FREE GMP AUDIT CHECKLIST

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

If you'd like to learn more about GMPs, check out our Good Manufacturing Practices guide which covers the 10 principles of GMP, the 5 Ps of GMP and more, as well as how to get GMP certified .

What is a GMP audit?

A GMP audit is a detailed evaluation process conducted by internal team members (e.g., a Quality Manager) or external auditors to ensure that a food manufacturer's operations comply with the established Good Manufacturing Practices.

This audit assesses various aspects of production, including materials, facilities, equipment, packaging, labeling, and laboratory controls, to verify adherence to quality standards and regulatory requirements. Depending on a facility’s risk level or compliance history, GMP audits can occur in one or a combination of the following ways:

- On-site

- Virtually

- Desktop assessment

Key points covered:

- A GMP audit is a comprehensive evaluation to verify compliance with Good Manufacturing Practices in the food industry.

- Audits can be conducted internally by qualified team members like Quality Managers or externally by independent auditors.

- Key areas of focus during an audit include materials, facilities, equipment, packaging, labeling, and laboratory controls.

- Audits can occur on-site, virtually, or via desktop assessment, depending on the company's risk level and compliance history.

- The GMP audit checklist is a crucial tool for systematically identifying and addressing potential non-compliance issues.

- The GMP audit procedure encompasses eight detailed steps, from defining the audit scope to following up with management.

- GMP audits are mandatory for regulatory compliance in industries like food and beverage, pharmaceuticals, and more.

- The frequency of GMP audits can vary, but businesses generally conduct internal audits annually and external audits every three years.

- The cost of GMP audits can range significantly, influenced by factors such as facility size, location, and audit scope.

- FoodDocs' food safety management software helps your team maintain compliance with Good Manufacturing Practices and pass internal and external GMP audits.

WHAT WE'LL COVER:

- What's a GMP audit?

- Why are GMP audits important?

- What's a GMP audit checklist?

- Key components of GMP audits

- What's the GMP audit procedure?

- How often should they occur?

- How long do GMP audits take?

- Are GMP audits mandatory?

- What industries are impacted?

- Who's responsible for GMP audits?

- How much do GMP audits cost?

- What's the GMP audit point system?

- 3 Tips for acing GMP audits

- Free GMP audit checklist download

- How FoodDocs can help

What's the main purpose of GMP audits?

The main purpose of a GMP audit is to confirm that products are consistently produced and controlled to quality standards, ensuring they are safe and meet customer expectations.

What's a GMP audit checklist?

A Good Manufacturing Practice audit checklist is a valuable tool for food manufacturers and producers to ensure compliance with GMP guidelines. If you're a Food Safety, Quality Assurance or Quality Control manager, conducting internal GMP audits using a checklist can help you systematically identify and address any potential non-compliance issues before they become major problems with corrective actions.

This proactive approach demonstrates a commitment to food safety to your staff, regulators, and customers.

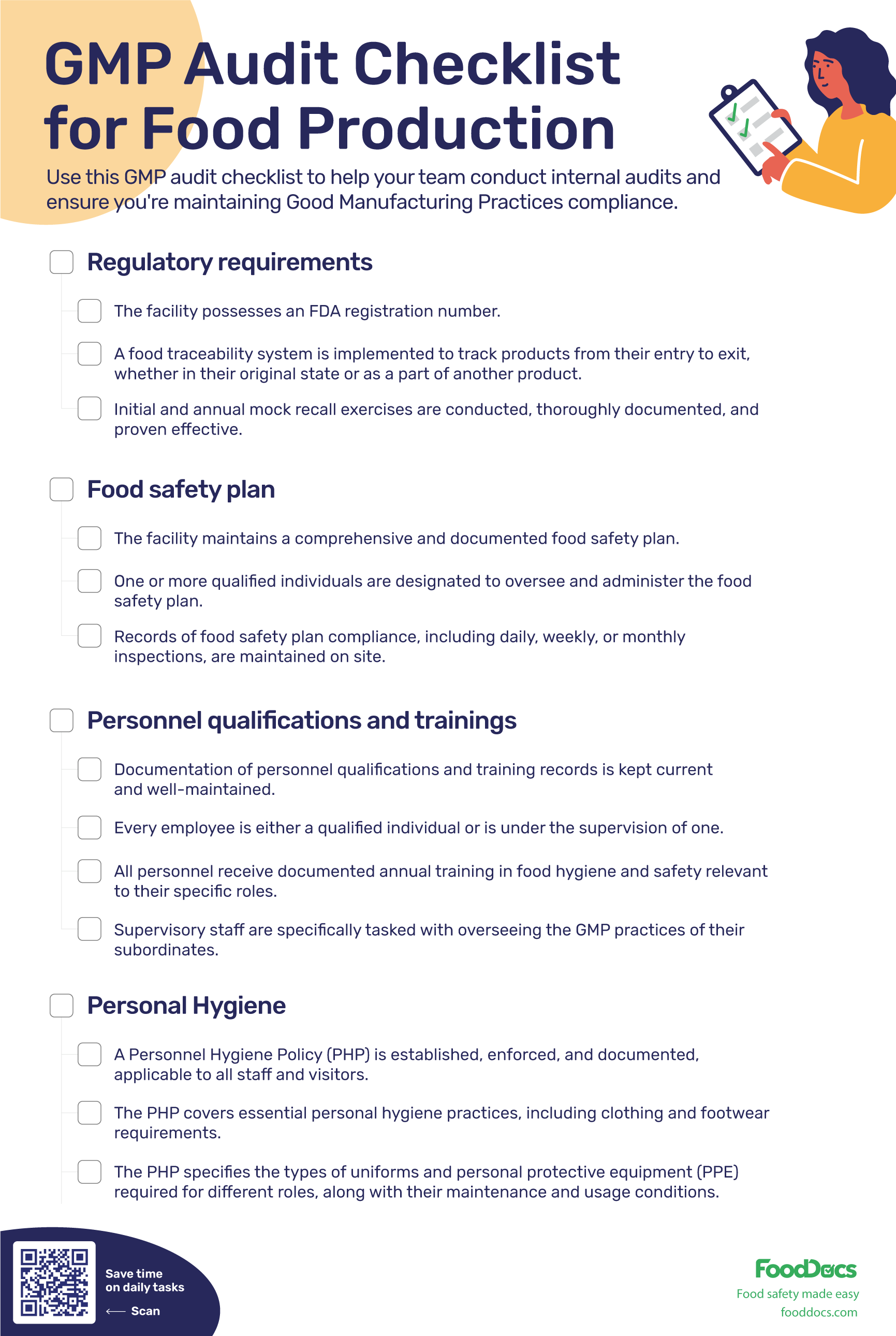

Key components of this internal GMP audit checklist

The key components of the internal GMP audit checklist above cover questions that'll help you determine whether or not your food facilities are compliant with Yes, No, or N/A answer options across the following topics:

- Regulatory requirements

- Food safety plan

- Key personnel qualifications and training

- Hygienic practices

- Supply chain

- Processes and controls

- Defect action

- Equipment and utensils

- Sanitary facilities and controls

- Maintenance and sanitation

- Warehousing and distribution

- Food by-products for animal food

- Facility and grounds

Addressing the state of your quality standards and internal quality controls through this internal audit process will give you a clearer picture of where your business stands in the context of GMPs.

What is the GMP audit procedure?

The GMP audit procedure involves the following eight steps. From the auditor's perspective, this is a general example of the GMP process you can expect:

1. Define the scope of the audit

Start by specifying the areas of the company and the products that will be included in the audit. Clear delineation of the audit's scope allows for targeted and efficient inspection activities.

2. Gather information about the company and its products

Collect detailed information about the company’s operations and products by reviewing documents, interviewing employees, and testing products. This foundational knowledge is critical for identifying potential compliance issues.

3. Perform an on-site inspection

Conduct a physical inspection at the company’s facilities to observe operations firsthand. Inspectors will assess GMP compliance, safety protocols, and quality control measures during this visit, utilizing tools such as a GMP Audit Checklist.

4. Review documents and records

Examine all relevant documentation, including manufacturing procedures, quality control reports, and employee training records. This review helps to understand operational processes and pinpoint compliance gaps.

5. Interview employees

Speak with employees to gain insights into daily operations and internal compliance challenges. These interviews can reveal practical insights into the company’s GMP practices and suggest areas for improvement.

6. Assess GMP compliance

Evaluate the company’s adherence to good manufacturing practices by analyzing the collected data. This assessment will highlight both strengths and areas requiring attention concerning safety and product quality.

7. Draft a report

Compile the findings into a comprehensive report that outlines observed compliance levels and recommends actions for enhancement. This document serves as a vital tool for guiding future improvements and subsequent audits.

8. Follow up with management

Discuss the audit findings and recommendations with the company’s management to ensure understanding and initiate corrective measures. This final step helps to close any gaps in compliance and reinforces the importance of continuous improvement.

How often should I conduct GMP audits?

Internally, you should conduct at least one GMP audit per year. You can schedule third-party (i.e., external) audits every three years if, for example, that's how long your GMP certificate is valid for (assuming you already have one). Ultimately, you should seek guidance from your governing body or agency for the exact timeframe.

How long do GMP audits take?

GMP audits typically take a few days to a couple of weeks, with an audit day lasting 6-10 hours. The duration of a GMP audit depends entirely on the:

- Facility size

- Operational complexity

- Scope of the audit

Due to the thorough nature of GMP audits, at least two internal team members who are familiar with the manufacturing process food safety program should spend the day alongside the auditor.

Are GMP audits mandatory?

Yes, GMP audits are mandatory for businesses in sectors overseen by regulatory bodies like the FDA. Non-compliance with GMP standards can result in severe repercussions, such as product recalls, financial penalties, and harm to a company's reputation.

What industries must complete regular GMP audits?

Here are the primary industries that need to complete GMP audits:

- Food and beverage manufacturers

- Pharmaceutical companies

- Cosmetics manufacturers

- Medical device manufacturers

- Dietary supplements manufacturers

- Biotechnology firms

GMP audits are necessary for a wide range of industries to ensure compliance with regulatory standards that guarantee the quality, safety, and efficacy of their products.

Who is responsible for conducting the GMP audit?

Typically, the quality manager or a designated quality management representative oversees the internal GMP audit process. These individuals must have proper training or qualifications to ensure they conduct these internal audits effectively and impartially.

If possible, auditors won’t have direct operational responsibilities for the areas they are inspecting to avoid conflicts of interest and maintain audit integrity. However, there are cases where potential conflicts of interest can arise when team sizes are small and qualified individuals are lacking. This is where offering training to other managers outside the quality department can be a helpful long-term auditing strategy.

Third-party organizations or regulatory authorities will usually conduct the “real” GMP audits. We use “real” here because these GMP audits will determine whether or not a manufacturing business becomes GMP certified.

External GMP auditors (any third-party auditor, really) are independent, which helps eliminate bias and provides an objective assessment of a company’s GMP compliance. This level of auditing is crucial for companies seeking to reassure customers and regulatory bodies of their commitment to quality and safety.

How much does a GMP audit cost?

Internally, a GMP audit costs your time, existing salaries, and any additional training. However, the cost of a third-party GMP audit for an average food manufacturer can range from a few thousand dollars to over $20,000 USD.

This price range typically includes the auditor's fees, expenses for travel, and sometimes additional costs for follow-up audits or corrective action assessments. Companies should also consider indirect costs such as the time spent by internal staff preparing for the audit.

The cost varies widely based on the following factors:

- Facility size: Larger facilities have more complex systems and processes, which can extend the duration and complexity of the audit, increasing costs.

- Location: Geographic location can affect travel expenses for auditors, which are often passed on to the manufacturing company.

- Audit scope: The specific requirements and standards being audited (e.g., GMP, ISO, HACCP) can affect the duration and depth of the audit, impacting the cost.

- Type of products manufactured: Different types of products may require specific testing and additional scrutiny, such as food products that require aseptic processing or have high-risk ingredients.

- Certifying body: Different certifying bodies have varying fee structures. Nationally- or internationally-recognized bodies might charge more for their services.

In an IFSQN forum discussion about audit costs, one member shared that their GMP audit cost $1,725 plus an additional $1,275 for travel and expenses. Another food safety audit consultant said that a price of $7,000 is reasonable, adding:

There are a lot of components involved with contracting to for an audit — most people focus on that one person that is doing the audit and negate everything else that is involved.

And there are a lot of things involved with getting that audit completed and it is a lot more than 1 person.

At our consulting company our rates are fairly close to an auditor rate on a per day basis and while a client may only see me they don't see the people in the office that do admin and research work etc.

Is there a set points system for GMP audits?

The are different points systems for GMP audits but ultimately, they’re tied to grades. You can score your GMP audit on a 0 or 1 (i.e., Yes or No), 1-3-point scale, or 1-5-point scale.

According to Glenn Oster, a food safety consultant:

I believe that each type of audit (SQF, BRC, IFS, GMP, Private Business, etc) has their own point/grade/scoring system. For instance I did cross country 2nd party food safety inspections for SuperValu private brands. The audits had a max of 100 points and minors beiing 1 point, majors being 25 points and Criticals being 50 points with a fail break at 70 points... Points are tied to grades — ours were A down to 90; B down to 80, C down to 71.

Other food safety professionals do the following:

- Rate them as High (-5), Medium (1) and Low (2) for conformance.

- Use rating 1 and 0 ( conformance or not to standard) for each parameter. And GMP score we use perceantage of conformity, GMP is good if conformity 90 % or up, 80 - 89 % is fair and below 80% is bad.

- High : 8-10; Medium : 6-8; Low: 4-6; Unsatisfactory: below 4

3 Tips for acing your GMP compliance audit

Preparing your team for an internal Good Manufacturing Practices (GMP) audit can be a daunting task, but it doesn't have to be. These three practical tips can empower your team and boost their confidence as they get ready for internal or external audits:

- Communication: When it comes to food safety, no one likes surprises. Transparently share with the team that the business is striving to become GMP certified and, to get there, everyone will have to learn and work together to get to that stage.

Clearly explain the purpose of the audit, what will be assessed, and the expected outcomes. Encourage team members to ask questions and provide clarification to alleviate any concerns or confusion. - Training and education: Ensure that your team is well-versed in GMP principles and practices. Provide comprehensive training sessions and resources to refresh their knowledge and highlight areas that may be assessed during the audit.

Food safety apps that include step-by-step instructions with visuals for every task will also increase consistency and solidify GMP compliance knowledge.Encourage team members to actively participate and engage in discussions to foster a deeper understanding of GMP requirements. If budget allows, having input from a GMP consultant could be beneficial. - Mock internal audits: Conducting mock internal GMP audits is an effective way to prepare your team. Practicing will help familiarize teams with what to expect during an audit, identify issues ahead of the actual audit with a third-party, and be better prepared to field potential GMP-related questions.

If possible, depending on schedules, have team members shadow the Food Safety Manager or Quality Assurance Supervisor who's conducting the internal audits. This will give employees in various parts of the business the ability to think like an auditor and evaluate your facility's compliance with GMP standards. It could be a truly eye-opening experience and is a great way to instill a stronger food safety culture.

Remember, the goal is to empower your team and make them feel supported, rather than scared, as they face an internal GMP audit.

How to use this internal GMP audit checklist

Start by familiarizing yourself with the checklist itself. Review each section and the specific criteria it covers. See what applies to you and simply delete the rows that do not. This will give you an idea of what areas of your business the checklist is designed to assess.

Next, gather any necessary documentation or records that may be required for the audit. These could include SOPs, training records, equipment maintenance logs, and any other relevant documents that pertain to the GMP guidelines.

With the checklist and supporting documentation in hand, begin your audit. Go through each section of the checklist and assess your business's compliance with the GMP requirements outlined. Take notes and document any areas where improvements or corrective actions are needed.

Once you have completed the audit, review your findings and prioritize any necessary corrective actions. Develop a plan for addressing any identified gaps or deficiencies and assign responsibilities for implementing these corrective actions.

Finally, regularly review and update your internal GMP audit checklist to ensure it remains current and aligned with any changes in regulations or industry best practices. Use this GMP audit template as an ongoing tool to continuously monitor and improve your compliance with GMP standards.

Time to download your free GMP audit checklist!

We’ve created a comprehensive 7-page internal GMP audit checklist PDF so you can conduct your own.

It covers regulatory requirements, hygienic practices, processes and controls, sanitary facilities and controls, facility and grounds and more. Get your free download below:

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Alternatively, you can learn...

How to prepare your team for GMP audits with FoodDocs

GMP compliance is your company's first line of approach to protecting public health by ensuring that your team is working in a clean and sanitary environment.

Food safety management software such as FoodDocs will help increase your team’s likelihood of passing their GMP audit with flying colors. Here’s how:

- Team preparation: Smart mobile app notifications and step-by-step instructions help food handlers keep in mind all needed compliance tasks, audit checklist prepares them for the audit, and also saves time on repetitive tasks.

- Transparency and oversight: Quality managers have access to a real-time overview dashboard that displays the status of their business’s GMP compliance. This overview — thanks to a red, yellow, and green traffic light system — will also give managers an accurate sense of their GMP audit readiness.

- Document preparation: Keeping all of your food safety monitoring logs, including all GMP-specific tasks, systematically organized makes it easy for auditors to access historical data at any moment, on-site or remotely.

Complete internal GMP audit checklist tasks to stay compliant

After setting up GMP audit tasks in FoodDocs’ digital food safety system, you can assign them to specific team members based on their roles. They’ll only receive mobile app notifications on the days that GMP compliance tasks need to be completed.

The mobile app also allows you to attach photos and other files, a helpful feature that auditors love. The more food safety evidence the better.

Using our smart Food Safety Management System will help to ensure you're consistently staying GMP compliant. Other product features include:

Customizable monitoring tasks to help maintain food safety compliance

Monitor and record all task information with the automatically generated monitoring tasks that our system can provide. When you sign up, our system will generate all the essential monitoring checks to keep you GMP-compliant through the information you provide.

Some of the customizable logs and checklists that you can get include the following:

- Receiving chilled goods log

- Fridge temperature log

- Temperature log

- Employee hygiene checklist

- Master sanitation schedule

Use these comprehensive monitoring tasks to record critical information and maintain a food-safe working environment in your food premises according to GMP requirements.

What makes these monitoring tasks more efficient is that you can customize them according to your business needs. As GMP guidelines may vary from one food business type to another, you can easily apply customizations to each task and tailor them according to your operations.

Step-by-step instructions to help training your team

Make GMP training programs easier and more efficient with the help of our software's step-by-step instruction tools. Each automatically generated monitoring task comes with detailed instructions on how to perform and monitor the task.

You can use this feature to train food handlers and remind them of the proper execution of tasks according to GMP guidelines. In addition, you can use these instructions to train new food workers and save time from conducting food safety training repeatedly.

Make employee training programs more tailor-fit to your business by uploading your own versions of the instructions. You can upload images or videos from your food business and make the instructions more understandable among your team members.

All-in-one Traceability System to help track and manage production flow

One of the main requirements of every GMP guideline is establishing a comprehensive traceability system. With our Food Safety Management Software, you can also get an intuitive Traceability System with production management features.

Using our Traceability System, you can log all critical information about your received goods and food ingredients, products, and batch operations. Access information about a particular production batch with the help of advanced search options.

FoodDocs also simplifies recall management, allowing you to instantly access detailed recall information about products and ingredients to ensure quick and effective responses.

In case of customer complaints or food recalls, you can use our Traceability System to retrieve information about a particular production batch and print it as a reference. With quick solutions such as our advanced search feature, you can minimize damages caused by potential hazards.

Frequently asked questions about GMP audits

What is the GMP audit process?

The GMP audit process is led by an external or internal individual or team that examines and verifies that a manufacturer is following its documented Good Manufacturing Practices.

What are the 10 principles of GMP?

There are 10 guiding Good Manufacturing Practices that any business striving for GMP compliance and certification should adhere to:

- Develop process-, facility-, and equipment-related Standard Operating Procedures (SOPs)

- Follow specifications of the SOPs

- Validate specifications of the SOPs

- Document everything

- Monitor the facilities and equipment

- Hire qualified and competent team members

- Protect products against contamination

- Control product components and processes

- Ensure quality across operations, manufacturing, logistics, and distribution

- Perform regularly scheduled third-party audits

Who is responsible for GMP audits?

Internal and external stakeholders both play important roles in the success (or failure) of a food business's GMP compliance journey. To understand each of their roles, let's look closer at the compliance responsibilities of both internal team members and external auditors.

- Internal GMP compliance responsibilities: Before the actual auditing starts, internal (or first-party,) GMP compliance requires a team that buys into the food safety culture and goal of striving for GMP certification. Led by Quality Managers, it involves team members who consistently upkeep and provide evidence of the food safety monitoring, and traceability tasks as outlined in the food safety plan and SOPs designed to meet GMP compliance.

- External GMP compliance responsibilities: External (third-party) GMP auditors play an especially important role for business's trying to become GMP-certified. Once you're ready, an third-party auditor that's recognized by the certifying body will conduct an audit similar to the internal audits you may have been conducting. In fact, it'll be highly thorough and unbiased since the independent auditor will be scoring your food facilities with fresher, more objective eyes.