FOOD TRACEABILITY TEMPLATES

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

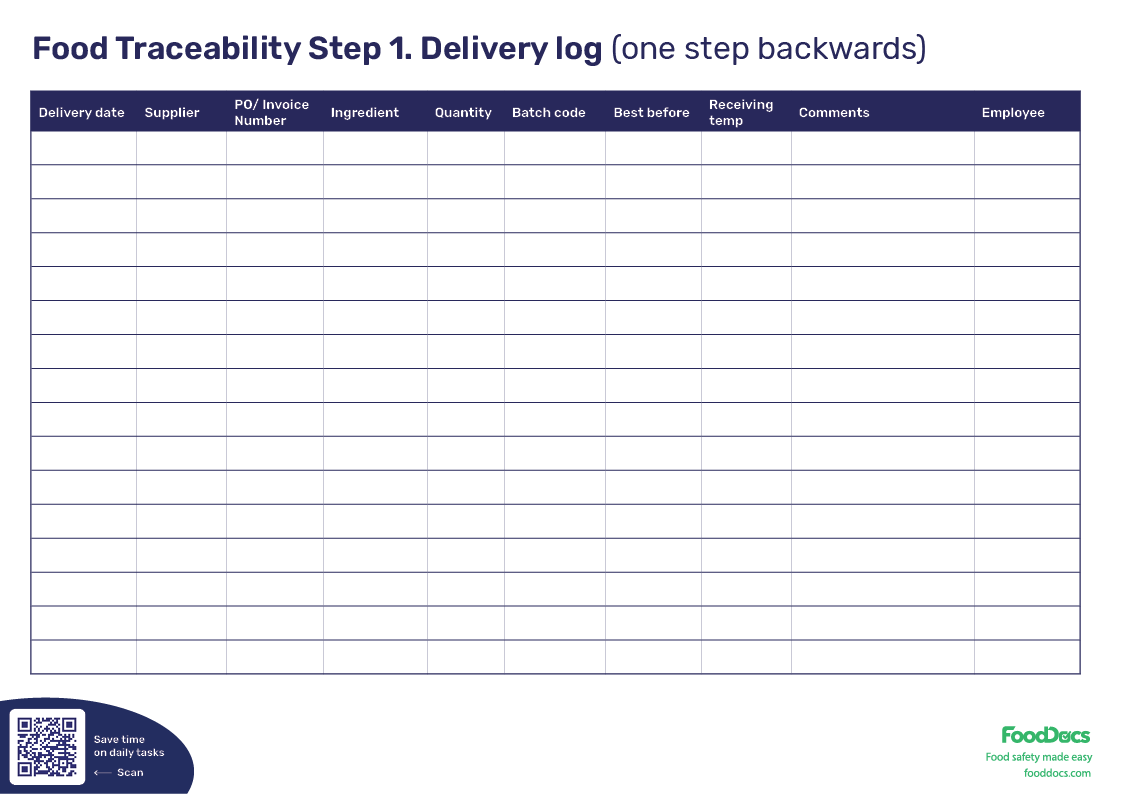

How to use FoodDocs' Food Traceability Template?

At FoodDocs, we provide free templates, charts, and posters to help food business owners manage their food safety tasks. Our Food Traceability Template is one of our most popular, free, and efficient tools. Food safety teams can use it to log information about your ingredients and finished products.

- Customize the template above by adding columns and rows according to your traceability system needs.

- Edit the prefilled information on the template as needed.

- Download the template above by simply entering your email address and clicking "download."

- Find the downloaded full-quality file from your downloads folder and print the template for use.

- Compile all Food Traceability Templates with encoded information in one folder for easy access.

- Explain to your team how the template works and which information is essential.

- Print more templates as needed.

Use this customizable form for conducting comprehensive traceability procedures.

Be always up-to-date with our free food safety posters, templates, interactive tools, and charts by regularly browsing our Template Hub. We also send useful newsletters once a month to acquaint you with our new content and free tools.

Get a more advanced solution for your traceability needs. FoodDocs' innovative Food Safety Management System features a two-in-one smart Traceability System with a Production Management module.

With this system, you can compile and access all product history information and their movement through the supply chain with just a few clicks. Learn more about how our system can help you from this article.

Ensure Safety and Accountability at all Times with the Food Traceability Template

Food traceability is a key component of any food business, whether production, food service, or retail.

Most of today's food business owners are moving towards a more visible supply chain. This means they are making information about operating conditions and ingredient sources more accessible to consumers and suppliers. A more visible supply chain improves accountability among food businesses and promotes customer confidence. The best way to achieve a visible supply chain is to have a comprehensive food traceability system.

In this article, we talk about how traceability in manufacturing is important and how you can improve your operations with our food traceability template and smart solutions.

Key points covered:

- Food traceability in manufacturing refers to the system that monitors food movement in the supply chain.

- Food traceability involves both ingredient and product tracking.

- A Food Traceability Template is a useful tool that consists of columns for tracking product information efficiently.

- Food businesses, manufacturing, service, and retail are required by law to have a comprehensive traceability system.

- A traceability system in the manufacturing industry will help you collect the necessary information in case of a food recall.

- An accessible traceability system can help minimize the potential risk of a foodborne illness outbreak by locating the affected products

- FoodDocs' Food Safety Management System includes a built-in two-in-one Traceability System to help you store product and ingredient information and intuitively track product movement.

Learn more about food traceability from this article and how you can get an intuitive digital Traceability and Food Safety System from our software.

Browse through the topics discussed in this blog post:

What is food traceability?

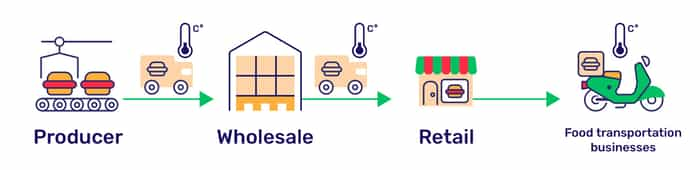

Food traceability is the ability to track the movement of your ingredients and food products throughout your production supply chain.

It gives you a clear report of your product's movement in all stages of product reception, production, processing, and distribution.

Food traceability systems can include different technologies, such as barcoding, RFID (radio frequency identification), legacy systems, and blockchain, as well as various databases and software platforms for managing and analyzing data related to food production and distribution processes.

Recent technological advances combine the most efficient software programs to improve accurate traceability systems and prevent negative food safety events.

Food traceability is an integral part of a company's food safety management system (FSMS).

The main objective of a food or product traceability system is to ensure the safety and quality of the products by providing a system that captures the actual production scenario and provides information about a potential issue.

This can help prevent foodborne illness outbreaks and also help to identify and address any issues with food quality standards or authenticity. Comprehensive food traceability systems capture production records for batch tracking efficiently.

What are the types of food traceability in manufacturing?

Food traceability is critical in the manufacturing industry. The system allows food producers to have the necessary information about their production process and immediately identify sources of food safety hazards in case of an issue.

In manufacturing, food traceability plans can be used for two main activities:

- Ingredient traceability. This process allows food manufacturing companies to track the movement of ingredients as your business uses them, including all the stages of receipt by food handlers. With food traceability, your team will effectively be able to monitor your inventory control regarding shelf-life and availability. More effective traceability systems can also track transactions with supply chain partners.

An effective traceability system can help food businesses identify a batch of ingredients that may be the potential source of foodborne illness incidents and immediately apply corrective actions. In addition, the proper food traceability procedures can help your team optimize ingredients before they go bad.

- Traceability of products. Traceability for food manufacturers also captures information on the movement of finished products. Comprehensive production traceability is an essential component of food manufacturing, as it enables manufacturers to track and monitor the movement of food items throughout the supply chain, from production to distribution and, ultimately, to the end consumer.

Effective traceability of produce items ensures that the finished products meet the necessary quality and safety food regulations while also providing a way to identify and respond quickly to any food safety events that may arise. Traceability systems can be used to prove your business's product quality control.

- reduce the likelihood of contamination

- prevent food fraud

- fast batch identification

- lower the risk of foodborne illnesses outbreaks in the food chain.

All this is achieved by recognizing hazards before the contaminated products reach your consumer. It also helps identify effective practices for safety control.

A proper food traceability system, together with a food recall plan, allows you to quickly identify and isolate the source and lessen the impact before it can have serious consequences for business customers and your food brand. In the event of a product recall or food withdrawal, production traceability enables a targeted withdrawal of the foods and acts as guidance for industry agencies and recall teams.

Use our Downloadable Product Recall Template to help deal with food safety recalls in your business.

Who should monitor food traceability?

Food traceability is the responsibility of all members of the food industry sector, not just food business owners. This includes manufacturers, retailers, distributors, food services, suppliers, and raw material producers.

Traceability standards and the obligation to record your traceability information vary in different countries, food industry sectors, business processes, and raw materials.

For example, in some countries, food traceability is a regulatory requirement for all food businesses' raw materials and the whole production chain. While in some countries, it applies only to products of animal origin, fish and sprouted seeds, and raw materials with the highest food safety risk.

Particularly in the US, the Food and Drug Administration provides a Food Traceability List as a reference for food items that must be documented appropriately for critical tracking events. Food products under this comprehensive list are most commonly associated with foodborne illness outbreaks. Food companies are mandated with additional recordkeeping requirements to protect public health as part of the food safety regulation.

In the UK, Regulation (EC) No. 178/2002 mandates all food and beverage businesses to have a comprehensive food traceability system. The food safety regulation aims to protect consumers from the risks of food contamination through proper food traceability procedures.

Why is food traceability challenging?

The biggest issue in food traceability is consistently marking down products' and ingredient data, including names, amounts, primary production processes, and best-before dates. The high volume of products and different batches make the process of production traceability slow and time-consuming.

Also, archiving accurate records and product recalls are challenging activities for businesses using pen-and-paper methods. Finding the necessary data during critical tracking events takes so much time that the damage is done before anyone can find the needed traceability sheet.

The traditional traceability method for food producers is also very prone to food safety risks and human error.

Luckily, there are modern ways to make traceability faster and easier for all food businesses—for example, FoodDocs. Using FoodDocs' two-in-one Traceability System, you can input and access all ingredient and product information quickly.

Get a solution to track the movement of your products, their shelf-life, and preparation information, and save your team's time from managing production schedules.

Why do you need a food traceability template?

A food traceability template is a useful and standardized tool that outlines the key information needed in tracking the movement of individual items and food products along the supply chain.

- Product name

- Ingredients list

- Batch number

- Production date/ Best-before date/ Expiration dates

- Supplier information (e.g., contact details and manufacturing address)

- Amount produced or used

- Barcode labels (if present)

The importance of using a food traceability template can be summarized through the following benefits of traceability:

- Food safety compliance. Using a Food Traceability Template helps food businesses with regulatory compliance related to tracking food ingredients and helps their continuous improvement. It also acts as a risk management tool for food safety hazards in your operations, contributing to protecting human health.

- Promote transparency. Using a customizable template can help improve transparency and accountability throughout the entire supply chain. Food traceability systems provide a clear and standardized traceability record of product movement throughout the entire production to help resolve food safety issues promptly.

- Improve customer loyalty and consumer trust. Product tracing can help build trust and confidence among consumers and other stakeholders. With clear information, you can assure consumers that your food company does not release unsafe food into the market food chain.

If you want a more intuitive solution for your food traceability documents, you can use FoodDocs' smart Food Safety Management System. Our smart software is equipped with a built-in Food Traceability System that lets you track the movement of your products and ingredients and intuitively reminds your team of ingredients that will spoil.

This system automatically calculates the product shelf-life according to the information you provide and can help you quickly access the essential traceability requirements to track a batch of products in case of a food safety issue.

Traceability System from FoodDocs software

Supply chain traceability systems work best for a food recall, and if you have an effective system that intuitively gathers information on the movement of food products, the process can become more efficient.

Using our modern food traceability solutions, you can minimize potential losses from food recall issues and even optimize the use of your ingredients while reducing food waste.

What are the supply chain visibility benefits?

In the food industry sector, a traceability system has become increasingly important, especially for consumers. In fact, the demand for transparency is a major challenge in the food safety industry.

As more consumers become concerned with human health promotion, they want to understand food origins and how the products they buy are produced. For food businesses to provide the information, they need effective traceability in food supply chain systems.

In addition to complying with consumer demands, supply chain visibility enables businesses to identify bottlenecks, inefficiencies, and areas of improvement within the production chain.

With real-time food supply chain data and insights, companies can optimize processes, reduce lead times, minimize entire inventory levels, and enhance overall operational efficiency.

They can also use the information from traceability measures for conducting root-cause analysis in case of reports of defective products.

Supply chain visibility with the correct information can also attract investors and patrons from around your business. The system promotes accountability and ensures investors and customers that you take food product safety and sustainability very seriously.

Modern manufacturers and processors use supply chain visibility as a way to achieve consumer confidence.

How can FoodDocs help in tracing product movements?

Whether your business is in the manufacturing industry, retail, or food service, keeping track of your ingredients, products, and processes is an important aspect of food safety and maintaining effective quality control measures. As mentioned, complete traceability can only be effective if your system can capture the key data elements from your manufacturing process.

FoodDocs developed a comprehensive Traceability System with production management features that are built into our smart Food Safety Management System. With this modern tool, you will achieve not only consistent maintenance of food product safety compliance but also keep internal traceability controlled.

When you sign up for our smart software, you can get the following Traceability benefits:

-

Comprehensive traceability System to track the movement of your products

-

Production management to minimize time on production planning

-

Smart recipe book to organize all recipes

-

Shelf-life tracker to help trace product shelf-life

Traceability System to track the movement of your products

Our Traceability System was made to be easy to follow yet comprehensive enough to log all details for effective ingredient and product traceability. Using our system, you can log product and ingredient information, including the following:

- Product name

- Ingredients

- Batch Number/ Production Dates

- Target amount

- Expiry date

You can easily access important product or ingredient information in case of recalls or customer complaints. Using our advanced search feature, you can instantly find information about a particular product and analyze it, whether for a recall or production optimization.

You can also print information about a particular batch of products or a range of products and perform in-depth analysis in case of recalls.

In addition, you can also attach monitoring logs from our monitoring system to traceability records, such as receiving logs, to further support your traceability information.

Traceability log with Production management from FoodDocs software

Production management to minimize time on production planning

A critical part of our Traceability System is the Production Management module, which helps food business teams plan production while tracking product movement.

With the help of this feature, teams can select recipes from uploaded lists and enter the planned amount for production. Our system will automatically recalculate the required ingredient ratio for you.

When you allow our system to perform recipe recalculation, it helps you improve the accuracy of your production by minimizing human errors.

Access production plans for the day and improve production efficiency using any mobile device through our Food Safety App.

Smart recipe book to organize all recipes

When you use our Traceability System, your team gets a Smart Recipe Book where you can upload all your business recipes.

With this feature, you can organize all recipes that include important ingredients, preparation instructions, allergen information, shelf-life information, and product images.

Our system can accommodate mass uploading if you have all your recipes in a CSV file or electronic records. With this, you can quickly get an organized and well-presented recipe book for reference.

Some of the major functions of our Traceability System are based on the information you input into your recipe book. The production recalculation and expiry date generation are based on your recipes.

Lastly, our Digital Recipe Book automatically generates an allergy matrix that features an overview of the allergens in your products. The matrix is automatically updated when you upload new recipes.

Smart recipe book from FoodDocs software

Shelf-life tracker to help trace product shelf-life

Based on the expiry dates you enter in the Digital Recipe Book, our system can help you automatically fill in shelf-life dates in your traceability logs. This feature can help you ensure that all expiry date labels on your products are always accurate.

In addition, our shelf-life tracker can help remind handlers whenever a product or item is nearing its expiration date and time. Our system will send intuitive alerts to food handlers, reminding them which batch to prioritize.

With the help of such an efficient tool, you can ensure that all your products and ingredients are optimized and will not go to waste. Protect public health and maximize your product usage with the help of our shelf-life tracker.

![]()

Shelf-life tracker from FoodDocs software

All of these food traceability features are in just one smart Traceability System. The great thing is you do not need any complex procedure to perform critical tracking events with our smart software. Setting up your own traceability system can be done in three clicks.

Our smart software was built for all types of food businesses. We aim to provide food safety compliance benefits for manufacturers, retailers, and food service stores. Switching to our digital solutions can help your food business become more flexible and adaptable to the fast-paced food industry. With our system, you can easily customize your food safety checklists and logs to fit suggestions for improvement from government inspectors.

What makes our system unique is that you can get all of these benefits and more in just 15 minutes. Our smart software can generate all essential tools to help you maintain food safety compliance using artificial intelligence and a machine-learning program.