Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Boost your retail food safety with essential practices and digital tools to protect customers and your brand, and learn how to improve food safety in your stores.

Running a retail food business means juggling many moving parts. You might be managing multiple store locations, training new staff, and handling a wide range of food products every day.

With so much going on, keeping retail food safety on point is a necessary challenge and one you can’t afford to overlook. Not only for the health of your customers, but for the health of your business’s reputation and finances.

And once your business has the foundational pieces in place, you can set them in stone with retail food safety management software to run operations more efficiently and profitably.

Thank you for downloading ebook!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Retail food safety is about protecting both customer trust and brand reputation, not just passing inspections.

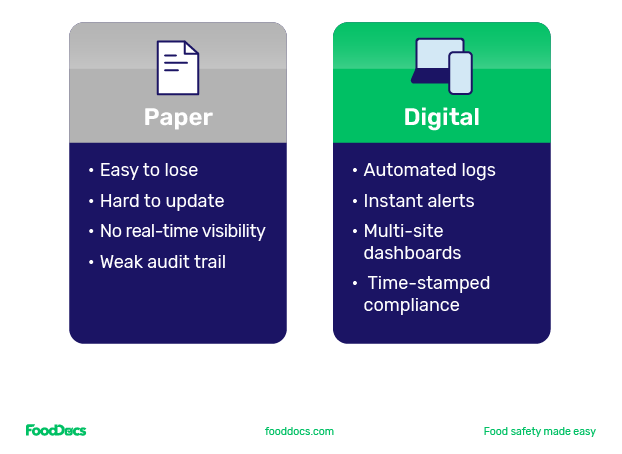

The biggest challenges in retail include high staff turnover, customer-facing risks, and the limits of paper logs.

The FDA Food Code provides the baseline for U.S. retail food safety, with similar guidance in the U.K. and Canada.

Cold foods must be held at 41°F or below and hot foods at 135°F or above to stay safe for sale.

Self-serve stations carry unique risks that require stricter utensil rotation, sanitation, and staff oversight.

Allergen management is a top priority in food retail, from accurate labeling to preventing cross-contact in prep and storage.

Daily checklists and clear SOPs help staff handle temperature checks, cleaning, labeling, and supplier inspections consistently.

Leaders at both store and regional levels should track metrics like on-time checks, deviation close-out times, and inspection trends.

Digital food safety systems improve accuracy with automatic logs, real-time alerts, and multi-site dashboards.

FoodDocs customers such as Bakery 79 show that going digital can deliver 5-star inspection ratings across every store, even during rapid growth.

Food safety is the foundation of any successful food business. In a retail setting like a grocery or convenience store that offers food to go, a single slip-up can have serious consequences.

Selling contaminated or spoiled food can lead to customers getting sick, which no one wants. Beyond the human cost, such incidents can trigger health department penalties or even store closures.

And they erode customer trust. Shoppers expect the prepackaged sandwich from your cooler or the hot soup from your deli counter to be safe every time. If they can’t trust your store’s food safety, they may not come back.

Strong food safety practices keep your operation running well day to day. When you and your team handle food properly (from storage temperatures to cleaning routines), you prevent waste and avoid disruptions. For example, keeping refrigerators cold enough means products last as long as they should and stay safe to sell.

On the flip side, if a cooler breaks or someone neglects to monitor temperatures, you might have to toss out hundreds of dollars of food. Good food safety practices protect your customers and help you avoid costly mistakes.

Retail food operations face unique challenges compared to restaurants.

You might have numerous employees, including part-timers, handling food throughout the day. Turnover can be high, and not everyone is a seasoned food handler.

Making sure every staff member follows the same procedures every day on every shift and at every location is tough. Without clear systems, things like handwashing, date labeling, or equipment cleaning can slip through the cracks.

Retail stores often carry a little bit of everything: raw ingredients in the back, prepared ready to eat items in the front, and customers browsing in between. This creates many points where contamination could happen.

Take a deli section as an example: meat slicers need to be kept clean and sanitized regularly, and raw meats must be kept separate from ready-to-eat foods.

Yet studies have found that many delis struggle to meet all recommended practices. For example, a CDC survey found issues like refrigerators running too warm in 1 out of 6 delis, and sanitizer solutions mixed at the wrong strength in 1 out of 4 delis.

Busy stores may miss these details, especially without a solid routine or when relying on manual checks.

If you’re using paper logbooks or checklists, it’s easy for them to get lost, damaged, or simply not filled out. A retail area manager might only discover after a week that a particular store hasn’t been completing its daily temperature logs or cleaning checklists.

By then, it might be too late. An inspector could have already popped in, or an incident might have occurred. Keeping track of all those records by hand is tedious and prone to errors, but it’s necessary to show health inspectors that you are in compliance. All these challenges make it clear why having a strong plan and the right tools matters for retail food safety.

The good news is that there are proven best practices that can greatly improve food safety in your stores. Here are 7 key steps and habits to focus on:

Make sure each employee understands how crucial their role is in keeping food safe. This includes teaching them proper handwashing, glove use, and personal hygiene, as well as how to handle foods properly.

Having at least one certified food safety manager or supervisor per location is a good idea, as it sets a knowledgeable leader in charge. They can give regular brief refreshers or huddles that can keep food safety top of mind for everyone.

From the moment food arrives from your suppliers to the moment it’s sold, temperature is key. Train staff to check deliveries (frozen and chilled goods should arrive at safe temperatures), and store everything appropriately right away.

Use thermometers in all refrigerators, freezers, and hot-holding units and check them daily. Log those temperatures so you have a record. Cold foods must stay at 41°F (5°C) or below in fridges, and hot foods should stay above 135°F (57°C) when holding for service. Consistent temperature logging will catch problems early.

For example, if a display cooler is creeping up in temperature, you can fix it before foods inside become unsafe.

Cleanliness is non-negotiable in food retail. Develop a regular cleaning schedule for all areas, from food prep counters and deli slicers to customer touchpoints like tongs, scales, or shopping basket handles. Use the correct sanitizer solutions at the right concentrations for surfaces and equipment that touch food.

Food contact surfaces, for example, should be sanitized at least every four hours in use (as in a deli), or more often if needed. Make sure your team knows how to mix and use these solutions properly.

Maintaining a cleaning log or checklist can help make sure no task is overlooked, whether it’s nightly floor mopping or weekly deep cleaning behind equipment.

to practice proper cleaning and sanitizing

Keep raw meats, poultry, or seafood well separated from ready-to-eat foods like salads, baked goods, or sandwiches. In storage, raw items should be sealed and placed below ready-to-eat items to prevent any drips.

On the sales floor, if you have self-service areas or open food displays, use barriers and separate utensils for different food types. Train staff to never use the same knife or cutting board for raw and cooked foods without thorough cleaning in between.

Emphasize allergen management awareness. For example, use dedicated tools for allergen-free prep if you offer gluten-free or nut-free items, and label everything clearly so customers with allergies can trust your products.

Good rotation practices (like “first in, first out”) ensure older stock is sold first and nothing expires on the shelf. Clearly mark prep dates on items made in-house (e.g., sandwiches or salads) and respect their shelf life.

An organized storage system helps. For example, don’t hide old stock behind new stock. This approach prevents selling spoiled goods and reduces food waste.

Have a routine for checking perishable items daily. If something is near expiration, you might discount it for quick sale or remove it, rather than risk it passing its date unnoticed.

Even the cleanest store can attract pests if you’re not vigilant. Keep the store and especially food areas clean of crumbs and spills that invite pests. Make sure trash areas are well managed and keep dumpsters away from delivery doors.

Regularly inspect for signs of pests like droppings or gnaw marks, and seal up any gaps or cracks where rodents or insects could enter. It’s wise to have a professional pest control service do routine checks.

Keep your equipment in good repair. A faulty fridge or a broken seal on a display case can compromise food safety, so fix issues promptly to avoid hazards.

Conduct your own internal audits or walk through the store when no one is expecting it, to see how it fares. Keep all your logs and compliance documents organized and accessible. That way, if an inspector comes in or if there’s ever a customer complaint about a food item, you can quickly show your records and steps taken.

Having clear Standard Operating Procedures (SOPs) for every routine, from cleaning to handling customer complaints about food, will guide your team on what to do. Treat every day like an inspection day, and you'll always be prepared if an inspector walks in.

When you, as a retail food safety leader, focus on these practices, you create a strong food safety culture in your stores. It’s not about one person doing it all, but everyone understanding their part and following through consistently.

Chain retailers often have an edge here. They implement the same policies and training across all their locations. If you run independent stores, you can adopt the same mindset: standardize your procedures and make food safety a daily habit, not an occasional concern.

Self-serve stations can feel like a convenience for customers, but they carry real risks. Shared utensils can transfer allergens, children may handle food directly, and sneeze guards don’t always stop contamination.

Keeping up with all the tasks and records required for food safety can be overwhelming, especially as your business grows. This is where technology can make a big difference for retail food operations. Digital food safety management tools like FoodDocs help automate and simplify many of the routines we just discussed.

Think about temperature logs. Instead of recording fridge temps on paper, a digital system might use smart sensors that automatically log temperatures 24/7.

If a cooler goes out of the safe range, the system can send an instant alert to the manager’s phone so problems get noticed and fixed right away, not hours later when someone finds thawed product in the freezer. Automation reduces the chance of human error and frees up your staff’s time.

As an area manager or food safety leader, you can review all locations at a glance on a dashboard. For example, FoodDocs provides an overview of compliance across multiple sites in real time, so you can instantly spot if any store is falling behind on tasks.

A great food safety software will include visual instructions (i.e., pictures or videos) alongside tasks, which is great for training new employees and giving old ones refreshers when necessary. If someone is unsure how to calibrate a thermometer or when to record a corrective action, the software can walk them through it. A well-designed FSMS makes it easier for your team to consistently do the right thing.

And then, of course, there are the cost and time savings. Cutting down on paperwork and preventing mistakes with digital systems will save labor hours (and stress). Using an automated system might save the equivalent work of a full-time employee at each location by streamlining routine checks and paperwork.

It’s not about replacing people. It’s about letting your team focus on serving customers and running the business, rather than chasing paperwork. Over time, fewer safety incidents and more efficient operations can translate into better profits, while you continue to uphold high food safety standards.

And that's what Bakery 79 did by digitizing food safety management...

Bakery 79 is a food-to-go chain, is an example of digital food safety success in the retail industry. They use FoodDocs software to maintain top compliance across 12 locations and growing.

The image above highlights their results, including 100% 5-star food hygiene ratings at all stores and streamlined training for staff.

Chloe Hammond

Food Central Operations Manager

Park Garage Group

Even as they grew quickly, they did not drop the ball on safety or quality. According to their managers, having a centralized digital system was key. It eliminated the old problems of missing paperwork or last-minute scrambles. All routine checks were digitally tracked, giving both store managers and upper management a clear picture of compliance in real time.

One manager noted that higher-ups could simply glance at a dashboard each week and see that everything was 100%.

Matt Cundrick

International Food Operations & Commercial Leader and Founder

FTG Navigator

The company’s chairman commented that FoodDocs “more than paid for itself,” thanks to efficiencies gained.

And the brand’s reputation got a boost. Customers see those 5-star hygiene certificates on the doors and know that this place takes food safety seriously.

Investing in the right smart food safety tools helped this company maintain high safety standards across a dozen locations without needing an army of extra supervisors. When done right, digitizing food safety isn’t just about avoiding mistakes. It actively contributes to more efficient operations and greater customer confidence.

If you’re still using pen and paper logs or fragmented systems, it may be time to consider going digital. You’ll need to onboard the software and train your team on it. But modern solutions are becoming increasingly easy to use and quick to implement.

FoodDocs even speeds this up by generating a personalized food safety plan for your business in minutes after you answer a few questions, and provides templates for all your routine checks.

Think about the scale of your operations and where you face the biggest challenges…

A digital system can tackle these issues. It acts like a diligent assistant that never forgets a task, never misplaces a record, and always keeps you informed and up-to-speed.

The goal is to serve safe, quality food that keeps people coming back. How you achieve that becomes much easier with the right tools. Try FoodDocs today with a 14-day free trial — no credit card required.

Keep cold holding at 41°F or below. Check and log case temperatures at opening, mid-shift, and closing. If food rises above 41°F for more than four hours, discard it.

Keep hot holding at 135°F or above. If hot food drops below 135°F for more than two hours, discard it. Use a calibrated probe, not the case display, to verify.

Log at least three times per day at opening, mid-shift, and closing. In busy stores, add a check every four hours. Investigate any trend that shows drift.

Swap utensils and sanitize the holder at least every four hours. Replace sooner if dropped, soiled, or used across different foods. Keep backups ready at the station.

Use clear labels, separate tools, and color cues for allergen items. Store allergen products apart from ready to eat foods. Train staff to confirm ingredients before answering a customer.

Include product name, full ingredient list, allergens in plain language, and use by date. Labels must be legible and match the recipe used in prep. Spot check labels daily.

Record what went wrong, the time, who acted, and the fix taken. Add the root cause and what will stop it next time. Close the entry only after the manager verifies the fix.

Check weekly with ice water at 32°F and boiling water per altitude. Calibrate any device that is off. Replace damaged probes right away.

Keep any staff with vomiting, diarrhea, jaundice, or sore throat with fever off food tasks. Follow your exclusion and return to work policy. When in doubt, send them home.

Keep case doors closed and note the start time. Discard cold foods above 41°F for more than four hours and hot foods below 135°F for more than two hours. Document what was discarded and why.

They will ask for temperature logs, cleaning and sanitizer logs, labels for grab and go, and your corrective action records. Have these organized and easy to access. Walk them to the cases and prep areas with confidence.

Keep supplier contacts, lot codes, and delivery records in one place. Pull affected stock at once, post a notice if required, and document every step. Close the loop with your supplier and local authority.

Yes, ice is a food. Clean and sanitize ice machines on the maker schedule, keep scoops off contact surfaces, and never use glass to scoop.

Track percent of checks on time, average time to close deviations, repeat issues by site, and inspection score trends. Set targets and review them weekly with store leaders.

Start with one pilot store for two to four weeks. Load your checklists, labels, and training clips, then review the dashboard daily. Fix gaps, then roll it to the rest of the stores with short coaching sessions.

Use a short risk scan that covers temperatures, labels, sanitizer strength, and self-serve controls. Score each store on the same checklist. Follow up within 24 hours on any red item.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...