WALK-IN COOLER FOOD STORAGE CHART | FREE DOWNLOAD

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

A walk-in cooler food storage chart offers an efficient way to manage cold storage, minimize risks of cross-contamination, prevent health code violations, and optimize the use of space in busy commercial kitchens and food production facilities.

Key points from this article

- A walk-in cooler food storage chart is a must-have for various food businesses to maintain an organized and safe kitchen, especially for restaurant and production kitchens.

- Storing food in a walk-in cooler helps ensure maximum freshness and food safety.

- As a best practice for storing food in walk-in coolers, organize it like this (from top to bottom): fruits, vegetables, and RTE foods on the top shelf; pre-cooked foods next followed by dairy products; raw meats; and thawed foods at the very bottom shelf.

- Some benefits of storing foods in a walk-in cooler include minimizing food waste, keeping ingredients fresher for longer, preventing cross-contamination, and more.

- The ideal temperature range for walk-in coolers is 35-38°F (1.7-3.3°C).

- FoodDocs' Food Safety Management software offers kitchen teams the easiest to use monitoring system to log walk-in cooler temperatures and so much more.

Interested in our other free cold food storage charts and posters? Check these out cold storage resources:

- Freezer temperature chart

- Freezer storage chart

- Cold food storage rules

- Cold holding food temperatures

- Fridge organization chart

- Fridge temperature chart

- Fridge layout food safety poster

- Vacuum-sealed food shelf life chart

- How long can a fridge and freezer go without power?

- Proper freezer storage times chart

These printable cold temperature, fridge, freezer, and storage charts should cover all your related needs.

Who needs a walk-in cooler food storage chart?

A walk-in cooler food storage chart is a must-have for various food businesses to maintain an organized and safe kitchen. Here are a few key food handler groups that can benefit from having one:

- Restaurant kitchen staff: In busy restaurant kitchens, staff are constantly under pressure to work quickly and efficiently while maintaining food safety standards. A walk-in cooler storage chart helps them stay organized, making it easier to find ingredients during service and ensuring everything is stored in the right place to prevent cross-contamination.

It also simplifies the process of rotating stock, which is crucial for minimizing food waste and keeping food fresh. With a clear system in place, food handlers can avoid foodborne illness risks by following best practices for safe food storage. -

Production kitchen staff: Production kitchens, such as those in food manufacturer facilities or catering operations, typically deal with large quantities of food and a more complex range of ingredients. A storage chart is essential for these kitchens to manage inventory efficiently. Following this chart will help food handlers quickly locate items and keep track of large volumes of perishable goods, ensuring they are using ingredients in the correct order (i.e., the first in, first out method).

This helps avoid food spoilage bacteria and waste, which is especially important when handling bulk orders. In addition, production kitchens often face stricter health code regulations, and an organized cooler system helps them comply with food safety standards, ensuring that there's no potential contamination of food throughout the production process.

How to properly store food in a walk-in cooler

Storing food in a walk-in cooler isn’t just about making things fit; it’s about placing items where they belong to ensure maximum freshness and safety. Below is a breakdown of where different food groups should go once they've been vacuum sealed or are stored in airtight containers, starting from the top shelf to the bottom.

Fruits and vegetables (very top)

Fruits and vegetables should always be stored on the top shelf. These items are typically consumed raw or with minimal cooking, so they need to be kept away from raw meat or dairy that could leak and cause contamination. By placing them at the top, you minimize the risk of cross-contamination from other food items.

Pre-cooked foods

Pre-cooked foods go on the shelf directly below fruits and vegetables. They can also stay on the same shelf depending on your walk-in cooler space. Since these items have already been cooked, they are at lower risk of bacterial growth. However, keeping them higher up in the cooler ensures they are separated from raw food ingredients that may harbor bacteria.

Dairy

Dairy products, like milk, cheese, and butter, should be stored just below pre-cooked foods. Dairy needs to be kept cold to prevent spoiled food, and this middle shelf is perfect for maintaining the required temperature without being exposed to contaminants from raw foods.

Raw meats

Raw meats must be placed on the lower shelves of the walk-in cooler. This ensures that any juices or liquids food items such as meat cuts, ground beef, and other ground meats won’t drip onto other foods, which could cause dangerous cross-contamination. By keeping raw meats lower, you minimize the risk of spreading harmful bacteria to other items.

If there are at least three shelves you can use for raw meats, place fish, pork beef higher, ground meats in the middle, and chicken and poultry products lower.

Thawing foods (very bottom)

Foods that are thawing should always be stored on the very bottom shelf. This prevents any liquid from seeping onto other items during the thawing process, which is critical to maintaining food safety standards.

7 Benefits of storing foods in a walk-in cooler this way

1. Minimize food waste

Proper organization helps reduce food waste by keeping ingredients stored at the correct temperatures and in the right locations. This ensures that your supplies stay fresh for longer and prevents spoilage of food due to poor handling.

2. Keep your ingredients fresh

Ingredients are expensive, especially in today’s market. Keeping them stored in the right conditions ensures they remain fresh longer, improving the food quality of your dishes while reducing unnecessary waste and costs.

3. Prevent cross-contamination

By organizing foods based on their storage requirements, you significantly reduce the risk of cross-contamination, which is crucial for food safety. Separating raw meats from ready-to-eat foods, for instance, keeps your kitchen safe from harmful bacteria.

4. Comply with health codes

Proper organization of your walk-in cooler aligns with safety regulations and health codes, giving you one less thing to worry about during inspections. It helps ensure that your kitchen meets all food safety requirements, keeping your business compliant and running smoothly.

5. Make taking inventory easier

A well-organized walk-in cooler makes inventory checks faster and more accurate. When everything has a designated place, there’s less time spent searching for items, and you’re less likely to overlook stock, which helps prevent shortages.

6. Reduce labor

Having a clear storage system reduces the time your kitchen team spends on stocking, searching for ingredients, and cleaning up. This streamlined process frees up your workers to focus on other tasks, helping them work more efficiently and allowing them to finish their shifts quicker.

7. Extend the life of your walk-in cooler

Proper storage practices not only help your food stay fresh but also reduce the strain on your walk-in cooler. By organizing items to allow for proper airflow and ensuring the cooler doesn’t have to work overtime to maintain the right temperature, you can extend its lifespan and reduce maintenance costs.

What's the ideal temperature for a walk-in cooler?

You should set your standard walk-in chiller temperature between 35-38°F (1.7-3.3°C). But be mindful of not letting the temperature of your walk-in cooler go below that because you might have food start freezing that should not be frozen.

Cold temperatures won't increase the growth of microorganisms. But if left unchecked, food items from fresh vegetables to frozen mean can suffer from freezer burn, which can lead to grayish-brown leathery spots and taste loss.

How food safety software can help streamline walk-in cooler tasks

FoodDocs is a Food Safety Management software that makes food safety easy by digitizing daily monitoring and traceability tasks. Try it free for 14 days!

Save time on logging walk-in cooler temperatures and similar daily tasks

At the beginning of your food safety monitoring system setup, you can choose to use automatically generated logs and get set up fast! You can also create custom temperature logs based on your business's specific freezer conditions.

There are two features that especially make life easier for team members who are responsible for logging fridge, freezer, and cooler temperatures:

- Smart notifications: Team members responsible for food safety tasks such as logging walk-in cooler temperatures, receiving temperatures, and cleaning checks during a shift will get timely notifications so they never miss another task.

- Corrective action prompts: If a team member inputs a walk-in cooler temperature that's outside of your pre-defined acceptable range, FoodDocs' mobile app will immediately prompt them with corrective action instructions according to your food business's standards.

If your business uses freezer temperature sensors, FoodDocs also sensor integration partners and an API that can help automate the freezer temp monitoring process.

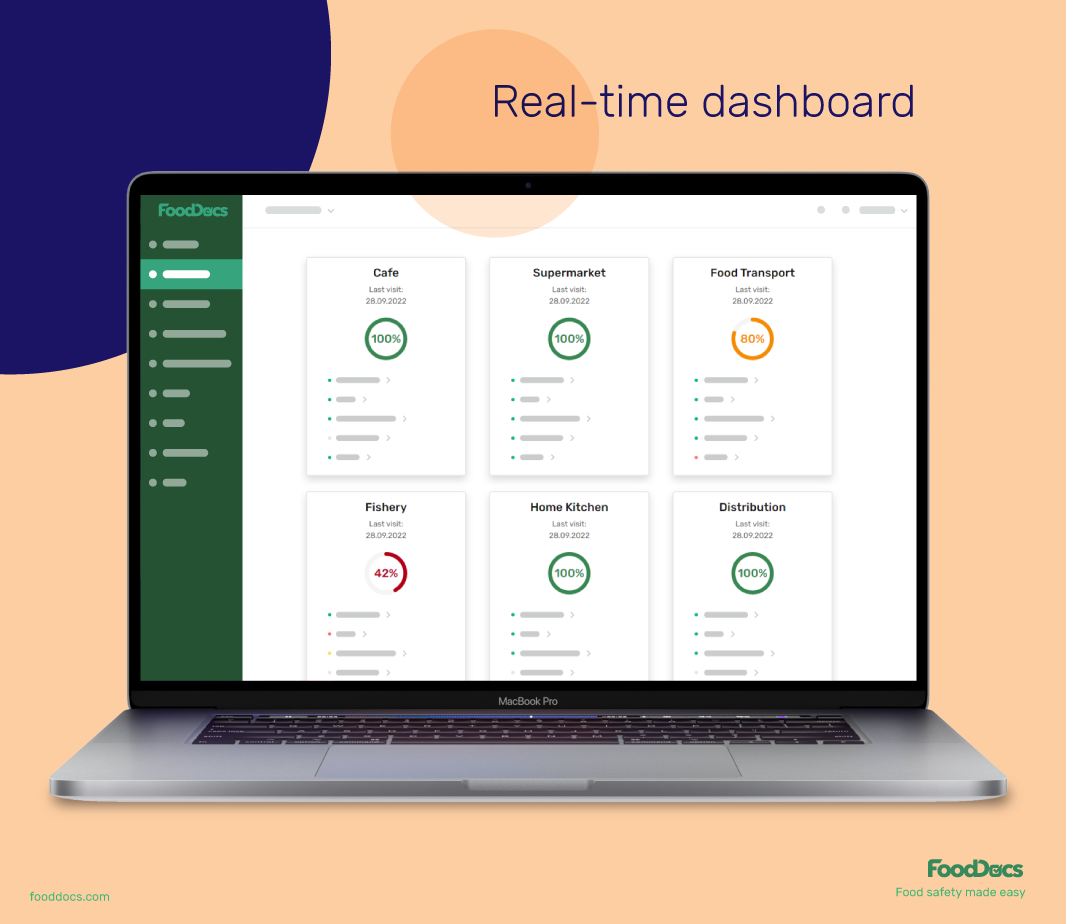

Know your business's food safety compliance status at any time with a real-time overview

Whether you're on-site or remote, the real-time overview dashboard offers a high-level view of each business unit's or department's food safety task completion.

This is a perfect tool for Supervisors or Food Safety/Quality Managers who can easily spot non-conformities and quickly address them before they become food safety incidents.

Our digital food safety system's Verification features also gives you the option to set up monitoring food safety tasks that always need to be verified once team members complete their entries. This feature is essential for food establishments that hold their food safety operation to very high standards.

Frequently asked questions

How do you stack food in a walk-in cooler?

When stacking food in a walk-in cooler, it’s important to prioritize both food safety and organization. Follow these general food safety guidelines:

-

Top Shelf: Store ready-to-eat foods, fresh fruits, and fresh vegetables. These items are least likely to cause contamination and should be kept away from raw foods.

-

Middle Shelves: Store pre-cooked meat and other foods including dairy products. These need to be stored in cool, stable conditions but pose less risk than raw meats.

-

Lower Shelves: Store raw meats on the lowest shelves to prevent any drippings from contaminating other foods. Always ensure meats are wrapped or sealed tightly.

-

Bottom Shelf: Keep thawing foods here to prevent any liquid from contaminating other items.

Avoid overpacking your cooler as this restricts airflow, which is essential for maintaining proper temperatures throughout the cooler. Always use designated storage containers and shelving to maximize space and ensure proper organization of items.