Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Butchers are living in a time and place where the meat market is steadily rising along with the demand for higher food safety standards (from regulators and consumers).

But before we get to the best food safety software for butcheries, let's set the stage with some statistics and studies to get a better idea of what this means.

The meat market is predicted to grow to $215.76 billion by 2028, up from $172.94 billion in 2021.

Several studies link red meats (e.g., beef, pork, and products derived from them) to the root of foodborne illness outbreaks.

WHAT WE'LL COVER:

First, let's acknowledge that this is good news for butchers and meat cutters! Fortune Business Insights predicts the meat market to grow to $215.76 billion by 2028, up from $172.94 billion in 2021.

At the same time, according to the International Journal of Food Microbiology, several studies exploring the root of foodborne outbreaks continue to link the culprits back to red meats (e.g., beef, pork, and products derived from them).

In 3M's article "Managing Food Safety Contamination Risks in Meat Processing", author Matthew Taylor (Ph.D., Associate Professor of Food Microbiology, Texas A&M University Department of Animal Science) emphasizes the growing importance of food safety management for meat businesses.

"This rapid expansion of how much people buy, prepare and consume meats has naturally resulted in larger amounts of these foods passing through a single processing facility. As a result, contamination continues to enter the food supply and people are still becoming ill due to meat they ingest. Recalls and outbreaks proliferate and the regulatory boundaries governing these activities tighten. It is incumbent upon meat manufacturers, therefore, to shore up their food safety programs, paying particular attention to the hygienic breakdowns that can happen during the high-risk activity of slaughter as well as the steps that follow."

For butchers and the food safety or quality managers that work at them, getting and staying compliant based on your government's food safety standards is no small feat. But it's by no means impossible.

Where it gets challenging — especially as your butchery grows in popularity and size — is trying to manage food safety monitoring and traceability tasks... on paper.

This is one of the most popular reasons why shops start exploring the best food safety software for butchers: keeping track of freezer temperatures, completing sanitation tasks, doing meat quality checks, and filling out transportation logs on a daily basis simply gets unruly.

But food safety software such as FoodDocs can digitize a butchery's food safety programs while:

The butcher businesses we talk to every month will attest to this...

Our regular conversations with butchers of all sizes, from less than 10 employees to around 50, prove that everyone’s food safety requirements are unique. Here are a few real-life examples of FoodDocs customers and what food safety looks like for them:

Butchery #1 uses many of FoodDocs' default food safety tasks with some modifications:

Butchery #2 uses many cleaning checklists which they've personalized to their own operational needs for their Meat Production Hall and Dry-Age Chilling, for example. This butchery also has monitoring checks, such as:

Butchery #3 has similar food safety tasks for thermometer calibration as well as temperature checks for fridges, freezers, and different rooms,. But they also use FoodDocs to customize monitoring tasks such as:

Butchery #4 has some different or additional food safety tasks, including:

Butchery #5 has checks that overlap with ones that the companies above also have. But some additional digital food safety monitoring checks include:

We also serve other butchers who just use our HACCP compliance product in order to operate their business.

Failing to accomplish some, if not all, of the things above could result in an undesirable food safety inspection rating, increased chances of causing foodborne illnesses, and unnecessary food waste.

As a butchery worker exploring what to look for in the best food safety software, you bring a lot of context and nuance into your search. Not every butchery is the same and your systems or operations might function differently.

That's why we've put together this article. We understand that butcheries require food safety software that's easy to use, customizable, and will help them stay compliant.

The are six key factors butcheries should always consider when choosing the best food safety software for their operations.

Across butcheries, you'll find different floor plans and layouts, different processes, different team structures, and more.

Ensuring that you can create and complete digital food safety monitoring and traceability tasks according to your specific needs will help your butchery stay compliant — as opposed to relying on non-customizable default tasks found in some food safety software.

Like you saw in the butchery examples above, while most butchers strictly sell raw cuts of meat, one of them sells hot food out of their front-of-house deli. This aspect of a butchery business requires another level of food safety tasks because now you need to incorporate a hot holding temperature log.

You can overcome these monitoring challenges by getting a fully customizable food safety system with FoodDocs — no matter how specific your butchery’s operations are.

You’ll be able to choose from:

Butchery owners and quality or safety managers can also create corrective actions from scratch or customize them within the app based on your food safety needs.

The FoodDocs food safety software also gives you or a supervising team member more control with the ability to:

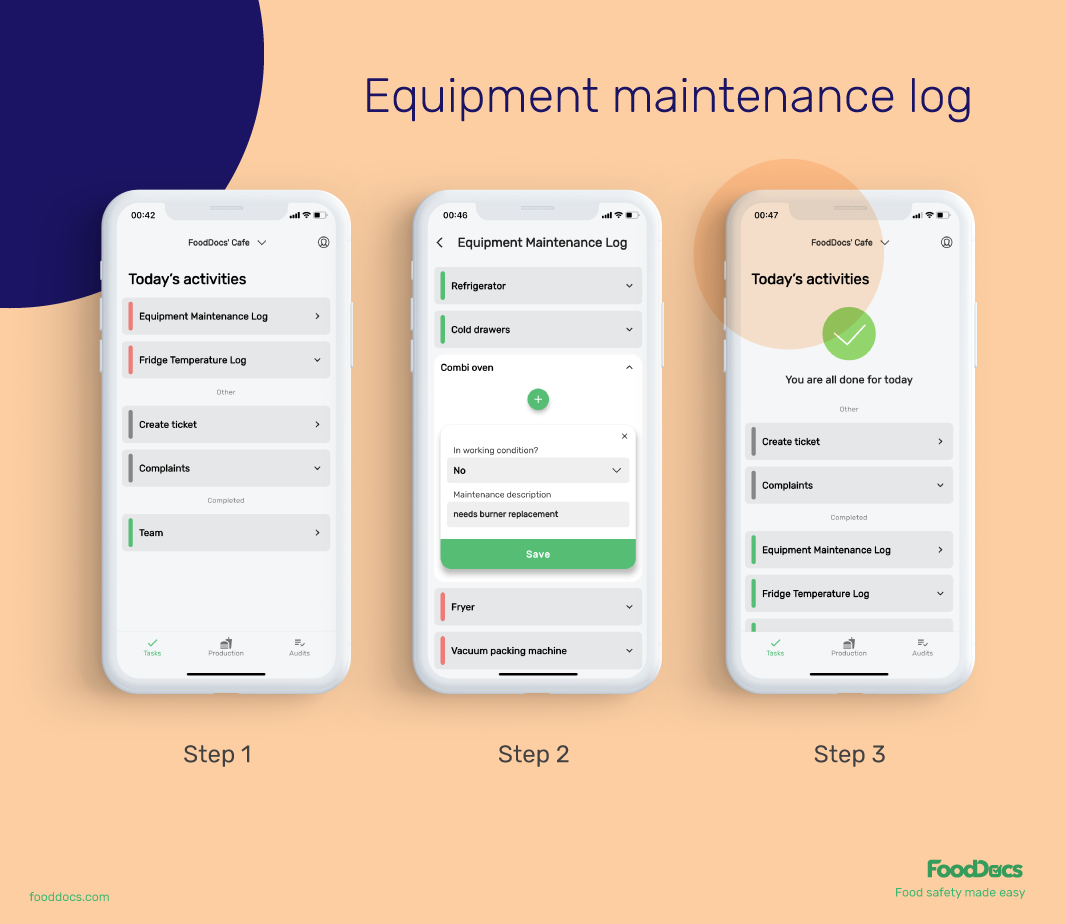

Once you’ve set up your food safety system in FoodDocs, all this is made easier with a mobile app that you can download for iOS or Android.

Example of the butchery equipment monitoring log in the FoodDocs mobile app.

Across the food industry, many people would agree that butchers are (or at least should be) held to a higher standard when it comes to food safety.

After all, it was a 1992-1993 contaminated beef scare linked to the American fast-food franchise Jack In The Box that truly put the importance of food safety standards — specifically HACCP principles — into the public spotlight.

The butchery industry is a key player in maintaining public health and safety and this is evident in the butchers who uphold meticulous sanitation, food handling, and meat storage practices. All of which ensure that every cut of meat butchers process is safe to consume.

This is why operations managers and safety or quality supervisors need to make it crystal clear who's responsible for completing each and every butchery food safety task.

And the best food safety software for butcheries will make it easy to do exactly that:

Butchery owners and quality managers use FoodDocs to completely remove the guesswork when it comes to achieving food safety compliance.

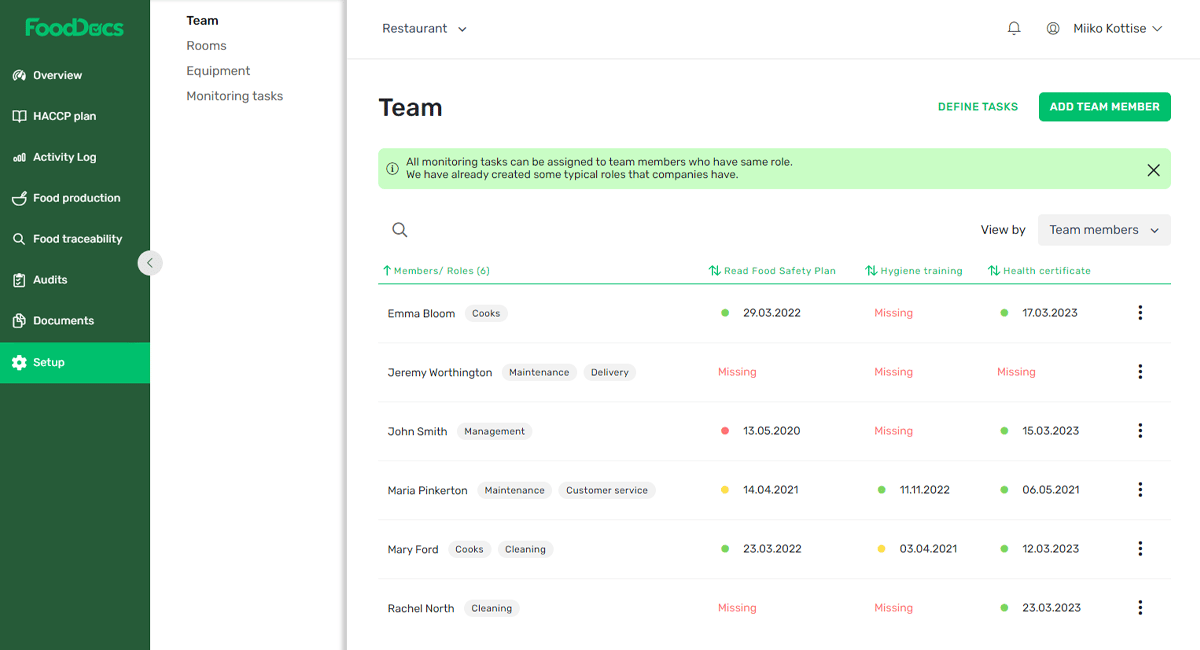

As you set up your butchery’s food safety monitoring system, you’ll be able to add team members and organize them into specific types of roles. For example:

When you create the butchery’s food safety tasks, FoodDocs ensures that each team member only sees the tasks that you’ve assigned them to on the exact day they need to complete them.

Given the strict food safety guidelines butcheries like yours must follow, staying on top of regular tasks can be challenging. To help minimize missed monitoring tasks, our mobile app will send team members smart notifications that remind them to complete their assigned tasks on time.

Preview of the Setup page in FoodDocs where you can add team members, define role-based tasks, and have an overview of each person's food safety status.

One butchery or ten butcheries, it doesn't matter how many you operate. You do need to be able to monitor your day-to-day food safety operations in a way that's clear and not time-consuming.

As someone managing multiple locations, you’re always racing against the clock. There’s only so many hours in a day, let alone a work day, so finding ways to increase efficiency is critical to your butchery business’s success.

A real-time overview of food safety is one way to increase that efficiency. It gives butchery owners or managers the:

From cutting room temperature logs to relative humidity checks and daily sanitation logs to equipment maintenance (e.g., cleaning meat slicers, meat grinders, meat saws), the best food safety software for a butchery should give you real-time overview capabilities.

FoodDocs’ food safety compliance software gives you remote control.

No matter where you are, using our food safety desktop or mobile app lets you both follow task progress and gives you insights into which units or departments are having issues in a timely manner.

It removes the need to visit butchery locations on site if you’re unable, while helping you easily maintain food safety consistency across all relevant tasks.

How? There are three relevant features that benefit butcher shops:

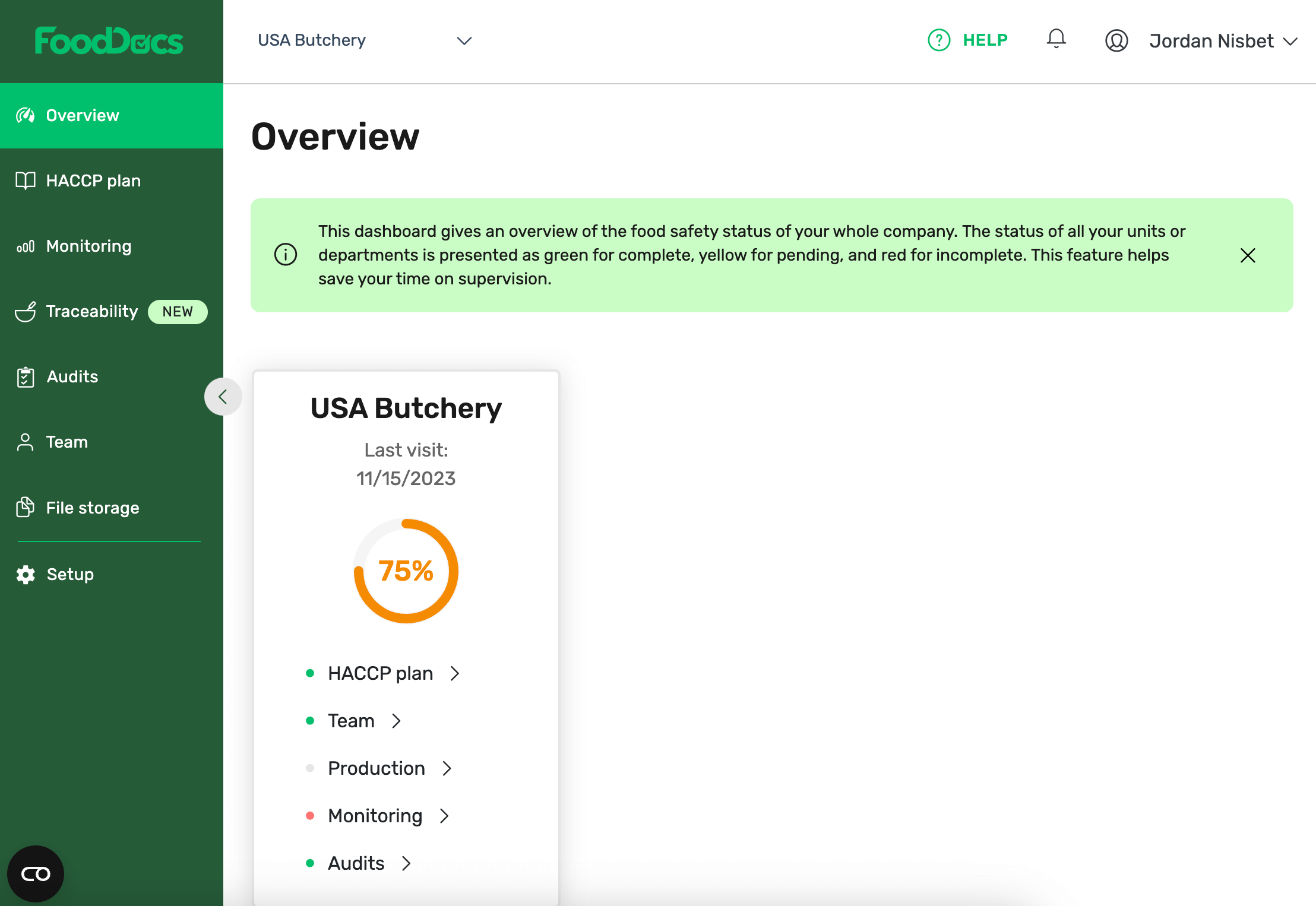

Food safety traffic-light system

FoodDocs' Overview dashboard is built like a traffic light to give you a clear overview of your food safety status across butchery locations.

Preview of FoodDocs real-time overview feature.

Multi-level overviews

As a butchery admin in your FoodDocs account and depending on what you need to know at any given time, you can choose to display different overviews at the:

If you were completing daily monitoring butchery food safety record sheets manually, you’d have to go through all of them — even the ones that are “green”. But using the overview feature, you can focus your time on the exact locations and specific tasks that need addressing.

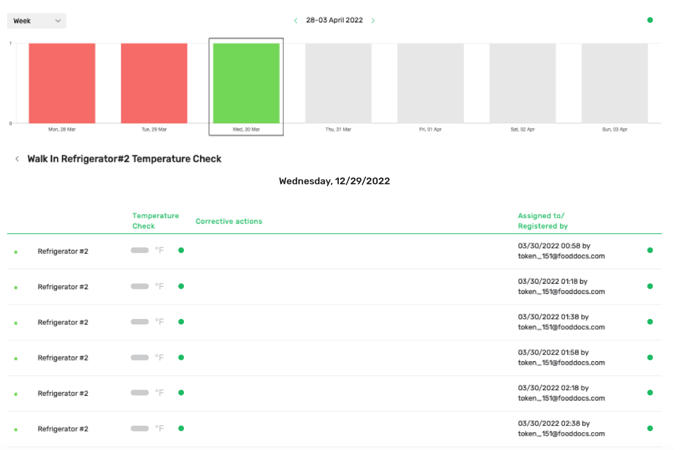

Digital monitoring logbook and task completion

If you want to see a detailed overview of your butchery’s completed tasks, open the monitoring logbook. Similar to the overview feature we described above, this helps food safety and quality managers save time from going on-site. It also helps them check task fulfillment, and find archived logs.

Another reason butchery staff love FoodDocs is being able to easily track all task completion details. This includes results, the person who performed the task, and the exact completion time. You even have the ability to add comments or improve the results accordingly.

Because of these overview and monitoring capabilities, we’ve found that FoodDocs customers save about 20% of their time every week on supervision. That’s one day per workweek that butchery owners and their staff can spend on providing higher-quality cuts of meat and experiences to customers.

Example of what your butchery's digital monitoring logbook could look like in FoodDocs' food safety platform.

Easy-to-find detailed records and exportable data

Compared to a pen-and-paper food safety system, digital logs enable you to find historical data for your local authority or auditor in seconds. Plus, if you want to improve your butchery’s operations on a yearly or even quarterly basis, you can specify a date range for your monitoring log and export your data to a spreadsheet (CSV, XLSX).

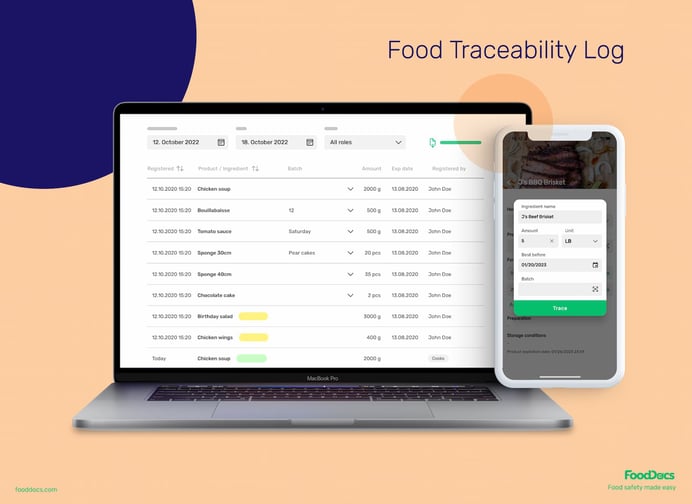

Butchers sourcing meat generally pay attention to three key pieces of information: animal welfare, product quality and — of course — traceability.

Food safety regulations such as FSMA specifically targeting traceability highlights the growing importance of butchers being able to trace the source of their meats back to the farm from which it came as well as where their meats are going.

What this looks like from butcher to butcher could vary, but some examples include:

Butchers must be confident in the farms and processing plants that the get their meats from. As a butchery staff receiving goods and a safety or quality manager maintaining a compliant facility, this means asking questions like is my butchery supplier:

And then having a place to safely store those answers digitally.

Each cut of meat prepared (or ready-to-eat meat product) made in your butchery will have their own food safety requirements. That’s why traceability is such an integral part of an effective food safety system for butcheries.

FoodDocs’ full food traceability system empowers your butchery with a tool that tracks ingredients and food items throughout your production supply chain.

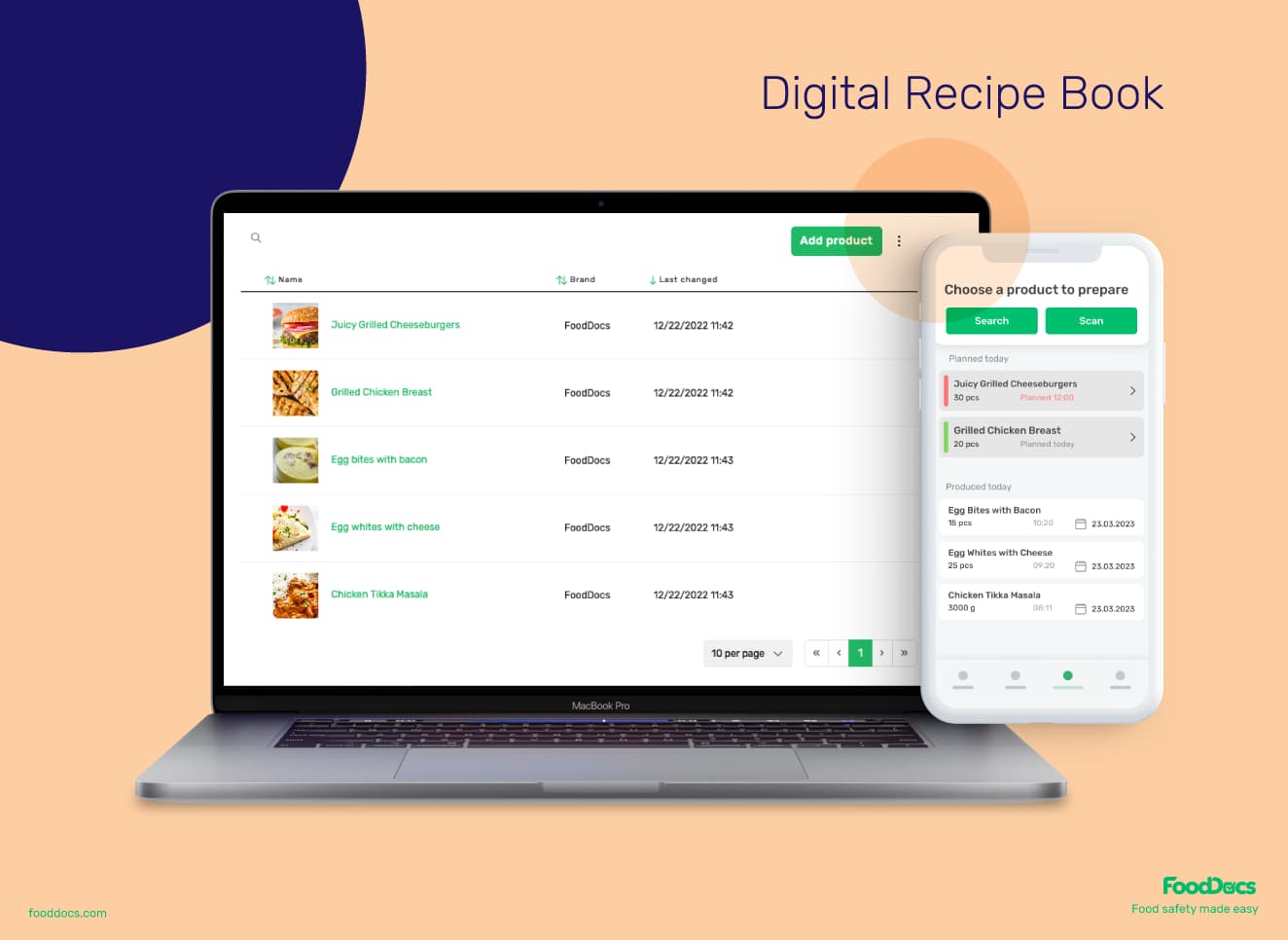

Smart recipe book

The digital recipe book makes creating and managing your butchery’s product roster easier than ever. There’s no limit on the number of recipes and custom ingredients you can upload. Butchers can also include photo or video instructions for what each cut of meat should look like to help train or remind other butchers and enable them to work more independently.

While a strictly butchered piece of meat won't contain any allergens, our Traceability feature does generate an allergy matrix to automatically inform your team of any allergens that are present in, for example, a beef pie that your butcher shop sells out front.

The smart recipe book also comes equipped with a calculation tool that helps butchery staff easily calculate ingredient quantities and plan accordingly based on your scheduled production or orders.

Use FoodDocs's Smart Recipe Book to organize your butchery's recipes and easily manage allergens.

All-in-one traceability

Completing a traceability log is simple once you’ve set up your smart recipe book. As you're planning your meat product for the day or week, all you've got to do is select the batches you plan to use.

As a result, you'll complete a traceability log and save your team from having to fill out twice the daily monitoring checks. To make the process even faster, the FoodDocs mobile app has a built-in scanner that you can use with EAN or QR codes.

And in the case of a meat recall, you can quickly pull up your digital traceability log, find the relevant product’s historical data by ingredient, product, batch, or expiry date, and provide the auditor or local authority to prove your butchery’s compliance with food safety.

FoodDocs' Traceability solution lets you plan meat production, complete traceability logs, automatically populate shelf-life dates based on previously filled data.

FoodDocs' Traceability solution lets you plan meat production, complete traceability logs, automatically populate shelf-life dates based on previously filled data.

Track shelf-life dates

Properly labeling and storing products starts with accurate shelf-life dates. Our smart app pre-fills shelf-life dates on the traceability log automatically according to data you inserted previously. All you need to do is confirm the logs!

This helps butchery staff maintain accurate shelf-life dates and reduce the frequency of human errors. (Don’t worry, you can change them if they’re different for a new production batch.)

This is just one more feature that helps save your team time on repetitive activities so that they can focus on more important things during the butchering process.

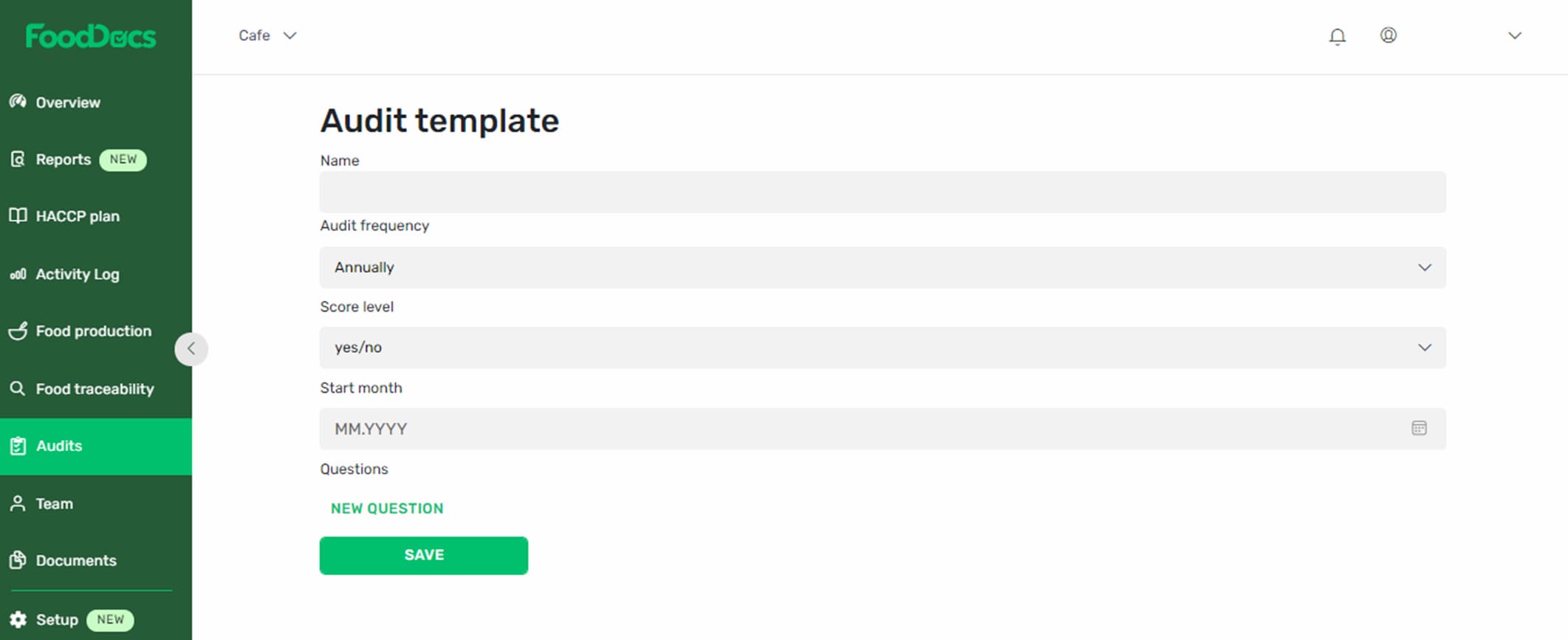

There are many food safety standards that butchers can strive to be compliant with. We mentioned earlier that HACCP came into the spotlight in a significant way in the early nineties with Jack In The Box. However, over the decades, the number of globally-recognized standards has grown.

Butchers that we work with are working to become compliant with HACCP, FSMA, BRCGS, and others. So choosing the best food safety software for them means having the option to conduct regular audits internally.

Internal (and customizable) audits are important because when the auditor shows up for the real inspection, it show them that your butchery cares greatly about high food safety standards.

Plus, your butchery team will also internalize that same high standard for food safety and create a sense of accountability which is a perfect recipe for good food safety culture.

The FoodDocs auditing tool makes it easier than ever for butcheries to:

Preview of the FoodDocs browser app where you can create audits with custom questions based on the food safety standard(s) that your butchery is striving to maintain.

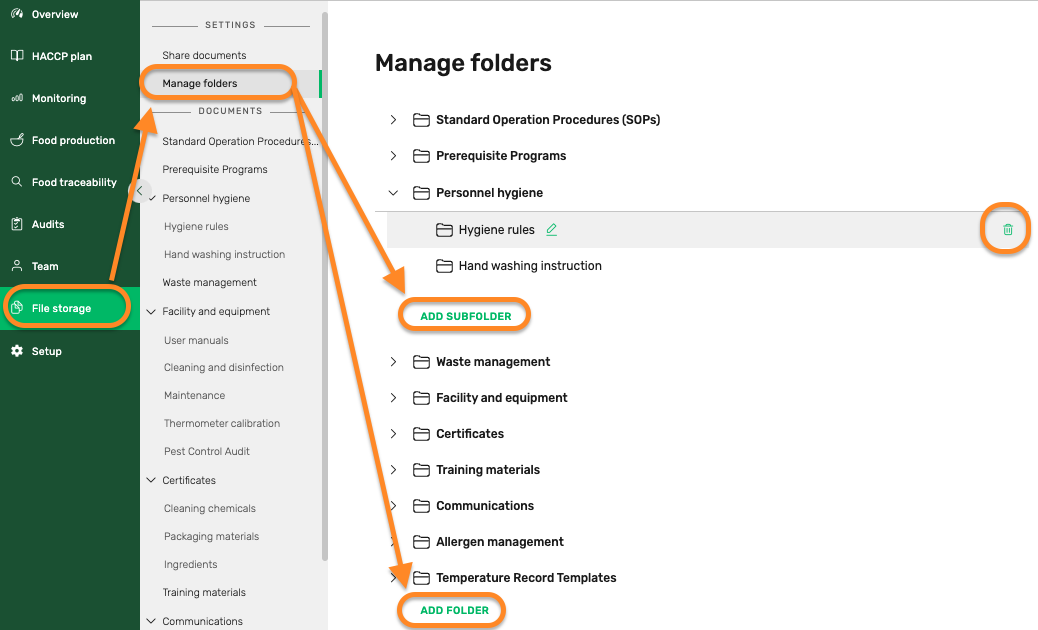

Add up the number of daily monitoring checks and traceability logs your butchery requires. Now add up the number of sheets of paper you'd need in a year to maintain all those food safety records...

It's a lot! That's why an effective food safety system can be so beneficial for your butchery's success — from making hundreds of documents manageable to being able to quickly produce relevant records for auditors or inspectors.

We can't understate the potential of cross-contamination in the meat industry, the importance of safe food handling, and everything that's required to ensure a high-quality butchery operation that produces high-quality meat products.

Critical control points, prerequisite programs, sanitation standard operating procedures, user manuals for butchering machinery, food safety certificates, HACCP plan, internal audits...

Under a paper-based food safety system, documents will pile up fast. And it's almost guaranteed that your food safety record sheets will get messy, creased, ripped, and (worse) lost.

FoodDocs keeps every single one of your butchery’s compliance documents in one place with safe and secure cloud storage.

Of course, you have access to these documents in the FoodDocs app — anytime, anywhere — so that when local authorities or auditors visit any of your butchery locations, you can provide whatever compliance documentation they need in a few clicks.

Preview of the cloud file storage feature in the FoodDocs' food safety software where you organize and store every type of file you need for you butchery to stay compliant.

As the authors in Lawrie's Meat Science concluded:

"Meat safety comprises one of the most important current and future societal concerns, and various challenges need to be successfully managed by the food industry and public health authorities if the burden of foodborne illness is to be reduced. Nonetheless, for such a goal to be attainable, it is crucial that integrated approaches extending throughout the food supply chain, from farm to fork, are developed and embraced."

Choosing the best food safety software for your butchery is a big deal. It helps form the foundation on which your food safety will either thrive (or crumble) on.

We’ve talked to a lot of butcher shop owners, quality managers, and food safety supervisors about what they look for in reliable, trustworthy food safety compliance software. So we hope that these six factors to consider help you on your journey to choosing the best one for your business.

When you’re ready, we’d love to learn more about your butchery business, give you a personalized walkthrough of FoodDocs food safety platform, and show you how it could be the right fit for you.

FoodDocs is a smart food safety software that butcher shops and their staff can use to quickly digitize food safety processes and:

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...