Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Australia uses the Food Standards Code to provide guidelines and highlight food regulations that will ensure the safety of its food supply chain and citizens.

Food safety is a major concern in Australia. Approximately 4.1 million cases of foodborne illnesses occur each year in the country. These cases contribute to 31 000 hospitalisations, approximately 1 million hospital visits, and 86 deaths annually. This number translates to 11 500 cases of foodborne illnesses per day. The Australian federal enforcement agency has identified that the majority of foodborne illness outbreaks in the country are caused by non-compliance with food safety legislation. Australia's main defence against these problems is the Food Standards Code.

Non-compliance with the Food Standards Code in Australia can result in many issues, including bad publicity or business closure, depending on the degree of offence. All food businesses are required to create a food safety program, but not all must create a management system.

In this article, we show you around the food standards system of Australia, emphasising food safety. We will explain how easily you can get and stay compliant to the Food Standards Code using FoodDocs HACCP-based digital Food Safety Management System.

Get to know about the Australian food safety system with the following topics ahead:

WHAT WE'LL COVER:

Non-compliance with food safety in Australia is a major concern. Foodborne illnesses cost the country at least AUD 2.81 billion each year (2023 inflation-adjusted estimate) every year due to loss of productivity and medical expenses.

A comprehensive study was recently conducted to estimate the costs of outbreaks and individual foodborne illness-causing factors to the food system of Australia. The study revealed that the highest cost diverted to addressing an outbreak in Australia was around AUD 365 million.

The national food safety and health agencies of Australia have focused on addressing such issues. In recent reports by the Australian Institute of Food Safety, the efforts of food safety agencies and the established regulations are reflected. Practices such as washing raw chicken have significantly decreased over the year. In addition, reported cases of salmonellosis saw a 27% reduction in 2020.

Learn more about the efforts of the Australian food safety agencies in addressing issues about food safety in the next chapters.

The Food Standards Code is the set of food handling rules and regulations for Australia, Australian states and territoris, and New Zealand. The Code contains standards and legal requirements that involve the labelling of food, additive use, handling, production, composition, and processing. It highlights the importance of food safety when running a food business.

The Food Standards Code is subdivided into four different chapters that explain and lay out the requirements of the Australian and New Zealand food supply chain. The chapters are as follows:

This chapter contains standards that apply to all foods produced in Australia, its states and territories, and New Zealand. It includes standards and requirements for additives, labelling, microbiological limits, and regulations for the genetic modification of foods.

Standards that are targeted for specific food categories, such as meat, cereals, eggs, dairy products, and alcoholic beverages.

Food safety standards under this chapter are only applicable in Australia. Chapter 3 identifies requirements for proper food handling practices in establishments that sell foods. It includes standards for training requirements, preparing, cooking, storage, and delivery of food products.

Chapter 4 includes standards for producing and processing agricultural commodities, including food safety management, food waste disposal, hygiene, and training requirements. This chapter only applies to Australian food businesses.

The main objective of the Food Standards Code is to lower the cases of food poisoning by enforcing legal food safety requirements for food businesses. In particular, the Code's primary functions include the following:

Unless stated otherwise, the Food Standards Code applies to every food business that operates in Australia and New Zealand. The Code regulations are mandatory, and non-compliance may be charged with a criminal offence if proven guilty.

Every food business can meet the Food Standards Code efficiently with a comprehensive food safety management system. Now, you can achieve food safety compliance in just a matter of minutes. Using our digital solution at FoodDocs, you can create a Food Safety Management System and a HACCP Plan if needed.

By simply providing information about your operations, our smart software can automatically generate the necessary monitoring logs for your team in an average of 15 minutes. Our solution can help you comply with all the requirements of the Food Standards Code. You can compile all records in one dedicated cloud storage space for your business that comes with our software.

Food businesses operating in Australia, regardless of category, are required to follow the Australia New Zealand Food Standards Code to be allowed to operate. As stated in the Code, all food businesses must be equipped with practicable measures that will protect food from potential contamination. In addition, employees working in the food industry must receive adequate training and knowledge in protecting customers from public health risks.

The Food Standards Code lays out the food law on which type of food businesses are required to follow particular requirements. An example of this rule is seen when identifying which businesses are required to document their monitoring activities. The Code categorizes businesses handling and preparing high-risk foods as Category 1, whereas those who are in retail and have minimal exposure to high-risk foods as Category 2.

Whether your business is considered a category 1 or 2, FoodDocs can help you comply with the Food Standards Code. From creating a HACCP-based FSMS to establishing a documentation system for your food safety activities, FoodDocs has got you covered.

Start exploring the benefits of HACCP-based monitoring system by browsing through our feature page.

The Food Standards Code highlights several food safety guidelines. Some of these guidelines are basic handling procedures when receiving or processing foods. In some areas, the Code also highlights hygiene requirements for food handlers.

These guidelines can be summaries into the 4 C's of food safety, namely:

In particular, the Code also highlights some food hygiene and safety procedures for employees, such as the following:

Every food business team must consist of knowledgeable and well-trained food handlers equipped to protect public health. All operations must be based on the most efficient handling practices that will minimise the probability of causing food poisoning outbreaks and other major food incidents from consuming your products.

Learn more about food laws and regulations from our detailed article on Food Safety Standards Comparison of the US, UK, Canada, and Australia.

The Food Standards Australia New Zealand, or FSANZ, is an independent food regulatory agency that was established under the Food Standards Australia New Zealand Act 1991. The agency was previously known as the Australia New Zealand Food Authority. This Australian government agency is mainly responsible for implementing and overseeing the established food standards for both Australia and New Zealand.

The FSANZ is accountable for securing the food system of Australia and New Zealand and protecting public health by ensuring that adequate food standards are in place. In particular, the national agency is responsible for the following tasks:

The Code is implemented by state and territory government agencies in Australia, whereas the New Zealand Government oversees it in their country. The FSANZ coordinates with a list of agencies in Australia and New Zealand to implement other food standards.

For example, food standards related to imported foods are enforced by the Department of Agriculture and Water Resources. In addition, food standards that apply only to Australia have their counterparts in New Zealand and are managed by the New Zealand Ministry for Primary Industries.

Otherwise known as the Food Safety Practices and General Requirements, the Food Standards Code 3.2 2 specifies legal requirements related to proper food handling that will prevent making food unsafe for consumption. It includes controls for receiving, storing, preparing, processing, packaging, transporting, and recalling foods. The Code is only applicable to food businesses in Australia.

The Code also identifies the required training skills and knowledge of food safety for all working food handlers in the industry. It highlights standards for employee health and hygiene, proper cleaning, and maintenance of the food premises and related pieces of equipment.

Food Standards Code 3.2 2 includes requirements for the food business and its employees. All food businesses, except those that are in the 'primary food production' category, must follow this Code.

Below, we examine some of the essential areas and duties of food businesses and food handlers that are discussed in the Food Standards Code 3.2 2

1. Food handling skills and knowledge

Under this standard, all food safety supervisors and handlers are required to have an adequate amount of training and understanding of food safety and food hygiene matters.

Food handlers must understand the importance and essence of proper food handling procedures and the consequences that non-compliance may have.

2. Notification

Before starting operations, every food business in Australia must provide essential contact information to health enforcement agencies. Information about the business, such as the following, must be submitted:

3. Food handling controls - Receipt

All food businesses in Australia are required to apply all possible control measures to ensure that the food supply that they receive is up to standards and free from the likelihood of food contamination. To fulfill this standard, food businesses are required to perform the following:

Use our free Receiving Temperature Log to monitor food supplies before receiving them for your food business.

4. Food handling controls - Food storage

Standards for food storage lays out requirements and directives for storing products that will minimise contamination. Under this standard, food businesses must observe the following:

At FoodDocs, we offer free food safety posters, such as for Cold Holding Foods, Proper Food Storage Chart, Temperature Danger Zone Chart, and a Fridge Layout Chart from our Food Safety Posters Hub. Use these free tools to guide food handlers.

5. Food handling controls - Food processing

This set of food safety standards identifies specific requirements for minimising the levels of contamination of food through processing. In particular, the section requires food handlers to perform the following operations:

Use our list of cooking temperature charts and cooking logs to guide food handlers in performing and properly monitoring processing procedures.

6. Food handling controls - Food display

Food businesses must practice applicable food handling procedures that will prevent contamination of foods during display. This standard highlights the following operations:

7. Food handling controls - Food packaging

Food businesses are required to follow these standards relating to food packaging:

8. Food handling controls - Food transportation

When transporting foods from the establishment to the consumers or from one establishment to another, the supplying business must follow these standards:

9. Food handling controls - Food disposal

The Food Standards Code also highlights the proper management of waste in food businesses. Under this standard, the term "foods for disposal" may refer to foods subject to a recall, return, not safe, or at least suspected to be unsafe. All food disposal systems must follow the rules such as:

10. Food handling controls - Food recall

All food businesses involved in wholesale supply, food manufacture, and importation must have a comprehensive traceability and recall system that is properly documented. This system will help the business team to handle and coordinate recall mandates and minimise any potential damage.

11. Health and hygiene requirements

Under this food safety standard, food businesses must provide all food handlers with the necessary training and orientation on maintaining hygiene and good health. This standard aims to prevent food contamination caused by food handlers.

The food business is also responsible for providing the necessary equipment and facilities for maintaining food hygiene matters, such as dedicated handwashing sinks, handwashing tools, and other related items.

The standard also specifies instructions on prohibiting sick food handlers from operating with foods. Food handlers previously affected by a contagious sickness can only work again with a proper endorsement from a qualified medical practitioner.

12. Cleaning and sanitising equipment

Food businesses must provide tools, facilities, and equipment that will help maintain a clean working environment. The facility must have the equipment such as:

All food utensils, equipment, and tools must be regularly maintained. Any damaged or chipped tool must be replaced or fixed to minimise the risk of physical contamination.

The food business management must also provide adequate food safety training for employees on how to clean and sanitise food contact surfaces properly.

13. Tools for temperature control

Tools used for temperature control, such as food thermometers, must always be accessible in any food business. Thermometers must be regularly calibrated and be able to read temperatures with a margin of error of +/– 1ºC or ºF.

14. Pest control

Only registered assistance animals are allowed to enter food service areas. A food business must take all necessary precautions to keep pests away from the area.

From the first food regulation to the last under Food Standard 3.2 2, you can quickly establish and maintain compliance using FoodDocs' digital HACCP-based FSMS. Using our software, you can get automatically generated monitoring logs and other smart solutions to help you monitor and document all compliance tasks.

You can maintain every standard in your food business using our digital solution. Managers can even improve management efficiency by using our provided real-time dashboard. Quickly identify any non-compliance and address them right away.

On December 8, 2022, a new annex to the Food Standards 3.2 2 was published. The new standard is set to be in full effect 12 months after its publication.

Following the existing Food Standards 3.2 2, the new extension is entitled Food Standards 3.2 2A Food Safety Management Tools. Below, we talk about, in detail, the new conditions discussed in this new national requirement.

The Food Standards Code 3.2 2A is an extension of Code 3.2 2 and is otherwise known as the standard for Food Safety Management Tools. Under this standard, food businesses are categorized based on the nature of their operations. Businesses that involve handling and preparing high-risk foods are category 1, whereas those that mainly retail prepared foods are category 2.

The Code requires each category to establish food safety management tools that will help maintain and ensure food safety throughout their operations.

Three main food safety management tools are highlighted in the standard:

Food Safety management tools under the Food Standard Code 3.2 2A are key requirements for food businesses in Australia. They are management operations that will help ensure food safety against known hazards in their food business.

Two or all three food safety management tools may apply to your operations. The nature of your business will determine under which category will your food business be. The safety management tools required for food businesses are based on the most effective food safety systems that ensure protecting public health.

Food Standards Code 3.2 2A applies to food service and related retail businesses, such as the following:

Learn more about what is food safety management system as required by the FSANZ from our detailed article.

To help you identify which food safety management tools apply to your food business, here is a summary of the two categories under this food regulation:

Food businesses that are considered caterers or in the food service line that handle high-risk food handling activities are under Category 1. If your business handles potentially hazardous and/ or ready-to-eat foods, then the standards for Category 1 will apply to your operations.

Food service businesses, such as restaurants and takeaway outlets, handle and process foods that customers will directly consume. As such, the potential food safety risks of hazardous contamination are very high.

Category 1 businesses are required to implement all three management tools mentioned above. This means that your business will have to establish a monitoring system to document all food safety operations, including the following:

Do not worry. All requirements are covered in FoodDocs solution. Sign up now to try them free.

Category 2 businesses include companies that produce and serve unpackaged, potentially hazardous foods, such as deli stores, supermarkets, and other retail food stores. This category includes businesses that receive and handle unpackaged products, such as salad ingredients, but do not further cook the food for sale on-site.

A good example of food production activity that describes category 2 food businesses is when a food business receives products, such as meat pies, and unloads them from a main container. The food handling team may reheat the food and put it on display for sale. In this operation, the food handler does not cook the pie from scratch. The products are simply reheated, repacked in a bag, and served to customers.

The key activity for category two food business is when food handlers unpack the food before reselling it in retail to customers. In this case, only the first two management tools apply to category 2 food businesses.

The Food Standards Code does not require category 2 businesses to document its food safety management system.

In case a food business has operations in between categories 1 and 2, the business is then considered a category 1 and will need to document their management system.

The objective of establishing a food safety management system is for a food business to monitor their food safety operations actively. This tool ensures that the business is compliant with the applicable food legislation.

Operations related to receiving supplies, food storage, processing, displaying, delivery of foods, cleaning, and sanitising of the faculty must be monitored and documented. Monitoring or recording, as described by the Code, must be performed every day.

At FoodDocs' you can get the necessary food safety documents, such as Standard Operating Procedures (SOPs), for your everyday operations. Using our digital HACCP plan builder, you can automatically get a digital food safety program that includes SOPs and prerequisite programs (PRPs).

You can also get a monitoring system based on this food safety plan that will provide monitoring logs to record your everyday operations intuitively. With our digital HACCP-based Food Safety Management System Software, you can get the essential logs and checklists needed to keep your system in check.

Our system can help you create a comprehensive system based on your location and operations using artificial intelligence and a machine-learning program.

The main purpose of a food safety program is to systematically analyse potentially present hazards in a food business and establish controls to minimise them and protect all customers. It is a written plan that ensures food safety for both local and imported food products.

Under the Food Standards Code, food businesses handling high-risk foods in Australia are required to establish a food safety program to protect public health. These food businesses may include primary producers, processors, transporters, and packers of high-risk foods.

The Food Standard 3.2.1 highlights the requirement to establish a food safety program based on the principles of the Hazard Analysis Critical Control Point (HACCP) system. Federal or local government agencies will then audit the established system to assess the suitability and appropriateness of the program.

The standard requires food businesses to conduct a thorough hazard analysis of potential risk hazards that can harm public health. Once hazards are properly identified, the business team must set up measurable activities that will control the hazards.

The food safety program is required to be properly documented and will be inspected by the assigned authorities. The documented program must be readily available for food safety auditors upon request.

Using FoodDocs' digital HACCP plan template builder, you can create what usually would take months to finish in just 1 hour. Our team of food safety and tech experts developed an AI-powered software that can automatically generate a comprehensive food safety program that satisfies the requirements of the Food Standards Code.

In approximately 1 hour, you will get a plan that has a complete set of the most relevant hazards related to your business and critical controls to minimise them. The generated plan also comes with SOPs in HACCP and important PRPs for your operations. You can further customise the comprehensive template and programs to tailor the documents to your specific operations.

Digital HACCP plan from FoodDocs

Every relevant agency aims to educate the food business team on the most effective and efficient food preparation rules that will only result in safe food products.

Foodborne illnesses caused by contamination can be easily addressed with clear and safe food safety procedures. We highlighted the 7 most essential rules for preparing safe food in the kitchen:

1. Use only safe and fresh foods

The initial state of a food ingredient may determine for how long will the final food product remain safe. Screen every food delivery from suppliers and determine their compliance with the same food standards codes of practice that apply to your business.

2. Cook foods thoroughly

One of the most critical operations that will minimise the risk of food poisoning is cooking foods up to the recommended internal temperature. This operation ensures that the raw food is cooked equally throughout.

3. Follow food storage guidelines Australia

High-risk foods must never be exposed to the temperature danger zone for an extended amount of time. Cold foods must remain cold, whereas hot foods must be held using hot-holding equipment.

4. Avoid cross-contamination

Cross-contamination in a kitchen is the fastest mode of transmitting foodborne pathogens. This event can be prevented by using separate utensils for preparing raw and cooked foods.

5. Always wash hands properly

Proper handwashing is one of the most effective ways to avoid contamination. The procedure can only become effective if properly done.

6. Regularly clean and sanitise all food contact surfaces

Food spills and leftover food can allow bacteria to stick to surfaces and become harder to remove. Regular cleaning and proper sanitation can significantly prevent this from occurring.

7. Protect foods and the facility from pests

Establish a pest control system that will prevent the entry of any type of pests into your facility.

One of the most effective ways to ensure that all food safety procedures are consistently observed is to establish a monitoring system. As highlighted by the Food Standards Code, food businesses are required to record their food safety activities as proof of compliance. Whether your business is under category 1 or 2, your company will benefit from establishing a comprehensive food safety management system.

Every food business in Australia that handles unpackaged, potentially hazardous foods must assign one certified food safety supervisor (FSS) for every shift. An FSS is a knowledgeable team member who has received adequate and advanced training on food handling practices.

Supervisors can become accredited and get a certificate by undergoing recognised food safety training. Upon successful completion, a certificate will be awarded to the individual as proof of proficiency.

Training programs include basic and advanced food safety courses, with a strategy introduction on how to implement food safety systems. The provided certificate will only last for up to 5 years and must be renewed.

An FSS certificate is required for a food business to secure a food operation license.

Is your business team aiming for an SQF certification? Learn more about the SQF program in detail from our comprehensive article for food businesses.

Two of the main requirements of the Food Standards Code Australia are for every food business to establish a food safety program and to document their food safety activities. Complying with these regulations is essential to run a food business in Australia and protecting public health while serving quality foods.

Building a food safety program is a complicated task that can take months of work and continuous updates and revisions. With such heavy requirements, compliance can become bothersome for food businesses. At FoodDocs, you can comply with these two major food safety standards in an average of 1 hour using our smart solutions.

Whether you are a category 1 or 2 business, our system can help you maintain compliance with a HACCP-based Food Safety Management System.

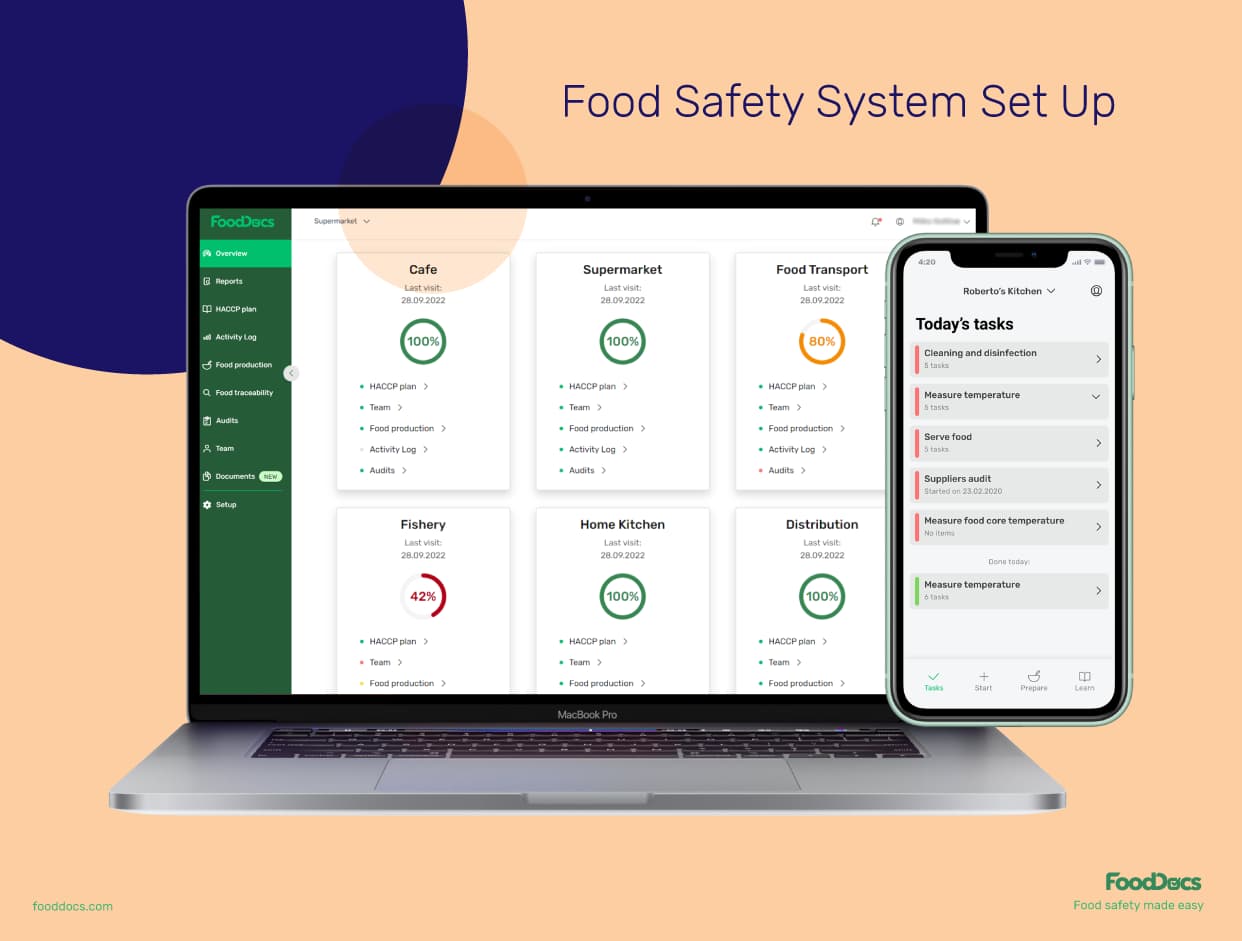

FoodDocs digital Food Safety System Set up

With our software, you can fulfill the Food Standards Code requirement of recording all your food safety activities, such as receiving supplies, cooking, preparing, storing, cleaning, and tracing food products. You do not have to create logs from scratch, as our system can generate them for you. Our system can also provide you with intuitive solutions that will help maintain food safety, such as the following:2

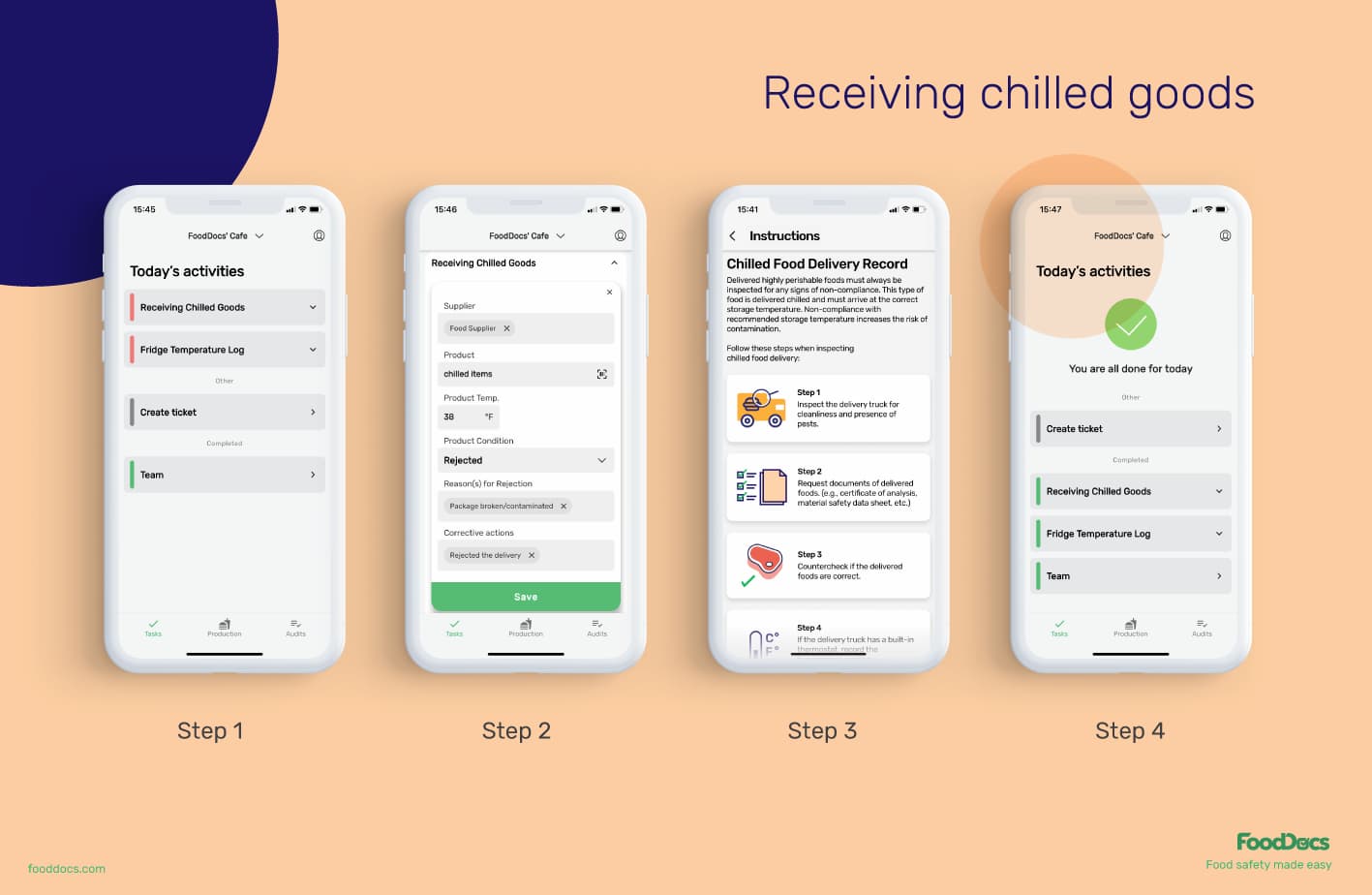

Receiving chilled goods log from FoodDocs

-png.png?width=1417&height=924&name=Cooking_temperature%20(1)-png.png)

Cooking temperature log from FoodDocs

Employee hygiene checklist from FoodDocs

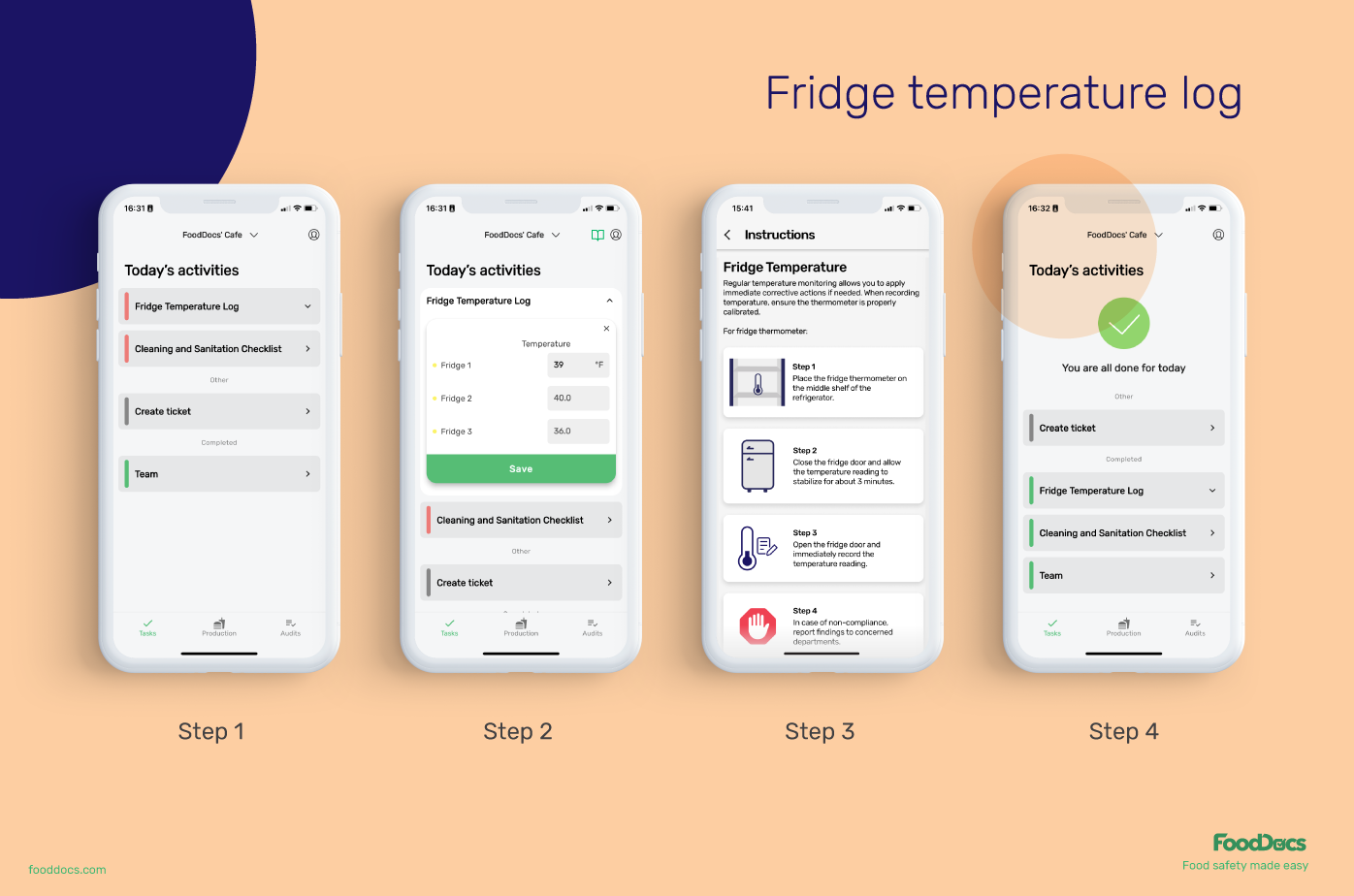

Fridge temperature log from FoodDocs

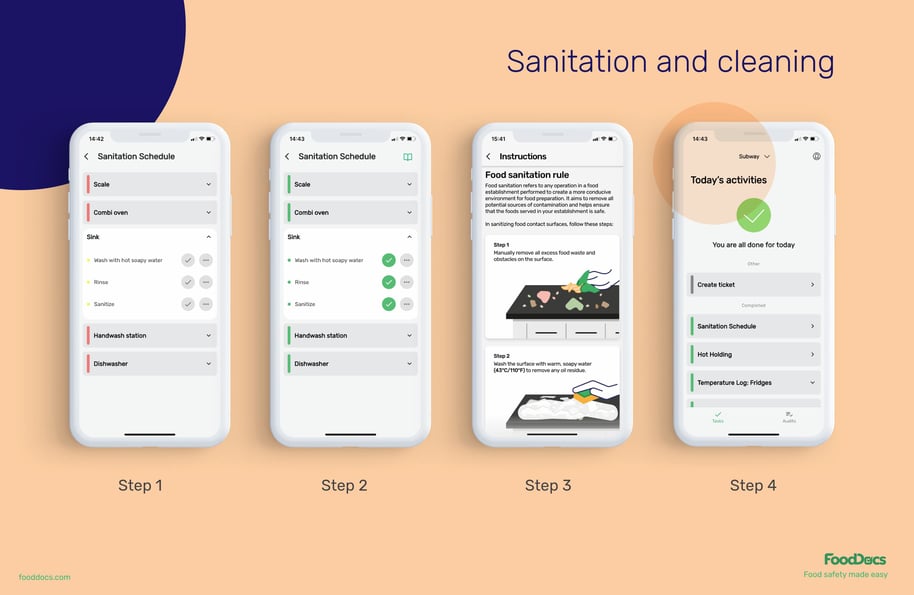

Sanitation and cleaning checklist from FoodDocs

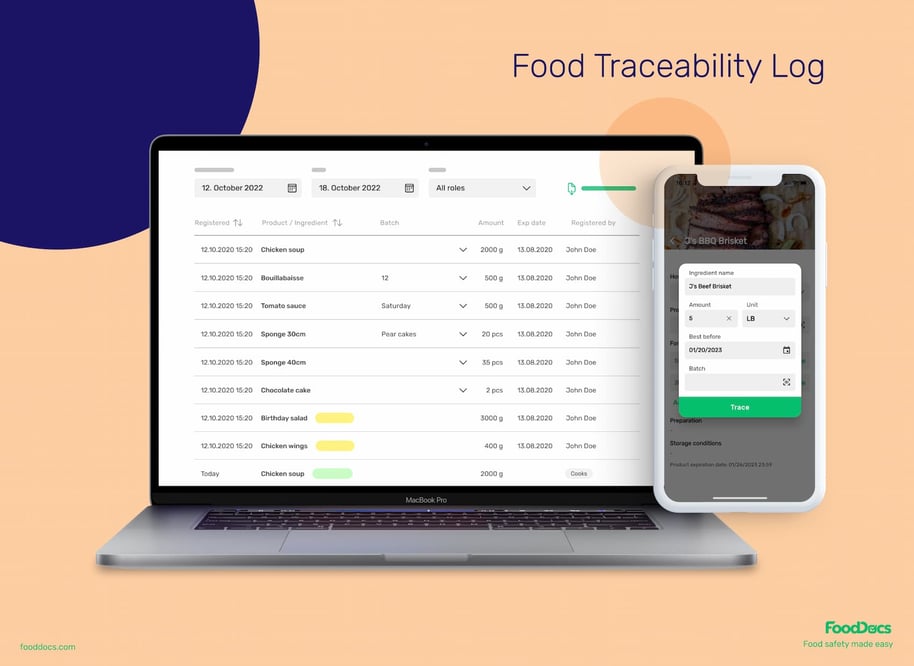

Food traceability log from FoodDocs

What's more? With FoodDocs' digital Food Safety Management System, you can get more than just compliance tools. Our system features tools that can help you improve management efficiencies:

With our HACCP-based Food Safety Management System, you can maintain compliance even with the newest addition to the current Food Standards Code. Your business can save up on time and focus more on improving your operations effortlessly.

In addition to complying with Food Standard 3.2.2 A, FoodDocs also offers solution for generating a comprehensive food safety program for businesses.

With our digital HACCP plan builder, you can get a food safety program exactly how the Food Standard 3.2.1 describes it in just 1 hour in digital format.

You can comply with the seven main steps in building a food safety program and get the following components:

.png?width=1065&height=924&name=HACCP_template%20(1).png)

Digital HACCP plan from FoodDocs

Our system can generate a customisable, comprehensive food safety program template based on your operations. In addition, our system can also generate the most relevant Standard Operating Procedures and Prerequisite Program documents for your team.

Get the necessary food safety documents to comply with Food Standard 3.2.1 by simply answering questions that will describe your operations to our system.

Achieve and maintain compliance with our smart digital solutions today. Join our list of more than 35,000 food businesses that are enjoying compliance with our software. Use our free 14-day trial now.

Are you operating a business in the Australian food sector, and do you have more questions about consumer food safety? Here are our quick answers to some of the most commonly asked questions about this topic:

The 5 most essential food safety rules for every food business includes the following:

The Food Safety Standards Australia, otherwise known as Food Standards Code, is a collection of food standards and regulatory guidelines for food businesses operating within the country. The food safety guidelines Australia provides food safety regulations for businesses. It includes requirements for handling, producing, packaging, labelling, importing, and delivery of foods.

The Food Standards Code lays out regulator information on food labelling, the addition of food additives, processing, and food safety to protect public health from foodborne illnesses. The Code highlights the following objectives:

According to the Global Food Security Index (GFSI) 2022, Australia ranks 22nd in terms of food quality and safety.

The main guidelines for food safety and hygiene in Australia are discussed in the Food Standards Code. This document emphasises the most important practices for maintaining food safety in every food business in Australia.

In this article about the food safety standards in Australia, we go into detail about the essential food guidelines.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...