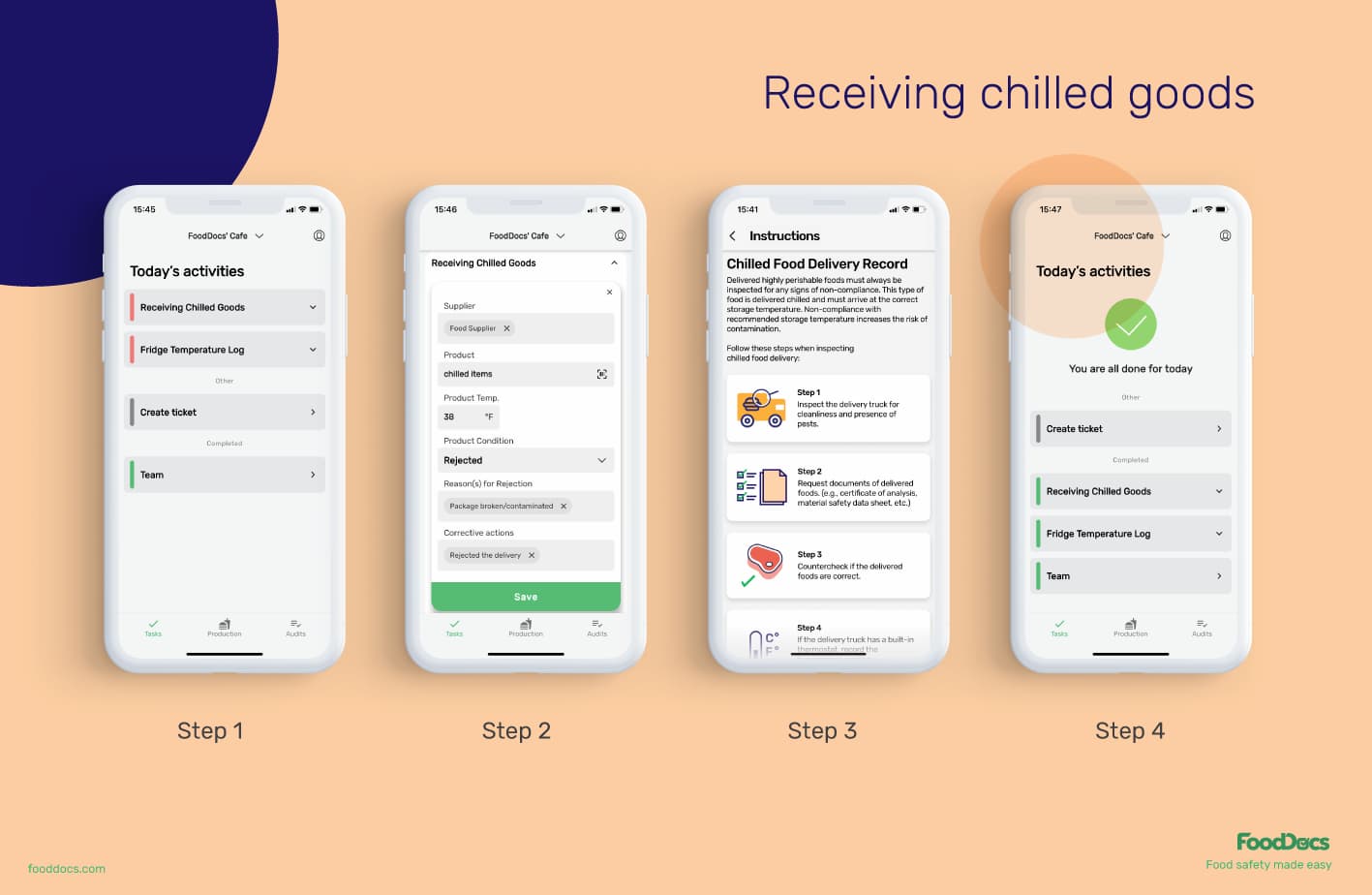

Receiving chilled goods log from FoodDocs

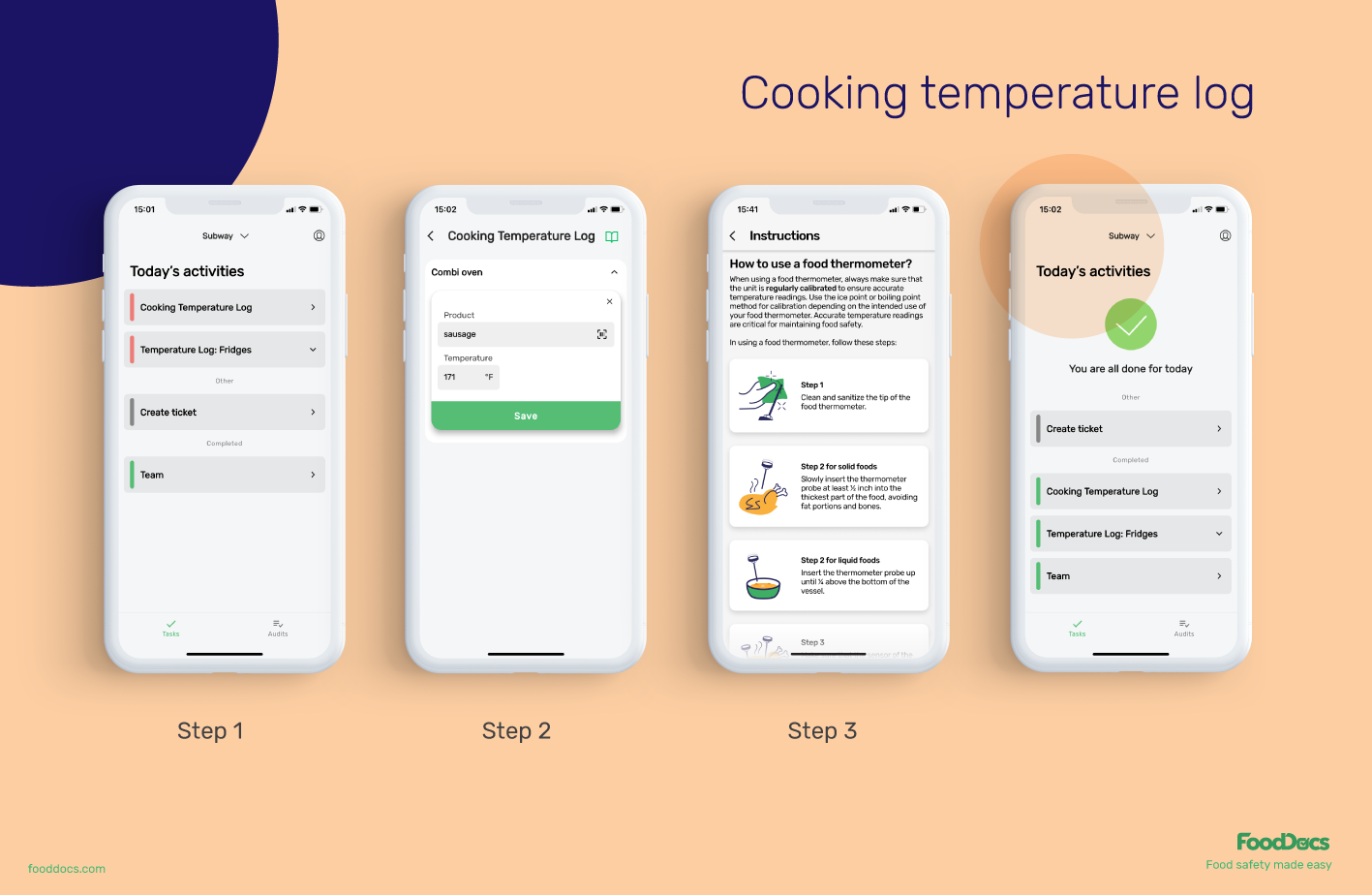

Cooking temperature log from FoodDocs

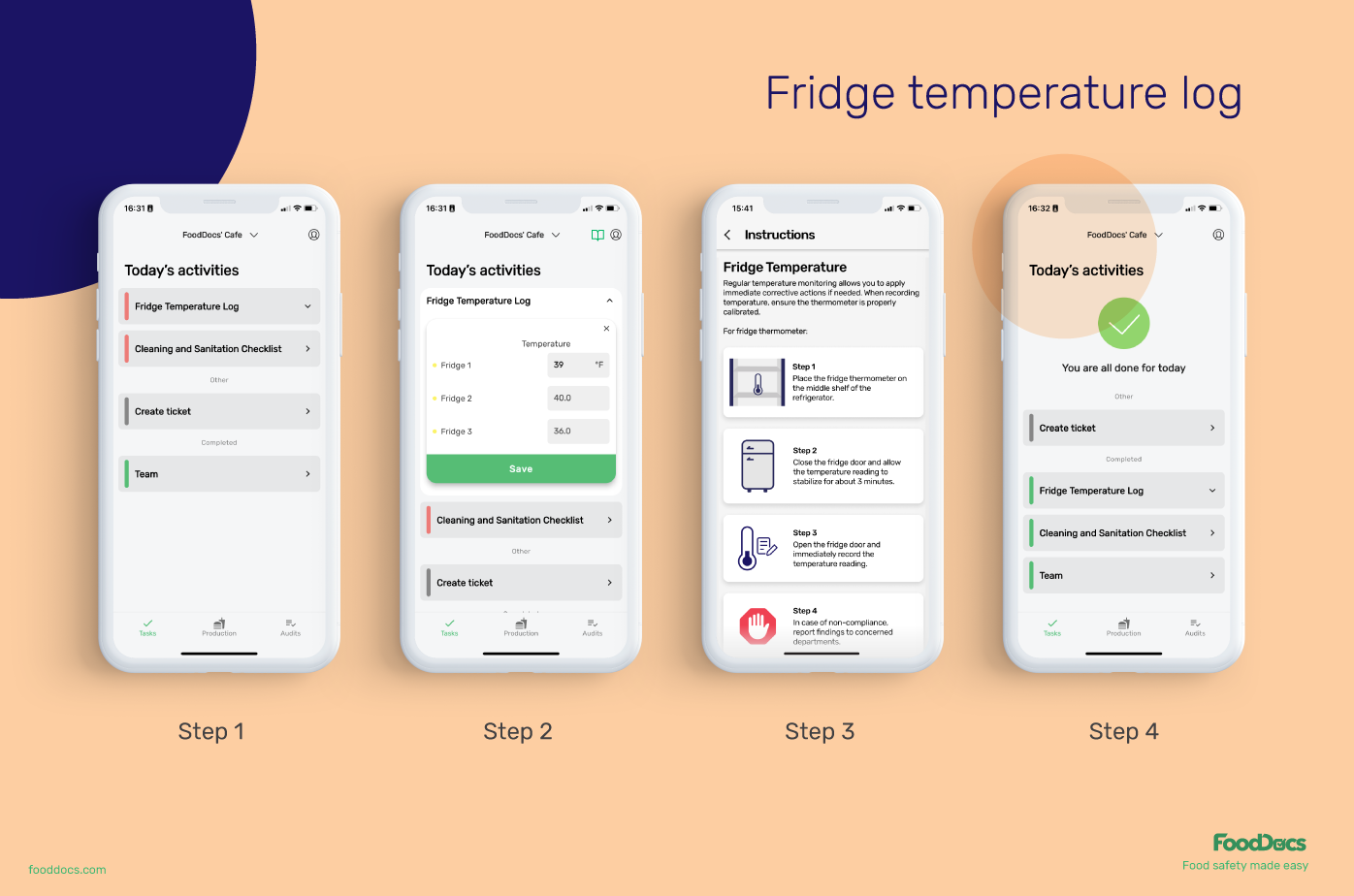

Fridge temperature log from FoodDocs

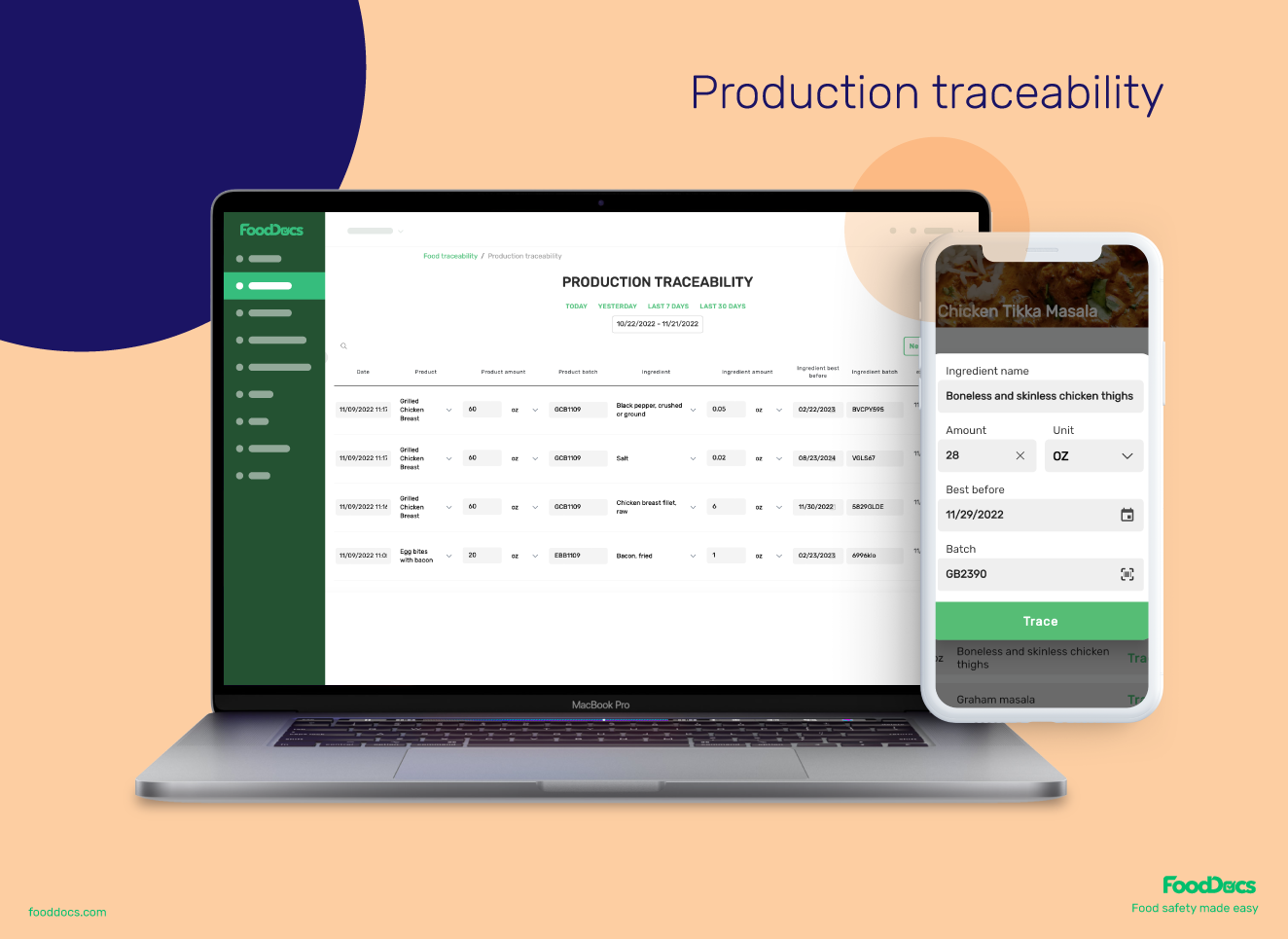

Production traceability system from FoodDocs

Improve your managing efficiency with the help of our HACCP-based digital Food Safety Management System. Our smart software also features systems that will help you manage your team and compliance easily:

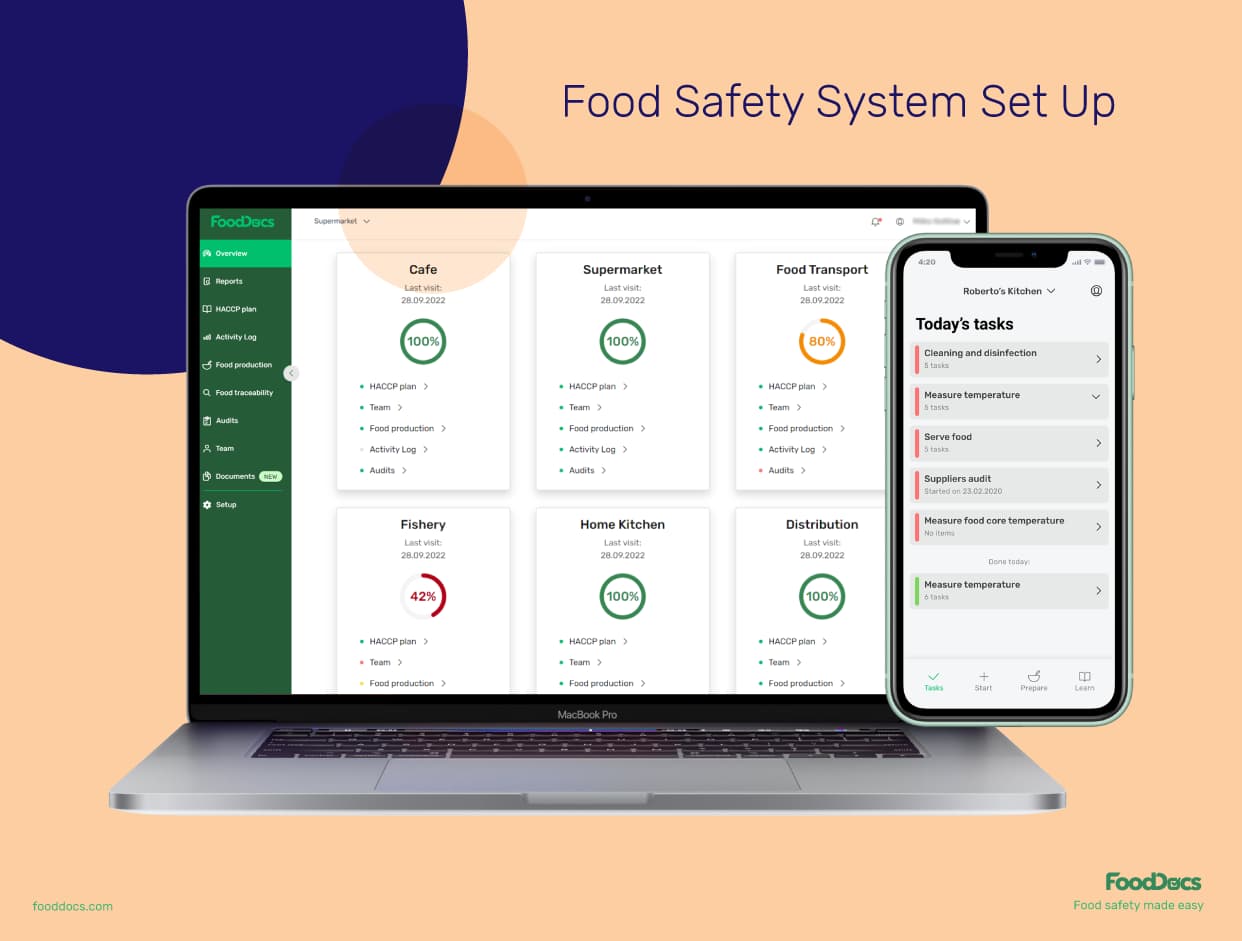

Food safety system set up by FoodDocs

With our smart solutions, you can effortlessly and continuously monitor FATTOM factors to ensure consistent food safety. Protect your consumers from foodborne illnesses while gaining more time to improve your services from the extra time you will be saving.

Improve every digital monitoring log and checklist that our system will generate, as they are all customizable. Apply inspector revisions or your personal touch to your monitoring logs in an instant.

Start your food safety monitoring journey with us and join the list of more than 35,000 customers enjoying food safety compliance using our solutions.

Sign up now and enjoy our free 14-day trial.

Below, we discuss more topics concerning the factors in FATTOM food safety.

The FATTOM meaning refers to the critical factors that affect microbial presence, and it stands for Food, Acidity, Temperature, Time, Oxygen, and Moisture.

The growth of microorganisms is significantly affected by six main factors: food, acidity, temperature, time, oxygen, and moisture.

By controlling FATTOM through different food handling operations, such as cooking and proper storage, the growth of microorganisms can be significantly reduced to safe levels. Food safety operations are structured based on tasks that will control FATTOM factors in favor of food businesses.

The best preventive controls for each FATTOM factor are the following:

Different microorganisms require a particular pH range for survival. Some microorganisms prefer low pH conditions, such as molds and yeasts, whereas some prefer neutral ranges, such as bacteria and viruses.

High-temperature ranges can inactivate microorganisms, whereas low temperatures slow down microbial growth. Temperature controls are used to determine the rate of multiplication or growth of microorganisms. The majority of foodborne pathogens optimally grow in the temperature danger zone range of 40°F to 140°F (5°C to 60°C).

Some types of microorganisms can only survive in the presence of oxygen, whereas others in their absence. Aerobic microorganisms require oxygen to grow, while anaerobic microorganisms grow in the absence of oxygen.

Water activity refers to the amount of available water in food, which can be used by microorganisms for growth and other biological processes. Microorganisms grow well in conditions rich in water content, whereas their growth is limited or stopped in its absence.

High-risk foods, such as meat, poultry, eggs, dairy products, leafy greens, and cooked rice, are most commonly prone to microbial growth. This group of food items is categorized as TCS foods or time/temperature control for safety foods.

Simple food handling operations in restaurants and food processing plants are regularly done to control FATTOM. Operations such as storage temperature control, cooking, shelf-life tracking, limiting air exposure, and ensuring dry conditions all contribute to controlling FATTOM factors.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...