Vacuum-sealed perishable foods, such as meat and vegetables, typically last 1 to 2 weeks in the fridge, significantly longer than their non-sealed counterparts, which last just a few days. Vacuum sealing slows the spoilage process by limiting oxygen exposure, which helps preserve freshness.

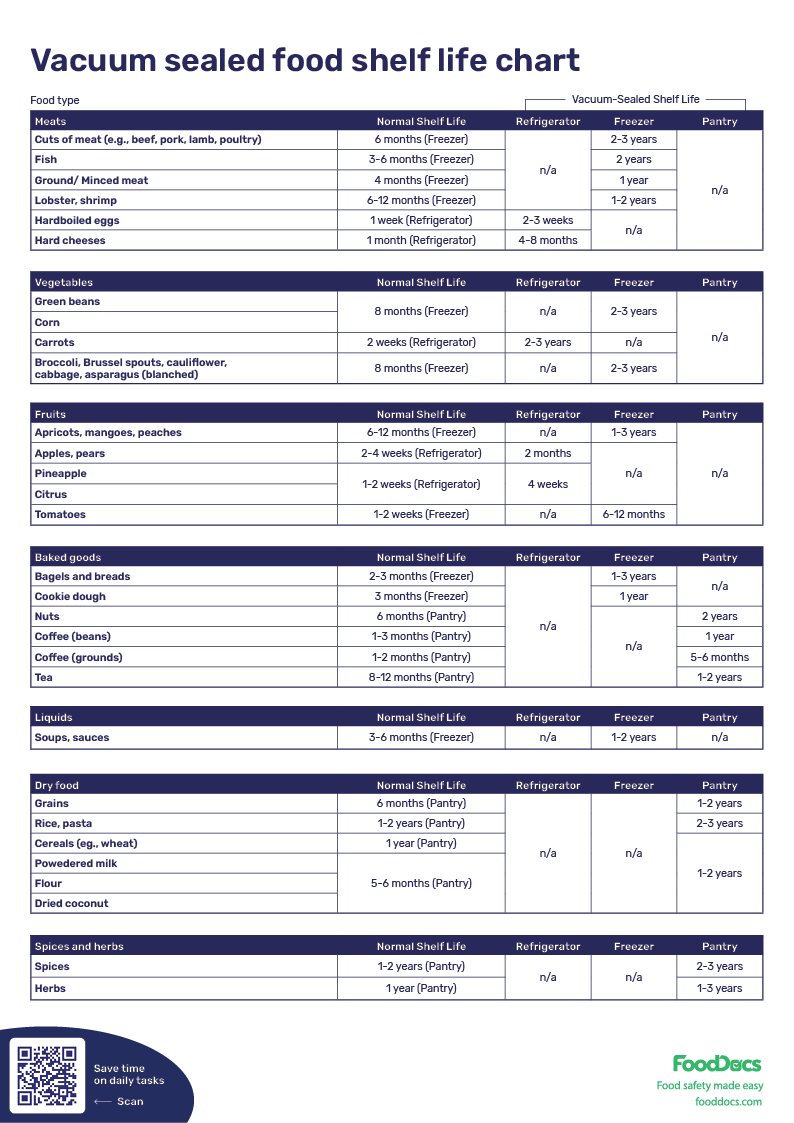

VACUUM SEALED FOOD SHELF LIFE CHART

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

Key takeaways

- Vacuum sealing removes oxygen to extend the shelf life of foods, preventing spoilage and bacterial growth. It can even extend a product’s shelf life up to five times, but it is not a complete solution.

- Vacuum sealing, also known as Reduced Oxygen Packaging (ROP), involves removing oxygen to prevent the growth of aerobic bacteria.

- For meat products, vacuum sealing preserves flavor and appearance by preventing oxidation.

- Vacuum-packed food is compact, making it easier to store and transport in bulk compared to other packaging methods.

- Vacuum sealing prevents the growth of oxygen-dependent bacteria, significantly extending shelf life and reducing food waste.

- In the food industry, vacuum-sealed products like meats and vegetables may require a HACCP plan to ensure food safety compliance.

- A Vacuum Sealed Food Shelf Life Chart is a helpful tool for food handlers to track the expected storage life of vacuum-packed foods.

- Proper hygiene and food safety practices must be followed during vacuum sealing to prevent contamination and ensure food quality.

- Some foods, like raw garlic, certain vegetables, and soft cheeses, should not be vacuum-sealed without special precautions.

- FoodDocs is an easy-to-use Food Safety Management software that will help you monitor and trace your vacuum sealed food's shelf life.

WHAT WE'LL COVER:

- What is vacuum sealed food?

- HACCP plan for vacuum sealer

- Why do you need a vacuum sealed food shelf life chart?

- Who needs this kind of chart?

- Most important things to remember when vacuum sealing

- What can go wrong when vacuum sealing?

- Which foods can you not vacuum seal?

- How food safety software can help your business

- Frequently Asked Questions

Download the vacuum sealed food shelf life chart PDF

The extended exposure of foods to oxygen may often cause changes and compromise safety. Several foodborne pathogens, such as spoilage bacteria and molds, require oxygen to spoil foods. As such, a food industry solution is to remove oxygen upon packaging foods through vacuum sealing.

Vacuum-sealed food such as frozen meats have a significantly longer shelf life than those stored in airtight containers. The absence of oxygen removes the likelihood of spoilage from oxidation and the effects of aerobic pathogens. Use a Vacuum Sealed Food Shelf Life Chart to guide food handlers on the recommended shelf life of vacuum-sealed foods.

Vacuum sealing foods can extend the shelf life of your food products up to five times longer. This preservation method is a great addition to your usual refrigeration and freezing operations. This operation is great for long-term food storage as it preserves the product quality while limiting the potential growth of microorganisms. Although your foods may last for a longer storage time, the effects of vacuum packing process is not necessarily absolute. This means that foods will still spoil or change in characteristics after a long while.

Learn how can vacuum-sealing foods help you manage your operations and how you can help your team remember important information such as the altered use-by dates of vacuum-sealed foods.

What is vacuum sealed food?

Vacuum-sealed foods refer to products or raw materials enclosed in a shrink film where oxygen is removed from the packaging. Vacuum sealing, otherwise known as reduced oxygen packaging (ROP), is the process of removing oxygen in a container to prevent the effects of oxygen from affecting the product and eliminate the likelihood of the growth of aerobic bacteria. Sometimes, the process is augmented with an oxygen absorber packet for more efficiency before passing through a vacuum packing machine.

Vacuum-sealed foods also stay fresh longer as the volatile flavors of the ingredients stay in the food and are unaffected by oxidation and other chemical reactions that require oxygen. For meat products, removing oxygen will turn the raw meat into a deep purple-red color and stay the same until opened.

Vacuum packaging also helps food handlers store foods in terms of space. Vacuum-packed foods are less bulky and can be easily transported from one place to another. You can store vacuum-packed food in bulk more efficiently.

One of the main objectives of vacuum sealing is to prevent the growth of bacteria that require oxygen for growth, otherwise called aerobic bacteria. This objective can help significantly prolong the shelf life of vacuum-packed products for a significantly extended period by limiting the biological processes of bacteria.

Employing a vacuum-packaging operation in your food business for commercial products may require a HACCP plan for food safety compliance.

Is there a HACCP plan for vacuum sealer?

Yes. As a food business in the raw vegetables, raw meat, raw poultry or other related industry, regulations will likely require you to have a HACCP plan for reduced oxygen packaging (ROP).

In the food industry, reduced oxygen packaging refers to the process of:

- Putting food into a package

- Removing the oxygen from the package

- Sealing the package

ROP techniques include:

- Vacuum packaging: Food is enclosed in special packaging, and a vacuum sealer machine extracts the air. Once the oxygen is removed, the packaging is securely sealed, either by heat or by crimping, to extend shelf life.

- Sous vide: This technique involves sealing raw or partially cooked food in a bag and cooking it at a controlled temperature close to the final desired level. The lack of oxygen in the sealed bag preserves the food, which can then be served right away, kept warm, or quickly cooled and stored in the fridge for reheating later.

- Cook-chill: After cooking, food is placed in bags while still hot, sealed tightly, and rapidly cooled before refrigeration. This process, which removes oxygen, helps maintain the quality and freshness of the food until it is reheated for service.

Some harmful bacteria, like Clostridium botulinum and Listeria monocytogenes, thrive in low-oxygen environments. If kitchen teams do not perform ROP properly, these bacteria can multiply in the food, posing a higher risk for bacterial growth. This is why a HACCP plan for reduced oxygen packing operations is necessary.

According to the latest FDA Food Code updates to Reduced Oxygen Packaging with One Barrier (Cook-Chill and Sous Vide) for TCS foods, there are four options businesses have for food storage:

- Cool to 34°F (1°C) within 48 hours: If unused after 30 days, discard.

- Keep at 41°F (5°C) for 7 days: Discard if not consumed within that time.

- Cool to 34°F (1°C) within 48 hours, then hold at 41°F (5°C) no longer than 7 days: Discard if not consumed within 30 days.

- Freeze indefinitely until used.

Below is an outline of what your HACCP plan for food vacuum sealers could include:

| HACCP plan section | Requirements |

|---|---|

| Covered foods | Raw vegetables, raw meat, and raw poultry. Only these foods can be vacuum packaged under this plan, and they must be stored in refrigerated conditions (41°F or lower). |

| Flow diagram | The process includes receiving, cooler storage, vacuum packaging, labeling, chilling (ice bath), and refrigerated storage (41°F or lower until used or discarded after 14 days). |

| Training program | Employees must be trained in: the allowed foods, food safety risks, equipment use, labeling requirements, handling and storage procedures, critical and operating limits at CCPs, and cleaning. |

| General operating Procedures | Only trained personnel can operate equipment. Only covered foods are allowed for vacuum packaging. Food-grade packaging must be used. Equipment must be cleaned every 4 hours or after use. |

| Labeling | Products must be labeled with "Maintain at 41°F or below" and "Use by (14 days from the date of packaging)." Unlabeled or expired products must be discarded. |

| Critical Control Points (CCPs) | Monitoring includes using calibrated continuous thermometers for refrigerated storage, visual checks twice a day, and review of data daily. Corrections required if temperature exceeds 41°F. |

| Corrective actions | If temperature exceeds 41°F, food must be evaluated by a process authority. Products deemed unsafe are discarded, and storage equipment must be repaired. |

| Verification | A manager/supervisor must review records weekly, including temperature logs and labeling checks, to ensure all critical limits are maintained. |

You can use our free and customizable HACCP plan template to create your own! Or try the FoodDocs HACCP Plan builder to get a done-for-you document in less than one hour. All you need to do is answer a handful of key questions about your business type.

Why do you need a food storage vacuum sealed food shelf life chart?

A vacuum sealed food shelf life chart can help guide food handlers with the shelf life expectancy of vacuum-sealed foods. Although vacuum sealing prolongs the shelf life of foods, your vacuum-sealed products may still spoil or deteriorate in time. The effects of vacuum sealing differ for every type of food.

For example, storing fresh meat such as ground beef at refrigerated temperatures may stay fresh for 2 to 3 days. When vacuum-packed properly to prevent freezer burn and refrigerated, fresh meat can achieve an extended shelf life of up to 10 days. On the other hand, lettuce can only stay 6 to 8 days fresh, even when vacuum-packed and refrigerated.

According to Kara Lynch, a Registered Dietician and Food Safety Educator at Michigan State University Extension, vacuum sealing reduces exposure to oxygen and can significantly extend food’s quality shelf life while reducing waste.

While vacuum-sealing food is very helpful, food handlers must still be oriented about how long would the storage life expectancy of the food would be.

A vacuum sealed food storage life chart shows foods' regular food storage shelf life and shelf life when vacuum packed. This chart can be used as a reference for labeling vacuum-sealed foods for their use-by date.

Who needs a Vacuum Sealed Food Shelf Life Chart?

Food businesses such as meal delivery services, food retailers, spice suppliers, and grocery stores that deliver vacuum-sealed foods can benefit from a vacuum sealed food shelf life chart. If your food business applies vacuum packing for food preservation or packaging foods, you will need a reference for labeling your products. Because of the diversity of effects of vacuum packing, it is hard to memorize every shelf-life expectancy of foods.

Emphasize that any U.S. business using vacuum sealing (from caterers to grocery suppliers) can use the chart to educate staff and comply with food safety date-marking requirements.

Food businesses delivering foods in vacuum-sealed packs will benefit most from this chart. The information from this chart can also be used to accurately guide consumers who will receive the vacuum-packed products.

What are the most important things to remember when dealing with food vacuum sealing?

Vacuum sealing is a packaging method that can only be effective in prolonging shelf life of food if the materials are prepared hygienically. Proper food handling practices and strict food safety standards must be applied. The effectiveness of vacuum food sealers in preserving foods is only as good as how the raw materials are prepared.

If unsanitary conditions were present during vacuum sealing, the likelihood of anaerobic bacteria could significantly increase. These pathogens can only grow in the absence of oxygen.

To help create a conducive environment for a successful vacuum sealing, follow these guidelines:

- Always use fresh raw ingredients in preparing foods for vacuum sealing.

- Refrigerate vacuum-sealed foods promptly at 40°F (4°C) or below, and freeze when long storage is needed. Vacuum sealing is not a substitute for refrigeration.

- Vacuum sealing doesn’t eliminate bacteria (i.e., it's not a kill step). It only inhibits aerobic spoilage organisms.

- Clean and sanitize all food contact surfaces and utensils in a restaurant kitchen.

- Employees must practice strict personal hygiene (e.g., proper handwashing practices, not attending when sick).

- Prevent cross-contamination between food handlers and food being vacuum-packed.

- Employees must be well-trained in operating the vacuum sealing machine to ensure effective sealing.

- Always label foods with a use-by date before refrigerating or freezing.

- Only use the recommended amounts of food for every vacuum sealing batch. Overfilling may make the process ineffective.

- If using reusable aseptic packages, always ensure they are sanitized before using them again.

- Use sturdy bags designed for vacuum sealing. Punctures on the bag will allow oxygen to enter.

- Refrigerate or freeze vacuum-sealed foods.

- When thawing vacuum-packed fish, remove it from the vacuum bag before thawing in the refrigerator, to prevent anaerobic bacteria like Clostridium botulinum from growing.

It is very important for food safety practices to be applied when performing vacuum sealing to make the food shelf stable. Failure to create a clean environment during food handling can attract contaminants and compromise the target shelf life of products.

Remember to use a Vacuum Sealed Food Shelf Life Chart to guide food handlers on the recommended shelf life of vacuum-sealed products. Place the chart in a visible area, preferably near the vacuum sealer, to remind them of the important shelf life information.

In addition, vacuum-sealed products must be properly kept under the safe temperature. Even when vacuum sealed, foods can spoil very fast if stored under ambient temperature or in the temperature danger zone. Instruct food handlers to keep them in refrigerated or freezing conditions and regularly monitor proper temperature for maintenance. Use a temperature log sheet for this operation.

You can find more useful food safety documents such as checklists, monitoring templates, and posters from our food safety template hub.

What can go wrong when vacuum sealing?

Vacuum sealing is very effective food preservation and storage method. To ensure the effectiveness of the process and maintain the safety of your food items, food handlers must be aware of particular guidelines in vacuum sealing and prevent spoilage or the potential risk of food poisoning.

Circumstances such as poor food handling or food hygiene can lead to food spoilage during vacuum packaging. Anaerobic bacteria, or bacteria that grow in the absence of oxygen, can grow on contaminated, moist products that were vacuum sealed. Such bacteria can contaminate food items through cross-contamination before vacuum sealing.

Dangerous microbial growth, such as the growth of Clostridium botulinum can form under vacuum conditions. The National Center for Food Preservation posted guidelines and warnings on food safety issues and concerns that can occur during vacuum sealing.

Pinholes on the food packaging or incomplete vacuum sealing can also promote contamination.

Which foods can you not vacuum seal?

Although there are many benefits to vacuum sealing, some foods cannot be vacuum sealed raw. Foods such as raw meat, cooked meat, pasta, white rice, herbs, fresh green beans, and dehydrated vegetables and fruits. On the contrary, you cannot seal types of food such as the following:

- Garlic

- Freshly cooked low-acid vegetables

- Broccoli

- Cabbage

- Arugula

- Turnips

- Soft cheese

Some foods, such as broccoli and foods under the same family (Cruciferae or Brassicaceae), naturally produce gas. Once the gas is produced, this will jeopardize the integrity of the plastic container or vacuum packaging. However, they can be vacuum-packed once blanched and/or augmented with oxygen absorbers for food storage.

In the case of unpasteurized fermented products such as soft cheeses, mold production to unsafe levels can significantly increase under vacuum conditions.

You might see additional items like raw onions and fresh mushrooms on lists of foods that should not be vacuum-sealed without special precautions, as these can create conditions favorable for C. botulinum.

How can you help your team ensure correct vacuum sealing?

To help your employees, provide them with a Vacuum sealed food shelf life chart as a reference for correct use-by-date labeling. The next thing you need is to determine a way how to remind food handlers regarding the maximum shelf life of vacuum-sealed foods once they are stored in the fridge or freezer. Additionally, you also need a more efficient way to ensure the correct storage conditions for these products. A simple chart cannot help you with this task.

At FoodDocs, we have the best digital solution for your vacuum-packaging woes. We offer digital solutions that can help you remind your team about food safety tasks such as temperature monitoring tasks to ensure that you will only be using and serving food fresh all the time.

Particularly, our digital solution can help you with the following benefits:

- Save time from filling repetitive temperature monitoring forms as our automatically generated forms are equipped with an auto-fill solution. Your employees would only need to verify the information.

- Our notification system can also send alerts for food safety tasks such as temperature monitoring of freezers and fridges. All temperature monitoring tasks can be done on time with this feature.

- Our digital monitoring logs also include informative and well-designed instructions that will help you train employees on how to correctly monitor temperature.

In addition to digital solutions for everyday monitoring tasks of employees, our digital Food Safety Management System can also help managers save time.

- Switching to our digital Food Safety Management System only takes an average of 15 minutes. At this time, our system can automatically generate a comprehensive and customizable FSMS for you.

- You can save at least 20% of your time managing your operations with a real-time dashboard from our digital solution. You can always stay up to date with your food safety tasks and remotely monitor areas that need more attention.

- You can also get digital cloud storage to help you manage, store, and easily access all digital documents.

While technical operations such as vacuum sealing can be challenging for some, you can help your team manage this operation with our help. Using our digital FSMS, compliance with food safety regulations on vacuum sealing can be achieved easier.

Maintain compliance and become more sustainable as you switch to our digital platform in just an average of 15 minutes. Experience an effortless food safety compliance with our help and protect your consumers from potential food safety issues.

You can experience our digital solution firsthand when you use our free, 14-day trial.

Frequently asked questions about vacuum sealed food shelf life

How long can you keep vacuum-sealed food?

The expected shelf life of vacuum-sealed food will depend on the nature of the food product and food storage temperature. On average, a vacuum-sealed product under freezing conditions can last up to 5 to 6 months or even 1 to 2 years, depending on your freezer capacity. On the other hand, refrigerated vacuum-sealed products can last up to 1 to 2 weeks.

What foods can you vacuum seal for long-term storage?

Shelf-stable and dry foods such as pasta, cereals, granulated sugar, dehydrated foods, white flour, ground coffee, and grains can be stored for even longer periods of time when vacuum-packed. This process can be used to preserve seasonal and perishable food for storage or serve as an emergency supply of food.

Does vacuum sealing extend shelf life?

On average, the process of vacuum sealing extends the shelf life of fresh food up to 3 to 5 times longer than a normal storage container. The length of shelf life may vary depending on the food type, packaging used, and the final storage conditions (e.g., a walk-in freezer for frozen foods).

How long is vacuum-sealed meat good for in the fridge?

The normal 3 to 5 days of maximum storage life of raw meat can be extended up to 10 days when vacuum sealed and stored in the refrigerator. In freezing conditions, meat can stay fresh for up to 6 months when vacuum packed.

How long does vacuum-sealed meat last in the freezer?

Vacuum-sealed raw meat can last 1 to 3 years in the freezer, compared to just 6 to 12 months when not sealed. The absence of air prevents freezer burn, preserving the texture, taste, and safety of the meat.

How long does vacuum-sealed food last at room temperature?

Vacuum sealing does not remove the potentially present harmful bacteria in food. We don't recommend, for example, vacuum-sealing perishable foods at room temperature because they'll spoil quickly and increase the risk of foodborne illness. In general, vacuum-sealed foods can only stay at room temperature for a maximum of 2 hours.

Non-perishable foods dry foods like pasta, rice, and grains that you've vacuum sealed can last 6 months to a year at room temperature due to the reduced exposure to moisture and oxygen. However, vacuum-sealing perishable foods at room temperature is not recommended, as they can spoil quickly and still pose a food safety risk.

How long does vacuum-sealed food last in the fridge?

How long does vacuum-sealed chicken last?

In the fridge, vacuum-sealed raw chicken can last 1 to 2 weeks, a significant extension from the typical 2 to 3 days without sealing. When frozen, vacuum-sealed chicken can be stored for up to 2 years without losing quality.

How long does vacuum-sealed meat last in the fridge?

Vacuum-sealed raw meat typically lasts 1 to 2 weeks in the fridge, which is longer than the 3 to 5 days for non-sealed meat. The vacuum seal preserves the meat by limiting oxygen, reducing bacterial growth.

How long does vacuum-sealed rice last?

Vacuum-sealed rice can last 1 to 2 years at room temperature, making it an excellent option for long-term storage. The vacuum sealing process keeps out moisture and air, both of which can degrade rice over time.

How long does vacuum-sealed flour last?

Vacuum-sealed flour can last 1 to 2 years in the pantry and up to 3 years if kept in the freezer, providing a much longer shelf life than non-sealed flour. The lack of air prevents rancidity and spoilage from pests like pantry moths.

How long does vacuum-sealed cheese last?

Hard cheeses, like Parmesan or cheddar, can last 4 to 8 months when vacuum-sealed in the fridge, while soft cheeses, such as brie, last about 1 to 2 weeks. Vacuum sealing reduces moisture loss and limits exposure to mold spores.

How long does vacuum-sealed fish last in the freezer?

Vacuum-sealed fish can last 2 to 3 years in the freezer, retaining its flavor and texture much longer than non-sealed fish, which lasts 6 to 9 months. Vacuum sealing prevents freezer burn, ensuring high quality for a longer period.

How long does vacuum-sealed bacon last in the fridge?

Vacuum-sealed bacon lasts up to 1 week in the fridge, which is longer than the 5 to 7 days for non-sealed bacon. Freezing vacuum-sealed bacon extends its shelf life up to a month while keeping its taste intact.

How long does vacuum-sealed ground beef last in the fridge?

Ground beef can last 1 to 2 weeks in the fridge when vacuum-sealed, whereas it would only last 1 to 2 days without the seal. The vacuum seal inhibits bacterial growth by reducing the air available to spoilage organisms.

How long does vacuum-sealed steak last in the fridge?

Steak can last 1 to 2 weeks when vacuum-sealed and stored in the fridge, compared to just 3 to 5 days for non-sealed steak. Vacuum sealing keeps the meat fresh by preventing exposure to oxygen, which accelerates spoilage.

How long does vacuum-sealed tuna last in the fridge?

Fresh, vacuum-sealed tuna lasts 1 to 2 days in the fridge, extending its freshness by a few days beyond non-sealed fish. When frozen, vacuum-sealed tuna can last up to a year while maintaining its flavor and texture.

How long does vacuum-sealed fruit last?

Vacuum-sealed fruit can last 1 to 2 weeks in the fridge, much longer than non-sealed fruit, which spoils within a few days. If frozen, vacuum-sealed fruit can last up to a year while retaining much of its original flavor and texture.

How long does vacuum-sealed ham last in the fridge?

Vacuum-sealed ham can last 1 to 2 weeks in the fridge, compared to about 5 to 7 days for non-sealed ham. The vacuum seal reduces spoilage by limiting bacterial growth and moisture loss.

How long does vacuum-sealed jars last?

Vacuum-sealed jars of dry goods can last up to a year or more, depending on the contents and storage conditions. For perishable items, the vacuum seal significantly slows down spoilage but refrigeration or freezing is still required.

How long does vacuum-sealed shrimp last in the fridge?

Vacuum-sealed shrimp lasts 1 to 2 days in the fridge, which is comparable to non-sealed shrimp. However, vacuum-sealed shrimp can last 6 to 12 months in the freezer without developing freezer burn or losing quality.

How long does vacuum-sealed pasta last?

Dry, vacuum-sealed pasta can last up to 2 years at room temperature, far exceeding the shelf life of non-sealed pasta, which typically lasts 1 year. The vacuum seal protects the pasta from moisture and air, both of which can lead to spoilage.

How long does vacuum-sealed bread last?

Vacuum-sealed bread lasts 7 to 10 days at room temperature, compared to 2 to 3 days for non-sealed bread. Freezing vacuum-sealed bread can extend its shelf life to up to 1 year, maintaining freshness and avoiding freezer burn.

How long does vacuum-sealed pork loin last in the fridge?

Vacuum-sealed pork loin lasts 1 to 2 weeks in the fridge, while non-sealed pork would only last 3 to 5 days. The vacuum seal slows down spoilage by reducing oxygen exposure and moisture loss.

How long does vacuum-sealed smoked meat last in the fridge?

Smoked meats can last up to 2 weeks in the fridge when vacuum-sealed, compared to just a few days without sealing. The reduced oxygen inside the package helps preserve the smoked flavor and prevents bacterial growth.

How long does vacuum-sealed salami last in the fridge?

Vacuum-sealed salami can last 1 to 2 months in the fridge, significantly longer than non-sealed salami, which lasts about 3 weeks. The vacuum seal keeps the salami dry and prevents mold growth.

How long does vacuum-sealed coffee last?

Vacuum-sealed coffee beans can last 6 to 9 months at room temperature, retaining much of their flavor and aroma. Ground coffee, when vacuum-sealed, lasts 3 to 5 months, as its finer particles degrade faster than whole beans.

How long does vacuum-sealed sausage last in the fridge?

Vacuum-sealed sausage can last 1 to 2 weeks in the fridge, extending its shelf life from the typical 1 week of non-sealed sausage. Vacuum sealing limits air exposure, which slows the growth of bacteria and mold.

How long does vacuum-sealed vegetables last?

Vacuum-sealed vegetables last 1 to 2 weeks in the fridge, compared to a few days for non-sealed ones. When frozen, vacuum-sealed vegetables can retain their quality for 1 to 2 years.

How long does vacuum-sealed butter last in the freezer?

Vacuum-sealed butter can last up to 1 year in the freezer, maintaining its freshness and preventing freezer burn. The vacuum seal prevents oxidation, which can cause butter to become rancid over time.

How long does vacuum-sealed garlic last?

Vacuum-sealed garlic can last 1 to 2 weeks in the fridge, which is a little longer than non-sealed garlic. When frozen, vacuum-sealed garlic can last up to a year without losing much of its flavor.

How long does vacuum-sealed lettuce last?

Vacuum-sealed lettuce lasts 5 to 7 days in the fridge, compared to 2 to 3 days without sealing. The vacuum seal reduces moisture loss and limits wilting, though lettuce is still prone to quick spoilage.

How long does vacuum-sealed cured meat last in the fridge?

Vacuum-sealed cured meats like ham or prosciutto can last up to 2 weeks in the fridge, compared to just 1 week for non-sealed versions. The vacuum sealing process preserves the flavor and prevents bacterial growth by reducing oxygen.

How long does vacuum-sealed bell peppers last?

Vacuum-sealed bell peppers can last 1 to 2 weeks in the fridge, compared to only a few days for non-sealed peppers. The vacuum sealing process helps retain the peppers' moisture and freshness, slowing down spoilage and preventing dehydration.

How long does vacuum-sealed cornmeal last?

Vacuum-sealed cornmeal can last up to 1 to 2 years when stored in a cool, dry place, while non-sealed cornmeal typically lasts 6 to 12 months. The vacuum seal protects against moisture and pests, maintaining its quality over an extended period.