Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Food preservation methods help food handlers prolong the shelf-life of food products and prevent food poisoning.

Food ingredients, whether highly perishable or not, have a maximum shelf life. Consumers and manufacturers all over the world understand this and use different methods to come up with ways to extend the shelf life of foods.

These methods are called food preservation techniques. Food preservation can extend the maximum shelf life and useability of food, and it can also change or improve some of its characteristics. Different methods of preserving food are also widely used to maintain food safety and protect consumers from foodborne illnesses.

Simple and everyday kitchen operations, such as cooking, refrigeration, and pickling, can be considered preservation methods. For every food preservation method to become successful, proper sanitation and hygiene must also be present. Without proper sanitation, even the strictest methods of preservation, such as canning, can become harmful to consumers.

WHAT WE'LL COVER:

Food preservation refers to the process of changing the internal and external conditions and composition of a food ingredient to slow down the growth of spoilage organisms and extend the shelf-life of foods.

Food preservation methods include a wide range of processes used in the food industry. It is a key operation in many food manufacturing facilities to produce stable food products displayed in the market.

In smaller-scale operations, such as food service, food preservation methods can be seen as cooking, freezing, and refrigeration. These operations reduce or slow down pathogenic bacteria's growth, prolonging food's shelf life.

As mentioned, food preservation changes the external or internal conditions of the food so that they will become unfavorable to the growth of food spoilage microorganisms. Some methods of preservation reduce the water content or moisture level, change the pH or acidity of the food, and others subject the food to intense heat.

These changes in the internal or external attributes of the food product are often achieved with the help of equipment, tools, food ingredients, and specialized techniques. Some food preservation methods can be done through the optimization of environmental factors, such as sun drying.

Food preservation processes greatly vary in principles and methods. What they all have in common is that every food preservation method must be done in a clean and sanitized environment of a commercial kitchen to avoid food contamination.

Some of the most popular methods to preserve food include:

These examples are just some of the most widely used preserving food methods. Food processors and other businesses can use a combination of two or more methods to develop a unique, preserved food product.

Each type of preservation method results in a different product with unique final characteristics. For example, fresh fruit slices dried through dehydration will have a shriveled appearance and very low moisture content compared with a freeze-dried product.

In addition, the product's resulting final shelf-life will also vary depending on the applied food preservation method.

A common question you might run into on a food handlers test has to do with a common food reservation technique:

The preservation technique that attempts to remove moisture is dehydration.

The first person to use heating processes to preserve foods was Nicolas Appert in the 1790s. He pioneered the application of heat on sealed glass jars to significantly preserve the shelf-life of foods and prevent spoilage.

Despite the early discovery of the canning process, food preserving, in general, has been used since ancient times. The food preservation history goes way back thousands of years ago. Some early civilizations used methods such as drying and dehydration to preserve their foods, whether in preparation for winter or general use.

Historians believe that early communities used preservation in combination with harvesting foods to store products in bulk and address the long-term shortages of food supply.

In some recorded literature, Romans were found to have built "still houses" to dry fruits, herbs, and vegetables. The houses were designed for dehydration through fire's heat and smoke.

Methods such as drying have been in practice since 12,000 B.C. It is one of the earliest forms of preserving foods. Other communities further developed methods such as drying by applying salt or salt solution to the food to draw out the excess moisture from food and hasten the drying process. Food handlers during this time also used the potential of spices for their antioxidant activity and even antibacterial activity. During these times, the method was a routine practice, yet the principles of the method were not fully understood.

The present-day understanding of the preservation method called fermentation came from the discovery of Louis Pasteur in 1857. Pasteur is also coincidentally the brain behind the process of pasteurization. In 1860, he recorded the contribution of microorganisms in the fermentation process.

The discovery of fermentation by Pasteur merely explained the process. In reality, fermentation has been in practice for thousands of years. Evidence of fermenting beverages has been recorded in Neolithic China dating back to around 7000 B.C.E.

The common goal of any preservation method is to prolong the shelf-life of food ingredients by preventing food spoilage while maintaining food safety.

Regardless of the main principle used in a preservation method, the desired result is similar. Preservation methods protect the food ingredient from the biological processes of microorganisms, thereby extending the food's life.

Food preservation serves many purposes for both food business owners and customers. It is a widely used concept in the food industry that allows sustainability and supply.

Some of the most notable importance of food preservation include:

Food businesses can significantly benefit from the application of different preservation methods of food. In addition to slowing bacterial cell growth, preservation methods can improve consumer perception towards your food products and help your business optimize your operations.

As previously mentioned, food preservation methods target the internal or external components of a food product. By changing these factors, the growth of bacteria and other pathogenic microorganisms is slowed or stopped. Manipulating internal for external factors are commonly the main principle of most preservation methods.

Some of the most prominent factors that affect preservation methods include the following:

Increasing the acidity of the food product through the addition of organic acids, such as vinegar or citric acid, will inhibit the growth of bacteria. Some low-acid foods are added with organic acids to prolong their shelf-life and prevent the growth of microorganisms, especially bacteria.

The other side of the temperature range is low-temperature preservation. Methods included in this category include refrigeration, freezing, and freeze-drying methods. Low-temperature preservation methods aim to either slow down the growth of harmful microorganisms or restrict their use of the available water through the formation of ice crystals during freezing.

The removal of water or restriction of available water is two different preservation methods that can be done in several ways. Foods can be dehydrated to remove the majority of the available water, or the water can be bound by using ingredients such as salts and sugars.

In preservation methods, such as canning and vacuum sealing, the oxygen from the environment of the food is evacuated from the container. In some methods, the air composition is modified with other food-safe gases that can preserve the optimal characteristics of the food.

Food handlers can use any of the mentioned food preservation methods to keep their foods safe for a longer time. In some cases, two or more factors are used to strengthen the effects of the preservation method by widening its protective capabilities.

In protecting foods against foodborne pathogens, the cleanliness and sanitation level of your working conditions significantly matter. For example, if you are trying to preserve fresh meat and it has a high microbial load, the normal preservation method conditions may not be enough.

As such, your team needs a strong food safety management system to ensure that your food facility is always compliant with food safety regulations. FoodDocs is an intuitive digital solution that can help you maintain compliance and reap food preservation benefits.

Use our digital Food Safety Monitoring System to get automatically generated monitoring logs, a smart notification system, and a real-time dashboard to help you improve compliance and operational efficiency.

Food preservation is a very wide branch of food processing, and it is composed of different operations that can produce unique products. Depending on the intended use, desired characteristics, and available storage conditions, the appropriate food preservation method type can vary.

Food preservation methods can be based on the following common principles:

The 2 methods of food preservation that are most widely known and used worldwide are heating and low-temperature methods. These two methods offer a wide range of potential to food handlers and allow them to come up with a versatile list of food ingredients.

Preservation through heating can be applied to both solid and liquid foods. Methods such as drying and dehydration are performed worldwide on raw meats, fresh fruits, vegetables, and other solid foods. On the other hand, pasteurization is common for liquid foods.

The application of controlled heat at a particular length of time allows destroys any present harmful bacteria and other pathogens without compromising the quality of the food. Like regular cooking, the internal temperature of foods during these processes must be monitored consistently to become effective.

Heating is commonly used in combination with other preservation methods to dry the foods faster or to make the process effective even at a less harsh level. This type of preservation method is used to produce some of the safest types and shelf-stable foods, which is through canning.

Along with the popularity of heating, low-temperature preservation methods are also very common worldwide. Methods such as refrigeration and freezing are very common and used in almost all kinds of food industries.

Low temperatures slow the growth of dangerous bacteria and other pathogens in food. This temperature range can significantly extend the shelf life of foods for up to months or years, especially with freezing. Similar to heating methods, low-temperature preservation methods must also be consistently monitored to remain effective and perform as intended.

Some preservation methods apply very intense elements to foods to make them shelf-stable. Exceedingly high or low heat can produce unwanted changes in the flavor and texture of foods.

In recent times, more modern preservation methods have been developed to eliminate harmful pathogens while maintaining close-to-the-original characteristics of the food.

Freeze drying is perhaps the most effective preservation method that relatively does not alter the flavor and texture of food. This method requires the food to be frozen the fastest way possible to create very small ice crystals from the water inside the food and reduce membrane damage.

Freeze drying can retain the color, flavor, and texture of foods as the ingredients are not subjected to heat. The moisture in the food ingredients is removed through lyophilization. This method also retains bioactive compounds in food for added human health benefits.

Other modern methods that can preserve the texture of foods include high-pressure processing and oscillating electric fields. Although the former method has been shown to produce some textural changes, the food texture alteration is minimal compared to heat treatments.

During preservation, chemical ingredients can be added to food to reinforce the process or create faster reactions. This method is a common practice in the food industry.

The chemicals used in food preservation are guided by food safety laws that have undergone a strict series of evaluations and research. Scientists and food legislators ensure that the approved chemicals and their applicable levels are food-safe and will not cause adverse health effects on consumers.

Some of the most common chemicals used in food preservation include the following:

Chemicals used in different forms of preservation go through a rigid approval process to protect the consumers. There is no point in using a chemical that helps the preservation process but will put customers in harm.

The chemicals used for preservation can either be synthetic or from natural sources.

Food preservation methods require particular sets of conditions to become successful. These requirements will depend on the principle of the selected food preservation method.

Like any food handling operation, preservation methods can be contaminated and ineffective when improperly done. Here are some common mistakes when preserving food:

Proper food hygiene and sanitation of the working environment are key factors in achieving proper food preservation. This condition must be consistently maintained throughout the preservation process to ensure the effectiveness of any method.

Food preservation is a food processing operation that requires attention and consistent monitoring. While the resulting food products may be shelf-stable, the process of getting these products may be more prone to food contamination.

To help you ensure that food preservation methods conducted in your business facility will successfully preserve food ingredients, follow these tips for food preservation:

In addition to these tips, food handlers must always remember that preservation does not make foods immune to contamination or bacterial growth. This process merely extends the shelf-life of foods and makes them less vulnerable to food spoilage.

Find more useful food safety materials for your team from our template hub.

With the monitoring tasks you need to do during preservation on top of your regular operations, it may be very hard to manage everything at once. What you need is an intuitive solution that can help you fulfill food safety tasks with digital solutions and help your team remember every task at the right time.

FoodDocs is a digital solution for your problems. Using our digital Foos Safety Management System, you can get an intuitive system to help you maintain food safety compliance every day.

With our digital solution, you can get the following features and benefits:

Cooking temperature log from FoodDocs

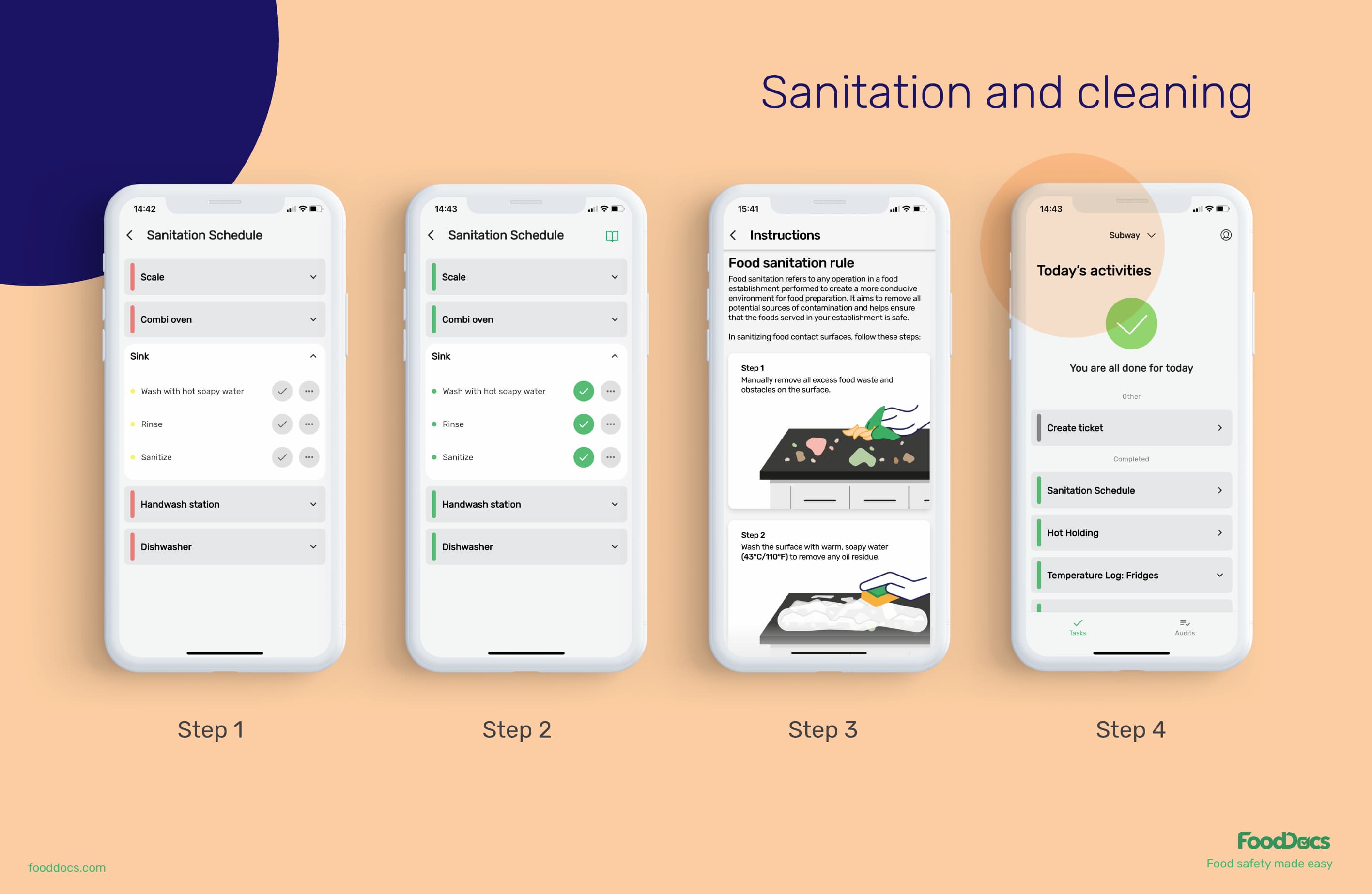

Master sanitation schedule from FoodDocs

In addition to features that help improve the efficiency and effectiveness of your team's food safety performance, our digital Food Safety Management System can also help food business managers improve management efficiency.

With our digital Food Safety Management System, you can ensure that your food preservation processes and food safety operations can simultaneously be fulfilled at all times. Keep your consumers safe from foodborne illnesses by ensuring food safety compliance at all times.

Experience all the benefits of our digital solution with our free 14-day trial and join our list of more than 30,000 customers enjoying food safety compliance through our products.

Need more information about food preservation? Here are some of the most frequently asked questions about this topic.

Food preservation is the process of extending the shelf-life of a food ingredient for a significant amount of time by hindering the growth of spoilage organisms and other biological processes that could spoil the food. Food preservation aims to retain the nutritional value, flavors, and safety of foods for a longer time.

Some of the most notable food preservation methods include the following:

Examples of natural compounds for food preservation include salt, sugar, honey, culinary spices, vinegar, and other organic acids.

Vinegar can significantly decrease the pH of a food product, protecting it from unwanted bacterial growth. Vinegar contains acetic acid, which is an organic acid, that has a very low pH.

Food preservation includes a wide range of operations. Simply freezing foods inside a freezer unit can be considered a preservation method. Other preservation methods involve heat treatments or high-pressure processing to make the food shelf-stable.

Commercial sterilization is an example of a preservation method that leaves a few bacterial spores incapable of multiplying. This type of preservation method targets vegetative cells of spoilage microorganisms but applies less extreme temperatures to damage spores.

Methods such as drying and curing both control microbial access to water. The difference between the two methods is that drying removes the available through heat, whereas curing binds the available water with solutes.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...