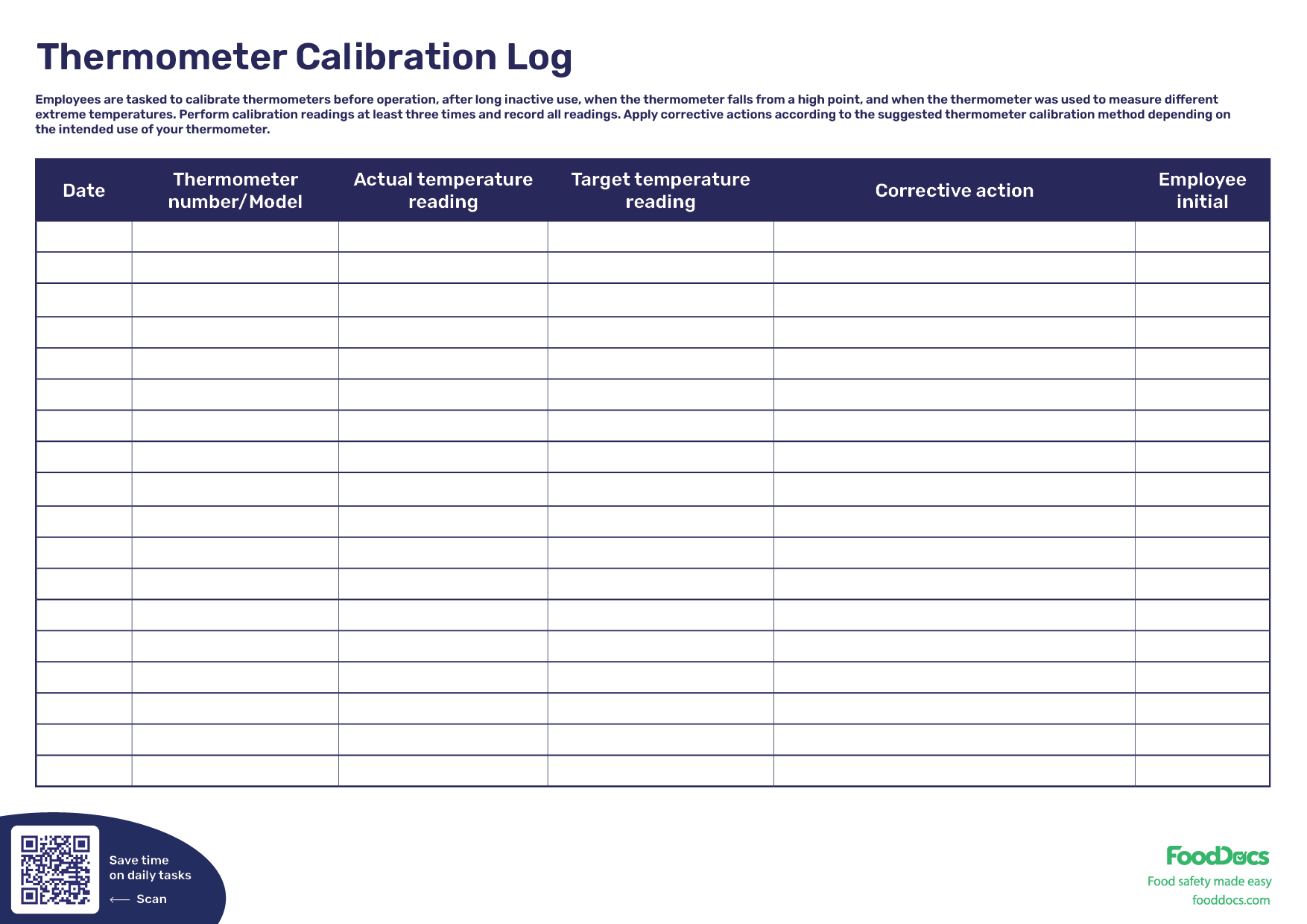

THERMOMETER CALIBRATION LOG

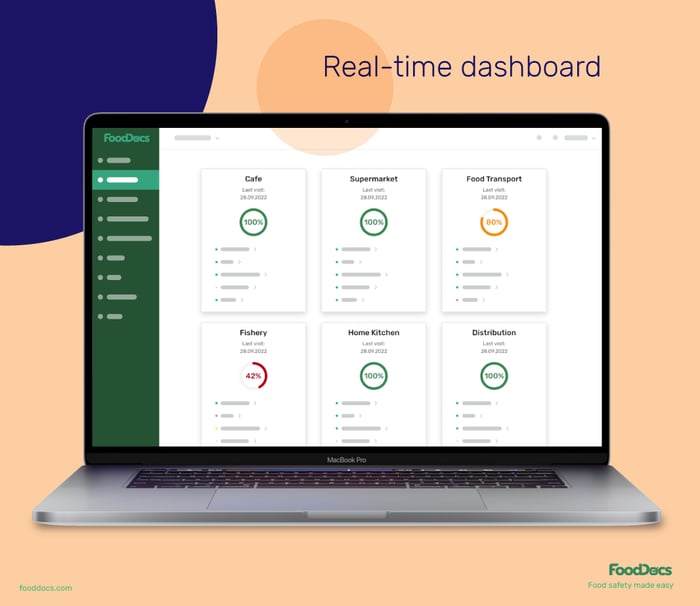

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

How to use the Thermometer Calibration Log

There are different types of thermometers in the food industry, but their main objective is to achieve clear, accurate, and precise temperature readings. To do this, calibration must be regularly performed.

Employees are required to record all gathered temperature and thermometer model on their thermometer calibration log.

Follow these steps to use the thermometer calibration log:

- Familiarize yourself with the calibration log.

- Download the chart. Enter a valid email address and click on "Download."

- Print the calibration log. The chart goes straight to your downloads folder. From there feel free to print it, in order to make the filling convenient for food handlers.

- Start using the log. Ensure that all calibration log entries are signed by the performing employee. Keep all calibration logs in one folder for easier verification.

Some quick tips to use this thermometer calibration log successfully include:

- Schedule thermometer checks based on how critical the equipment is. For example, food-contact thermometers should be calibrated daily, while fridge thermometers can be checked monthly.

- Always follow the manufacturer’s recommendations or your HACCP plan when deciding how often to calibrate.

- Record each calibration at the start of the day or shift to ensure equipment starts within safe limits.

Key points covered:

- Thermometer calibration is a critical task for maintaining food safety.

- A thermometer calibration log is a key document used to record temperature readings during calibration.

- Logging calibration information is an essential task for food safety compliance and helps address any instrument issues.

- All food businesses with temperature-related monitoring tasks require a thermometer calibration log.

- A thermometer calibration log must include the date of calibration, target temperature, corrective actions, the reason for calibration, thermometer model, and actual temperature reading.

- FoodDocs' smart Food Safety Management System can automatically generate a digital Thermometer Calibration Log.

Navigating the Thermometer Calibration Log: Your Ultimate Guide to Thermometer Calibration

Logging thermometer calibration readings helps create accountability and ensures accurate temperature readings in food businesses.

Any kitchen equipment may need some form of maintenance at some point. This is also the case for food thermometers. This kitchen apparatus is a piece of very common equipment. It is used to measure the temperatures of food and storage temperature.

WHAT WE'LL COVER:

- Thermometer calibration log definition

- Who needs a calibration log?

- Importance of calibration log

- Parts of a calibration log

- When to use a calibration log?

- Digital solutions for monitoring calibration

- Thermometer calibration logs for ensuring accurate temperatures consistently

- Detailed instructions to ensure proper calibration

- Smart notification system to remind food handlers about calibration

- Real-time overview to help supervise the team remotely

- Customizable system to fit unique operations

- Frequently Asked Questions

What is a HACCP thermometer calibration log?

A thermometer calibration log is a document where temperature readings during thermometer calibration are recorded. It also records the corrective action performed to resolve the inaccuracy of the thermometer.

This document serves as proof that your thermometer and product probe are duly calibrated and that it gives accurate readings. Whether for an oven, refrigerator, or dehydrator thermometer calibration, recording the results is important.

Accurate temperature readings through the correct use of thermometers are important for food safety practices such as cooking and cold storage.

The growth of pathogenic microorganisms depends on the surrounding temperature. Operations such as cooking aim to eliminate these microorganisms and improve the food's characteristics. For low temperatures, the growth of pathogens is controlled and significantly slowed down.

For operations such as these, their effectiveness depends on the accuracy of their temperature reading. Target internal temperatures for cooking particular raw foods are intended to target food safety hazards at a specific temperature change.

Who needs a thermometer calibration log template?

- Restaurants

- Food processing plants

- Food trucks

- Retail stores

- Institutional establishments (e.g., cafeterias or hospitals)

Generally, if your business operations require to be processed with a controlled temperature, you will need a thermometer calibration log.

This log is especially useful in operations where food temperature plays a critical safety role, like central kitchens, school cafeterias, long-term care facilities, and USDA-inspected plants. In many states, food inspectors check calibration logs as part of standard audits.

Thermometers measure temperature during cooking, refrigeration, hot-holding, and other operations. Accurate temperature reading for these operations can be achieved by regularly calibrating thermometers.

During calibration, actual temperature readings and calibrated thermometer readings must be recorded accordingly.

If you need a refresher, here's how to calibrate a thermometer.

Thermometer calibration log example of why it's important

Keeping a record of your calibration activities is an important food safety operation. Thermometers will require calibration depending on the frequency of use and other instances. Some thermometers are suggested to be calibrated before every start of your daily operations, whereas some periodically. For more sophisticated temperature calibration, thermometers are often sent to service facilities that specialize in calibrating thermometers.

For manual calibration, a thermometer calibration log can offer the following benefits:

- Prevention of false reading

- Assurance of accuracy. Calibration ensures the accuracy of readings. An inaccurate thermometer significantly increases the risk of causing foodborne illnesses as the product may be undercooked. Alternatively, if the thermometer is reading way over the correct temperature, the quality of the product may be affected.

- Diagnose faulty thermometers. During thermometer calibration, you can also assess from the temperature readings if the thermometer requires maintenance or replacement. Records on the thermometer calibration log can show non-compliant readings, which may affect calibration. Use the thermometer calibration log as a supporting document to request a new thermometer.

- Process optimization. Data gathered from calibration logs can be used to improve or develop food processing and help achieve consistent results.

- Food safety compliance

- Ensure food safety. With a properly working thermometer, food safety operations are ensured to be working correctly and are properly executed. This means the product you are processing in your kitchen is free from food safety risks. It also ensures that food safety standards are followed.

- Regulatory compliance. A thermometer calibration log will be used to record all calibration processes. Additionally, the corrective action, which is the calibration process, must also be recorded. The calibration process must be done at least three times to ensure that the thermometer is properly calibrated. A thermometer calibration log is an integral part of your food safety management system documentation, especially for audits and inspections.

- Data integrity

- Promote accountability. Keeping a calibration log demonstrates a commitment to professionalism and accountability among employees. Proof of calibration shows that measurements are taken seriously and steps are taken to ensure accuracy.

- Ensure data integrity. With a comprehensive thermometer calibration log, you can ensure that temperature measurements can be used for data analysis and produce reliable assessments for decision-making.

If a thermometer drifts and gives the wrong reading, it can lead to unsafe food. When calibrations are done daily, you can limit how much product may need to be discarded if there’s an issue. Accurate thermometers also prevent food waste and help catch equipment failures early.

A thermometer calibration log is more than just a monitoring document. The information that food handlers input on the log can help ensure food safety in your food business and it's helped by taking proper care of thermometers.

What data do you need to record in a thermometer calibration log?

A thermometer calibration log sheet must contain other important information in addition to the temperature readings during calibration. The information will help food handlers identify when or why the thermometer was calibrated.

Note: Time of calibration is helpful for traceability and can be important during inspections.

In calibrating thermometers, it's important to log the model or assigned number to identify the correct thermometer. Different thermometers are used to measure temperature for specific operations.

This would help employees identify which thermometer is faulty. Additionally, the corrective action refers to the process of realigning the temperature readings to a reference temperature. A thermometer calibration log does not have to be a complicated document.

In fact, you can use our free thermometer calibration log template.

This log document is only one of our many food safety templates. At FoodDocs, we offer several checklists, posters, and consumer advisory templates that you can use in your food business. You can easily download and print them for your convenience. Check out our Food Safety Templates Hub for more free resources.

When do you need to use a thermometer calibration log?

There are other instances when a thermometer requires calibration other than regular maintenance. In any event, food handlers can use the thermometer calibration log to record previous calibration processes.

Pair this thermometer calibration log with our Food Temperature Chart as a reference for accurate temperature readings.

Use the thermometer calibration log for the following operations:

- At the start of each shift: Check and record the calibration of thermometers used for cooking, cooling, or reheating food.

- Regular maintenance: A food temperature probe thermometer requires regular calibration to ensure accuracy. The process must be done every shift change or when the thermometer hasn't been used for a while. A calibration log ensures that calibration checks are performed on schedule.

- New instrument setup: When a food business acquires a new thermometer, manufacturers always suggest a routine calibration to ensure the instrument is not faulty.

- After repairs or adjustments: In case a thermometer was recently repaired, it must be calibrated to ensure it is functioning well. A log would help record when the calibration was done and determine the necessary intervals for the next calibration.

- Critical applications: In case of accidents, such as if the thermometer accidentally fell, the instrument must undergo routine calibration. On the log, the reason for probe thermometer calibration must be recorded as well.

- Long-term monitoring: If a thermometer is used non-stop during production, its accuracy must be determined at some point. The thermometer must be calibrated to retain its accuracy.

- Inspection: In a routine inspection, thermometers may be required to undergo calibration as a test. The readings and purpose of calibration must be recorded accordingly.

Calibration is an integral aspect of food safety assurance. It is a critical task that must be consistently observed to ensure that temperature-related operations are done accurately.

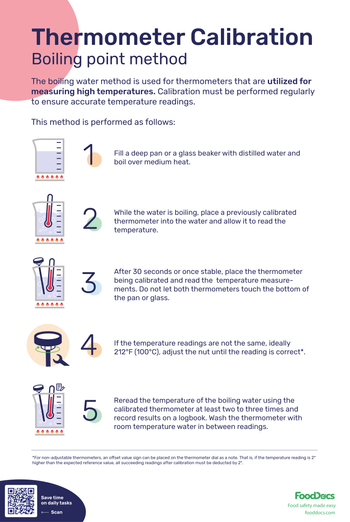

Calibration methods for thermometers

There are two main ways to calibrate thermometers:

- Ice-point method: Fill a glass with crushed ice and cold water. Stir and wait 3 minutes. Insert the thermometer without touching the glass. It should read 32°F.

- Boiling-point method: Boil water in a pot. At sea level, the thermometer should read 212°F. Adjust the expected value based on your local altitude.

Choose the method that best matches the range your thermometer will be used for. Always follow the manufacturer’s instructions when adjusting the thermometer.

Get your thermometer calibration posters

How often should you calibrate your thermometer?

How often you calibrate depends on the type of thermometer and how you use it.

| Thermometer type | Typical use | Calibration frequency |

|---|---|---|

| Digital probe thermometer | Cooking and reheating | Daily or every shift |

| Bimetallic dial thermometer | Oven or long-hold temps | Monthly or as needed |

| Infrared thermometer | Surface temp checks | Weekly or before each use |

| Fridge/freezer thermometer | Cold storage | Monthly |

| Industrial oven sensors | HACCP-critical points | Daily or per production run |

Thermometer calibration and food safety regulations

According to the FDA Food Code, thermometers used in food service must be accurate and routinely calibrated. Health inspectors often review calibration records during routine checks. Following a calibration schedule shows your business takes food safety seriously.

If your thermometer is off and you cannot adjust it, mark it out of service and replace it. Always document any corrective actions in your log.

What are the most common corrective actions to log?

If a thermometer does not meet the required reading during calibration, you need to take immediate action and document it. Recording corrective actions not only shows that your team responded properly, it also helps maintain food safety and regulatory compliance.

Examples of corrective actions:

- Adjust the calibration nut to correct the reading: Many analog thermometers include a calibration nut for manual adjustment. If the reading is off, adjusting it ensures the thermometer gives an accurate measurement moving forward. Logging this action shows that the device was corrected and brought back into proper working condition before being used again.

- Replace batteries in digital thermometers: A low battery can cause inaccurate readings in digital devices. If calibration fails and the issue is power-related, replacing the battery often fixes it. Logging the battery change confirms that the issue was identified and resolved, which protects food safety and equipment reliability.

- Tag the thermometer and remove it from use if it cannot be fixed: If a thermometer is significantly off and cannot be adjusted, it should be taken out of service immediately. Logging this action helps prevent anyone from accidentally using faulty equipment and documents that your team is taking proactive steps to avoid food safety risks.

- Use a backup thermometer until the primary one is serviced: When a thermometer is removed from service, a backup should be used to continue operations without disruption. Logging the use of a backup ensures there’s no gap in temperature monitoring, which is critical for food safety in busy kitchens.

Each of these corrective actions helps create a clear record of how your team handles equipment issues. Keeping this documentation up to date can protect your business during health inspections and support a stronger culture of accountability and food safety.

How to ensure accurate thermometer calibration with FoodDocs

The importance of thermometer calibration cannot be understated. This operation is a vital action for food safety.

You can ensure accurate and consistent thermometer calibration process readings with the help of FoodDocs' digital Food Safety Management System.

With our digital food safety management system, you can always stay on top of your daily food safety operations.

Use the following features:

FoodDocs has a thermometer calibration log example for ensuring accurate temperatures consistently

Get a digital Thermometer Calibration Log that you can use to record calibration readings digitally through your mobile device.

Access this digital log through any mobile device using our Food Safety App. In case of non-compliance, our system can automatically suggest clear instructions on how to calibrate thermometers properly.

Detailed instructions to ensure proper calibration

Calibration requires precision and accuracy of the process to become effective. To help food handlers perform proper calibration, our digital Thermometer Calibration Logs are equipped with step-by-step instructions for both Boiling Point and Freezing point methods.

In addition, you can upload your versions of the thermometer calibration program as an image or a video to improve the calibration process. For quality managers in food businesses, it is a priority task to ensure that all food handlers know how to calibrate a thermometer by providing a clear guide.

Smart notification system to remind food handlers about calibration

To help food handlers maintain a consistent calibration schedule, use our system's smart notification feature. This feature can alert food handlers to remind them when to calibrate the thermometer.

This system can also be used to remind food handlers about other time-sensitive operations. Ensure that no food safety task is forgotten with our notification system.

Real-time overview to help supervise the team remotely

Get a real-time overview of your entire food safety operations across your business branches with our real-time dashboard. Using this feature, you can immediately see areas where thermometer calibrations may be required.

The system will show you non-compliant temperature-related monitoring tasks. Such information can help you immediately address the situation and request a thermometer calibration.

Save at least 20% of your time from managing your food safety operations using the real-time food safety dashboard that you will also get.

Customizable system to fit unique operations

FoodDocs understands how every food business can have unique operations. As such, we made our smart Food Safety Management System 100% customizable.

Customize our temperature logs to fit different kinds of thermometers, such as meat, digital, or probe thermometers.

Customize and improve the digital FSMS based on your needs. You can input any unique operations into your food business, and our system will generate the digital monitoring forms.

With our digital FSMS, compliance with food safety standards can be easily maintained. Monitor multiple thermometer calibration logs, on top of other operations, with ease using our digital FSMS.

You can rest easy knowing that calibration is never forgotten and is always properly recorded with our system features to keep your operations food safety compliant. With our help at FoodDocs, you can significantly cut on the manual work while ensuring that no one forgets to do any food safety task.

Frequently Asked Questions (FAQs)

What are the methods of calibration of the thermometer?

The two most common methods of calibration include ice-point and boiling-point methods.

What is the purpose of the temperature log?

The purpose of a temperature log is to record temperature measurements over time. It helps track temperature variations, identify trends, ensure equipment accuracy, and provide a historical record for analysis, compliance, and troubleshooting.

Why is the calibration log needed?

The calibration log is needed to maintain the accuracy and reliability of thermometers. It serves as a documented history of calibration checks, ensuring compliance with regulations, supporting quality control, and mitigating risks associated with inaccurate temperature measurements.

How do you fill out a thermometer calibration log?

To fill out a thermometer calibration log, record the calibration date, the calibration method used, the reference standard utilized (if any), the measured temperature, and any adjustments made to the thermometer. Include the signatures of the individuals performing and verifying the calibration to certify its accuracy.

How often should I calibrate my thermometer?

You should calibrate your food-contact thermometers daily or at the start of each shift. Other thermometers, like storage ones, can be calibrated monthly.

What information should be in my calibration log?

In your calibration log, you should include the time and date, equipment ID, current reading, expected value, any difference, corrective actions, and initials.

What if my thermometer is not accurate?

If your thermometer is not accurate, try adjusting it using the manufacturer’s method. If that doesn’t work, take it out of service and document the issue.

Do I need to keep calibration records?

Yes, you need to keep your thermometer calibration records organized and available for audits or inspections. Many local and state food safety laws require it.

Can I use digital logs?

Yes, you can use digital thermometer calibration logs. Digital logs are acceptable as long as they are complete, secure, and accessible when needed.